Technology of butt electric welding of metals

It should be taken into account that butt welding is a special case of contact welding. That is why both technologies involve the use of almost the same equipment. The welding machine used is characterized by the following features:

- Electric current is generated by installing a high-power transformer.

- Electric current is transmitted through a stationary electrode.

- The design also has a movable electrode through which energy is supplied.

- To move the main element, a different drive can be installed.

- There is also a process control system.

Design features are determined by exactly how butt welding is carried out. It is worth considering that the butt welding scheme is characterized by the following features:

- There is no need to generate large current. This is due to the fact that the consumable material used ensures the maintenance of a stable arc.

- The method involves only local heating of the surface. Due to this, the efficiency of the process is significantly increased and the costs of the amount of current consumed are reduced.

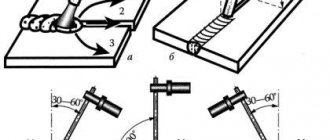

Resistance butt welding diagram

In general, we can say that the technology is characterized by a fairly large number of features that must be taken into account. The power welding transformer generates voltage from 2 to 10 volts.

Algorithm of electrofusion welding technology

This method assumes that the worker has a simple transformer and the electric coupling itself, in which the heating element is initially installed. The welding process is quite simple: both pipes are connected to the coupling, and electric current is supplied to it.

The work is performed as follows:

- The pipes are prepared in the same way as in all previous methods, starting with cutting at right angles and ending with stripping.

- The pipes are inserted into an electrical coupling and current is supplied to it from the transformer.

- When the connected pipes have cooled down, you can disconnect the wiring, but the coupling will remain as an element integral with the pipeline.

Manual welding process

Today, welding is performed using the technology in question to obtain high-quality products. Features of the process include the following points:

- Before starting work, the workpieces are placed in special fixtures. Electrodes act as such elements.

- The clamps used closely follow the shape of the future product. Due to this, you can get a quality product.

- Special consumables are used as electrodes, which are characterized by good resistance to mechanical stress.

- Due to a special drive, both workpieces are brought closer to each other. The transmitted force can be quite large, thereby improving the quality of the connection.

After firmly clamping the connected workpieces, the transformer turns on. Through the electrodes, current is supplied to the part of the workpiece being processed. The high current provides local heating of the metal.

Manual Hydraulic Butt Welding Machine

The above information indicates that resistance butt welding can be carried out using special equipment. Due to their features, it is possible to automate the process and improve the quality of the resulting products.

Reflow welding process

Butt welding technology is a type of contact welding. It is this point that determines the use of similar welding machines, which are characterized by only a small number of differences. The features of the equipment used include the following:

- Thermal effects require a high power welding transformer.

- The electrode is stationary and is selected for the welding work in question.

- Movable electrode.

- Control system for the procedure being carried out.

The butt connection is made when a low current is generated. This is due to the fact that local heating is provided, and not the entire surface.

The process of flash welding is characterized as follows:

- The workpieces are fixed in special clamps. Moreover, they are represented by special electrodes with a high level of mechanical strength.

- The clamps used must follow the shape and dimensions of the welding seam, since they are the ones who will melt the metal.

- When making a butt joint using the method under consideration, pressure is applied to the clamps, which ensures reliable connection of the workpieces.

- After the products are pressed against each other, voltage is applied to the clamps. The passage of a large but short-term current ensures melting of the metal in the contact zone.

Continuous reflow welding scheme

The features of this technology determine that it allows you to obtain high-quality seams.

Advantages

The technology in question has a fairly large number of advantages, which has determined its spread. An example is the information below:

- There is no need for careful preparation of the processed edges.

- In conventional welding, in some cases it is necessary to perform thermal surface preparation. This is due to the fact that local exposure to high temperature allows you to achieve the best result.

- The resulting connection is characterized by increased reliability and strength. As practice shows, if all recommendations were followed during the work, the connection can last for a long period.

- The method under consideration is characterized by simplicity and ease of implementation. That is why the master does not have to have special skills.

- The thermal and mechanical effects provided ensure the production of a homogeneous metal. That is why it is possible to obtain metal with high strength.

- Under certain conditions, it is possible to automate the process.

- High performance value.

Welding pipes for storm drainage

A fairly large number of advantages of resistance welding determine its spread. However, it is necessary to take into account some disadvantages of the technology, which we will discuss in more detail later.

Flaws

There are also several significant disadvantages to consider when considering the resistance welding procedure. They are as follows:

- Quite high electrical costs. This is due to the fact that a high voltage current must be supplied to melt the material.

- There are high demands on the dimensions of the elements to be connected.

- The equipment used is characterized by high cost. Therefore, it is practically impossible to carry out the work in question at home.

Such shortcomings determine that the technology has become widespread.

Butt welding methods

It is worth considering that there are several different butt welding methods. The most widespread are:

- Reflow welding.

- Resistance method.

All technologies are characterized by their own specific features that need to be taken into account.

Resistance butt welding

The common resistance butt welding is characterized by quite a large number of features. They are as follows:

- The workpieces are exclusively pressed against the electrodes with special jaws. This ensures rapid passage of current through the materials being processed.

- The use of special sponges eliminates the possibility of parts slipping between the electrodes used, through which voltage is applied to the surfaces being treated.

- The next step is to apply electrical current. Due to this, the metal in the treated area is heated.

- After this, sediment is applied, due to which the buildup is reduced. The next step is to apply a strong current to heat the surface as much as possible.

With electrical resistance, parts with a small cross-section can be processed. The maximum cross-sectional thickness is 40 millimeters. In this case, a strong connection is formed at the joint without melting the metal.

Flash butt welding

The technology in question has also become widespread. To heat the ends of parts, special equipment is used, which makes it possible to obtain a high-quality seam. Among the features of contact welding, the following points can be noted:

- The connected elements are brought together at low speed.

- The voltage remains constant throughout the entire process.

- Due to the uniform supply of the elements being connected, all micro-irregularities are leveled out.

- The surface is melted to ensure maximum contact area.

- There is no need for thorough surface preparation.

Reflow welding

Exposure to high temperature leads to the appearance of a high-quality connection, which is characterized by strength and reliability.

Second welding option

In the second welding method, the welding transformer is first turned on, and then the ends of the parts to be welded are slowly brought together.

- When the ends of the parts touch at individual points of contact, “an electric current passes and the metal at these points instantly melts and splashes out due to the action of electromagnetic forces and metal vapor pressure.

- When the rod clamped in a movable electrode moves slowly, such melting is stable and occurs until the ends are heated to the required temperature.

- Then the rods are quickly compressed with great force and the welding current is turned off.

Flash butt welding, in turn, is divided into continuous flash, described above, and intermittent reheat.

The welding process with intermittent heating differs from welding with continuous reflow in that before reflow begins, the ends of the parts are compressed and the current is turned on several times for preheating. Then the ends of the rods are separated and only after that the melting begins.

Advantages:

The advantages of this method are: lower required machine power, the ability to weld steels with an increased tendency to cracking, and reduced allowances for melting and upset. The main disadvantage of this welding method is its lower (2-3 times) productivity.

Butt welding of plastic pipes

The technology in question is used to connect plastic pipes. Among the features of butt welding, we note the following points:

- It is worth considering that plastic does not allow current to pass through. That is why it is necessary to use special equipment with a contact heater.

- Both elements being connected must fit tightly to each other. That is why the diameter of the pipes must match each other perfectly.

- In order to heat the surface evenly, a special nozzle is used that follows the shape of the pipe.

- At the moment of exposure to heat, the nozzle is slightly compressed. When exposed to pressure, a high-quality connection is formed.

Welding of polyethylene pipes

After the surface has been melted, it takes some time for it to cool. There are simply a huge number of different special tools on sale for obtaining high-quality connections of PVC pipes.

Performing butt welding of elements

Scheme of butt welding of polyethylene pipes.

Butt welding is performed using a similar technology both when it is necessary to connect fittings and when working with polyethylene pipes.

Carrying out this kind of connection when working with fittings, HDPE pipes and other materials appears as a type of resistance welding. The technology is based on the thermal effect of current. Compression must be applied to the elements being welded. Butt joints can be made by heating the area to a plastic state - this method is called “resistance welding”. The parts are secured in the clamps of a special apparatus, after which they are pressed together as tightly as possible by those areas that are to be connected. An electric current is passed between them until the surfaces of the parts become plastic. Then the current will be turned off and the surfaces will be tightly compressed. Another option is heating until the material melts, that is, “fusion welding.”

Defects can occur in cases where the areas of parts to be joined have not been well prepared.

It is necessary to completely remove uneven areas, oxidized areas, and any contaminants from them. This leads to uneven heating and the appearance of defects.

Errors when butt welding pipes.

When welding the root of a seam, you should not use a strong welding current: this can damage the structure and pores of the metal. The arc should be short. Welding the root should be done as efficiently as possible - then other actions will be easy to carry out.

Welding of butt seams when working with HDPE pipes and other parts should be carried out taking into account the cross-sectional area of the surfaces being bonded. The higher this indicator, the more the quality of the connection deteriorates. This happens for the reason that oxides form at the joint, which interferes with the full implementation of work tasks. Therefore, you should not resort to resistance welding for elements with a cross-sectional area of more than 200 mm². It is more convenient to use this method for parts with a small cross-section such as wire, rods, pipes made of low-carbon steel.

A good result can be obtained when working with metals that, in a plastic state, are characterized by normal coagulation. This applies to alloys of copper and aluminum, structural steels, low-carbon, low-alloy.

Seam properties

The spread of technology can be primarily associated with the high quality of the resulting seam. It is characterized by the following properties:

- Increased decorative qualities. During conventional welding, a wide shaft can be formed, which must be further processed to obtain a flat surface.

- Reliability and strength of connection. The seam can withstand a wide variety of impacts, including variable loads.

- In the area where the weld is located, the metal does not lose its properties, since local heating of the metal occurs.

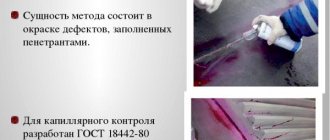

As a rule, the quality of the resulting seam is checked visually. On a high-performance line, special equipment can be used for this.

Devices for carrying out the process

Resistance welding equipment can be used to fully automate the process. In most cases, all you need to do is place the workpieces correctly and press one key. Other features of butt welding machines include the following:

- Good performance.

- Possibility of process automation.

- High cost of equipment.

- When carrying out work, the possibility of making an error is eliminated.

Butt welding machine

You can find equipment from a variety of manufacturers on sale. It is recommended to pay attention to products only from well-known companies.

Types of welding wire

When carrying out butt welding, you should correctly select the most suitable wire. It can be used to obtain a quality product. Specialists must distinguish between types of wire and be able to select the most suitable one. The following wire is on sale today:

- Copper has become widespread when joining low-carbon steels.

- Stainless steel suitable for chrome and other alloy steels

- Aluminum is most often chosen when working with sulimins or duralumin.

Copper Welding Wire

In addition, quite a lot of attention is paid to the choice of cross section. It is selected depending on the contact area of the elements being connected.

Process Features

The process under consideration has a fairly large number of features. When welding pipes, the following information is taken into account:

- The polarity of the current is selected depending on the wall thickness, type of material and the selected electrode. It is worth considering that all information about the parameters under which the electrode should be used is indicated by the manufacturer.

- It is worth considering that the connection of pipes is also carried out taking into account the current strength. This indicator can be determined by multiplying the thickness of the rod by 30 or 40. The current strength that is installed on the device is determined in a similar way.

- The speed of welding is not regulated in any technical documentation. However, you should not keep the electrode in one place for a long time, as this can lead to smudges. In addition, too high a temperature can lead to burning of the edge.

In order to simplify the task, preliminary fastening of the elements to be connected is carried out. Such welding features must be taken into account in order to improve the quality of the connection.

Application areas of butt welding

The spread of this method can be associated with their various advantages. Butt welding is used:

- In construction in the manufacture of monolithic structures. They must be designed to withstand heavy loads.

- In metallurgy, the method is used to join rolled sheets and wires. Butt welding allows you to obtain a continuous high-quality surface.

- In the railway sector, rails are being created without joints. They allow the technology to develop quite high speeds. It takes a relatively small amount of time to connect individual sections.

- In the automotive industry, butt welding technology is used to produce body products. The features of the equipment used make it possible to produce products of complex shapes.

- When creating a cutting part from alloy steel, resistance welding is also used. That is why during operation the cutting edge does not cling to the surface being processed. The strength of the connection is quite high, so the tool can withstand the applied load.

- The connection of steel and plastic pipes is also carried out when using the method in question. By using a special tool, you can obtain a uniform, high-quality seam.

Pipelines for supplying gas and oil products are also created using resistance welding. The technology allows connecting pipes with a diameter of up to 1420 mm. High performance allows you to make a sealed connection within 5 minutes.

In conclusion, we note that resistance welding in most cases can replace the common technology associated with the supply of high voltage current to the workpiece. In this case, the metal does not melt and the basic performance qualities do not change.

Butt welds without edge preparation

Small thickness parts are welded without cutting edges. Such welding can be one-sided or two-sided, it also depends on the thickness of the metal being welded. During such welding, the electrode performs transverse oscillatory movements. During the metal welding process, it is necessary to carefully monitor the uniform melting of both welded edges to the required depth. Particular attention should be paid to the penetration of the lower part of the joint (the root of the weld).

One-sided butt welds without beveled edges are made with coated electrodes for manual arc welding. In this case, if the thickness of the welded edges is no more than 4 mm, then the diameter of the electrode must be equal to their thickness. When the thickness of the sheets being welded is more than 5 mm, welding is performed with a double-sided seam. The strength of the welding current, the recommended gap between the parts and the diameter of the electrode can be selected from the table, based on the thickness of the metal being welded:

| Recommended clearance, mm | Electrode diameter, mm | Current strength, A | ||

| 3-4 | Unilateral | 1,0 | 3-4 | 180 |

| 5-6 | Bilateral | 1,0-1,5 | 4-5 | 220 |

| 7-8 | Bilateral | 1,5-2,0 | 5 | 260 |

| 10 | Bilateral | 2,0 | 6 | 330 |

In this case, the maximum permissible value of welding current should be selected according to the electrode data sheet, in accordance with the manufacturer’s recommendations.