Types of adapters for sewer pipes

To install sewerage in a private house, special pipes and fittings must be used.

Without them, it is impossible to connect pipes. These shaped parts are made from a variety of materials, which affect their service life and sales value. Modern polymers are considered the most popular material for the production of pipes, adapters and fittings. Such products are much more convenient to use than installing their cast iron counterparts. Moreover, all the main parameters of such parts are exactly the same as those of steel elements.

Polymer pipes, as well as additional fittings, are made from several materials:

- Polypropylene - PP,

- Polyvinyl chloride - PVC.

To make a pipe connection, special adapters are used. They are very easy to maintain and install.

Purpose and main characteristics

Living in an apartment or in a private house involves the use of water drainage and sewerage systems, the different elements of which must be hermetically connected to each other. For example, it is required to connect a cast-iron pipe of a common riser with internal plastic, an outdoor septic tank (Tank, Rostock, etc.) with a drainage system, pipes of different diameters.

Adapter design:

- Concentric. They are used only in the installation of vertical sections of the highway.

- Eccentric. Used on horizontal pipeline lines.

Adapter functions:

- Changing the direction of wastewater flow;

- Switch to another element size;

- Connecting parts from different materials.

Material:

- Steel;

- Cast iron;

- Rubber;

- Plastic.

The most popular material these days is plastic. This is not surprising; polymer products have many advantages.

Main advantages:

- Light weight. Allows easy installation of even large parts;

- Huge assortment. There are several hundred types of plastic fittings;

- Low cost;

- Corrosion resistance;

- Long period of operation.

Don't forget about the shortcomings. The main disadvantages of polymer products:

- Deformation under the influence of high temperatures;

- Plastic cannot be used for chemical waste;

- Low frost resistance.

In everyday life there are no such temperatures or aggressive environments under the influence of which polymer adapters can be destroyed, so their use is quite convenient.

Why do you need an adapter?

Such parts belong to pipeline fittings, without which it is impossible to connect parts of different diameters. Moreover, such adapters are capable of connecting parts made of different materials.

Note that adapters are used when installing any type of sewer system; they remain the most indispensable part.

Today, a variety of materials are used to make them. They may differ in shape and size. Basically, the following popular materials are used for manufacturing:

The design of adapters has several types:

- Concentric. Used only when installing a vertical line;

- Eccentric. Parts are used only when the pipes are horizontal.

Basic properties of adapters

When laying sewer pipes yourself, PVC adapters are always installed. They make it possible to create any, even the most complex, pipeline configuration, as well as connect the necessary plumbing devices to it.

Thanks to sewer adapters, several technological operations can be carried out:

- Change the direction of the pipeline;

- Change to another size;

- Dispose of sewage when its temperature does not exceed 60 degrees;

- Remove chemical waste.

Polypropylene bends for sewerage

Sewage outlets made of gray polypropylene are used only indoors; for outer diameters of sewer pipes of 110 mm, products with rotation angles of 15, 30, 45, 67, 87 degrees are used. Products made of polypropylene plastic have the following main characteristics:

- Polypropylene is afraid of ultraviolet radiation, so it is used only indoors.

- Neutrality towards acid, alkaline and alcohol solutions and inorganic compounds.

- The melting point of the material is about 170 C., during operation, the permissible temperature of the working fluid should not exceed 95 C.

- The brittleness temperature of the material ranges from -20 to -25 C.

Rice. 7 Varieties of bend angles

What types of adapters are there?

As mentioned above, various materials are used to make adapters. Details are divided into several groups:

- Transitional couplings. They are used to connect pipes of the same diameter. They are made in the form of a barrel. With such a coupling, the internal diameter is equal to the external size of the pipe used;

- Corners. Their bend is in the range of 45–90 degrees. The industry produces corners with threads on one side so that it is possible to connect a mixer;

- Crosses, as well as their analogues, tees. The parts are used in areas where several pipes are connected at the same time. Each side of the tee can have a specific diameter. There are metal tees equipped with an external thread at one end. The other end has an internal thread.

- Contours. These special devices make it possible to reduce the number of pipeline connections. Thanks to a certain bend, they can be used to bypass the pipe;

- Compensators. A device for smoothing temperature changes. The parts take on powerful shocks occurring in the system;

Properties of adapters installed on cast iron pipes

Many houses still have cast iron items. Therefore, when installing a sewer system, situations quite often arise in which it is necessary to connect pipes made of completely different materials. Most often you have to join plastic with cast iron.

To perform such a technological operation with high quality, it is simply impossible to do without a special adapter for cast iron. He will help you do this work quickly with minimal cost.

To ensure tightness, a rubber cuff is used. It is installed during any transition.

The inner cuff is inserted into the cast iron socket. This makes it possible to insert a plastic pipe of a certain diameter.

The outer diameter of the cuff is equal to the diameter of the socket. Therefore, the connection does not require additional treatment with sealant.

If there is no socket, a special external adapter is used to make the connection.

When the cast iron connection is completed, you can continue installing the plastic sewer system.

Basic properties and types of adapters for pipes made of different materials

To select the necessary adapters, you should know what the plumbing market offers and how they can be used. There are two groups of sewer adapters:

- concentric – intended for installation on vertical sections of communications;

- eccentric - installed on a horizontal pipeline.

We recommend that you read: Welding methods for connecting polyethylene pipes

Sewer adapters are installed both on internal sections of the pipeline and on outdoor ones.

They make it possible to connect different materials without dismantling the entire pipeline.

Conventionally, they are divided according to the method of connection into:

- glued;

- welded;

- threaded;

- with a sealing rubber band when connecting into a socket.

By design they are distinguished:

- couplings;

- angles of 45, 67, 90 degrees (in sewer connections, an angle of 90 degrees is avoided);

- crosspieces for wiring;

- compensators;

- inspections - opening fittings for cleaning sewers.

When switching from cast iron to plastic, adapters are used in the form of a rubber cuff, which can be internal or external.

Inner cuff

An internal cuff is a sewer adapter from cast iron to plastic, which is inserted inside a PVC socket or cast iron pipe. This is the most used option for connecting cast iron and plastic pipes when replacing a sewer system in a separate apartment in an apartment building.

Connecting a plastic sewer system to a common cast iron pipe is simple:

- The inner surface of the socket is cleaned of caulking residues from the previous joint (cement mortar or sulfur), and of sharp, protruding formations. The socket must be made as smooth as possible from the inside so that the adapter fits better to the walls.

- Coat the surface with sealant and insert a cuff of the appropriate diameter inside.

- The outer part of the cuff is not treated with sealant, since the plastic pipe with the rubber cuff is connected hermetically.

If the cast iron part of the sewer pipe ends in a straight section, then an external adapter is used to connect it and the plastic system.

Outer cuff

The sewer crossing through a plastic socket has a more multi-stage connection. You will need:

- saw off the section of the cast iron pipe evenly, clean it of sharp elements, and coat it with sealant;

- a rubber cuff with an additional rubber ring is put on top;

- A plastic adapter is installed on the rubber adapter;

- connect a plastic pipe with a socket and a rubber sealing ring.

We recommend that you familiarize yourself with: Flange adapter for connecting PE pipes

Note! If the connection has a gap greater than 2 mm, then caulking with a cement solution (when connecting into a cast iron socket) or linen plumbing winding is used for sealing.

For greater reliability of the connection, both sealing methods are often combined - a sanitary sealant is applied to the caulking material.

Types of compression adapters for HDPE

Please note that any compression fittings are complete products. Such adapters are divided into several types:

- Couplings. Manufactured in different sizes. The industry produces compression fittings equipped with metal threads. The design of the couplings provides for external thread cutting. Internal threads can also be cut;

- Corner outlet. This part helps change the direction of the highway. Manufactured with different threads;

- Tee. Helps to move the pipeline away from its original position, maintaining 90 degrees. The tee design is equipped with couplings on each side. The required thread is cut on one of them;

- Saddle. The part has two parts that crimp the pipe. It is used only when it is necessary to insert into a pipeline;

- Flanges. With their help, it is easy to connect metal products and HDPE pipes;

- Stub. It is installed on the end of the pipe and seals the pipe hermetically.

Depending on the connection method, adapters are divided into certain groups:

Types of fittings for PVC and polypropylene

Not only pipes, but also fittings are divided into types. Products intended for connection with PVC and polypropylene pipes are divided into the following types:

- Clutch. Used to connect two parallel pipelines. Couplings with built-in holes, intended for inspection or cleaning of a given area from blockages.

- Reduction or adapter for combining two plastic pipelines having different diameters. They are used to combine plastic products with cast iron fittings.

- Tee. Designed for branches with inclination angles of 45, 65 and 90 degrees.

- The crosspiece is two-plane. Allows you to get two perpendicular bends. Moreover, the crosspiece can have branches of the same or different diameters.

- Single-plane cross. It is used to obtain two branches that will be parallel. Branches can have divergence angles of 45 or 90 degrees. They are often used for installing drains from bathtubs, sinks and other plumbing fixtures.

- Retraction. Designed to rotate the pipeline at an angle of 30, 40 and 90 degrees.

- Compensation pipe. It is used when it is necessary to repair or replace damaged areas.

- Stub. With its help, the path of liquid transportation is blocked. Plugs are used in order to be able to carry out repair work on the pipeline line.

- Quad sewer. A fitting that has 4 holes. Designed to connect three pipes to one riser.

- Aerator or valve. Designed to limit the release of sewer gases into the room through the toilet. The reasons for the penetration of an unpleasant odor are hidden in a violation of the vacuum in the riser, which is why devices such as aerators are used.

Above are fittings for installing internal sewerage. Similar types of products can also be used when arranging an external system. When installing an external type plastic waste system, the following products are additionally used:

- Check valve. A device designed to block the reverse flow of liquid. Such a valve must be installed when the slope of the external sewer pipeline is less than 2 cm.

- Double siphon. Allows you to connect two parallel pipes, forming a bend at the junction. This bend prevents the entry of unpleasant gases on the return journey.

However, not all types of fittings that are used to connect plastic pipelines are presented above. In addition to differences in design, they also differ in diameter, so you need to know the size of the pipe used for installing the pipeline.

Products that are painted brown or orange are polyvinyl chloride. They are used for installing an external type drain. Light gray products are made of polypropylene and are used mainly indoors. However, they can also be used for outdoor drainage.

Special adapters for steel pipes

The connection of metal pipelines is carried out using special adapter designs. These include:

Straight fittings. They are used when there is a thread on the internal cone, for a threaded connection along the internal cone. The part helps to join pipes and go from 4 mm to 11 mm, from 20 mm to 29 mm.

Straight fittings where the thread is cut on the outer cone. M8 is connected to the transition M10, M39 with the transition to M45.

They can also connect the threads of the outer cone and the sealing rubber. Thus, a connection is made between M12 and M16 threads and more.

Straight fittings in which the ends of the part are made to allow the use of a threaded connection. In this way, the copper parts are connected. The device is installed in domestic and technical water supply systems. 1/8 - 4 inch pipes are joined. Threaded connections can be made using external threads. It is possible to install a coupling with an internal thread.

Transitions. This special part is designed for welding joints of parts with a diameter of 20 - 1000 mm.

The fittings discussed are made from a variety of materials. Moreover, all of the above fittings are made from various structural materials and non-ferrous alloys. The main ones are:

- Low carbon steels;

- Copper;

- Alloys based on copper.

Some adapters have their own “natural look”. Most parts are produced with a special, additional coating. For example, nickel adapters. The main material is steel coated with a nickel alloy. As a result, the corrosion resistance of the part is greatly increased.

Adapters for different materials

You have to deal with mismatches of materials quite often. For example, plastic pipe and cast iron. Dealing with such a problem is very difficult.

There may be several reasons for the mismatch of pipeline materials:

- I would like to save money on a certain section of the highway;

- Application of new technologies;

- It is impossible to buy a part from the required material.

For example, a working water supply system was installed many years ago. The pipeline was made of steel.

To modernize the structure and replace steel pipes with polypropylene pipes, you will need adapters. With their help it will be possible to connect various materials. They connect any materials to each other. For example, a threaded adapter makes it possible to connect polypropylene to steel parts. One part is equipped with a brass thread, and the other with a plastic thread. Sometimes, instead of such a thread, the adapter is equipped with a special end for welding.

Adapters for plastic products

The modern market offers a wide range of plastic adapters. Of course, their reliability is much lower than their steel counterpart, but the cost of such parts is affordable for almost anyone. The installation can be easily done by hand. Polyvinyl chloride adapters 250 mm, designed for installation in systems where there are rubber cuffs. Tight and strong fixation is achieved thanks to the internal, elastic ring. To install the part, you do not need to have any special specific tools.

Fittings made of PVC and mounted with glue cannot work under high pressure. The industry produces threaded parts made of polymers, specifically for creating connections. But under heavy load, the seal breaks down. Such parts are installed very rarely. They can only be operated at low pressure.

There are also adapters made of polypropylene for a diameter of 250 mm. Their installation is carried out using welding. This results in a strong, permanent connection. The work is performed with a special soldering iron and special nozzles. The size is maintained equal to the diameter of the pipeline.

Some companies produce structures for a diameter of 250 mm, where plastic parts act as inserts into a metal or composite product.

As you can see, choosing plumbing pipes and PVC adapters for sewerage for any task is not difficult.

Source

Product range

Plumbing pipes and PVC adapters for sewerage have dimensions and design that allow the construction of any drainage system configuration.

Connection design

For the installation of sewerage systems, two types of polyvinyl chloride structures are used, differing in the connection method:

- Using a bell;

- Glue method.

Connection using a socket is borrowed from cast iron pipes

One end of the product has an extension and a rubber seal in the form of a ring is installed in it. The smooth end is chamfered and is thinner than the main part. This ensures easy installation. The use of sealant gives the pipeline additional reliability, and antibacterial additives prevent the formation of mold and mildew.

Advice. If the pipe is shortened to the required length, the smooth surface area should be processed and chamfered. If this is not done, significant physical effort will be required, leading to rupture of the sealing ring.

Manufacturability is achieved by the fact that there is no need to use consumables: cords and putties. You can begin using the structures immediately after assembling the structure.

Method of adhesive connection

A layer of adhesive is applied to the outer surface of the pipe and the inner surface of the socket. By connecting the segments, they are glued.

The disadvantage of this method is the inability to dismantle the structure without destroying it. Replacing individual sections becomes a difficult task.

Adapters for sewer pipes are structurally similar.

Important! When assembling a sewer system, there should be a socket in the upper part, along the drain, and a smooth end in the lower part. This connection will protect against leakage during deformation. The connection will not have any protrusions as the drains are evacuated.

Strength

According to strength characteristics, there are three types of products:

- Lightweight – designated SN2 and withstands pressure of 2 kN/m²;

- Medium SN4 – safe load 4 kN/4m²;

- Heavy SN8 – respectively 8 kN/m².

Sewerage inside residential buildings is equipped with products marked SN2. In private homes, they can also be used to drain water from precipitation.

SN4 is located under the road surface with light traffic loads. In this way, you can equip the drainage of wastewater from the house to the receiving well.

SN8 are rarely used in everyday life - their purpose is to lay under highways and in industrial construction. Increased strength brings with it a significant increase in cost.

Geometric dimensions

The parameters of manufactured products made from unplasticized polyvinyl chloride (PVC) are established by GOST 32412-2013.

Marking and technical characteristics indicated therein

When choosing sewerage components for your home, the following characteristics are important:

- Diameter;

- Length of segments;

- Wall thickness.

For example, the photo above shows a pipe made of unplasticized polyvinyl chloride of strength category SN2. Diameter – 160 mm, wall thickness – 3.2 mm. 160.5 – average outer size along the entire length. The length of the product is two meters. Astu denotes the technical conditions according to which the pipe is manufactured. For the buyer, the information is reference - those who are curious can find the standard.

Manufacturers produce plastic pipes of different diameters. The standards provide dimensions for internal sewerage (in mm): 32, 40, 50, 63, 75, 90, 110.

For sewerage inside blocks from 160 to 2000 mm. To connect with large cross-section pipes, connecting sewer wells are installed. Adapters 160x110 are used to connect risers in entrances.

Attention! To achieve complete tightness of the sewer system, it is advisable to use products from one manufacturer. Products from different factories may have slight differences, and assembly may be difficult. Backlash in connections is a source of leaks.

GOST establishes such a parameter as the effective length.

Effective length, according to GOST

Picture A shows a pipe with a socket for an O-ring, B – for an adhesive joint, C – a pipe with a chamfer. The places between which measurements are taken are indicated by arrows.

For ease of installation, a standard set of lengths is available: 0.5, 1.0, 1.5, 2, 3 m.

For industrial use, the size is increased to 6 or 12 m.

When designing a sewerage system, the length of individual sections of the wiring is specified. By combining pipes of different lengths, equipment is installed in the right places.

According to the standard, the minimum wall thickness for products with a diameter of up to 90 mm is set in mm - 3, the maximum - 3.5. For a pipe with a diameter of 11 cm, 3.2 and 3.8 mm, respectively.

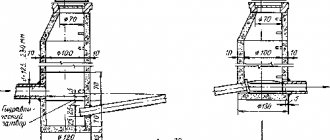

The illustration shows the connecting dimensions for pipes with a diameter of 50 (A) and 110 mm (B)

Another parameter that needs to be taken into account is the length of the pipe end. It indicates to what depth the end of the pipe will enter the socket when connected. For the most common diameters of 50 and 100 mm, this length will be 37 and 54 mm, respectively. This is the distance you should leave when cutting off excess.

Shaped parts

Manufacturers produce a full range of fittings for various types of connections. GOST defines the geometric dimensions for pipes and fittings of all specified diameters. The assortment includes various elbows, crosses and couplings, and PVC adapters.

Fittings for PVC pipes 50 and 110 mm

To connect to an external sewer in a private house, a 160x110 mm adapter is used. Additionally, the figure shows elements of fastening to the walls: clamps and clamps.

Connections of polyvinyl chloride and cast iron products

When reconstructing a sewer system, if its cast-iron riser is not dismantled, a transition to a cast-iron pipe is used. GOST establishes the permissible dimensions of cast iron sewer pipes.

A pipe with a diameter of 81 mm has a nominal internal passage of 65 mm. Product 118 – 100, 144 – 125. As you can see, these dimensions do not coincide with similar dimensions of PVC structures. Therefore, adapters must be used for articulation. The industry produces all the necessary standard sizes.

Transition from PVC to cast iron pipe

Due to the discrepancy between the diameters, it is necessary to use a rubber adapter. Adapters are available in various forms; the illustration shows one of the options.

Pairing of PVC and HDPE products

Water supply and sewerage systems are sometimes made from HDPE (low-pressure polypropylene) pipes.

HDPE is produced in black color, they do not transmit light and are therefore protected from the development of mold and bacteria inside the pipeline.

For low-pressure polypropylene connections, two methods are used: welding and fittings. The first method is performed using a special welding machine. The connections are reliable, but disassembling the pipeline requires mechanical destruction of the structure. For sewer systems in apartments and country houses, this option is inconvenient.

The appearance of connections using fittings turns out to be unattractive; inside the structure there are obstacles in the form of pipe flanges, which interferes with the movement of drains through the pipe, leading to blockages.

Based on all that has been said, the internal wiring is made of polyvinyl chloride pipes, and adapters for HDPE pipes are used to connect to the riser.

To connect PVC and HDPE products, adapters for HDPE are used. They are often found on sale under the name “socket restorer”.

Bell restorer

Before purchasing, you must accurately measure the internal cross-section of the HDPE pipe. The reducing agent corrugation is installed in HDPE (in the figure on the right). PVC is fixed in a conventional connection (in the picture on the left).

Color coding

By the color of PVC pipes you can determine their conditions of use.

Pipes for interior spaces are available in gray or black. Products for external networks are colored orange or yellow. White and blue - intended for casing wells.

The industry-produced range of PVC pipes and fittings for them makes it possible to construct sewer networks of any complexity. When choosing, you must take into account the reliability of the manufacturer. The applied marking can serve as a sign of the quality of the product. Manufacturers who do not care about their reputation do not pay attention to such “little things”.

Correctly selected parts of the sewer system will help to produce a reliable, durable structure that will not present surprises.

Purpose of fittings

The role of adapters in the sewerage system cannot be overestimated. Without their help, not a single repair of plumbing pipes or construction of a new line can be completed. Fittings are of particular value in cases where it is necessary to make a transition from pipes of one diameter to pipes of another - larger or smaller. Adapters are indispensable when carrying out repair work indoors, when it is not possible to change the entire sewer system, and only a certain section of it has to be changed.

Materials used

The materials used to make adapters are steel, copper, cast iron and modern polymers. Plastic is the most common type of raw material, and is gradually replacing metal analogues. For the manufacture of polymer fittings, polypropylene and polyvinyl chloride are used. The use of such parts significantly simplifies installation work and significantly reduces the time it takes to complete it.

The great popularity and high consumer demand for plastic adapters is due to a number of undeniable advantages of such parts:

- the low weight of the fittings allows you to easily install large parts of external systems yourself;

- a huge assortment of more than 100 types of plastic adapters allows you to quickly select the right part;

- products made from PP and PVC are not subject to corrosion processes, which distinguishes them from their metal counterparts;

- fittings are characterized by high strength and long service life, which allows you to forget about repairs for a long time after their installation;

- low cost and wide consumer availability make it possible not to skimp on material and to form a high-quality pipeline for little money.

The disadvantages of plastic adapters include the likelihood of deformation from exposure to high temperatures, the inability to use plastic to drain chemical waste, and low resistance to cold.

Cast iron is also used to make adapters. Despite the fact that cast iron pipelines are gradually being replaced by plastic ones, the material is still quite widely used for repairing communications in old housing stock. Cast iron elements are installed at the joints of cast iron and plastic pipes. Installation is carried out using a threaded connection. To ensure high tightness, the fittings are equipped with rubber cuffs.

Shaped parts made of cast iron also have a number of advantages.

- The service life of cast iron adapters is much longer than the service life of steel and plastic products and reaches 80 years.

- After dismantling, cast iron fittings can be reused, which cannot be done with plastic and steel counterparts.

- High tightness of joints. Sometimes, in particularly problematic sections of the pipeline, the joints are coated with polymer sealants, and then tightened using a locknut.

- Unlike steel and plastic fittings, which are attached to pipes by welding or crimping, cast iron adapters are mounted using the threaded method. This greatly simplifies installation and makes it accessible even to a novice plumber. In addition, if there is a need to clear a blockage, the plastic fitting needs to be soldered, while the cast iron fitting can simply be unscrewed.

The disadvantages include the large weight of cast iron products, the presence of a high coefficient of linear expansion inherent in cast iron, and the need for periodic inspection of connections in order to tighten loose nuts.

Metal adapters are used to connect steel pipelines and are made from copper and copper alloys and mild steel. Some models are plated with zinc or nickel. This allows you to improve their anti-corrosion properties and increase their service life. The connection of metal adapters to pipes occurs using the threaded method, and the threads on the fittings can be cut both internally and externally.

The advantages of such parts are wide consumer availability, ease of installation and a wide range of products. The disadvantages include susceptibility to corrosion processes, which is why such adapters often “stick” to the pipe and dismantling such a connection can be very difficult.

Types of fittings for PVC sewerage

Manufacturers of PVC pipes for sewerage have provided fittings for various configurations of wastewater drainage systems in order to simplify installation as much as possible and ensure the possibility of the most complex schemes. In addition, there are adapters for connecting to old cast iron pipes with a diameter of 50 mm and 110 mm.

Scope of application

PVC pipes and waste adapters are most often used when equipping domestic sewage systems:

- for continuous drainage of liquids whose temperature does not exceed +80°C;

- short-term exposure to temperatures +95°C (no more than 1 minute);

- chemicals with acidity from 2 to 12.

The most common types of fittings:

- coupling - designed to connect parallel pipes;

- inspection coupling - equipped with a special openable gap for cleaning the drainage system;

- reduction - connects pipes of different diameters and with cast iron elements;

- tee - for parallel or inclined branches with an angle of 45°, 65° and 90°;

- two-plane cross - for creating 2 perpendicular branches from pipes with the same or different diameters, with angles of inclination - 45° and 90°;

- single-plane cross - for 2 parallel branches with an angle of 45° and 90;

- bend - allows you to rotate 2 pipes at an angle of 30°, 40° and 90°;

- compensation pipe - installed when replacing a damaged cut section;

- plug - used to block the lumen of the pipe during repair or inspection of sewer systems;

- aerator - installed at the top of the sewer riser to prevent the release of gases through the toilet.

Dimensions of sewer fittings and installation recommendations

The sizes of PVC pipes and fittings are selected in accordance with GOST requirements for free-flow and pressure sewer systems, and the sizes of connectors and adapters must exactly fit the pipes.

For the installation of external sewerage, there are the following standard sizes of shaped structures:

- couplings - 110-400 mm (inspection up to 315 mm), length 120-330 mm;

- bends - 110-400 mm, distance between sockets - 15-90 mm;

- tee - 450-110-400 mm, side sockets - 140-530 mm, height from the socket to the end part - 140-500 mm;

- check valve - 110-250 mm, length - 300-520 mm;

- two-arm siphon - 110-200 mm, length - 510-820 mm.

For installation of internal systems, fittings with a diameter of 50-200 mm are produced. Fastening to the walls is done with plastic clamps, which are seated using 2 anchors.

The installation process is divided into stages:

- Cutting pipes into pieces of the required size using pipe cutters, a grinder or a hacksaw with the obligatory creation of a perpendicular axis.

- The edge is carefully sanded with a file and sandpaper.

- If adhesive fittings are used, the joints are degreased. Only after this is the glue applied. The excess is removed after joining the elements with a clean rag.

- Fittings with rubber seals must first be joined and the entry boundary must be marked. In the future, it will be necessary to provide a compensation gap of 1 cm.

- To minimize the risk of leaks, contacting surfaces are coated with silicone sealant.

Dimensions of tees for sewer structures

All plastic tees have the same design, which consists of a simple inlet pipe and 2 inlet sockets, which provide connection to the ends of the pipeline. They are equipped with special rubber gaskets.

For standard drainage systems, PVC tees have diameters of 110, 160, 200, 250 and 315 mm; for larger pipelines, it is possible to manufacture custom parts with diameters of 400 and 500 mm.

Tees with angles of 45°, 87° and 90° are equipped with pipes of different sections, therefore they support the transition of structural elements with the following dimensions:

- 50x50x45°,

- 50x50x87°,

- 110x50x45°,

- 110x50x87°,

- 110x110x45°.

Advantages of PVC fittings

Components for sewage systems made of polyvinyl chloride are primarily characterized by high strength and resistance to aggressive wastewater environments. PVC fittings have a guaranteed service life of 30-40 years, but in fact they can last much longer.

The big advantage of these PVC products is their simplicity and ease of installation. This does not require special skills, knowledge or special equipment. The whole process is comparable to assembling parts of a construction set - one element is inserted into another with the placement of a rubber gasket or the application of a thin strip of glue. If necessary, all repair work is carried out quickly.

Another important advantage of PVC structures over analogues is the low cost of components with high performance characteristics.

Classification

On the modern market of shaped elements, adapters are represented quite widely. In addition to the material of manufacture, fittings differ in their installation location and functionality. Depending on the installation location, adapters are available in eccentric and concentric models. The former are intended for installation on horizontal pipelines, while the latter are used on vertical pipelines.

However, the main feature by which adapters are classified is their functional purpose.

- Coupling. This fitting is used to form a pipeline from pipes of the same diameter. The size of the internal cross-section of the coupling corresponds to the outer diameter of the pipe. Couplings can be produced with both external and internal threads or be compression (capable of being attached using the crimp method).

Dimensions

The standard sizes of the adapters fully correspond to the sizes of the pipes involved in the formation of sewer systems. For the arrangement of internal networks, the most common section sizes are 110, 100, 50 and 32 mm. Such fittings can be installed either using a threaded connection or by welding, in contrast, for example, to dimensional products with a diameter of 250 mm, the installation of which is carried out only using a welding machine. In this case, the connection turns out to be completely permanent, and to dismantle it you will need to cut the connection.

Adapters used for joining plastic pipes with cast iron pipes are available in cross-sectional sizes of 50 and 110 mm. Connection fittings for toilets are bent at an angle of 45 and 90 degrees and have a common diameter for all models - 128 mm. The cylindrical part of such adapters can vary and be 112, 133 and 232 mm.

Types of transitions for plastic internal and external sewerage

Adapters for sewer pipes made of plastic can be welded, glued, threaded, or rubber ring according to the connection method.

In fact, adapters for sewer pipes come in a wide variety, for example, some of them are:

Types of sewer adapters

- coupling, perfect for connecting pipes where there is no socket;

- reduction – allows you to connect pipes of different diameters;

- an inspection with a lid is needed so that you can penetrate the pipe and remove the blockage. If you need to install it for external sewerage, then a design for a manhole is suitable;

Bends change the direction of the main line

branch, allows you to change the direction of the main line at an angle of 30, 45 and 90 degrees.