Plastic is widely used in the production of dishes, toys and even in space technology. The beauty of the material lies in the cheapness of the raw materials, which is why stores are filled with disposable cups and plates.

Therein lies the catch - plastic does not decompose and pollutes the environment. To reduce the harm to the material, they use specially designed devices - plastic crushers; making them yourself is not difficult.

Required tools and materials

To assemble the chopper, you will need metalworking, welding and grinding tools: drill, file, grinder. Welding joints are usually used to connect the frame and body, and bolted joints are used to attach the engine and cutting part. The materials you will need are metal elements:

- sheets;

- corners;

- stripes;

- pipes and profiles;

- hardware: bearings, bolts, pulleys, coupling (the list depends on the design).

A bucket or tank with solid walls is suitable for the storage tank to prevent the loss of fine particles. The rotary motor is connected to the shaft using a drive, and knives or circular saws are placed on the axis.

Do-it-yourself plastic crusher - drawing up a project and assembling homemade equipment

Plastic processing is one of the freest niches for doing business in Russia.

However, the issue of opening it most often depends on the cost of the equipment.

Entrepreneurs often start not with a full processing cycle with finished granulate at the output, but with the collection and grinding of polymer waste.

Even then, purchasing a shredder and/or crusher may not be affordable. One of the most discussed solutions to the problem is making your own shredder.

Such projects are quite feasible if two “constant quantities” are known - raw materials and product.

Next, we will talk about how to make a shredder and how to avoid gross mistakes when designing and making your own plastic crusher.

Assembly of finished units

In order for the design to be repairable, the body should not be welded.

It is better to make a bolted connection.

Then the chopper can be disassembled at any time for resharpening or replacing knives.

One of the common problems with rotating mechanisms is increased vibration.

To avoid this phenomenon, it is necessary to align the actuator, gearbox and motor, i.e., align their axes.

Another reason for vibration is imbalance (imbalance) of the rotors. To eliminate it, you need to carry out balancing.

We invite you to watch a video on how to implement the idea of a plastic recycling business using homemade equipment:

Conclusion

Not all the difficulties that will have to be encountered in the process of designing and assembling a plastic shredder have been considered.

Manufacturing can only be called independent, since it requires a whole fleet of machines, and some units have to be purchased assembled. The whole process can take months, and financial investments will be required in any case.

Those who have already had experience in manufacturing shredders believe that the idea is justified in two cases: if there are no strict time restrictions or if it is planned to establish serial production of such units. For practical plastic recycling tasks, it is usually easier to choose a ready-made model.

Do-it-yourself plastic and plastic crusher: scheme for creating a homemade crusher for PET

Polymer materials have become very firmly entrenched in our lives and can now be found in any industry.

But due to the fact that these materials do not decompose naturally, they cause serious damage to the environment.

A positive feature is the possibility of their recycling.

To do this, the plastic is first prepared and brought into the necessary state for this, it is crushed. To do this, special devices were invented - crushers (shredders, machines, shredders) for plastic. You can make such a crusher with your own hands.

Process of creation

Design features of a grain crusher: https://6sotok-dom.com/instrumenty/drobilka-dlya-zerna.html

Schematic diagram of a plastic crusher

After preparing everything necessary for work, you can begin the manufacturing stage:

- First, a cutting block is made by putting it on a pre-prepared axis of circular saws. To ensure that the necessary space remains between such improvised knives, it is worth using nuts.

- Next, we install the structure on the pulley and, using bearings, ensure free rotation.

- Now we make a rectangular frame and supporting frame from prepared metal materials.

- The next step is to weld the legs, adjusted in height, also using welding.

- Next, the frame is covered with a steel sheet; to do this, we weld it to the frame. We make a hole of the required size in it and mount the engine at the correct distance from the cutting elements. The protective cover and material supply container are required for safety and operational reasons.

- After creating the frame, we begin the last stage of assembling the plastic crusher. To do this, a so-called protective casing and a hopper are put on the knives, through which the raw materials will be supplied. When installing the casing, it is worth pre-providing a hole in it to connect the axle to the pulley.

- The final touch is to connect the cutting unit to the motor shaft using a belt. That's it, the design is ready.

Operating principle of a wood crusher: https://6sotok-dom.com/instrumenty/drobilka-dlya-dereva.html

The recommendation that experts give is the need to draw up a drawing of what the planned structure will look like before starting work. This will make it possible to avoid inaccuracies and discrepancies in the sizes of individual parts.

Having designed and assembled such a unit with your own hands, you can, knowing its entire design, easily make changes and modify it.

The crushed plastic will have the size that is included in the design capabilities of the unit itself.

When choosing a power unit, you need to decide in advance how often the device will be used. If the work on it is rare and the loads are insignificant, then a low-power electric motor will suffice, but for active use you will need a more powerful option with a higher number of revolutions.

And so as not to have to collect processed fractional material on the floor, it is advisable to provide a place under the saws for attaching a special container in which it will be collected.

Watch a video review of a high-quality, homemade plastic crusher:

- DmitriiG

Try to do without a wheelbarrow at the dacha or in a country house, it won’t work.

It is necessary for moving cargo, harvested crops, and fertilizers.

A one, two, or four-wheeled assistant in a store is inexpensive, however, if you assemble it yourself, it will be no less useful.

What are there

A wheelbarrow is distinguished from a cart by the number of wheels. A design with one wheel is called a wheelbarrow; if there are more than one wheels, we are dealing with a cart.

One-wheeled “equipment” is indispensable for the garden. Vehicle maneuverability is good for narrow stitches.

The minimum width of the wheel will help you carefully transport the load without damaging the plants. The cart is not suitable for such tasks. But it is necessary at a construction site, barnyard, cleaning up garbage accumulated after winter and much more.

It is reasonable to have both types on the farm; the wheelbarrow is not stable, one wheel requires tension when moving. It is more convenient to carry loads on two or four-wheeled structures.

Advice: a wheelbarrow is made for certain purposes, those jobs that require the presence of such wheeled vehicles. For example, for applying fertilizers.

Another reason to get both a wheelbarrow and a cart is to use it for different purposes. If manure is first removed from the livestock farm, then it cannot be used to transport crops from the garden or vegetable garden. Therefore, making yourself an assistant is the right decision.

Where to begin

From a drawing, a diagram suggested by imagination. Everything made with your own hands lasts longer, brings more benefits, and also beautifies the world around you.

Drawings and diagrams are offered in abundance by folk craftsmen, you can watch videos, scroll through photos, but you still have to make a sketch yourself. Do not buy parts in the store when there is an abundance:

- metal scraps;

- wheels from an old cart, bicycle, motorcycle, moped, scooter, baby stroller, furniture wheels preserved from Soviet times;

- pipe cuttings;

- parts from a broken exercise machine;

- corner;

- parking brake stop from a bicycle or motorcycle;

- fastening and connecting parts.

With all this, you can assemble more than one mobile structure.

Transportation for one bucket

We assemble a garden wheelbarrow for a summer residence from metal from the base:

- we measure metal sheets;

- We weld them together into a container of the required geometry;

- We make a frame from pipes with the required axle load to suit the dimensions;

- we connect the base to the container using fasteners or welding;

- fasten the wheel;

- we make parking stops;

- We put rubber hoses on the handles for convenience.

The hand wheelbarrow is ready. You can conduct a crash test and send the product to the garden.

Trolley from a construction barrel

You can adapt any barrel to a baud container - plastic, metal, wood. With the last one, you'll have to tinker. A barrel makes two wheelbarrows or carts!

A construction or garden wheelbarrow is assembled in this order:

- cut the barrel condemned to be thrown away in half;

- we make a frame similar to “A”;

- we attach the side posts to the frame, securing the half of the barrel;

- where the top of the letter is, we attach the wheel.

Important to know: don't throw away old things, reusing them can be both fun and useful!

We decorate the handles using electrical tape and cellophane, and the homemade design is ready. Now let's start assembling the second assistant.

Trolley from an old bed

If there are wheels from a motorcycle, an old Cossack, or a moped lying around, and a bed with armored mesh is in the way in the attic, we can assume that there is already a two-wheeled or four-wheeled self-propelled cart for the household:

Assembly:

- cut out the mesh;

- We mount wheelsets for welding or fastening;

- We make the bottom and side walls from a large metal sheet; wood and pipes are suitable for this;

- We adapt the handle, U-shaped, it’s more convenient.

The cart is powerful. Depending on what kind of bottom it has - metal or another, you can transport a small cart of hay. It will be useful for transporting firewood and building materials, and will be especially relevant if construction is planned.

Landscape decoration

An old wheelbarrow or trolley that has served its purpose can become an exclusive decoration of the site.

Where can I get the drawings?

You need to understand that manufacturers of equipment for shredders and crushers will not make drawings publicly available.

The easiest way to get diagrams for a homemade shredder or crusher is in two ways:

- Read forums on the topic, like this one. The likelihood of finding accurate and detailed drawings of plastic shredders is very low. Often, resource users recycle some unclaimed equipment from a related industry, for example, a lopper. And if a crusher is made from scratch, few people care about documenting all stages of production. Nevertheless, it’s worth reading the forums: analyzing discussions and other people’s design mistakes will help you make a more advanced plastic shredder with your own hands.

- Take measurements from the existing shredder. It will not be possible to obtain complete information, since the owner will not allow you to disassemble a working machine. But even a visual assessment will help in making your own homemade crusher.

An attempt to reduce the cost of a design using secondary parts, as a rule, leads to mistakes.

Do-it-yourself crusher for PET bottles

Plastic processing is one of the freest niches for doing business in Russia.

However, the issue of opening it most often depends on the cost of the equipment.

Entrepreneurs often start not with a full processing cycle with finished granulate at the output, but with the collection and grinding of polymer waste.

Even in this case, purchasing a shredder and/or crusher may not be affordable . One of the most discussed solutions to the problem is making your own shredder.

Such projects are quite feasible if two “constant quantities” are known - raw materials and product.

Next, we will talk about how to make a shredder and how to avoid gross mistakes when designing and making your own plastic crusher.

What is the difference between a shredder and a polymer crusher?

Both types of equipment perform the same task - crushing.

When processing plastics, this process is usually divided into two stages :

- coarse grinding - shredders are used for this;

- obtaining fine crumbs - a crusher is used for this.

The operating principle and kinematics of both units are most often the same, and they differ only in some details, for example, the size of the sieve cell, the overlap of the knives and the configuration of the cutting edges.

The process is divided into two stages in order to increase productivity and optimize energy costs.

Shredder design for plastics

When choosing the design of a plastic shredder, you should pay attention to the proposals of equipment manufacturers.

It is better to take other people’s work as a basis for a project and have certain guidelines than to reinvent the wheel and end up with a non-working model.

The most popular are single- and double-shaft rotary shredders.

Single shaft shredders are used for the initial shredding of most varieties of polymers .

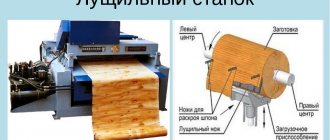

It consists of a rotor on which movable knives (2) are fixed and a housing with fixed or stator knives (1). The raw materials are fed through the loading window from above, and the finished crumbs are poured under their own weight through the calibrating sieve (3).

The shredding process involves repeated cutting and continues until all the plastic has gone into the receiving hopper.

The configuration of the rotary knives is selected depending on the material being processed:

- Dovetail and inclined – for processing film materials, PET containers and other soft waste.

- Straight – for crushing sprues, boxes, thick-walled blow moldings, PET bottle caps. Such knives are often made in the form of separate segments, which are arranged in cascades. Segmentation is performed to reduce shock loads on the drive, reduce noise and vibration.

Stator knives for single-shaft polymer crushers are made solid (type P).

Where can I get the drawings?

You need to understand that manufacturers of equipment for shredders and crushers will not make drawings publicly available .

The easiest way to get diagrams for a homemade shredder or crusher is in two ways:

- Read forums on the topic , like this one. The likelihood of finding accurate and detailed drawings of plastic shredders is very low. Often, resource users recycle some unclaimed equipment from a related industry, for example, a lopper. And if a crusher is made from scratch, few people care about documenting all stages of production. Nevertheless, it’s worth reading the forums: analyzing discussions and other people’s design mistakes will help you make a more advanced plastic shredder with your own hands.

- Take measurements from the existing shredder. It will not be possible to obtain complete information, since the owner will not allow you to disassemble a working machine. But even a visual assessment will help in making your own homemade crusher.

Many attempts to make a crusher on their own reach a dead end due to the fact that the designer tries to attach to an existing unit . For example, “fit” all the elements to a worm gearbox found in the garage.

An attempt to reduce the cost of a design using secondary parts, as a rule, leads to mistakes.

It is better to start production with a clear definition of the tasks of the shredder, that is, you need to know the type and quantity of raw materials being processed, and the size of the output fraction.

After this, we find a model from any well-known manufacturer that fits these parameters and take its technical characteristics :

- engine power;

- loading window dimensions;

- number and diameter of rotors;

- knife configuration.

Drive design

In factory crushing plants, two methods are used to transmit rotation from the motor to the gearbox:

- Direct drive (via clutch). Torque transmission occurs without loss, the design is compact in size. If you manage to select a ready-made geared motor, the dimensions and weight of the installation will be even smaller. However, in this case, it is necessary to provide for manual (and ideally automatic) reversing in case of jamming of the rotors.

- Belting . Efficiency losses and relatively high dimensions are compensated by the smooth start of the mechanism. If the shredder becomes jammed, the only risk is that the belt will break or slip.

The transmission of rotation between the rotors (in the case of using one engine) is most often carried out through an open gear drive. When designing, you need to be prepared to calculate it. Most likely, gears will have to be ordered .

Knives

Finding a suitable knife configuration is not difficult.

Types of shredders

They are divided into options:

- The design looks like V-shaped blades on scissors and is suitable for shredding plastics such as acrylic, film and nylon.

- A type that is used mainly in factories where plastics are produced, as well as in recycling plants.

By design, they come in several types: hammer, cone or jaw crushers. They are used for processing large plastic products, such as window profiles.

- The most common option has a rotor design and is used for processing thin-walled plastics such as bottles and polystyrene foam.

A plastic shredder will allow its owner to contribute to the environment and even earn money. For domestic purposes, a rotary version of the crusher is usually used. Its design consists of a rotor on which the knives are securely attached.

Mesh for crushers

After turning on (and it can work either from a liquid fuel engine or from a conventional electric motor), the axis with knives begins to rotate and, as a result, under quick and strong blows, the raw materials that get inside such a device are crushed.

At the bottom of the grinding body there is a grid that has a certain cell size. It is determined depending on what diameter the fraction should ultimately have.

The raw material is processed in the device until it reaches the desired size and exits through this sieve.

Construction and types

The design of the crusher is extremely simple. Its main element is a rotor that rotates inside a special chamber. The distance between the rotor and the chamber walls is small. At the bottom of the chamber there are steel knives. When plastic enters the crusher, it is strongly pressed against the knives and, as a result of movement along them, is crushed.

Varieties and differences

The knives located in the chamber can be of different shapes. The two most common are:

. They are located at an angle, due to which they better capture the material entering the crusher. Most suitable for working with various films and PET containers.

Inclined- Double . At the end the knife splits into two blades. This makes cutting more efficient. This blade configuration is also suitable for polymer films and PET containers.

- Direct . In this case, the knives are located at an angle of 90 o, that is, directly perpendicular to the rotor. This configuration is suitable for shredding large and solid waste (such as PET bottles, plastic boxes and others).

Knives can be movable (stator) and fixed (rotor). In the first case, they are placed on a shaft that rotates perpendicular to the crusher rotor. In the second, they are fixed to the bottom of the unit’s chamber (sometimes on the side walls).

Knives can be placed on both rotors at the same time. Units with this design are more efficient and productive.

If there is only one shaft and the knives are stator, use one drive. If the knives are movable, two drives are used. However, in the latter case, sometimes one is still used. You need to understand that this will affect the performance of the device for the worse.

Crusher design

A plastic shredder consists of several elements:

- engine;

- cutting mechanism;

- drive;

- sieves (filters);

- loading pocket;

- storage capacity;

- frames and housings.

The main unit that ensures the operation of the entire shredder is the engine and the cutting mechanism. They are connected by a drive, and all components are fixed on a frame, which is covered with a housing to comply with safety regulations.

The entire design of the device is based on the choice of engine type: single-shaft or double-shaft.

Single shaft shredders

Single shaft design is suitable for plastic crushing to increase the density of raw materials. When passing through a single-shaft structure made from plastic waste, it will not be possible to obtain crumbs suitable as finished recyclable materials. The cutting tools are placed on a single shaft, which rotates to cut the plastic into small pieces.

A single-shaft plastic waste shredder is the simplest do-it-yourself shredding device. To do this, a shaft with knives is placed inside the housing, which rotate when a rotary engine, sometimes supplemented with a hydraulic press, operates. The design is compact enough to fit into a home and is used for the primary processing of large and solid plastic waste.

Twin shaft crushers

Higher productivity and precision during crushing is ensured by the double-shaft design of the crusher. Two shafts are designed so that the cutting elements are staggered relative to each other. Due to this, the entire surface of the loaded raw material is crushed. This is in contrast to the single-shaft design, where the plastic can slip through the knives and large pieces must be “driven” through the shaft several times.

In a two-shaft design, each axis rotates towards each other, ensuring that plastic is “sucked” into the knife mechanism, so additional reinforcement through a hydraulic press is not necessary for a two-shaft design.

Schemes and drawings

Self-assembly of the chopper must be carried out only according to the drawing. This will protect against damage to materials, help organize work and take into account the nuances in the design of the device. When drawing up a diagram or drawing, the operating conditions, assembly conditions, and the availability of available materials are taken into account in order to reduce the cost of purchasing new ones.

A ready-made diagram or drawing can be downloaded from the Internet, but in this case there is no full guarantee of the functionality and safety of the structure. There is no point in drawing up such drawings according to the rules of design documentation, so their interpretation may be complicated due to the author’s specifics.

Initial data for design

When drawing up the project, the types of waste that will be crushed in the device are taken into account. The choice of design, type of engine and cutting elements, and size of the device depend on this. In addition to the composition of the waste, it is necessary to consider the volume of input that will be processed in the shredder.

A universal grinder for producing fractions of different sizes allows you to change the number of knives and sieve density. By compacting the knife mechanisms and the sieve, a fine fraction can be obtained.

If it is expected that homogeneous waste will be processed, then it is sufficient to design the shredder with a rigid structure.

How to melt plastic waste at home

You can melt plastic waste at home using one of the previously described devices (press, injector, extruder). However, their creation requires certain skills and time. You can resort to melting plastic using more primitive methods. For example, to obtain a plastic screw cap, you can build a metal syringe and a solid mold.

Process description

Polypropylene (marked “PP”) can be used as a raw material. The crushed material is placed into a manufactured syringe and compacted with a metal piston. A syringe filled with plastic is placed in a conventional oven for about 30 minutes at a temperature of 220-240°C. Then the molten plastic mass is squeezed out of the syringe into the prepared mold, and the material must be kept under pressure for some time. After cooling, the finished product can be removed from the mold.

Read also: C547b transistor characteristics and its Russian analogues

About the benefits of home creativity

Fantasy can turn a trough into a car. After construction, it remained to build a beautiful wooden carriage from the scattered beams.

The wooden structure is suitable for landscaping. You can collect everything from improvised parts.

The advantages of such creativity have different sides:

- financial - money is not spent, but the object is purchased;

- Aesthetics - beautifully made things change the interior;

- Education sets a good example for the younger generation;

- creative - the embodiment of fantasy does not make life boring.

How to build a car with your own hands is explained in the instructions in the following video:

Page 3

It's nice to have your own country house or villa with beautiful green lawns and even paving slab paths.

If you don't have a lot of money to spend on this decorative item, you can go the extra mile and build a vibrating table for making floor tiles yourself.

We make the crusher ourselves

Owners who decide to assemble a plastic shredder themselves can find a lot of options for this useful device online and choose the most suitable one. Making this device with your own hands is not so difficult - you just need to be patient and have minimal operating skills. You can assemble a high-performance plastic processing unit without the use of special equipment. To complete the work, you only need a welding machine or a household inverter.

Tools

Each master can, at his own discretion, make changes to the diagram below, but in any case, a homemade plastic crusher will include the following required elements:

- Drive unit. Usually an electric motor is used as it. If you don’t have what you don’t need, you can go to the store and find an inexpensive model with the required power among the range offered. A crusher equipped with an electric drive is also advantageous in that it runs more quietly, so it can be used not only outdoors, but also indoors.

- Circular Saw. It will be responsible for processing plastic waste. Make sure you have a sufficient number of saws with different tooth shapes so that you can shred waste efficiently. Given the task at hand, it is ideal if you install at least 20 saws on one axis.

- A working axis designed for mounting saws.

- A metal profile that can be replaced with a pipe of a suitable diameter. The supporting frame and frame of the crusher will be made from it.

- Protective cover and feed hopper. To make them, you can use galvanized sheets. You will also need a special tool - metal scissors, a hammer and a vice.

- A pulley, a pair of bearings and a special belt that will support the interaction between the electric motor and the rotor.

- Various types of fasteners - metal screws, washers and nuts.

Making a crusher

After you resolve the issue with materials and tools, you can proceed directly to the crusher manufacturing process.

The process begins with the manufacture of a cutting block. Take the axle and put the circular saws on it

Please note that the saw seat must have the same diameter as the axis. Make sure there is enough space between the improvised knives to place the metal washers

To ensure secure fastening of the saws, you need to put nuts on the ends. After this, you can install the axle itself on the pulley. You need to put two bearings on it, then the structure will rotate freely.

At the next stage, we begin to make the supporting frame. We take a welding machine and make a rectangular frame using a metal corner, profile or pipe. Next, you need to weld the legs to it, calculating their height in advance. We lay a sheet of metal directly on the frame and weld it to the frame. You need to make a hole in the sheet, which should be the same size as the cutting block. Now you can install the engine, which we place near the knives.

After the work on manufacturing the frame is completed, we move on to the final stage of assembling the chopper. We take the protective casing, put it on the knives, and attach a hopper on top through which the raw materials for grinding will be supplied. Don't forget to make a hole in the casing for subsequent connection of the axle to the pulley. Next, you need to put on a special belt that will connect the motor shaft to the cutting unit. At this point, the work of making a plastic crusher with your own hands can be considered complete.

Making a plastic crusher with your own hands

Polymer materials have firmly entered modern life, and there is not a single industry where they are not used, from the production of containers to space technologies. Every year about 180 million tons of various plastics are produced on the planet. Most of them cannot independently decompose into simple components and be disposed of independently.

This causes irreparable damage to nature and can cause an environmental disaster. A positive feature of almost any polymer (plastic) is the possibility of recycling, thanks to which old plastic items can get a “new life” as useful items. Recycled plastic is slightly inferior in strength characteristics to primary polymer, but at certain proportions, products made from recycled plastic are practically no different from the original one.

Types of shredders

Before recycling can be produced, any plastic must be shredded. There are special devices for this - crushers . Depending on the physical properties of the polymer placed in them, devices can be classified into several categories:

- for shredding PVC film, nylon or acrylic. The design resembles large scissors with “V”-shaped blades;

- for large plastic waste. Most often used in recycling plants or plastics factories. They come in hammer, jaw or cone designs. With their help, window profiles and large parts and housings are crushed;

- for PET bottles and thin-walled plastics. The most common version of the chopper is structurally called rotary.

You can purchase the required type of device or make it yourself. We are talking about a small household appliance from the third category. Making a plastic crusher with your own hands is quite easy and does not require serious knowledge or specialized tools, except for a welding machine.

Learn more about the rotary shredder

The most common design is the impact crusher. It consists of a rotor on which the knives are fixedly mounted. Under the influence of the driving force - from a diesel, gasoline engine or electric motor, the axis with knives begins to move and with quick blows crushes the raw materials that have fallen under the knives. Depending on the purpose, there are low-speed machines and high-speed units.

A sieve or grid with a certain mesh size is installed at the bottom of the working chamber, depending on the required quality and diameter of the resulting fraction. The raw materials are processed cyclically with knives and gradually pass through a sieve.

Particular attention is paid to the quality of the metal from which the knives are made - it should be good hardened steel, which prevents rapid wear and ensures that the sharpness is maintained for a long time.

We make the crusher ourselves

There are several of the most popular types of plastic shredders that are made at home. In order to assemble this device with your own hands you will need a little patience and minimal skills. All you need as a special tool is a welding machine or a household inverter.

A do-it-yourself plastic crusher, the design of which will differ slightly depending on the level of skill of the manufacturer and his imagination, has the following common elements:

- drive unit. The most commonly used is an electric motor. Thanks to the large selection and affordable prices, you can choose the model of the required power. In addition, the electric drive crusher is quieter and can be used both outdoors and indoors;

- circular saws. This will be the basis of our apparatus. It is necessary to select a sufficient number of them and different configurations of teeth for better grinding of waste. The optimal number of saws on the axis is about 20;

- the axis on which the saws will be mounted;

- metal profile or pipe for making the support frame and frame of the crusher;

- protective cover and feed hopper. You can make them yourself at home from galvanized sheets using metal shears, a hammer and a vice;

- a pulley, two bearings and a special belt, which creates interaction between the electric motor and the rotor;

- fasteners (nuts, washers and metal screws).

Types of shredders

There are only three options for such devices, which differ in the ability to process a particular polymer material.

They are divided into options:

- The design is similar to the V-blade on a pair of scissors and is suitable for shredding plastics such as acrylic, foil and nylon.

- This type is mainly used in plastics factories, but also in processing plants.

They are offered in various designs: hammer, cone or jaw crushers. They are used for processing large plastic products such as window profiles.

- The most common version has a rotating design and is used for processing thin-walled plastics such as bottles and foam.

A plastic shredder allows its owner to contribute to the environment and even earn money. The rotating version of the crusher is usually used for domestic purposes. Its design consists of a rotor on which the knives are securely fastened.

After switching on (and can work with both a liquid fuel engine and a conventional electric motor), the axis of the knife begins to rotate, so that the raw materials are crushed in such a device under the influence of fast and strong impacts.

On the underside of the crusher body there is a grate with a certain mesh size. This is determined by the final diameter of the fraction.

The raw material in the device is processed to the desired size and exits through this sieve.

To assemble a welding machine at home, certain skills in working with a welding machine are required.

A plastic shredder consists of elements such as, for example,.

Since this is the basis of the entire machine, they should be selected only according to the quality and various tooth configurations, which allows for better grinding of waste;

- The best control method is to use the electric motor option. The reason for this is the greater choice and possibility of use not only outdoors, but also indoors;

- saw axis;

- The metal profile is also needed to make the frame and frame;

- various fasteners;

- a funnel through which the processed material passes, and a protective casing;

- A special belt is required to connect the rotor, as well as a pulley and several bearings.

Choosing the wrong saw for your crusher can result in an imbalance in the axle, which can lead to vibration and faster wear on the structure.

Materials and tools for work

To make this device at home, you will need some skills in working with welding equipment.

The entire plastic shredder is made of the following parts:

- circular saws. Their standard number is approximately twenty pieces. Since this is considered the basis of the entire device, you should choose only high-quality ones and with different tooth configurations, which helps to grind waste well;

- Instead of a drive, it is worth taking an electric type of engine. The reason is a longer choice and the ability to use not only in an open area, but also in the room itself;

- axis for fastening saws;

- for the manufacture of the frame and frame you will also need a metal profile;

- various parts for fastening;

- a hopper through which materials for processing will be supplied, and a protective casing;

- To attach the rotor, you will need a special belt, as well as a pulley and a pair of bearings.

The wrong choice of saws for a crusher can lead to problems on the axis, causing the structure to vibrate violently and quickly break.

Safety precautions when working with a shredder

Sources of danger in the operation of a shredder are: the cutting device, flying crushed particles, and the structure itself. The cutting device is dangerous if the operator has free access to its elements. The entry of human limbs into the working knives is prevented by covering this part of the structure with a casing.

An additional protective measure is to install a loading channel longer than the size of a person's limbs to physically prevent intentional or unintentional penetration of cutting devices. In addition, when working, you must follow a simple rule: turn off the power source if the shredder is not working. This will help avoid injury when cleaning the cutting device if, for example, it works by applying force.

The casing around the cutting device will protect not only from cut injuries, but also from flying chips. For the same reason, the output channel must also be made in the form of a closed casing so that the crushed particles fall into the storage tank in an orderly manner. The structure itself poses a danger in the event of destruction, which occurs due to insufficient fastening or excessive vibration. You can avoid destruction with the help of reinforcing elements: a rigid base, corners, metal strips.

vote

Article Rating

Device design

In order for a self-assembled plastic shredder to work with the greatest efficiency, choose a design that is suitable for disposing of the waste you are going to work with. Installations vary in complexity and equipment (filter screens, bearing units, type of saws, pre-pressers, etc.)

Single-shaft

This is the simplest design in which a rotor equipped with cutting edges rotates inside a stationary housing. Waste enters the device through the loading window. The crushed raw materials are sifted through a sieve under the influence of their own weight.

To make recycling faster, most single-shaft rotary shredders are equipped with a hydraulic pre-presser. This device presses pieces of debris against the rotor blades, reducing the risk of pieces of plastic slipping.

Single shaft shredder teeth

Some devices are additionally equipped with a pneumatic system for unloading raw materials. The single-shaft design is good for its simplicity, reliability and ease of assembly. It is better to use it for the primary grinding of particularly hard polymers.

Twin-shaft

Twin shaft shredder

In a more complex shredder, two rotors installed in one housing rotate towards each other. This design makes it possible to do without a pressing element, since the waste is pulled into the gap between the rotors. Better grinding is achieved, and the high torque allows you to load elastic plastic, rubber and elastomers into the crusher.

Where can I find a drawing or diagram

There are no drawings of shredders in the public domain, as manufacturers do not want their devices to be copied or produced without a license. Valuable tips, diagrams and sketches can be found on the forums. If you have a prototype product, carefully inspect it, or better yet, disassemble it by measuring the dimensions of the main parts.

Initial data for design

Decide which waste you will have to work with more often. Approximately calculate the amount of work and, based on it, determine the installation parameters:

- power;

- raw material supply window size;

- diameter of rotors and their number;

- configurations of knives or teeth (their size, relative position, sharpening, material).

In order not to calculate everything manually, find a factory crusher that would suit your needs, and build on its technical characteristics.

Manufacturers

Approximately 60 percent of the Russian crusher market is made up of Chinese products. It should be noted that China has good teachers, thanks to which their equipment is of good quality. The fact is that many well-known manufacturers from Europe and Japan locate their production in this country. These are the German company Zerma, the Japanese Genox, Enma from France and many others. But their products are expensive.

Crushing equipment from Chinese companies is much cheaper. True, the quality of products is at different levels, depending on which countries they are produced for. For example, the companies HUARE, JWELL, WENSUI produce units for the markets of North America and Europe: they use European or Chinese high-quality components, complement the equipment with various options, pneumatic transport systems, etc. Such equipment is quite expensive.

For the Middle East, Ukraine, Russia and for its fellow tribesmen, China produces grinders fully equipped with elements of Chinese origin. The knives in such units are of low quality. All this undoubtedly affects the price: middle-class equipment is relatively inexpensive.

In China, a small manufacturer is also engaged in the production of this type of equipment, whose name does not mean anything to anyone. Such companies usually copy grinders from domestic Chinese manufacturers. The quality of the product is reduced to the minimum acceptable, although at first glance it looks attractive.

Such equipment can be bought for literally pennies, but it does not last long. With the same success, you can build a plastic crusher with your own hands, and with maximum effort, a homemade one can turn out to be more reliable. Especially if the craftsman is able to draw up competent drawings of a plastic crusher.

Well-known European companies produce high-quality equipment that can last for decades. An example of this is the German company Gross , which produces VOTECS crushers. They can work for 30 years, and then they are restored and sold again, and the cost of the restored ones is in no way inferior to new ones.

In Russia, good shredders are produced by the polymer engineering plant AtlasMash. The company produces three series of equipment: light, medium and heavy classes. It must be said that Russian ones are much cheaper than German ones: their price is in the mid-level range.

Selecting the right engine

This is perhaps the most important point in the process of making a vibrating table.

As mentioned above, the motor of an old washing machine works very well, but its disadvantage is its short service life: it breaks down quickly, with a maximum of about 30 operating cycles. Usually the bearing either seizes or the shaft becomes loose.

If the vibrating container is carefully manufactured, we recommend installing a potentiometer with which the vibration frequency can be adjusted. This will help you adjust the vibration frequency according to the type of solution you want.

A little trick in making a vibrating table:

Pay attention to the choice of material for the stove. The basic requirements must be strong and withstand vibrations as well as static and dynamic loads; Calculation of vibration amplitude

The quality and appearance of the products depends on the amplitudes; Install the motor at a specific location as shown in the drawing.

Thus, you have managed to create your own mini floor tile making machine at home. Not only do you save money (buying a new table will cost many times more), but you also have the opportunity to make tiles to your own size and shape.

You will learn how to build a vibration table with your own hands from the instructions in the following video:

The device of a crusher for plastic (polymers) and the principle of operation

Polymer waste is heterogeneous: it includes polymer film, PET bottles, and body parts. They have different mechanical properties, therefore, the methods of grinding them are different. Film, for example, can be easily cut, but it cannot be shredded by impact. But ABS plastic, which we most often find in the form of body parts, can be crushed with an impact tool. In addition, raw materials vary in thickness, and this also affects the choice of grinding method. Accordingly, crushers for PVC waste and polyethylene have a number of design features depending on their purpose.

Drafting

Most people are content with a mini-crusher, which does not require expensive materials. However, for a DIY device to work correctly, you will need to study the theory of strength of materials. If you do not have minimal technical knowledge and experience in designing machines, it is better to invite an experienced person.

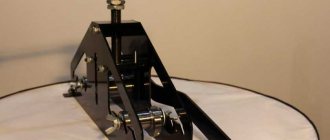

Designing a single-shaft shredder involves:

- choosing an electric motor of suitable power;

- calculation of shaft strength;

- determination of the diameter and length of the rotor, the width of the loading window;

- selection of bearings;

- calculation of the gear ratio, selection of a suitable factory model.

Development of the shredder element

The drawing is made on graph paper or using the AutoCAD program. Calculating parameters “by eye” without drawings is fraught with a decrease in the productivity of the installation and increased danger when working with it.

Learn more about the rotary shredder

Rotary plastic crushers demonstrate high productivity and crushing depth. Thin-walled waste is crushed by high-speed devices processing up to 100 liters per hour.

For thick-walled waste, machines with low rotation speed but high torque are used; their power reaches 10 kilowatts. Capacity is limited to 15 liters per hour; they can handle the hardest plastics. Medium and large processing plants typically have both types of rotary shredders. At low speed, solid waste is pre-crushed and then finally crushed using high-speed devices.

The working bodies of such devices are the massive corrugated rotor itself and fixed side knives, numbering from 3 to 7. Raw materials enter the working chamber from the loading hopper and fall between the rotor knives and the fixed knives, where they are crushed.

Crusher with built-in shredder-thermocompactor

Rotary shredders are available with one or two rotors. Some models add a grate. It acts like a hammer grinder.

Classification of shredders

Plastic waste crushers are classified according to design and purpose.

By purpose:

- polymer film shredders (polypropylene, acrylic, polyethylene, nylon, polyvinyl chloride, etc.). They are equipped with V-shaped polymer crusher knives that cut the material like scissors;

- shredders for thin plastic products and PET bottles. The design includes cascade cutters. A feature of such equipment is the direct dependence of productivity on the volume of one load of waste. The highest level of productivity is observed at maximum equipment load;

- installations for grinding large products: window profiles, cabinet parts.

By design:

There are several types of units, each of which is designed for grinding a specific type of polymer:

- jaw: the main working body of this type of shredders are steel corrugated plates, with the help of which the plastic is crushed;

- hammer (impact type): waste is crushed under the influence of impact hammers hinged on the rotor;

- conical: equipped with two steel cones, between which the raw materials are crushed;

- rotary: the most common type of shredders. They have high productivity and efficiency, designed for grinding thin-walled materials - high speed. Their power exceeds 10 kW. The applicability of high-speed machines is limited by the strength of the plastic, but its grinding speed reaches 100 l/s. Crushing of thick-walled products is carried out on low-speed machines with a power of up to 10 kW. Their maximum speed is only 15 l/s, but they successfully cope with the thickest, high-hardness waste. In large industries, it is advisable to have both types of equipment: in this case, the low-speed one can perform preliminary grinding of large waste, and the high-speed one can perform the final grinding. This compensates for the low performance of the low-speed machine.

Recommendations from experts

The main advice that the craftsmen give is the need to make a drawing before starting work in order to know exactly what the structure you are planning will look like. This will help avoid inaccuracies and errors with the dimensions of individual parts.

Having planned and assembled such a device with your own hands, you can, knowing its design, calmly make changes and improve it. The processed plastic will have a size that is included in the design capabilities of a particular device.

When choosing such a device, you need to decide in advance how often the unit will be used. If there will be little work on it, and the loads planned are small, then a low-power electric motor will suffice, but for active use you will need a more powerful device with a huge number of revolutions.

And in order to avoid the need to collect processed fractional material from the floor, it is worthwhile to provide an angle under the saws for securing a strong container.

Plastic is widely used in the production of dishes, toys and even in space technology. The beauty of the material lies in the cheapness of the raw materials, which is why stores are filled with disposable cups and plates.

How to shred a plastic bottle at home – Metals, equipment, instructions

Polymer materials have been present in our lives for quite some time, and now they can be found in any industry. But due to the fact that plastic does not decompose in the usual way, it causes enormous damage to the environment.

The possibility of its recycling is considered a positive factor. To do this, the plastic is first prepared and brought into the state it needs, then it begins to be crushed. To accomplish this, special devices were created - crushers (shredders, machines, special grinders). You can make any of them yourself.

There are 3 types of such devices, which can be divided according to the capabilities of processing all the material. They are divided into the following options:

- the design’s appearance resembles unusual blades on scissors; it is suitable for working with types of plastic such as acrylic, film and nylon;

- the type that is most often used in factories where plastic is made, as well as in plants for processing old material;

- hammer, cone or jaw devices, which are used for processing large plastic parts, for example, window profiles.

Materials and tools for work

To make this device at home, you will need some skills in working with welding equipment.

The entire plastic shredder is made of the following parts:

- circular saws. Their standard number is approximately twenty pieces. Since this is considered the basis of the entire device, you should choose only high-quality ones and with different tooth configurations, which helps to grind waste well;

- Instead of a drive, it is worth taking an electric type of engine. The reason is a longer choice and the ability to use not only in an open area, but also in the room itself;

- axis for fastening saws;

- for the manufacture of the frame and frame you will also need a metal profile;

- various parts for fastening;

- a hopper through which materials for processing will be supplied, and a protective casing;

- To attach the rotor, you will need a special belt, as well as a pulley and a pair of bearings.

The wrong choice of saws for a crusher can lead to problems on the axis, causing the structure to vibrate violently and quickly break.

Recommendations from experts

The main advice that the craftsmen give is the need to make a drawing before starting work in order to know exactly what the structure you are planning will look like. This will help avoid inaccuracies and errors with the dimensions of individual parts .

Having planned and assembled such a device with your own hands, you can, knowing its design, calmly make changes and improve it. The processed plastic will have a size that is included in the design capabilities of a particular device.

When choosing such a device, you need to decide in advance how often the unit will be used. If there will be little work on it, and the loads planned are small, then a low-power electric motor will suffice, but for active use you will need a more powerful device with a huge number of revolutions.

And in order to avoid the need to collect processed fractional material from the floor, it is worthwhile to provide an angle under the saws for securing a strong container.

Making a plastic crusher with your own hands

Polymer materials have firmly entered modern life, and there is not a single industry where they are not used, from the production of containers to space technologies. Every year about 180 million tons of various plastics are produced on the planet. Most of them cannot independently decompose into simple components and be disposed of independently.

This causes irreparable damage to nature and can cause an environmental disaster.

A positive feature of almost any polymer (plastic) is the possibility of recycling, thanks to which old plastic items can get a “new life” as useful items.

Recycled plastic is slightly inferior in strength characteristics to primary polymer, but at certain proportions, products made from recycled plastic are practically no different from the original one.

Learn more about the rotary shredder

The most common design is the impact crusher. It consists of a rotor on which the knives are fixedly mounted. Under the influence of the driving force - from a diesel, gasoline engine or electric motor, the axis with knives begins to move and with quick blows crushes the raw materials that have fallen under the knives. Depending on the purpose, there are low-speed machines and high-speed units.

A sieve or grid with a certain mesh size is installed at the bottom of the working chamber, depending on the required quality and diameter of the resulting fraction. The raw materials are processed cyclically with knives and gradually pass through a sieve.

Particular attention is paid to the quality of the metal from which the knives are made - it should be good hardened steel, which prevents rapid wear and ensures that the sharpness is maintained for a long time.

We make the crusher ourselves

There are several of the most popular types of plastic shredders that are made at home. In order to assemble this device with your own hands you will need a little patience and minimal skills. All you need as a special tool is a welding machine or a household inverter.

A do-it-yourself plastic crusher, the design of which will differ slightly depending on the level of skill of the manufacturer and his imagination, has the following common elements:

- drive unit. The most commonly used is an electric motor. Thanks to the large selection and affordable prices, you can choose the model of the required power. In addition, the electric drive crusher is quieter and can be used both outdoors and indoors;

- circular saws. This will be the basis of our apparatus. It is necessary to select a sufficient number of them and different configurations of teeth for better grinding of waste. The optimal number of saws on the axis is about 20;

- the axis on which the saws will be mounted;

- metal profile or pipe for making the support frame and frame of the crusher;

- protective cover and feed hopper. You can make them yourself at home from galvanized sheets using metal shears, a hammer and a vice;

- a pulley, two bearings and a special belt, which creates interaction between the electric motor and the rotor;

- fasteners (nuts, washers and metal screws).