A straight-through bent turning cutter is a special tool for processing metal structures, which is primarily designed to eliminate irregularities on the outer surfaces of various rotating parts, such as cylindrical rolls and other conical-shaped elements.

Due to their universal operating capabilities, such cutters have gained greater popularity than similar straight-type tools. With the help of bent cutters, the following work is performed:

- roughing and finishing processing of external and internal planes of parts;

- facing of conical and cylindrical workpieces;

- chamfering at a certain degree;

- thread cutting;

- elimination of unnecessary structural elements.

Geometric characteristics GOST 18877 73

The main component of the cutter is its head, located on the top of the tool shaft and fixed in the tool holder. The cutter head has one leading edge and two rear edges (main and auxiliary). The leading edge allows for better chip flow from the surface of the workpiece.

The main work of the tool is carried out using a special vertex in the cutter, which is formed at the intersection of the main, auxiliary and leading edges. In any model, its own angle is formed, which allows the product to be produced to best meet the requirements and conditions of use. For example, for the process of forming a step-type part, a cutter with a total angle of 90 degrees is used.

Tips for choosing a boring tool

To choose the right boring cutter for processing a specific hole, you need to consider the following points:

- what material should the working part be made of: here you need to know what metal will be processed and what processing modes;

- geometry of the cutter - its working part: this parameter comes from the processing tasks;

- an indicator of vibration resistance and strength of the tool body and the cutting edge: the fundamental thing here is the processing mode, the presence or absence of a coolant;

- the size of the cutter and its shape is dictated by the size of the hole and the processing tasks;

- design and method of fixing the cutting plate, if it is removable;

- type of chip separation from the surface during processing;

- shape and type of tool holder in the machine.

Advantages and disadvantages

It is quite difficult to determine the pros and cons of such a product. First of all, its versatility in operation will be an undoubted advantage. With this tool you can perform many types of actions (rough and fine finishing, thread formation, trimming of various parts, and many others).

The downside of such a tool is its expense. Turning cutters are primarily consumables and during operation they often break, grind down and become unusable. Therefore, before performing any turning activities, you should stock up on tools for future use.

Varieties and classification

Pass-through bent cutters can be divided into two categories: roughing and finishing. Roughing tools allow you to perform rough processing work on products. Their overall radius of curvature is significantly lower than that of cutters used for finishing work, but at the same time such tools have a fairly good level of stability and can be used for a longer time.

Finishing devices have a smaller radius of curvature than roughing ones, which, in turn, makes it possible to process the working surface more accurately and achieve the desired effect. As a rule, they are used at the final stage of manufacturing small parts.

In addition, left and right through bent incisors are distinguished. This classification is based on the position of the cutting edge of the cutter. The movement of left-type turning tools is from left to right. Moreover, if such a cutter is placed on the left hand, then the common cutting edge of the tool will be located on the side of the thumb.

The movement of right-hand turning tools is from right to left. Such incisors are most widespread. And if you put the right incisor in your right hand, then the situation is similar, with the left incisor the common edge will rest against the thumb.

Also, bent cutters can be divided according to the material from which they were made. Most often, such cutters are made from hard alloy materials, but there are also cutters made from high-speed steel.

Types and purpose

Using pass-through cutters, they roughly peel off workpieces made of steel, alloys and non-ferrous metals, and also perform fine turning. Their types are described below.

Straight

Used for cutting conical and cylindrical parts.

The heads are straight. If turning goes from left to right, use a passing left cutter. When the caliper moves from right to left, the right incisor is placed. Well suited for rough peeling because they have great rigidity.

Bent back

The working part is curved to the left or right. For processing conical, cylindrical, end surfaces and chamfering. You can work close to the chuck jaws. Universal than other types and more often used.

Persistent

Thrust tools allow cutting workpieces in steps. Can shoot up to 5 mm. metal thickness per pass.

Often performed with bends in the working part to the right or left.

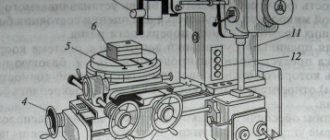

Prefabricated

The working part of the cutter 1, into which the pin 3 is seated, a carbide plate 2 is put on it. It is secured with a wedge 5 and a screw 4. This way it is securely clamped in the cutter body.

The plates are produced in 3, 4, 5 and 6-sided versions. Advantages: reduced time for processing the part, good chip removal. Instead of sharpening, they rotate the plate.

The blades are cheaper than a whole chisel. You can place plates from different alloys on one holder in turn. Optimal for fine turning.

Selection criteria

Despite the fact that turning cutters are considered consumable elements of a lathe, their choice, like the choice of any other tool, should be approached responsibly. A correctly selected turning tool will allow longer operation and better processing of products. First of all, it is worth considering what work will be performed.

If the range of work is quite wide and includes processing different types of parts, then it is worth stocking up on not just one type of cutter, but several at once. It is preferable to purchase a set of cutters. This way you will be as calm as possible in the event that you do not have the cutter you need on hand.

Also, you should take into account the size of the workpiece being processed. The choice of cutter size also depends on the size of the workpiece. Most often, a medium-sized incisor is purchased. They are more versatile and allow you to work with various products without requiring replacement.

Another selection criterion should be the material used to make the tool. When the workpiece is made of soft and unhardened metal, cutters are chosen, the material for which is high-speed steel.

In cases where processing will take place on hard materials, I use cutters made of carbide materials. Such cutters are resistant to vibration vibrations and temperature changes, and their service life is much longer.

What are the operating modes?

The operation of straight bent turning tools is quite simple, and depending on the shape of the workpiece and the processing method, it can be carried out in the longitudinal or transverse direction. At the very beginning, rough surface treatment is carried out with only one tool, which will be intended for these purposes.

It is worth noting that tools intended for rough work are not recommended for use in finishing work and vice versa. During rough work, it is allowed to remove up to 5 millimeters of metal from the treated surface in several passes. After rough work in order to comply with more accurate metric indicators of the product. The thickness of the metal being removed should not be more than tenths of a millimeter.

Bent through cutter

Tools of this type can be divided into finishing and roughing types. Finishing ones have a significantly larger radius of curvature. This allows you to obtain a more accurately machined surface. They are used at the final stage of production and to create relatively small parts. If you need to achieve special smoothness and cleanliness, then, as a rule, blade cutters are used, which help achieve better results.

Roughing machines are used for rough processing. Their radius of curvature is lower, but their strength is noticeably higher. They are great for applications where large amounts of metal need to be removed from a workpiece. Their working life is much higher, therefore, from an economic point of view, processing with two types of cutters is much more profitable. They have less accuracy, but they will make the first stage of removal faster.

In addition, we can also distinguish such types as bent right and left passing incisors. Here they differ in the location of the cutting edge, as on many other types of these tools.

Main dimensions of bent cutters

| Height, mm | Width, mm | Length, mm |

| 16 | 10 | 110 |

| 20 | 12 | 120 |

| 25 | 16 | 140 |

| 25 | 20 | 170 |

| 32 | 25 | 170 |

| 40 | 25 | 200 |

| 40 | 32 | 240 |

| 40 | 40 | 240 |

| 50 | 40 | 240 |

| 50 | 50 | 240 |

The bent cutter is made mainly from carbide materials, because the workpieces mainly consist of hard materials, but tools made of high-speed steel can also be used.

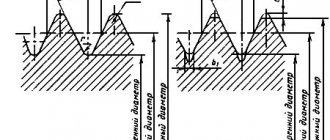

Geometry of a bent cutter

The main working part of the cutter is its head, which is located on the rod. It is inserted into the tool holder for subsequent work. On the front surface of the head there is a surface that ensures chip flow. There are also two trailing edges - auxiliary and main. They are those surfaces that face the part being processed.

The main cutting work is carried out by the main cutting edge. This part is formed at the intersection of the main back and front surfaces of the tool. The design also includes an auxiliary cutting edge formed at the intersection of the auxiliary front and rear surfaces. The intersection of the secondary and main cutting edges forms the tip of the cutter. Each model creates its own unique angle, which makes the product more suitable for certain purposes. For example, to process a step-type part, a cutter with an angle of 90 degrees is required.

Selecting a beveled cutter

Bent-through turning cutters are available in several versions, which differ in size, cutter material and other parameters. When choosing, you should pay attention to what kind of workpieces you will have to deal with. If a wide range of parts is used in production, then you should have not just one curved cutter, but a whole set for various cases.

The size of the product is selected according to the dimensions of the workpiece. The most common are the medium options, which do not require replacement for most jobs with various types of products. “Advice of professionals! Frequent replacement of cutters leads to a large loss of time in work and equipment downtime, so the most optimal options should be determined in advance.”

Regarding the material, there is a simple trend here when soft and unhardened types of metal are processed by bent left and right cutters, which are made of high-speed steel. They are cheaper, but less practical when it comes to hard materials. In this case, you should use a bent through cutter with a cutter made of carbide materials. They perfectly withstand vibrations and temperatures that rise during operation, therefore, their service life is much longer.

Cutting modes

The bent straight through turning cutter is used in fairly simple operating modes. It carries out longitudinal and transverse movements, depending on the processing profile. You can select and order self-tapping screws for metal profiles at the best price in Ukraine on Stream. It is recommended to start with roughing with one tool designed specifically for this purpose, and then make a finishing pass on the almost finished surface. If in roughing the thickness is gradually removed up to several millimeters, then in finishing this figure is tenths of a millimeter in several passes.

Marking

Using the example of such a tool as the bent cutter T15K6, we can consider an example of marking. The working surface here is made of carbide materials that belong to the titanium-tungsten group. The cobalt content (K6) is 6%, and titanium carbide (T15) is 15%.