Spring wire or what springs are made of

Spring materials

One of the most important decisions made by the designer when designing springs is the decision on the purpose of the spring material.

For springs, it is advisable to use high-strength materials that provide the ability to operate at relatively high voltages. Springs made from a material with high tensile strength have less weight and compact dimensions, saving the working space of components and mechanisms. However, it cannot be said that this type of material for a spring is bad, and this one is good. The decision on the choice of material must be made based on economic feasibility and many factors: spring service life, the presence of cyclic or shock loads, relaxation resistance, operating temperature conditions, exposure to aggressive environments, etc.

It is equally unreasonable to assign an expensive scalped valve wire to an irresponsible one-time actuation spring, or to install a spring made of cheap carbon wire into an expensive and responsible steam pressure regulator, trying to “save” a little. And if the first option is fraught with only unreasonable expenses, then the second option can lead to a serious accident.

Each type of spring material has its own advantages and disadvantages. The designer’s task is to choose the best option.

Cold-drawn cold-drawn spring wire

1. Cold-drawn cold-drawn steel wire according to GOST 9389

Wire in accordance with GOST 9389 is used for tension and torsion compression springs of classes 1 and 2 in accordance with GOST 13764. Wire of class 2 differs from wire of class 1 in reduced tensile strength and increased ductility.

2. Piano wire

Piano wire is made from high quality carbon steel. This wire is widely used for small coil springs operating under severe stress conditions. The surface quality is comparable to valve spring wire. The high strength of piano wire is achieved through carbon alloying in the range of 0.7-1.0%, cold multi-stage drawing to size using special patenting operations.

3. Patented carbon wire according to EN 10270-1, DIN 17223-1

Patented carbon wire according to EN 10270-1 is an analogue of domestic cold-worked carbon wire according to GOST 9389-75, while having better mechanical properties and surface quality.

4. Wire made of alloy steel grade 60S2A according to GOST 14963 and GOST 14959

Wire made of alloy steel grade 60C2A has high elastic and tough properties. It is characterized by an increased tendency to graphitization and insufficient hardenability with diameters greater than 20 mm.

5. Patented oil-hardened steel wire according to EN 10270-2

Oil-hardened steel patented wire according to EN 10270-2 is an analogue of domestic grades of alloy steels 60S2A, 51KhFA, 60S2KhA.

6. Wire made of alloy steel grade 51HFA according to GOST 14963 and GOST 14959

Wire made of alloy steel grade 51HFA has increased heat resistance. As a result of its elastic and viscous properties, it is the best material for class I springs according to GOST 13764. It is unsuitable for class III springs due to insufficiently high hardness.

7. Wire made of alloy steel grade 65S2VA in accordance with GOST 14963 and GOST 14959

Wire made of alloy steel grade 65S2VA has high elastic and tough properties. It is characterized by increased hardenability.

Stainless and heat-resistant spring materials

8. Stainless high-strength spring wire grade 12Х18Н10Т according to TU 3-1002-77

Stainless steel high-strength spring wire 12Х18Н10Т is used for compression, tension and torsion springs operating without coatings in distillate, water vapor, solutions of salts and alkalis, alcohol, sea water, nitric acid or its vapor, in organic substances, in tropical climates.

9. Stainless steel high-strength spring wire X10CrNi18-8 AISI 302 EN 10270-3-1.4310, X5CrNi18-10 AISI 304 EN 1.4301

Stainless high-strength spring wire AISI 302 EN 10270-3-1.4310 is an analogue of the domestic stainless alloy 12Х18Н10Т. Widely used for compression, tension and torsion springs operating without coatings in distillate, water vapor, salt and alkali solutions.

10. Acid-resistant stainless steel spring wire X5CrNiMo1810 N 10270-3-1.4401

Acid-resistant cold-drawn stainless steel wire X5CrNiMo1810 EN 10270-3-1.4401, designed for marine equipment, food industry, medical equipment and other conditions where the environment imposes very high demands on corrosion resistance.

11. Spring wire made of molybdenum-chromium-nickel alloy Hasteloy C-276

Hasteloy C-276 tungsten molybdenum-chromium-nickel alloy spring wire has exceptional resistance to strong oxidizing agents, high concentration mineral acids, and can be used in a variety of highly corrosive environments. The alloy is particularly resistant to pitting and crevice corrosion.

12. MP 35 N alloy spring wire

Spring wire made of MP 35 N alloy on a nickel-cobalt base uniquely combines qualities such as high strength and ductility, as well as exceptional corrosion resistance. MP 35 N alloy resists corrosion in hydrogen sulfide, salt water and other chloride environments. Exceptionally resistant to cracking and corrosion loads in sulfuric acid solutions, sea water and other harsh conditions of use. MP 35 N is recommended for applications where high strength and high corrosion resistance are required.

13. Heat-resistant spring chromium-nickel wire KhN77TYUR (EI437B) TU 14-131-904-96

Heat-resistant spring chromium-nickel wire KhN77TYUR (EI437B) TU 14-131-904-96 is used for tension and torsion compression springs operating in the temperature range from minus 253 to +500? C.

14. Heat-resistant spring wire made of Inconel X-750 alloy

Heat-resistant spring chromium-nickel alloy Inconel X-750, hardened by dispersion hardening. It has a high coefficient of long-term heat resistance up to a temperature of 700°C.

15. Heat-resistant spring nickel-chrome-cobalt alloy Nimonic 90

Heat-resistant spring nickel-chromium-cobalt alloy Nimonic 90, hardened by precipitation hardening, has high strength under heavy load conditions at temperatures up to 950°C.

16. Heat-resistant spring chromium-nickel alloy Inconel 718

Spring chromium-nickel alloy Inconel 718 is hardened by hardening using the precipitation hardening method. It has high heat resistance and resistance to residual deformation at temperatures up to 700°C.

17. Wire made of heat-resistant alloy KhN35VTYu (EI787)

Wire made of heat-resistant alloy KhN35VTYu (EI787) is used for the manufacture of springs operating in the temperature range from minus 253 to +550°C.

18. Wire made of precision alloy 68NHVKTYU-VI (EP578-VI)

Wire made of precision alloy 68NHVKTYU-VI (EP578-VI) is used for elastic sensitive elements operating in the temperature range from minus 196 to +500°C.

19. Wire made of precision alloy 36NHTYu (EI702)

Wire made of precision alloy 36NHTYU (EI702) is used for compression, tension, and torsion springs operating in the temperature range from minus 253 to +300°C.

20. Wire made of precision alloy 70НХБМУ

Wire made of precision alloy 70НХБМУ is used for compression, tension, and torsion springs operating in the temperature range from minus 196 to +650°C.

21. Wire for springs made of heat-resistant steel grades 10Х11Н23Т3МР (EP33), 10Х11Н23Т3МР-ВД (ЭП33-ВД).

Wire for springs made of heat-resistant steel grades 10Х11Н23Т3МР (EP33), 10Х11Н23Т3МР-ВД (ЭП33-ВД) is intended for compression, tension and torsion springs operating in aggressive environments in the temperature range from minus 196 to +550°C.

22. Wire made of precision alloy 44НХТУ

Wire made of precision alloy 44НХТУ is used for compression, tension, and torsion springs operating in the temperature range from minus 196 to +200°C.

Non-magnetic spring materials made of non-ferrous alloys

23. Cold-drawn wire BrKMts3-1 GOST 5222-72 from silicon-manganese bronze for the manufacture of elastic elements

Cold-drawn wire BrKMts3-1 made of silicon-manganese bronze, intended for the manufacture of springs and elastic elements operating in atmospheric conditions, water vapor, fresh and sea water, contact springs of all types in the temperature range from minus 40 to +200°C.

24. Cold-drawn wire BrB2 GOST 15834-77 from beryllium bronze for the manufacture of elastic elements

Cold-drawn wire BrB2 made of silicon-manganese bronze, intended for the manufacture of springs and elastic elements for critical purposes, operating in atmospheric conditions, fresh and sea water, in the temperature range from minus 253 to +150°C.

25. Tin bronze SS 5428-7, DIN 17670/17677: SuSn6

Tin bronze SS 5428-7, DIN 17670/17677: SuSn6, is an anti-magnetic, corrosion-resistant spring material for springs with moderate tensions.

26. Berrylium copper CuBe 250, DIN 17670/17677: CuBe2

Beryllium-copper alloy CuBe 250, DIN 17670/17677: CuBe2 has anti-magnetic and acid-resistant properties and excellent spring properties. This alloy has medium strength and easily takes the desired shape.

Production and Application

The wire is manufactured in accordance with the requirements of two State Standards - 9389−75 and 14963−78, which regulate the technology of drawing (broaching) initial workpieces through a series of holes with an unequal, gradually decreasing cross-section. Then heat treatment is carried out. It improves the spring properties of the finished product.

Heat treatment helps to increase the tensile strength of products. In most cases, a calibration die is installed at the last hole for drawing along the drawing mill. This is done when, according to technical conditions, it is necessary to produce calibrated products that have a smooth and as even surface as possible.

The production process cannot do without preliminary tempering of steel and its hardening. With the help of these manipulations, the strength indicator is significantly improved.

Winding of springs can be carried out in two ways - hot and cold. Products obtained as a result of using a hot method are distinguished by high quality, in which raw materials are heated to a temperature that releases the metal, after which it is hardened.

Nowadays, spring wire is of great interest among professional designers, who use details from it to create unique solutions for housing, offices and shopping centers. The wire for springs bends easily, you can create elements of almost any shape. The properties of the material were also appreciated by furniture manufacturers: the springs of sofas, tables, cabinets, chairs and beds are made from it.

Types and main characteristics

Gosstandart determines that the degree of accuracy can be either increased or normal. According to mechanical characteristics, there are four classes (3, 2A, 2, 1) and three grades (A, B, C). Class 2A - always increased accuracy.

There are a number of main characteristics of PP:

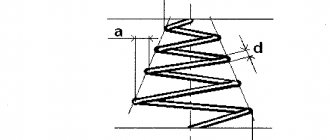

- with a diameter of 0.14−8 mm (maximum permissible deviation ±0.05);

- ovality - up to 50% of the deviation parameter;

- tensile strength - 1030−1230 (class 3, section 8 mm) and 2740−3090 (class 3, section 14 mm) N/mm2;

- the number of twists that can withstand is 4−35 (the exact number depends on the raw materials, as well as the type and class of products);

- weight is calculated per 1000 m of finished products - 0.1208−394.6 kg.

According to the conditions of GOST 9389−75, spring carbon wire, which is used in the cold method without hardening, must be made only from carbon steel grades. But upon request, PP can be made from other alloys with a minimum content of phosphorus and sulfur. Waviness, rust, hair, captivity, sunsets, shells, cracks, and complete decarbonization are not allowed.

The wire can be supplied in coils or skeins. Twist it in such a way that there are no “figure eights” when unwinding. On reels and skeins whose weight does not exceed 250 kg, the PP is wound in one piece; if more, there may be three pieces. In places of separation, special plugs must be installed.

Spring wire GOST (9389-75)

The requirements for the functional qualities of steel spring wire are determined by the GOST 9389-75 .

As for dividing the product into conditional categories, spring wire is classified according to manufacturing accuracy, grades and classes of mechanical strength, as well as in accordance with the grade of steel used to produce the product. Depending on the manufacturing precision, steel spring wire can be:

- Normal accuracy.

- Increased accuracy (symbol P). This variety is used in the production process of the most critical components of certain devices.

In accordance with the indicators of mechanical strength, carbon steel spring wire is divided into grades (A, B, C), as well as classes (1, 2, 2A and 3).

The diameter of the finished product can range from 0.2 to 8 millimeters. Its final cost depends on this indicator, as well as on the accuracy of manufacturing the spring wire.

Thus, a wire with a smaller diameter will cost more than a thicker analogue.

After manufacturing, the product is in most cases treated with a special preservative oil that protects the wire from the negative effects of corrosion. The coils and skeins in which the finished product is supplied are packaged with polymer film and moisture-proof paper. The surface of the spring wire should not have nicks, cracks, dulls or rust.

GOST 9389-75 Carbon steel spring wire. Specifications (with Amendments No. 1-5)

CARBON STEEL SPRING WIRE

Carbon steel spring wire. Specifications

MKS 77.140.65 OKP 12 2100

Date of introduction 1977-01-01

1. DEVELOPED AND INTRODUCED by the USSR Ministry of Ferrous Metallurgy

2. APPROVED AND ENTERED INTO EFFECT by Resolution of the State Committee of Standards of the Council of Ministers of the USSR dated July 17, 1975 N 1830 Change No. 5 was adopted by the Interstate Council for Standardization, Metrology and Certification (Minutes No. 20 dated November 1, 2001) Voted for adoption:

Name of the national standardization body

State Standard of the Republic of Belarus

Gosstandart of the Republic of Kazakhstan

3. INSTEAD GOST 9389-60

4. REFERENCE REGULATIVE AND TECHNICAL DOCUMENTS

5. The validity period was lifted according to Protocol No. 2-92 of the Interstate Council for Standardization, Metrology and Certification (IUS 2-93)

6. EDITION with Amendments No. 1, 2, 3, 4, 5, approved in February 1983, December 1984, December 1987, January 1990, March 2002 (IUS 5-83, 3- 85, 3-88, 4-90, 6-2002) Amendments were made, published in IUS N 7 2003, IUS N 6 2007

Amendments made by the database manufacturer

This standard applies to cold-drawn carbon steel wire used for the manufacture of springs that are cold-wound and not subject to hardening. (Modified edition, Amendment No. 3).

TYPES AND MAIN SIZES

1.1. The wire is produced:

a) by mechanical properties: grades A, B, B; classes 1, 2, 2A, 3. Recommendations for the use of spring wire depending on the grades and classes are given in Appendix 3.

b) in terms of manufacturing accuracy: normal accuracy; increased accuracy - P. Wire of classes 1, 2, 3 is manufactured with normal and increased accuracy, class 2A - increased accuracy. (Changed edition, Amendment No. 3, 4).

1.2. The wire diameter and maximum deviations along it must correspond to those indicated in Table 1.

Nominal wire diameter

Maximum deviation for wire diameter

Notes:1. At the customer's request, it is possible to supply wire of intermediate diameters. In this case, the maximum deviations in diameter must correspond to those established for the nearest larger diameter.2. The theoretical mass of the wire is given in the appendix.

(Changed edition, Amendment No. 3, 4).

1.3. The ovality of the wire should not exceed half the diameter tolerance range.

Examples of symbols:

Wire grade A, class 1, increased precision, diameter 1.20 mm:

Wire A-1-P-1.2 GOST 9389-75

The same, brand B, class 3, normal accuracy, diameter 2.0 mm:

Wire B-3-2 GOST 9389-75

The same, brand B, class 2A, increased accuracy, diameter 1.20 mm:

Wire B-2A-1.2 GOST 9389-75

(Changed edition, Amendment No. 3, 4).

TECHNICAL REQUIREMENTS

2.1. Steel carbon spring wire must be manufactured in accordance with the requirements of this standard according to technological regulations approved in the prescribed manner, from carbon steel in accordance with GOST 1050, GOST 14959, GOST 1435 or according to regulatory and technical documentation, as well as from steel grades KT-2 and 3K -7, the chemical composition of which is indicated in Table 2, and other special smelting steels manufactured according to regulatory and technical documentation. In this case, class 2A wire must be made of steel with a mass fraction of sulfur not exceeding 0.030% and phosphorus not exceeding 0.035%.

At the request of the consumer, the wire is made from a certain grade of steel. (Changed edition, Amendment No. 2, 3).

2.2. On the surface of the wire there should be no cracks, films, sunsets, hairlines, shells and rust. Risks with a depth of no more than half the tolerance field in diameter are allowed, as well as remnants of technological coatings applied to the surface of the wire to prepare the metal for drawing. Class 2A wire for aviation industry must be without traces of technological copper plating of the surface. (Changed edition, Amendment No. 3).

2.3. The mechanical properties of the wire must comply with the standards specified in Table 3.

Wire diameter, mm

Tensile strength, N/mm (kgf/mm)

Dispersion of temporary tensile strength in a batch, no more, N/mm (kgf/mm)

Number of twists, not less