Sharpening tool

For abrasive sharpening of the cutter, a sharpening machine or lathe can be used. For carbide tools, green carborundum of medium hardness is used. For initial processing, the abrasive value of the wheel should be 36-46, at the end of the process - 60-80. For high quality sharpening, a whole circle is required, without defects and geometry violations.

Diamond wheels are also widely used for sharpening turning tools, which ensures high cleanliness of cutting surfaces. In comparison with carborundum wheels, the surface cleanliness of the cutter increases by two classes, and work productivity increases. The use of diamond wheels also increases the service life of the tool - the possible number of cutter regrinds increases by 20-30%. But it should be taken into account that it is economically feasible to use sharpening with a diamond tool with an allowance of no more than 0.2 mm. For larger values, preliminary sharpening with a carborundum wheel is recommended.

Read also: What is a manual jigsaw

Order and features

Depending on the nature of wear and the design of the equipment, sharpening is carried out on the front, back or both surfaces. The figure below shows all the surfaces of a turning tool

For standard cutters, as a rule, sharpening is used on all cutting surfaces. With minor wear, only the geometry of the rear surface is restored. Equipment for multi-cutting machines is restored only on the back surface, shaped – only on the front.

Standard sharpening order:

- Main back surface.

- Auxiliary back surface.

- Front surface.

- End radius.

The back surface sharpening parameters are shown in the figure below.

Figure (a) shows the back surface with one sharpening plane, figure (b) shows several. When brazing carbide inserts, the rear surface has three planes:

- along a chamfer with a height of not less than 1.5 mm at an angle a;

- along the remaining height at an angle a+3°;

- along the holder at an angle a+5°.

Sharpening the front surface of carbide cutters has many more varieties (see figure below).

Basic forms:

- Flat with a positive rake angle (a).

- Flat with a negative angle (b).

- Curvilinear with a negative angle (c).

- Flat with negative angle for roughing (d).

- Curved with a negative angle for stainless steels (d), and other materials (e)

During the sharpening process, it is necessary that the cutting edge of the tool being processed is located on the line of the center of the sharpening machine or below by no more than 3-5 mm. The direction of rotation of the circle should ensure that the plate is pressed against the holder, i.e., it should go towards the plate. During operation, a continuous supply of coolant is desirable. With periodic cooling, overstressing of the material structure and the appearance of microcracks is possible.

When sharpening, light pressure and constant movement along the surface of the wheel are required to form a smooth surface. After sharpening is completed, the geometry of the tool is checked using templates or special instruments.

How to choose the best one

When choosing an electric sharpening machine, you need to consider how often the device will be used, as well as whether other tools or equipment will be sharpened on it.

Device class

Sharpening machines are divided into household and professional.

The former are characterized by significantly lower power and low resource. They are designed for fairly rare, periodic use with light load. The latter contains a significant margin of safety. At many enterprises, machines are turned on for the entire work shift, so electric motors have cooling systems and are also equipped with bearings of appropriate quality.

Sometimes there is a separate category of semi-professional equipment. It occupies an intermediate position and is used in small businesses and advanced private owners.

Weight and size

The more powerful the machine, the larger it is. In order to place large equipment in a garage, workshop or office, you will need a lot of space. For occasional sharpening of knives, small electrical appliances can be used, which do not even require stationary placement, but are simply placed on any surface on a stand, held on it by non-slip legs and their own weight.

Good devices can be fixed in one place. For this purpose, holes or eyes are provided for bolts. Being installed through a rubber mat or sealing washers, the machine receives the necessary immobility with minimal transmission of vibrations to the working surface.

Power

For home devices that are intended only for small objects with a small cutting edge area, there is no reason for high power. Many tabletop machines cost 100, 160, 200 watts. But for devices that will be installed on a workbench in the garage and will serve not only for tidying up knives, but also axes, as well as other garden tools, it is better to choose motors rated at 400 - 600 W.

Expert opinion

Levin Dmitry Konstantinovich

Devices larger than a kilowatt do not make sense in a household, but they can be useful as standard equipment in small mechanical workshops.

Speed

Most standard AC induction motors are high speed. This means that they will spin the disk at high speed. This will allow you to quickly get the desired result, but it requires more concentration, since at high speed you can easily remove the “extra”.

The main disadvantage of high-speed machines is the risk of overheating of the workpiece. If the steel has rainbow streaks, this is a sure sign that it is “burning.” In the process of such sharpening, the hardening of the product is released, and the knife subsequently becomes dull very quickly.

Which knife sharpening machine would you choose?

ManualElectric

The spindle speed of most household machines is from 2.5 to 5 thousand revolutions per minute. Sometimes you can find universal sharpening machines with 1500 rpm. Some devices are designed with a reduction gearbox for one of the circles. It doesn't just spin slower, its casing can fill with water to cool it down.

Some models may have smooth or stepped speed control.

Additional features

Some sharpening machines have special adapters so that a sanding belt can be installed instead of a wheel. This significantly expands the functionality of the device.

Other products may have a flexible power take-off shaft as an option. Any equipment designed for an external drive can be connected to it. Most often this is an engraver.

Pay attention to the additional equipment if you plan to use it.

Tool finishing

After sharpening, sequential grinding of the working surfaces is necessary in the same order as sharpening was carried out. When finishing, it is necessary to remove all roughness and polish the surface to a mirror shine. The cleaner the surface, the lower the friction during turning and the higher the tool life.

Finishing is carried out using boron carbide abrasive pastes on a rotating cast iron disk (no more than 2 m/s). GOI paste or other special polishing materials can be used. For polishing, paste is applied to the disc. Further, when the disk rotates, the cutter is pressed and the grains of the abrasive paste smooth out the existing roughness. Thus, the geometry and original cleanliness of the working surface of the cutter are completely restored, and its suitability for further use is ensured.

Read also: Steel s235 analogue of st3

Technological operations carried out on a lathe with workpieces using special devices are associated with ultimately obtaining a product of the desired configuration shown in the drawing. And in order for turning to be rational and accurate, sharpening of metal turning tools is necessary, which will produce the required profile, angles of the required size and the corresponding parameters of the working part. The preparation of such a tool is given great importance.

Rules for sharpening turning tools

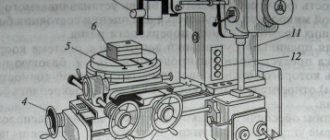

In order for the processing of workpieces on metal lathes to be effective, high-quality and accurate, the cutters should be regularly sharpened, thereby giving their working part the required shape and obtaining angles with the required parameters. Only tools whose cutting part is made in the form of a disposable carbide plate do not need sharpening. To perform such an important procedure in large manufacturing enterprises, machines with special devices are used, and a separate structural unit is engaged in this.

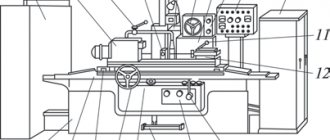

In order to sharpen a turning tool with your own hands on a home machine or do it in a small enterprise, you can use various techniques. This procedure can be performed using chemical reagents or using conventional grinding wheels. It should be noted that sharpening turning tools on specialized or universal machines that use an abrasive wheel is the most inexpensive but effective method of giving cutters the required geometric parameters.

Options for sharpening cutters with cutting inserts

Of course, the highest quality metal turning tools are sharpened on a machine specially designed for this procedure. If you don’t have such equipment at your disposal, you can use a universal machine with a grinding wheel. When choosing such a circle, it is important to pay attention to the material from which the working part of the tool being processed is made. So, in order to effectively sharpen a carbide cutter, you will need a carborundum wheel, which has a characteristic green color. Tools, the working part of which is made of carbon or high-speed steel, are perfectly processed on machines with medium-hard wheels made of corundum.

Sharpening of turning tools for metal can be done without cooling or with cooling, which is more preferable. If sharpening is carried out with cooling, then cold water should be supplied evenly to the place where the turning tool comes into contact with the grinding wheel. In the case when cooling is not used during the sharpening process, after sharpening it is impossible to immediately cool the tool sharply: this can lead to cracking of its cutting part.

You can learn how to sharpen turning cutters on a sharpening machine with your own hands using an instructional video. When performing this procedure, it is important to adhere to a certain sequence. First of all, the rear main surface is processed on the grinding wheel, then the rear auxiliary surface, and lastly the front surface is sharpened. The last stage of sharpening is processing the tip of the cutter - giving it the required radius of curvature.

During the sharpening process, the cutter is constantly moved in a circle, trying not to press it too hard (this can be seen in the video). It is necessary to adhere to this recommendation so that the surface of the circle wears evenly, and also so that the cutting edge of the turning tool is as smooth as possible.

Purpose of the cutter, design, types

To obtain parts from a metal ingot when turning on lathe equipment, a special tool is used. They are made of steel, and the hardness of the material is higher than that of the workpiece being processed. The holder rod and the working head, the main structural elements of a metal cutter, are used to secure the tool on the lathe.

The function of the second component is to cut off a layer of the metal surface during processing. The holder rod or the body of the cutter has a square or rectangular cross-section. The main cutting edge of the working head is shaped (wedge) or straight in cross-section. Metal cutting parts require regular sharpening during operation. In modern conditions there is a sufficient choice of incisors.

Turning tools for metal processing with replaceable inserts

When choosing gear, you should take into account such an indicator as angles. The classification of species is as follows:

- checkpoints;

- cutting;

- pruning;

- boring;

- shaped;

- grooved:

- chamfered;

- persistent;

Pass-through, this type of device processes cylindrical blanks. A cutting tool is used for cutting rods. Trimming is performed at a given angle. A cutting-type device is also used to cut grooves for various purposes in them. Scoring, this type of device is used for trimming blanks and reducing ledges. Boring, this tool is used to machine holes of the required diameter in workpieces or parts on a lathe.

Grooving - the purpose of such a device is to form internal and external grooves on a cylindrical surface, maintaining the required angles. Sometimes a cutting-type function is required when it is necessary to remove part of the metal from the workpiece. Thread-cutting machines use this device to cut threads on lathes. Shaped - the purpose of this cutter is to form protrusions and grooves on the blank being processed, thereby obtaining angles with the required parameters.

Read also: How to sharpen knives yourself

Chamfering - with this device, after sharpening, internal and external chamfers are made on the product. The persistent one is used for turning metal parts with small ledges. To reduce vibration when working on a lathe, you need to check its position. Thrust is used for non-rigid parts.

Types of cutters are also divided according to the direction of processing of turning equipment into left and right, according to the material from which they are made, according to the method of attaching the cutting part to the holder and other parameters.

Procedure and rules for sharpening tools

To prevent the occurrence of chips and scuffs on the workpieces, breakage and other undesirable factors when working on a turning unit, proper sharpening of the cutter is required. This procedure is performed when a new device is being manufactured or an old device is worn out. The process of sharpening cutters itself consists of giving the required shape and the required angle to a dull or new device.

The cutting part can be restored using special metal equipment with a sufficient level of skill and knowledge of the worker. After all, labor intensity and productivity depend on the correct sharpening of turning tools. At large enterprises, divisions have been created to prepare equipment. On small ones, sharpening is performed by a turner.

At the moment, there are the following methods for sharpening turning tools:

- abrasive;

- chemical-mechanical;

- using special devices;

Sharpening angles depending on the type of turning of steel and cast iron

Abrasive sharpening of the cutter is performed using a special sharpening unit or standard emery cloth. When using the latter option, it is difficult to maintain the required angles when processing the fixture. Sharpening units have two circles. White electrocorundum abrasive is used for turning a high-speed steel cutter. Sharpening of devices made of carbide is done with a green silicon carbide wheel.

A diamond disc is used for finishing grinding on a lathe or other unit. The chemical-mechanical method involves turning in a special composition. The sharpening accuracy is checked using templates.

If you find an error, please select a piece of text and press Ctrl+Enter.

The best universal inexpensive machines for sharpening tools at home

Caliber EZS-65MF

An inexpensive machine for sharpening knives, scissors, chisels and drills - it’s cheaper to sharpen by hand. It can sharpen drills with thicknesses ranging from 3 to 10 mm. There is also a holder for knives and scissors, as well as for chisels and blades. Even ceramic knives are sharpened.

The diameter of the grinding wheel is 49.3 mm and its thickness is 7.5 mm. Also pay attention to the mounting hole with a diameter of 10 mm - you will need to buy the appropriate consumables. The standard wheel is set to coarse-grained, so the knives will need to be polished on a block. The machine is, of course, Chinese, but it gets its money’s worth.

Whirlwind TS-200

This is a good machine with an average power of 200 W for sharpening lawn mower blades, axes and kitchen knives. There are two sharpeners with a diameter of 150 mm and a thickness of 16 mm. The diameter of the mounting hole is 12.7 mm. The unit weighs 5.2 kg, which in principle is not that much for a sharpening machine with two wheels. But at the same time, it stands stably on the workbench without additional fastening. And thanks to the rubber feet, vibration is practically not felt.

There is a good illumination built in here with a flexible tripod, which really helps when sharpening the tool. Please note that the backlight only turns on when the shaft is active. After purchase, we advise you to remove the protective cover and tighten the screws, since some users receive the machine with loose screws.

DIOLD MZS-03 M

This sharpening machine has several modifications. The letter “M” at the end of the name indicates the presence of a flexible shaft with which you can engrave metal workpieces. The rotation speed of the flexible and rigid shafts is 6700 rpm. As in the Caliber EZS-65MF model, there are three attachments for sharpening drills, knives and scissors, chisels and blades. Among other things, it can be used to sharpen slotted screwdrivers and chisels. For each item, you can set your own sharpening angle depending on what kind of edge we need to get.

The machine copes with its tasks and sharpens the tool efficiently, without the need for additional finishing. Unfortunately, there is no speed control, which would be convenient when working with a flexible shaft. The machine is equipped with a diamond-coated metal wheel with a diameter of 48 mm and a thickness of 8 mm. For the money, this is a good device with a nice bonus in the form of a flexible shaft.

Makita GB602

Excellent Japanese machine with two grinding wheels. Each circle with a diameter of 150 mm has a thickness of 16 mm. Unlike many competitors for the same price, the machine from Makita is assembled very high quality without any backlash, “shortness” or stone beating. Users note fairly quiet operation.

Transparent plastic covers are installed above each circle to protect from sparks and chips. They also provide a good overview of the workplace. The manufacturer additionally included safety glasses in the kit. If you need a good, reliable sharpener that will last for years, then go for the Makita GB602.

What else is useful to have in the house:

- Let's do without gasoline: rating of the best electric chainsaws 2020

- We cut at any angle: rating of miter saws with broaching 2020