TURNING CUTTERS AND CUTTERS-INSERTS WITH MECHANICAL FASTENING OF CUTTING REPLACEABLE MULTIHEDAL INSERTS

Designations

Turning toolholders and cartridges with mechanically clamped indexable inserts. Symbols

MKS 01.080.30 25.100.10 OKP 39 0240

By Decree of the USSR State Committee on Standards dated March 25, 1985 No. 760, the introduction date was set

01.07.86

1. This standard establishes the symbols of turning cutters and adjustable cutters - inserts with mechanical fastening of cutting interchangeable polyhedral inserts.

The standard fully complies with ISO 5608-80 and ST SEV 4599-84.

2. The designation of incisors consists of symbols, the meanings and sequence of which are given below:

1 - symbol indicating the method of fastening the cutting plate, see paragraph 4,

2 - symbol indicating the shape of the cutting insert, see paragraph 5,

3 - symbol indicating the type of cutter, see paragraph 6,

4 - symbol indicating the rear angle of the cutting insert, see paragraph 7,

5 - symbol indicating the cutting direction, see paragraph 8,

6 - number indicating the height of the holder, see paragraph 9,

7 - a number indicating the width of the tail part of the holder or a symbol indicating the type of cutter insert, see i. 10,

8 - symbol indicating the length of the cutter, see i. eleven,

9 is a number indicating the size of the cutting insert, see i. 12.

| Examples conditional 1 2 | s X 3 | designation 4 5 6 | i: 7 | 8 | 9 | 10 | ||

| Incisors: R | S | IN | N | R 32 | 25 | M | 16 | F |

| Insert bits: C | T | J | R | R 12 | SA | — | 16 | — |

10 - a symbol indicating the accuracy of some parameters of the cutters, see i. 13 (specified if necessary).

3. It is allowed to include in the symbol an additional symbol consisting of a maximum of three letters or numbers, which must be separated from the symbol in the 10th place by a dash and must not be identical to it.

4. Symbols indicating the method of fastening the cutting plate are shown in table. 1.

Reissue.

| Table 1 |

| Official publication Reproduction is prohibited |

| Continuation of the table. 1 | |||

| 5. Symbols for the shape of the cutting plate are determined according to GOST 19042-80. 6. Symbols indicating the types of cutters are shown in table. 2.

|

What types of metal turning tools are there and where are they used?

Very often they buy metal turning tools in our store, and if the suppliers who understand them name each type of tool correctly, ordinary citizens often confuse the tools. In this article, I suggest you familiarize yourself with the main types of turning cutters - look at the photo, find out the size range and scope of each type.

All models are from the Kanash plant, their products are one of the highest quality on this market.

Important! All models of cutters are made with inserts of different brands - most often these are VK8, T5K10 and T15K6. Other hard alloys are used quite rarely (for example, T30K4 and the like).

Cut-off

One of the most popular incisors. Used for cutting workpieces. It cannot be confused with anything else - a thin leg with a soldered carbide plate. Area of application: cutting at right angles; they can also be used to cut thin grooves.

Photo:

There are right- and left-handed ones. In the photo you can clearly distinguish the right from the left - the one on the left is just left-handed. All others are standard right-handers; in 90 percent of cases they are required for work. It is very easy to distinguish - take the incisor with the plate down (like a knife) and if the leg is on the right, then the incisor is right. Left means left (less common). Look at the photo, you can see everything there.

Size range of holders:

— 16*10 mm — for small “school” machines — 20*12 mm — 25*16 mm — the most popular — 40*25 mm — large cutters, rarely found on sale, only on order.

Pass-through bent

The name itself speaks about its field of application - it is used to process the ends of workpieces and also chamfer. The bent part seems to go around the workpiece from the side. Photo:

The size range is also very decent:

- 16*10 mm - small for school machines - 20*12 - non-standard size - 25*16 mm - the most popular - 32*20 mm - 40*25 mm - rarely found on sale, usually only made to order

Pass-through persistent bent

The prefix “bent” is, as a rule, not used in everyday life; the incisors are simply called continuous persistent ones. But you can see the bend; there are also ones without it.

Another note: Stainless steel drills - which ones are worth taking and which ones are not?

Area of application: some of the most needed cutters. Used for processing cylindrical workpieces. The bend just allows you to grind round parts, removing as much metal as possible in one pass of the cutter. The part is processed along its rotation!

Photo:

The size range is also wide:

— 16*10 mm — 20*12 — 25*16 — 32*20 — 40*25

There are also left-handed and right-handed. In the vast majority of cases, right-handed models are used.

Passing straight

The area of application is the same as that of the bent through, however, it is all the more convenient to remove chamfers. And straight metal surfaces are most often treated. Rarely used in production.

Photo:

Size range:

— 25 by 16 mm — standard with a rectangular holder — 25 by 25 mm — non-standard holder, for some special work

Trimming bent

Most often it is confused with the persistent pass-through. The scoring blade has a triangular plate, pay attention! Photo:

Scope of application: workpieces are processed across the axis of rotation (perpendicular). In addition to bent models, there may also be persistent ones (but they are not usually in demand).

Dimensions:

— 16*10 mm — 25 by 16 mm — 32 by 20 mm

For external thread cutting

Scope of application: the name speaks for itself - threads are cut with these cutters. Which one? If you take a cutter from the factory, it is usually “sharpened” for a metric thread. For other types of threads it will need to be re-sharpened.

The plate is installed “spear-shaped” (its correct name is cut-off, sold separately), can be of different alloys (grades are indicated at the beginning of the article). The resulting external thread on the workpiece (the so-called “male”) is a bolt, stud, etc.

Photo:

Most popular sizes:

16*10 mm 25*16 mm 32*20 mm - not used so often

For internal thread cutting

While external threads can also be used to cut small threads, internal threads can only be used to cut large diameter threads. This can be understood by the size of the incisors themselves. Photo:

Important! Do not confuse this cutter with boring tools for blind holes, they are similar in appearance, but fundamentally different! Boring tools below in the article, compare.

Dimensions:

— 16*16*150 — 20*20*200 — 25*25*300 mm

Also note: Photo review of a manual compact pipe cutter

The first and second numbers are the size of the holder (it is square in cross-section), and the third number is the length of the holder. The longer it is, the deeper the thread can be cut inside the workpiece.

Please note that in order to use such a cutter, your machine must be equipped with a device called a “guitar”.

Boring machine for blind holes

Area of application: for boring blind holes. They work as if from the end, which is why they need a sort of “bend” of the head. Whereas the “internal” (see below) completely enters the workpiece with the holder.

- The plate of this cutter is triangular, the same as that of the scoring cutter (see above).

Photo:

Dimensions:

— 16*16*170 mm — 20*20*200 mm — 25*25*300 mm

The larger the cutter size, the larger the diameter of the holes you can bore!

Boring machine for through holes

Area of application - they are used to bore parts “inside” along the entire length. The longer the holder, the more you can bore inside. Most often, the part is bored after drilling it with a large drill; you can also work according to existing dimensions.

Photo:

The plate is straight, there is no protrusion, which means the cutter easily goes inside the “tube” resulting from drilling and bores it from the inside, passing right through. The layer of chips removed is approximately equal to the bend of the cutter head

Dimensions:

— 16*16*170 mm — 20*20*200 mm — 25*25*300 mm

Prefabricated

One of the rarest incisors. They are also called universal, because they are equipped with different plates, which makes it possible to process workpieces of various shapes at different angles. They differ from each other both in the size of the holder and in the shape of the plate that can be clamped.

The photo below shows 3 different models:

The smallest cutter has a 20 by 20 mm holder and is equipped with a 4-sided square insert.

The slightly larger one has a 25 mm holder and the plate is also square, but larger in size. Well, the third cutter is similar in parameters to the second, it has a 5-sided plate installed by default, but you can take it out and put it the same as on the second one - a large square one.

In terms of money, these cost around 300 rubles apiece, but they are difficult to find on sale, and even bringing them to order is sometimes problematic.

Another note: Three-sided cutters for metal - an overview of types and their GOSTs

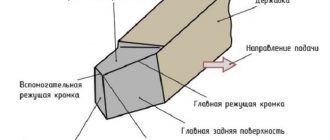

Structure

Consists of two main components:

- Working head – sharpened at different angles.

- Holder (body) – fixed in the tool holder.

The main cutting edge does most of the work. Surfaces of the working part: front, two rear.

Angles:

They are located in the main cutting plane, perpendicular to the main cutting edge, the main plane.

There are four main angles:

- Points.

- Cutting.

- Front.

- Main rear.

They are designated by Greek letters (alpha, beta, gamma).

Expensive

They differ in structure - they have threaded plates, functionality - processing of wooden and metal objects.

5th place HSS Line Profi 16 mm Narex 819316

Cost: 7,230 rubles.

(Czech Republic).

Purpose – processing of wooden blanks. Consists of a handle (elongated shape, material – light natural beech), a brass cap. There is a steel blade and a hard alloy roller.

Dimensions (mm):

- total length – 395;

- plate diameter – 16;

- blade – 150;

- handle – 315.

Product weight (packed) – 360 g.

The product is made of HSS steel with hardness HRC 64 (blade), natural beech (handle). The surface is ground and polished.

Advantages:

- high quality steel;

- blade strength;

- for wooden elements;

- comfortable handle shape made of natural wood.

Flaws:

- high price.

4th place Cutting groove for replaceable inserts MGEHR1010-1.5

Price: 903 rubles.

Manufacturer – . Designed for processing metal elements. Features: Replaceable plates (MGMN150).

Dimensions (mm):

- length – 100;

- width – 10;

- height – 10.

Weight – 100 g. Made in right-hand version (R).

Functions: processing of external grooves, cutting of the required size.

Advantages:

- replaceable plates;

- GOST standards;

- available for sale.

Flaws:

- plates must be purchased separately.

3rd place Cutting tool for replaceable inserts ZQ2525R-4

Cost: 1,283 rubles.

The product is manufactured.

Purpose: cutting grooves, cutting metal elements. Features: replaceable inserts with one cutting side, rigid structure, low deformation.

Parameters (cm):

- length – 15;

- width – 2.5;

- height – 2.5;

- plate width – 0.4.

Weight – 720 g. Depth of the resulting groove – 2 cm.

Correct execution of the product. Plate type – SP400.

Advantages:

- processing of metal parts;

- high-quality element designs;

- long-term use;

- one functional side of the plate.

Flaws:

- not identified.

2nd place For replacement inserts for external turning 25mm WWLNR2525M08

Price: 1,283 rubles.

.

Features: W-trigonal shape of the plate, angle – 95⁰, fastening W-clamp with a wedge clamp on a pin.

Dimensions (cm):

- total length – 15;

- holder section – 2.5*2.5;

- width – 7.

Weight – 850 g.

Product brand – WWLNR, plate – WN-0804.

Functions: chamfering, trimming, external turning.

Advantages:

- reliable fastening;

- plate shape;

- functional;

- durability of materials.

Flaws:

- plates are not included.

1 place Thrust and contour pass-through for replaceable inserts MDJNR1616H11

Cost: 1,074 rubles.

The product is manufactured (Russia).

It differs: fastening system – M (combined clamp), main angle 93⁰, right-hand feeding direction.

Characteristics (cm):

- length – 10;

- width, height – 1.6;

- cutter length (working part) – 3.15.

Weight – 230 g. Suitable plates DN-1104.

Functions: contouring, longitudinal, transverse turning.

Advantages:

- performs many tasks;

- suitable for roughing;

- combined fastening.

Flaws:

- not found.

Sets

They consist of several items (from 5 to 12 pieces) and have different functionality (working on metal, wood).

5th place Woodworking set Enkor 10430, 8 items

Price: 7,440 rubles.

Manufactured (Russia, Voronezh) in China.

The set consists of 8 tools. Sold in a light-colored wooden box with a hinged lid. Contents - instructions for use.

The tools consist of a blade, a handle, and a ferrule.

Materials: blades - high-speed steel, handle - wood with a multi-layer cherry varnish coating.

Case parameters (cm):

- length – 44.5;

- width – 31.5;

- height – 4.5.

The weight of the box with tools is 2.6 kg.

Functionality: roughing, cutting off excess parts, facing, turning rounded shapes.

Advantages:

- the number of different blade shapes in one set;

- comfortable handle;

- easy to store and transport;

- suitable as a gift for a beginner;

- attractive tool design.

Flaws:

- sharpening required.

4th place Set METALMASTER 18978, 5 pieces, wood

Cost: 11,499 rubles.

Manufacturer – (Russia).

Consists of 5 tools, wooden box with lid. There is a company logo sticker on the top of the lid. Bottom sides - the inscription “Made in Russia”, compliance with GOST.

Specifications (mm):

- blade length – 150;

- handle length – 330;

- blade width – 24.

Material: blade – steel R6M5 (hardness HRC 64), wooden handle – birch.

The set includes cutters:

- Cut-off.

- Right oblique.

- Rip-off.

- Section 30 mm.

- Section 12 mm.

The tools are manufactured according to GOST 19265-73 standards and are intended for working with wooden products.

Advantages:

- quality steel;

- high hardness;

- comfortable handle;

- popular assortment;

- beautiful wooden case.

Flaws:

- only 5 items.

3rd place Set Proma (25330808), 11 pcs

Price: 4.020-4.455 rubles.

Manufactured (Czech Republic).

Consists of 11 items, with a soldered VK8 plate. Suitable for Proma SM-300,350 lathes, mini-machines from other companies.

Dimensions (cm):

- length – 8 (9 pieces), 12.5 (2 pieces);

- cross section – 0.8*0.8.

Weight (with packaging) – 0.600 kg.

Packaging – cardboard box (length – 16 cm, width – 6 cm). Each tool is packaged in an individual zip bag.

Equipment:

- Passing straight.

- Passing bent right.

- Boring passage.

- Boring persistent.

- Shaped.

- Threaded (external thread).

- Grooved.

- Passing bent left.

- Cut-off.

- Tortsovy.

Functions: longitudinal grinding, trimming, cutting, external threading, chamfering.

Advantages:

- a large set of items;

- performs basic types of work on the machine;

- simple packaging;

- affordable price.

Flaws:

- needs sharpening;

- no internal thread cutting.

2nd place Cutters for lathe FD 150/E, 6 x 6 x 60 mm, 6 pcs. Proxxon (24524)

Cost: 6,072 rubles.

Manufacturer: German.

It is used when processing metal and plastic elements.

Consists of 6 tools, packaged in a wooden box with a retractable lid.

Product parameters (cm):

- length – 6;

- cross section – 0.6*0.6.

Material: cobalt high-speed steel (HSS), case-hardened.

Suitable for the tool holder of the FD 150/E lathe.

Advantages:

- common types of incisors;

- quality work;

- durability of products;

- convenient packaging.

Flaws:

- recommended only for a specific machine.

1 piece Set of turning tools for metal 10x10 VK8 12 pcs

Price: 5.627 rubles.

The set consists of 12 pieces with soldered plates and a wooden box. retractable cover.

Equipment:

- Passage bent.

- Passing straight.

- Grooved internal.

- Left trim.

- Cut-off.

- Passing persistent straight double-sided right.

- Passing persistent straight double-sided left.

- Boring (blind holes).

- Boring (through holes).

- Trimming.

- Passing bent left.

- Threaded (external thread).

Material – hard alloy VK8.

Compliance with GOST standards. Suitable for household machines.

Weight (packed) – 1.3 kg.

Advantages:

- a large number of tools;

- high-quality alloy;

- multifunctional;

- convenient storage, carrying;

- Suitable for most machine models.

Flaws:

- not identified.