The bolt looks like a cylindrical rod with an external thread cut at one end. At the other end it ends with a head. The thread can be cut only on parts of the rod or all the way to the head. The appearance of the bolts will differ depending on their purpose. The article mainly examines the option of hardware with an internal hexagon, which is used in construction, the automotive industry, for assembling furniture, in components and mechanisms, and in wood.

Allen Bolt

Giving a hexagonal shape

At this stage, it will be more convenient to work if the metal is heated. (I did not maintain a constant temperature and was unable to bend the entire piece in one piece).

Clamp the strip in a vice at the level of the previously made recess.

Use a hammer to bend the section protruding from the top of the vice.

Check if the angle fits by trying it on the corresponding nut.

Repeat for each segment.

As my strip cooled, the metal became more difficult to work with. This led to a breakdown over the third segment. In my case, this worked to my advantage, because when I started bending the fourth section, it turned out that its length was not enough and I needed to grind off a little metal so that the nut would fit properly. (I think adding a millimeter to each cut will help avoid running out of length on the inside edge of the key).

So I got a part consisting of two parts, each with three sides. (It may be easier to work with this than with a solid piece curved into a ring, as I originally planned to do).

Check that the workpiece fits properly onto the nut. But not too tight. (If necessary, you can grind off part of the inner surface of the edges)

How to unscrew a hex without a key

How to unscrew small bolts without a screwdriver

Other ways to unscrew a bolt without a hexagon are as follows:

- If the size of the bolt is not too small, you can use a chisel or an ordinary hammer: they strike at an angle in the direction of unscrewing the fastener.

- Method using a spanner or gas wrench.

- If you have a problem with how to unscrew a “licked” hexagon, you can use a wrench with an attachment. The bolted connection is unscrewed using a hammer mechanism.

- Method of using welding: a small amount of metal with a nut or any piece of reinforcement is welded to the fastener, with the help of which it is then unscrewed.

- The extreme measure for unscrewing hex hardware with an internal axis is to completely dismantle the fastener, when cuts are made with a hammer and the fastener is disassembled.

Hexagon alternative

This type of fastener is very inconvenient to use in the absence of special tools.

There are several ways to replace a hex key:

- First of all, you can use a screwdriver of a certain size. In this case, you should rest its edges on opposite sides of the groove and try to turn or tighten the bolt.

- Bolt with a set of nuts. They are screwed onto the thread and placed inside the hexagon. In this case, tightening is done using a wrench. It should be noted that bolts and nuts must be selected according to the standard size of the hexagon.

- As a tool, you can use a triangular file of a specific size or an “asterisk”.

- If the design allows, you can cut a small hole in the hexagon for a flat-head screwdriver and then work.

It should be noted that unscrewing such a connection is somewhat easier than tightening it properly. For such cases, it is advisable to use a special tool. It is often sold in whole sets, which allows you to select it for any type of fastener.

If you need to remove the hexagon, you can cut off the head and knock out the bolt (if you have access). You can also turn the bolt by hitting a hammer and screwdriver along a certain edge of the product.

All these methods are not universal and can damage the hexagon design, which will lead to its replacement.

Thanks to this video you can learn how to quickly replace a hex key:

What not to do

How to unscrew a soured bolt in a silent block

“Craftsmen” invent exotic ways of unscrewing secret bolts, the use of which most often leads to damage to wheel rims. You should not take risks using the following, somewhat barbaric methods:

- Freezing secretions with liquid nitrogen. Ultra-low temperatures make the metal brittle, so the bolt can be broken with a hammer and pulled out in parts. However, when treating a bolt from a spray can, there is a risk of nitrogen entering other parts and subsequently destroying them when hit with a hammer.

- Gouging out the bolt with a chisel and hammer. The secret is simply broken and removed from the hole in parts. This method most often leads to damage to the wheel rim.

- Used to unscrew a gas wrench. In rare cases, this method works on stamped discs. But most modern manufacturers install a rotating wheel on the bolt, which prevents the head from being grabbed with a gas wrench.

To avoid the problem of unscrewing the secret, you should keep the key to it in a safe place. One of the right decisions is to purchase a special case for storing the key, which is attached to the wheelbrace. In this case, the tool will always be at hand and will not get lost.

Unscrew and tighten the nuts

How to unscrew a nut with torn edges + photo - video

You can tighten or unscrew the large nut on the mixer even if the thread on it has already been torn off as a result of unsuccessful dismantling attempts. There are several ways to solve this problem:

- The head of the hardware is clamped in a carpenter's vice or clamp and with their help, performing rotational movements, the problematic hardware is unscrewed. The same tools can be used to tighten the hardware if necessary.

- A nut with a large diameter is put on top of the horizontally located hardware with force, and then this structure is unscrewed with a tool suitable for the size of the upper fastening element.

In the case when you need to unscrew round-shaped hardware or hardware in which all edges are completely smoothed, you can use the following methods:

- Place another hex nut of the appropriate diameter over the round hardware. Next, you will need to clamp the nut with a vice or clamp and unscrew the hardware.

- Place another larger auxiliary nut on top of the round loose nut. At the junction of the nuts, drill a hole into which to insert a pin or drill. Next, you need to unscrew the nut using a pin driver.

- A metal pin is welded to one side of the hex fastener, then another pin is welded to the pin to form an L-shaped lever. Using the resulting lever, the hardware is unscrewed.

In some cases, you can unscrew the problematic hardware by destroying it:

- Using a chisel and a hammer, you can shake out problematic hardware. The chisel is placed on the edge of the nut and the chisel is struck with a hammer. So all the edges are passed in turn several times.

- If you drill several holes in the hardware, then using a chisel and hammer you can destroy its structure.

- The fastening element is cut off using a grinder cutting disc or sawed off with a hacksaw blade.

Sometimes you need to unscrew a tightly screwed plastic nut. In this case, the following manipulations will help:

- With the help of a steel tape, which is tightly wrapped around the nut head, a rotational movement is performed, using the ends of the tape as a handle.

- 2 wooden planks are pressed against the edges of the hardware, placing them opposite each other. Holding the ends of the planks with your hands, make a rotational movement counterclockwise.

- To unscrew/tighten, you can use an adjustable gas wrench or jaws of pliers set in different directions.

You can tighten the hardware with a simple device:

- take a long auxiliary bolt and screw a nut onto it;

- after it, another one is screwed in, but a gap is left between the nuts, into which the head of another screwed bolt or nut is placed;

- both hardware are tightened on the auxiliary bolt so that they firmly clamp the head of the mounted fastener;

- then perform rotational movements in the direction of twisting.

When the procedure is completed, the fastenings on the auxiliary bolt are unscrewed and the device is removed. This method is also suitable for the process of loosening nuts.

Unscrewing the internal hexagon

If the edges are knocked down, you can use a needle file, with which you just need to bore the hex hardware corresponding to the size of the existing key. It is also possible to use Torx.

With its help, you can make new splines and reapply hardware. However, it must be taken into account that in the future such a bolt can only be unscrewed with a Torx asterisk.

If you don’t have a hexagon at hand, you can use alternative methods. However, you need to take into account that they are not universal and can damage the structure, which will ultimately lead to its replacement.

Alternative methods are ideal for unscrewing, but they are extremely difficult to tighten the bolt properly. Therefore, you should resort to them only in extreme cases.

Table of types and sizes of internal hex bolts and their characteristics

Hardware of this type is made of carbon and stainless steel. They have thermal diffusion or galvanic coating with oiling; sometimes they produce samples with oiling, but without coating.

The color of the coating is light gray, dark gray and golden yellow. Black bolts do not have a protective coating, so they cannot be used in areas with high humidity or structures in contact with water.

The protective layer should cover the product with a uniform cover without bald spots or bumps. The first indicates that the coating is peeling off, the second indicates low quality hardware.

An internal hex screw ensures reliable fastening of parts and is universal, but, first of all, it is necessary to select hardware of the appropriate type and size.

Types of hexagon socket bolts according to DIN standard

| DIN standard | Status | Dimensions and DIN designation | GOST standard | ISO standard | Schematic illustration |

| DIN 912 | replaced by DIN EN ISO 4762, DIN EN ISO 21269 | Socket head screw with hexagon socket, full and partial thread; diameter from M2.5 to M64, length from 4 to 600 | GOST 11738-84 | ISO 4762, ISO 21269 | |

| DIN 6912 | valid | Low socket head screw with hex socket (hex bolt), diameter M4 to M30, length 6 to 180 mm | |||

| DIN 7380 | replaced by DIN EN ISO 7380 | High strength pan head screw with full thread hexagon socket | ISO 7380 | ||

| DIN 7984 | valid | Hex socket head cap screw, full thread, reduced head height; diameter from M3 to M24, length from 5 to 150 | GOST 11738-84 | ||

| DIN 7991 | replaced by DIN EN ISO 10642 | High-strength screw with countersunk head and internal hex key; diameter from M3 to M24, length from 6 to 200 | ISO 10642 |

In terms of size, hardware corresponds to three accuracy classes: A, B and C. The marking on the head of the hardware corresponds to its class. The accuracy class determines how accurately the rod will correspond to the diameter of the hole prepared for it, taking into account the size of the bolt.

| Class | Deviation, mm |

| A | 0,3 |

| B | 1-1,5 |

| C | 2-3 |

Due to the high degree of deflection, a Class C screw can become deformed under dynamic loads, however, it is easier to install because it fits easily into the prepared hole.

According to the accuracy class, the price of the product will increase. Fasteners with accuracy class A are more expensive than class C hardware. If you purchase a large number of fasteners, the difference will be a significant amount.

The parameters of bolts (screws) manufactured according to GOST 11738 / DIN 912 / ISO 4762 are presented in the table:

Hexagon socket bolt measurement diagram

DIN912 parameter table

Experts advise buying domestically produced products, since imported hardware may be labeled in an unusual way and vary in size.

Features and Benefits

An internal hex bolt differs little from ordinary bolts in appearance, but, nevertheless, their minor design feature makes them more durable, reliable and convenient.

Advantages of hexagon socket bolts:

- To tighten the screw, there is no need for free space around the hardware because the key used to tighten the fastener is inserted directly into the head, rather than overlapping it.

- The slot on the head is not so easy to lick off; it is more durable compared to the slot of a regular bolt, since the material of the hardware is denser than the material of the key, and the key is more likely to deteriorate than the fastener slot.

- A hexagon socket wrench is cheaper than an open-end or socket wrench.

- The head of the fastener does not have sharp outer edges.

- Bolts with an internal hexagon are used in hard-to-reach places, and after screwing in, the head does not remain on the surface, but sinks flush.

Countersunk screw - Galvanized hex bolt hardware can be used in wet conditions because they are more resistant to corrosion.

- Hardware of this type can be dismantled and used again, just like the structure itself assembled with their help. Bolts can be used in combination with a nut: in this case, they are inserted into the hole, and the nut is screwed on the other side; or without a nut, then they are screwed into a threaded hole.

The hexagon socket screw is unscrewed clockwise.

Types and their features

There are several types of secrets:

- with external turnkey profile;

- with internal profile;

- cone-shaped.

Each of these types of secrets has its own design features, advantages and disadvantages. Locks with an external profile are a fairly simple, but not very reliable way to protect wheels from removal. In essence, it is a regular bolt or nut with a slightly modified profile. It can be triangular, in the shape of a star or some other type, the main thing is that it is not a hexagonal one (like a regular key).

Such secrets are inexpensive, and you will never have problems with dirt when unscrewing them. But it won’t be too difficult for an attacker to unscrew them. The fact is that even an ordinary wheel wrench or a socket wrench with a suitable size, when put on such a lock, is capable of catching on the bolt profile with its edges.

The second option that an attacker can use is powerful pliers or pliers with extended handles. With this tool he can easily grab the bolt and unscrew it.

Security bolts with an internal profile are more reliable in terms of protection. In such secrets, the profile for the key is made in the form of a recess or hole of a complex shape (star-shaped, multi-beam, asymmetrical, etc.), and the key is a rod of a certain shape that exactly fits the shape of the hole. The outer profile of a bolt or nut has a perfectly round surface.

It is impossible to unscrew such a secret without a key. Using pliers or pliers will also not bring results, since their jaws will simply slide off the round surface.

Some models of such secrets are equipped with additional elements - protective rings around the outer circumference. These rings rotate freely on the bolt, so it is impossible to snag on the outer surface of the bolt. This further increases the protective function of secretions.

But this type of lock is more expensive, and there is one serious problem when using them - during operation, the internal profile becomes clogged with dirt, so it is often very difficult to unscrew such a lock, even with a special key for it. This problem is especially relevant for fasteners with very complex hole shapes. Dirt or ice (in winter) simply clogs the edges and the key cannot be installed. Therefore, the car owner has to very carefully clean the hole, which, due to its complex multifaceted shape, is not so easy to clean.

Some models of secret boxes with an internal profile are equipped with protective caps that protect the holes from contamination, which somewhat eliminates the problem of clogging.

Video: 5 ways to remove wheels. Will McGard secrets help?

The third type - cone-shaped bolts have a tip made in the form of a cone with an offset center. It is impossible to unscrew such a bolt using a regular wheel wrench or pliers, since the surface of the cone is smooth and it is impossible to catch on it.

But this type also poses inconvenience to the car owner himself. The fact is that it is very difficult to create the force necessary for unscrewing with the key of a lock that has the form of a rod with a hole for a cone; the key simply moves relative to the center of the cone.

Turning: process features

The hexagon is turned from a steel bar on a sharpening machine.

The first main stage of work will be turning a shaft of a certain cross-section from an existing rod. It must correspond to the size of the hexagon that is needed in this particular situation. A caliper will be used for measurements. This is a fairly accurate tool with which you can easily take all the most necessary measurements. So, the workpiece is installed in the lathe. It must be attached on both sides using special holders. By the way, it is worth noting the fact that it is not possible to make a small hexagon using this method. Only a tool of impressive size can be produced at the output.

From the back side, the future hexagon is pressed using the headstock. Now everything is set strictly horizontally, which means you can safely start processing. It can be just rough, or you can bring the instrument to shine. This doesn’t matter, because later you still have to make edges.

So, the machine is started, which means that all that remains is to control all the necessary dimensions. The output should be a rod that has a diameter equal to the size of the hexagon. This is done extremely simply. Most importantly, do not forget to constantly take measurements using a caliper. This is the only way to get a truly correct figure at the end. After the work is completely completed, we can state the fact that the pre-workpiece is ready for further processing. It will be done using a vice and a grinding machine.

Return to contents

All sizes can be measured with a caliper.

So, the turning operations are completed, which means that we can proceed to obtaining the edges. To do this, you should not focus solely on your skill. First you need to make a stencil on paper, which will fully correspond in its geometric parameters to what you want to get at the output. Then it is outlined on the finished shaft. So, all measurements have been made, which means that the part can be safely clamped in a vice. It is completely ready for processing. In a vice it is clamped in a horizontal position.

For grinding, you can use a rough wheel, since you will have to remove several layers of metal.

It is very important to do all the work as competently and accurately as possible. After the work is completed, you can check the edge for compliance with the dimensions. This is also done using a measuring tool. In this case, you can use a regular caliper. If the size does not correspond to the declared values, then it is necessary to adjust it to them. This is done through post-processing.

The hexagon is sanded using sandpaper.

Now you can turn the future hexagon over to the other side and continue sharpening the edges. This will take approximately half an hour. After this, you can check the entire device for compliance with the required geometric parameters. If everything is normal, then the result should be consolidated. For subsequent sanding, you can use regular sandpaper. Be sure to remove all burrs and excess metal. After this is done, you can begin further work. It consists of checking the functionality of the tool. You just need to install the hexagon into the desired bolt and try to unscrew it. If everything was done in strict accordance with the technology, then it should unscrew without any problems.

Of course, the resulting design has several disadvantages. The most important of these may be the incorrect shape of the tool. It turns out strictly straight without any bends. If we talk about a standard hexagon, it is made at an angle of 90 degrees for ease of use. Of course, this drawback will not prevent the necessary bolts from being unscrewed. The resulting tool can be additionally equipped with a handle or simply use pliers to loosen the bolts.

Thus, now you know exactly how to make a hexagon using the tools at hand. As is clear, this process is quite complex, but it is quite possible to carry it out without particularly straining. The main thing is to have all the most necessary tools at your disposal. Of course, you simply cannot do without skills in working with turning tools and a machine. The sanding machine must also be operated correctly. Otherwise, it will be quite difficult to obtain the required tool with the specified quality characteristics. This is where everything comes to its logical conclusion. It is hoped that the resulting tool will serve you for many years.

Is there a pencil near you? Take a look at its cross-section - it is a regular hexagon or, as it is also called, a hexagon. The cross-section of a nut, a field of hexagonal chess, some complex carbon molecules (for example, graphite), a snowflake, a honeycomb and other objects also have this shape. A giant regular hexagon was recently discovered in Doesn't it seem strange that nature so often uses structures of this particular shape for its creations? Let's take a closer look.

A regular hexagon is a polygon with six equal sides and equal angles. From the school course we know that it has the following properties:

- The length of its sides corresponds to the radius of the circumscribed circle. Of all, only the regular hexagon has this property.

- The angles are equal to each other, and each measure is 120°.

- The perimeter of a hexagon can be found using the formula P=6*R, if the radius of the circle described around it is known, or P=4*√(3)*r, if the circle is inscribed in it. R and r are the radii of the circumscribed and inscribed circle.

- The area occupied by a regular hexagon is determined as follows: S=(3*√(3)*R 2)/2. If the radius is unknown, substitute the length of one of the sides - as is known, it corresponds to the length of the radius of the circumscribed circle.

A regular hexagon has one interesting feature, thanks to which it has become so widespread in nature - it is able to fill any surface of a plane without overlaps or gaps. There is even the so-called Pal lemma, according to which a regular hexagon, the side of which is equal to 1/√(3), is a universal cover, that is, it can cover any set with a diameter of one unit.

Now let's look at constructing a regular hexagon. There are several methods, the simplest of which involves using a compass, pencil and ruler. First, we draw an arbitrary circle with a compass, then we make a point in an arbitrary place on this circle. Without changing the angle of the compass, we place the tip at this point, mark the next notch on the circle, and continue this until we get all 6 points. Now all that remains is to connect them together with straight segments, and you will get the desired figure.

In practice, there are cases when you need to draw a large hexagon. For example, on a two-level plasterboard ceiling, around the mounting location of the central chandelier, you need to install six small lamps on the lower level. Compasses of this size will be very, very difficult to find. What to do in this case? How do you even draw a large circle? Very simple. You need to take a strong thread of the required length and tie one of its ends opposite the pencil. Now all that remains is to find an assistant who would press the second end of the thread to the ceiling at the desired point. Of course, in this case, minor errors are possible, but they are unlikely to be noticeable to an outsider at all.

This problem often arises when the hex bolt is torn off and it is not possible to unscrew it with a wrench. The causes of this problem may be the sticking effect, displacement of the parts being fastened, over-tightening when installing hex hardware, as well as the use of inappropriately sized keys.

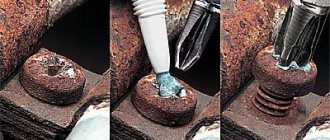

Whatever the reasons for the situation when the bolt stops unscrewing, the following steps should be taken before plumbing:

- Before unscrewing the hexagon, to reduce the coefficient of friction, it is necessary to open the bolted fasteners with lubricant such as WD-40, kerosene or brake fluid. You can start unscrewing the bolt 30-60 minutes after application.

- A stuck bolt can be gently tapped with a hammer so as not to further disturb the thread.

- If the location of the fastener allows, you can heat it with a gas burner so that the metal becomes more pliable and rust and dirt turn into ash.

How to remove a drill from a damaged chuck

Here we will also talk about cases when the drill itself is damaged.

Damage usually occurs in the form of a broken cam or damaged threads. It also happens that the drill is damaged, for example, by turning between the cams. As a result, chips are formed, which interfere with normal rotation, as they are driven into different slots, which prevents rotation.

So, first you can try to relax your fists. This can again be done using two gas keys or one in conjunction with a vice.

In the first case, each part of the cartridge is clamped with its own key and rotated to unscrew. In the second, one of the parts is fixed not with a key, but with a vice. Since this creates a fairly large force, unlocking occurs quite easily.

In addition, in the absence of a gas wrench, you can clamp one part in a vice, and apply gentle tangential blows to the second with a hammer. Relaxation occurs due to the vibration created.

If the previous methods do not help, for example, because the threads on the cams are broken, then you will have to resort to the next step.

First you will need to unscrew the chuck from the electric drill. I have already described how to do this on this page. Then we clamp it in a vice and knock out the drill from the inside with a punch of a suitable diameter, which is threaded through the hole into which the spindle is inserted.

Removing the screw

Screws with torn edges cause a lot of trouble. Unscrewing such screws is not easy, but there are several ways to solve this problem. To make it easier to unscrew them, you need to do the same preparatory measures as for the bolts.

In the simplest case, when the screw protrudes above the surface, you can try to grab it with pliers, wire cutters or another similar tool and unscrew it in this way. But most often there is nothing to grab onto. Then you can try the following methods:

- Sometimes it helps to use thin rubber, for example, from a balloon. A piece of such rubber is placed on top of the screw and unscrewed, pressing the screwdriver through it. This increases friction and prevents the screwdriver from slipping.

- A screw with a curly head can be converted into a flat-head screwdriver by sawing through the groove with a hacksaw.

- In order to solve the problem of a screwdriver slipping, you can use cyanoacrylic-based glue; this glue dries quickly and holds metal surfaces together efficiently. The procedure is simple: the screw and screwdriver are degreased, glue is applied to the head of the screw and the screwdriver is pressed against it, maintaining alignment. To speed up the setting of the glue, you can sprinkle it with soda. Wait until the glue has completely hardened and try to unscrew the screw.

In order to avoid such problems in the future, renew all threaded connections with taps or taps before assembly. Replace any damaged fasteners. Be sure to lubricate the threads and fasteners in general. It is best to use graphite lubricant for these purposes.

I fully support what arnis wrote. I will add that if we are talking about a screw, and you can “get close” to its head with pliers (pliers, round nose pliers, etc.), then you need to try to “touch” it by grabbing the head from the outside with the above tools. If you try to immediately twist it with a screwdriver, you can tear off the slots, and then you will still have to resort to using pliers, but then you will have to unscrew the screw completely with pliers, and this can be very inconvenient. And if, without damaging the splines, you just “rip it off” by turning it at least 1/10 of a turn, then it will go further. Sometimes it happens that at first the screw unscrews quite easily, but in some intermediate position it “sticks”. In this case, there is no need to continue to twist it “forcibly”. You need, on the contrary, to twist it back, in the direction of twisting, and with such very small movements “back and forth” gradually unscrew it.

If you don’t have WD-40 liquid on hand (about 20 years ago a similar product was called “unisma”), then it is best to wet the rusty area with kerosene or diesel fuel. Sometimes wetting the rusted threads with some acid helps, if you have it on hand. Hydrochloric or phosphoric acid (rust converter) is best. At worst, acetic acid or citric acid solution will do.

Over time, the fasteners rust, so it is impossible to unscrew them using improvised means without effort. Many people face this problem. This is especially true for motorists, owners of private houses where various iron structures are forgotten on the street, as well as those who begin repairing and replacing old plumbing. While the task may seem overwhelming to some, there are actually many ways to remove rusted nuts, bolts and screws without damaging them.

How to unscrew a broken hex bolt

To unscrew a protruding hex or star bolt, you can use the following methods:

- Using a hacksaw or a grinder, make a neat and clearly vertical cut across the screw head. After these steps, you can unscrew it with a regular flat-head screwdriver.

- Using a Torx star: you need to drive it into the recess for the hex key in the hardware head. The size of the sprocket should be such that its splines do not fit into the hole. Then the hardware is unscrewed with a sharp jerk. It is not recommended to use a Torx with a hole in the center; the sprocket can break off.

- Before unscrewing the hexagon with torn edges, a drill with drills and extractors is used to drill a hole in its center. After this, the extractor is driven into it, then pulled out with pliers along with a hex screw.

- Using a drill with reverse rotation, a thin hole is drilled, then a hammer is inserted into it with left rotation and the fasteners are unscrewed. In this case, the rotation of the drill should be slow and the pressure should be strong.

Method for unscrewing a torn hexagonal protruding bolt

To unscrew such a bolt, you need to use some recommendations.

- If a small hexagon needs to be unscrewed, make a small indentation in its head. Its shape should match the shape of a flat-head screwdriver.

- Make a hole in the cap and drive the extractor into it. Pull it out with pliers along with the screw.

- Using a drill with reverse rotation, make a hole in the head of the bolt. Then insert a drill into it with left-hand rotation and unscrew the fasteners.

What can be used instead of a hexagon

Andrew Taylor (taylor.a), flickr.com CC BY

Fasteners in modern technology are distinguished by significant diversity. These include regular hex bolts and nuts, flat and Phillips slot screws, Torx sprockets and many others. Parts with an internal hexagon stand apart here. Unscrewing them without a suitable tool is quite difficult.

The internal hex spline was first patented in 1936 by the German company Bauer & Schaurte. In foreign technical literature, such screws are usually referred to under the brand name Inbus. This is an abbreviation of the German phrase Innensechskantschraube Bauer und Schaurte - a hexagon socket screw from Bauer & Schauerte.

Advantages of internal hexagon

Hexagon socket bolts and screws have a number of advantages over conventional fasteners. Firstly, there is no need to leave space around the head with such a slot for the fastening tool. In this case, you can completely “recess” the screw into the part, which is very convenient for all kinds of drain plugs.

Secondly, the torque transferred to the part can be almost ten times greater than that of a Phillips-head fastener. Therefore, the Inbus slot is often used in units operating under heavy loads (metalworking machines, road equipment). This also allows the use of small heads for screws with large shank diameters, ensuring that the same tool size can be used to service different assemblies. Cyclists know this well - one hex key is enough to service a bicycle on the road.

Thirdly, when using a suitable high-quality wrench, it is quite difficult to break the notches of the internal hexagon

The notches hardly wear out, the fasteners can be used repeatedly, which is important for fastening various types of inspection hatches that require frequent opening and closing

Fourthly, the internal hex wrench is simple and cheap compared to open-end, box and socket wrenches for external hexagons.

And finally, screws with an internal hex head are much safer, since they do not have sharp outer edges, and they also look more aesthetically pleasing.

How to unscrew a hexagon without a key?

Of course, a hex wrench is not out of reach these days. In any store or car market you can pick up a hexagon of any size. But is it worth buying a relatively cheap wrench just to unscrew a tricky screw just once?

This problem is often faced by car enthusiasts who decide to repair their car themselves. The hex socket almost always has a drain plug on the transmission and often a plug in the engine oil pan.

A home craftsman may encounter hexagons when repairing a bathtub faucet or ball valve - ordinary fasteners simply do not fit there.

Moreover, in all these cases the size of the hexagon is quite decent. What to do? A bolt with a regular hex head will help.

The bolt head is inserted into the hexagonal slot and unscrewed by the rod with a gas wrench. You can also screw 3-4 nuts onto the bolt threads, wedge them well together and unscrew them with a regular spanner.

When unscrewing, you need to twist the nut closest to the head, and when tightening, vice versa, by the farthest one. If the hexagon has a non-standard size, then the head of the key bolt can be sharpened with a file or on a sharpening machine.

What to do if the hexagon is torn off?

It happens that attempts to unscrew a hexagon socket screw using improvised means or a wrench of a slightly inappropriate size lead to the edges breaking off. In this case, too, there is a way out.

If the hexagon is small, then you can hammer a TORX sprocket of a suitable size into it and unscrew it. If the head is accessible, then you should try to unscrew the screw using pliers, a gas wrench or a hand vice.

If you have space, a hammer and chisel almost always helps. The chisel should not be very sharp, and blows should be struck tangentially in the direction of unscrewing. By the way, check, maybe the thread on the screw is left-handed?

For steel bolts and hexagon socket screws, you can weld a nut, piece of rebar, or something similar to the head so that the bolt can be removed.

And remember that one person screwed it on, another can always unscrew it.

Here's another way to remove problem screws using an engraver with a cutting wheel. This can be done on a large scale using a hacksaw or grinder.

Twisting methods

In cars, a screw with an internal hexagon is used to secure the plug in the engine sump and the transmission drain plug. In everyday life, a plumbing bolt with an internal hexagon is used to secure parts of a ball valve or mixer. Despite the strength of this type of hardware, the edges still break off under certain conditions, for example, if the hexagon is inserted incompletely or at an angle. Ways to solve a problem depend on the factors accompanying the problem.

In particular, if you cannot unscrew a bolt because it is stuck, you must first treat it with a rust converter and then with a lubricant like WD-40. Instead of WD-40, you can use kerosene or brake fluid - easy-flowing compounds. They penetrate into the smallest cracks and pores, lubricating the part and destroying rust. 30-60 minutes after applying the lubricant (sometimes you should wait longer - up to 10-12 hours), try to move the bolt from its place along the thread.

WD-40 lubricant

If the hardware still does not give in, you can gently tap it with a hammer or heat it. Heating should be carried out with an open flame of a gas torch, blowtorch or acetylene torch. Due to this effect, rust will turn into ash in some places, and the metal will become more pliable.

If it was not possible to unscrew the bolt without a hexagon using these methods, it is necessary to increase the applied force using a lever. To do this, select a metal tube of a suitable diameter, insert a key inside, one end of which is fixed in the stuck hardware, and, manually or using a hammer, try to unscrew the bolt.

Without hexagon

A regular hex bolt that can be used as a tool

A hex key is S-shaped or L-shaped and is often included with a furniture hex bolt kit for assembly. If you don’t have a wrench, you can use a bolt with an external hexagon of a suitable diameter and pliers, or better yet, a gas wrench. To tighten or unscrew a bolt with an internal hexagon without a hexagon, you need to screw 3-4 nuts onto the shaft of the hexagonal bolt, which is used as a tool, and jam them, insert the hardware with a hexagonal head into the recess, grasp the nut well with an open-end or gas wrench and turn a few times until fully tightened/unscrewed.

If for one reason or another the hexagon turns out to be useless, unscrew the bolt using one of the following methods:

- If the dimensions of the hexagon bolt are large enough (M8 or larger), you can unscrew it using brute force, using a chisel and a hammer. The chisel is placed at an angle and the hammer strikes the tool so that they are directed in the direction of unscrewing. Dents on the metal are acceptable, but the hardware should not be bent. When the bolt moves out of place, stop knocking on it to avoid damaging the thread.

- The possibility of unscrewing the fasteners using a spanner or gas wrench cannot be ruled out. If the key is new and has small serrations (cobra type), then even small hardware can be unscrewed.

- The licked bolt can be unscrewed with a socket wrench. The impact mechanism helps loosen the connection.

- A nut or piece of reinforcement is welded to the fastening element, and then, using a tool, it is unscrewed. The method is applicable only when the head is protruding.

Using the welding method

If all else fails, they resort to extreme measures - labor-intensive drilling. The work begins with the use of a thin drill: drill a hole exactly in the center. Then, using thicker drills, carefully drill it out. Eventually the bolt will crumble as the metal becomes thin.

Broken hex bolt

If the head of a bolt for a hex key or an asterisk protrudes above the surface and is not immersed in it, then the torn hardware can be unscrewed in the following ways:

- Using a grinder or a hacksaw for metal, make a transverse cut strictly perpendicular to the head. The depth of the cut should not be the entire depth of the head, but only 75%, otherwise it will break off.

- Then select a flat-head screwdriver of the appropriate width and unscrew the bolt like a regular screw.

- You can also unscrew the stripped hexagon screw using a Torx star. The size of the bit is selected so that the edges of the sprocket extend beyond the hole for the hex key. The Torx must be hammered into the recess, and then the hardware must be unscrewed with a sharp movement. It is important that the sprocket is solid, without a central hole, otherwise there is a risk that the sprocket will break. If that fails, you might want to try a 12-point bat. The main thing is that the bit is installed completely and without distortion.

12-beam bit - You can unscrew the broken bolt using an extractor and a drill. A hole is drilled in the center of the hardware. The diameter of the hole for the extractor should be 2-3 mm less than the thread. Then the extractor is driven into this hole. It is grabbed with pliers and removed along with the screw. As an extractor, you can use a tap with a left-hand thread. It is necessary to drill a hole for it, exactly the size required according to the corresponding table of values. The threads are then cleaned and any residue removed. Note! In the latter case, it is easy to damage the mating thread of the structural part.

- To remove a stripped bolt using the method described below, you need a left-handed drill and a drill. A small diameter hole is drilled with the tool. Then insert a drill into it with left-hand rotation and slowly, applying strong pressure on the tool, unscrew the fastener.

- If the thread is damaged and the screw turns, you need to use a flat-head screwdriver or other similar tool to lift the bolt under the head until it stops, and then unscrew the hardware.

Internal hexagon with torn edges

If you insert the hexagon incorrectly: not deeply enough or skewed, the edges of the internal hexagon in the fastener can be torn off. Then certain difficulties will arise with unscrewing the hardware.

Hardware with torn internal edges

- You can unscrew a bolt with an internal hexagon by boring a hole to the next larger size. Boring is done with a needle file.

- Another way is to use a Torx star. Use an asterisk to punch out new splines and unscrew the fasteners. If desired, this hardware can be reused, but then you will need to screw it in and unscrew it not with a hex wrench, but with a Torx asterisk.

- If the edges for the hexagon are torn off, you can also cut a slot in the head for a screwdriver and use a flat-head screwdriver to unscrew the hardware. However, this method is applicable in most cases only if the bolt head is above the surface. It is not always convenient to make a cut in a recessed piece of hardware, just as it is sometimes inconvenient to use a screwdriver later.

- If the bolt head is not recessed, then you can grind it down under the external hexagon with a file or using a sharpening machine and unscrew it with a regular key.

The hexagon socket bolt is more reliable and durable. Its scope of application is much wider compared to a conventional hex head bolt. It can be used in hard to reach places. There are several design types of screws, including those that are installed flush with the surface. Hardware protected by a special coating can be installed in places of high humidity. A key marked DIN 911 is provided for tightening and unscrewing the hex screw. But it can also be unscrewed in other ways, for example using a regular hex bolt. To unscrew a stuck, torn bolt, hardware with torn edges of an internal hexagon, use specific tools and universal methods for unscrewing damaged screws.

Did you manage to solve your problem using the recommendations from the article?

Yes!

45.45%

No. More answers required. I'll ask in the comments now.

38.29%

Partially. There are still questions. I'll write in the comments now.

16.25%

Voted: 363

Bolt with torn edges

Now we will figure out how to unscrew a bolt with torn edges. As a rule, the reasons for this problem lie in the following:

- The parts held by the bolt were misaligned in an unnatural way. This leads to pinching and damage.

- The bolt itself was very tight when tightening.

- The tool used to tighten it was the wrong size and improvised means were used (screwdrivers or chisels are often placed in larger keys when there are no suitable small ones).

Before unscrewing a broken bolt or nut, you need to do some preparation. This will allow you to spend less time and effort, and sometimes save expensive equipment.

Sequencing

- Coat the joint with liquid to aid unscrewing. Such a liquid can be the famous WD-40, brake fluid or kerosene. Take your time and let the liquid do its job. As practice shows, you can safely leave the part alone for thirty minutes, or even an hour.

- Take any available tool and lightly, not forcefully, tap the hardware from all accessible sides. Your goal, in this case, is not to launch the bolt like a golf ball, but just to slightly loosen it at the place where it is attached. While performing this activity, there is a danger of damaging the thread, so balance the strength and swing.

- If you have the opportunity and space, try heating the bolt. A gas burner is suitable for this. Make sure there are no flammable liquids or objects near the workplace. Also, before you start warming up, make sure that in case of an emergency you have somewhere to retreat. Do not heat the part with an open flame in enclosed spaces. It is better to open the gate or move the bolt to the air. Rust and grease scorched in this way will turn into ash and will no longer prevent the bolt from being unscrewed.

However, it often happens that it is the screw that jams that cannot be reached with a torch or tapping tool. In this difficult case, you should use a grinder or any available tool such as a chisel to make a deep cut on the preserved cap. This will become the hook that will allow you to pull out the entire bolt.

Now you can, clinging to this protrusion, try to unscrew the stubborn screw. Press the screwdriver into the recess, and while lightly hitting the handle of the hammer in the direction of unscrewing (not clockwise), slowly turn the bolt.

This is interesting: How to unscrew a bolt - thermal method, solvents, tapping

How to unscrew a hex without a key

Other ways to unscrew a bolt without a hexagon are as follows:

- If the size of the bolt is not too small, you can use a chisel or an ordinary hammer: they strike at an angle in the direction of unscrewing the fastener.

- Method using a spanner or gas wrench.

- If you have a problem with how to unscrew a “licked” hexagon, you can use a wrench with an attachment. The bolted connection is unscrewed using a hammer mechanism.

- Method of using welding: a small amount of metal with a nut or any piece of reinforcement is welded to the fastener, with the help of which it is then unscrewed.

- The extreme measure for unscrewing hex hardware with an internal axis is to completely dismantle the fastener, when cuts are made with a hammer and the fastener is disassembled.

How to replace a hexagon

The hex key can be replaced:

A hex wrench is a common tool, especially in furniture production. It is used to loosen or tighten bolts that have a hexagonal groove in the head.

Sometimes this tool is not at hand and you need to look for a way to replace the hexagon at home.

To fix bolts with outer edges, wrenches are used, which cannot always be used because the edges of the part are damaged in some way.

To unscrew them, you can also use improvised means.

Step-by-step instructions for unscrewing the hexagon

There are several options for step-by-step instructions for unscrewing a hexagon.

- On a bolt with a protruding hex head, the head is cut using a grinder or a hacksaw. It can then be unscrewed using a regular screwdriver. The cut must be made with the utmost care so that the screwdriver does not jump off it during operation.

- A suitable Torx sprocket is driven into the place where the hexagon is inserted. When driven in, it cuts through the head with splines and inserts into it. The bolt is pulled out with a strong jerk. If unscrewing is carried out slowly, the splines will break and the operation will have to be done all over again. Torx with a central hole cannot be hammered, since when hammered it is destroyed.

- Unscrewing the hexagon can be done using a drill and a regular drill, and various extractors that are purchased in the store. Using a core, a future drilling point is marked strictly in the central part of the bolt being processed, at which a hole is then drilled. With a little force, an extractor is inserted into the resulting hole with a hammer. Then, using a handy tool, it is unscrewed. The extractor can be reused after this procedure.

- Can be unscrewed with a drill with left rotation and a construction drill with reverse. A drill with a thin diameter drills a hole in the head of the element. Then a drill of a smaller size is taken compared to the diameter of the damaged bolt. The drill is inserted into the drill and set to inverse rotation. The speed of the drill should be low and the pressure strong. When the element is pressed firmly, the drill will screw into it and pull it out.

A bolt or hex screw can become damaged at any time. Various available tools can help in its repair, but the use of special tools may be required, without which it is impossible to unscrew the hex head of the damaged element.

Therefore, it is important to know all currently available methods for repairing this element. The hexagon is found in various types of indoor water faucets, in car spare parts

At the moment, these bolts are considered quite convenient fasteners, so they are widespread and found in many mechanisms.

Their use is advisable where a reliable power connection is required. This type of fastener is perfectly adapted to high loads and significant physical pressure. These bolts are especially often used in industries such as construction and mechanical engineering.

If we turn to the process of creating a hexagon, it becomes clear that the process of their manufacture is long and quite labor-intensive. These bolts are made from steel wire rod, which then softens after being in a hot oven for a long time. Then the wire rod is placed in a sulfuric acid solution for some time to completely remove rust particles. After being washed with water and treated with phosphates, the steel becomes resistant to rust and is then sent to be formed into a hex head element.

In the process of creating these products, many people are involved, providing the Russian market with modern, high-quality fasteners.

How to make a hex key

Good day to all!

Exactly 4 years ago I wrote a blog post to Note. TORX keys and tightening torques.

and this post interested people.

There have been a lot of shares and recommendations for this post, thanks to everyone! I am very pleased that someone found the information useful, and someone was simply interested in reading it and giving it a “ Like!”

" this post. I was asked to write about other types of “unusual” keys, but somehow never got around to it. Today I decided to correct myself and continue the topic.

Today I decided to write a post about the not very well-known Inbus key, the Allen key, but almost everyone knows the “hexagon”, and this is the same thing.

1.Description:

Hexagonal slot is a type of slot in threaded fasteners in the shape of a regular hexagon.

The head of the fastener is usually cylindrical in shape with a hexagonal recess.

The nominal size of the slot and key is the distance between the opposite parallel edges of the hexagon, which is expressed in millimeters (for the key, see GOST 8560-78 for measurement methods and tolerances) or fractions of an inch.

History of the name:

Inbus key - INBUS (read as inbus)

is a registered trademark of Acument Global Technologies, denoting the shape of a hex key and the corresponding recess in the fastener.

The name inbus is an abbreviation for it. In

nensechskantschraube

B

auer

u

nd

S

chaurte - Bauer & Schaurte hexagon socket screw.

As a rule, it is made in the form of an L-shaped bent hexagonal rod, and is often called a hex key. The hexagonal slot should be distinguished from other similar types, for example, in the form of a six-pointed star (eng. TORX)

.

There are also hex wrenches and socket wrenches with an internal hexagon (in the form of a hexagonal tube). The latter are designed to work with nuts and regular hex head screws and bolts.

It is believed that in the years 1860-1890 several patents were registered for different types of splines, among which the hex key also appeared, while it is stated that the keys were not produced due to the limitations of existing technology. In 1936, from Neuss in Germany (today owned by the Textron concern), a new type of screw with a hexagonal recess was used, which made it possible to increase the torque by about 10 times compared to the cross-shaped recess. Allen Key

- In 1908, Peter Robertson was the first to patent a method for making square keys, and already in 1910, William Allen patented the manufacture of hex keys, which were produced by his Allen Manufacturing Company of Hartford. In addition, Sir Howard Galowell sets out another version of events, according to which the foundation The Standard Pressed Steel Company (SPS) independently developed a method for making keys in 1911 and began producing them after encountering the difficulties of making Robertson square slot fasteners.

Markings and sizes

Wrenches and screwdrivers are measured by the distance between parallel edges. Modern markings for metric wrenches only contain the wrench size in millimeters. Sometimes keys are marked with the letter “M”

, for example

M4

or

M6

.