When working with fasteners and related mechanisms in construction work, rolled steel with a hexagonal cross-section is often used - steel hexagon .

Hexagon is one of the types of rolled metal. The scope of use of the hexagon is quite wide. A metal rod with a hexagonal cross-section is used for the manufacture of machine parts, complex mechanisms, bolts, nuts, and fasteners.

Hexagonal profile manufacturing technology

At this stage of development of the metallurgical industry, there are three types of steel hexagon production :

- Hot rolling;

- Hot pressing;

- Cold rolling.

When producing a hexagon by hot rolling , the dimensions of the product reach a limit of 100 mm. According to GOST 2879-99, a wide range of hexagon sizes is provided, and for a profile product less than 20 mm, it can be supplied in coils. Due to the presence of surface scale during hot-rolling production, the hexagon is subjected to chemical or mechanical cleaning.

The production of hexagonal rolled metal by hot pressing involves the production of a hexagon from special and heat-resistant tool steels. The profile is pressed on powerful hydraulic presses, most often of the horizontal type. With increased profile accuracy, the pressing tool is characterized by relatively low durability.

The cold rolled hexagon produces a more precise size and is therefore suitable for the needs of precision engineering. According to GOST 8560-88, cold rolling of a hexagonal profile is possible from a diameter inscribed in the hexagon of a circle equal to 3 mm. Profile blanks are pre-phosphated to reduce specific loads.

Hexagonal metal profiles are produced in different sizes - length and diameter from carbon steel and other types of steel. To correctly distinguish between the use of hexagons of different sizes, there is an extensive classification.

Size range, weight and basic geometric parameters

The size/number of a hexagonal section is determined by the diameter of the circle d inscribed in it (d is equal to the distance between parallel edges - “key size”). According to the GOCT 2879-2006 assortment, the minimum permissible size is d=8 mm, maximum d=103 mm.

Step size range of hexagonal rolled products:

- for d from 8 mm to 20 mm, the step is 1 mm;

- d from 20 to 30 mm, step 0.5 or 1 mm;

- d from 30 to 40 mm step 1.5 or 0.5 mm;

- d from 40 to 50 mm the pitch can be: 4.5 mm, 2 mm, 2.5 mm, 3 mm, 0.5 mm;

- d from 50 to 103 the step is 1, 2 or 3 mm.

GOCT 2879-2006, weight of a linear meter of a steel hexagon with an inscribed circle d, mm

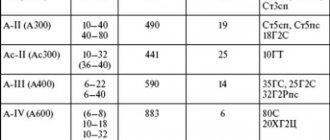

| No. of hexagonal rolled products, d of inscribed circle, mm | Weight 1 m/linear, kg | Whole meters per ton | No. of hexagonal rolled products, d of inscribed circle, mm | Weight 1 m/linear, kg | Whole meters per ton | No. of hexagonal rolled products, d of inscribed circle, mm | Weight 1 m/linear, kg | Whole meters per ton |

| 8 | 0,435 | 2298 | 18 | 2,203 | 453 | 67 | 30,518 | 32 |

| 9 | 0,551 | 1814 | 19 | 2,454 | 407 | 72 | 35,242 | 28 |

| 10 | 0,680 | 1470 | 20 | 2,719 | 367 | 78 | 41,361 | 24 |

| 11 | 0,823 | 1215 | 20,5 | 2,857 | 350 | 85 | 49,118 | 20 |

| 12 | 0,979 | 1021 | 23,5 | 3,754 | 266 | 88 | 52,646 | 18 |

| 13 | 1,149 | 870 | 28 | 5,330 | 187 | 90 | 55,066 | 18 |

| 14 | 1,333 | 750 | 42,5 | 12,279 | 81 | 95 | 61,355 | 16 |

| 15 | 1,530 | 653 | 47,0 | 15,017 | 66 | 98 | 65,291 | 15 |

| 16 | 1,740 | 574 | 55 | 20,565 | 48 | 100 | 67,983 | 14 |

| 17 | 1,965 | 508 | 60 | 24,474 | 40 | 103 | 72,123 | 13 |

The weight of a linear meter of a hexagon can also be calculated with greater accuracy using one of two formulas:

- on the side of the hexagon M = 0.007850×a²×(3√3)/2 = 0.020395×a² (kg/m), where a is the side of the hexagon in millimeters;

- along the radius of the inscribed circle (half the distance between any two parallel faces) = 0.007850×r²×2√3 = 0.027193×r² (kg/m), where r is the radius of the inscribed circle in millimeters.

For example, for hexagonal rolled steel No. 10, the weight of a linear meter (according to formula No. 2) is equal to:

0.027193×52 = 0.679825 kg (the rounded table value according to the product range is 0.680 kg).

The side length a(mm) of the hexagon is calculated by the formula:

a = d (mm)/√3 = d (mm)/1.73205; for example, the side of hexagonal roll No. 10 will be equal to: 10÷1.73205 = 5.8 mm.

Classification of hexagonal profile

It is quite difficult to classify a hexagon, since a large number of parameters of the metal profile are taken into account: production method, grade, steel used, chemical composition, processing, surface quality of the product, as well as the purpose of the hexagon profile.

By type of hexagon production:

- Hot rolled;

- Cold rolled;

- Made by hot pressure method.

The length of the hexagonal profile is distinguished:

- Unmeasured length;

- Measured length;

- Multiple measured length.

Depending on the chemical composition of the rolled metal product:

- High Quality;

- Regular quality.

According to the state of the hexagon material:

- Cold-hardened;

- Heat treated;

- Not subject to heat treatment.

Rolling accuracy can also vary:

- Normal accuracy - category “B”;

- Increased accuracy - category "B".

According to the quality of surface finishing of the hexagonal profile:

- Hot rolled;

- Forged;

- Calibrated.

Classification depending on the curvature of the rods:

- Class one, with a curvature of 0.5% of the length for a rod with a size less than 40 mm, and 0.4% for a size greater than 40 mm;

- Class two, with a curvature of 0.5% for the entire size range.

The metal profile of hexagonal cross-section is made from unalloyed tool carbon steel, in accordance with GOST 1435-99. Using this production method, calibrated hot-rolled hexagons are obtained. If production takes place in accordance with GOST 2879-88, high-alloy or carbon alloy steel is used. For hexagons with a cross-section from 3 to 100 mm, steel “St45” is used in accordance with GOST 8560-78.

Each rolled metal product, after checking all the parameters in accordance with GOSTs, must have marks indicating its parameters - section size, steel number, caliber.

Special types of screwdrivers

L-shaped screwdrivers have become very popular lately. That is, in their design there is no handle, but there is a kind of key resembling the letter “G”, a long curved part of the rod. They are widely used for fastening hexagonal working profiles. Thanks to this shape, high torque is ensured. Often the handle may fail during operation. It can either fall off or crack, and this bent shape of the rod makes the tool reliable.

Manufacturers achieve this shape due to the length of the working rod, leaving the tip, working area and part for torque. Chrome vanadium steel is used for its manufacture. The surface of this screwdriver has a polished finish. This allows not only to extend the service life, but also creates additional ease of use. It is also impossible not to call it a spanner screwdriver; it has a hexagonal end, but it is not a working one, it kind of serves as a blank, which is inserted and secured in some kind of holder, for example, a screwdriver with interchangeable attachments.

Read also: Types of rollers for painting walls

The spanner will be one of the attachments. And from the working end it looks very specific, like a two-prong fork, it is also called a two-prong fork. Often such a connector on the head of hardware is found in equipment, and from a branded manufacturer, as if hinting that not everyone can open and repair it. However, now there is a spanner in almost every set of attachments, so manufacturers have switched to more cunning techniques.

A hex wrench, also called an imbus wrench, is a structurally simple tool in the shape of an L-shaped metal rod with a 6-sided cross-section. Thanks to this design, its torque is ten times greater than that of a cross-shaped tool.

This device has a number of advantages: low cost, ease of production and versatility. These factors have made this type of key widely used, and in some cases, it is even included in the product package, requiring additional assembly by the buyer.

Distinctive qualities of the tool over analogues:

- simplicity of design;

- light weight;

- 6 screw contact surfaces;

- applicable to headless bolts;

- low cost of production;

- high maintainability.

It is worth distinguishing this wrench from tools of a similar configuration, such as a polygonal star wrench or a six-sided tube wrench used for working with hex-head fasteners.

Brief contents of the article:

Advantages of steel hexagon

The advantages of steel hexagon as a type of rolled metal are:

- This profile is quite resistant to high temperatures;

- In the manufacture of the profile, a steel grade is used that provides resistance to mechanical damage;

- The profile is not susceptible to acids, to the effects of organic and inorganic substances, and is also moisture resistant;

- Easy weldability;

- Affordable price;

- Long service life.

Step-by-step instructions for unscrewing the hexagon

There are several options for step-by-step instructions for unscrewing a hexagon.

- On a bolt with a protruding hex head, the head is cut using a grinder or a hacksaw. It can then be unscrewed using a regular screwdriver. The cut must be made with the utmost care so that the screwdriver does not jump off it during operation.

- A suitable Torx sprocket is driven into the place where the hexagon is inserted. When driven in, it cuts through the head with splines and inserts into it. The bolt is pulled out with a strong jerk. If unscrewing is carried out slowly, the splines will break and the operation will have to be done all over again. Torx with a central hole cannot be hammered, since when hammered it is destroyed.

- Unscrewing the hexagon can be done using a drill and a regular drill, and various extractors that are purchased in the store. Using a core, a future drilling point is marked strictly in the central part of the bolt being processed, at which a hole is then drilled. With a little force, an extractor is inserted into the resulting hole with a hammer. Then, using a handy tool, it is unscrewed. The extractor can be reused after this procedure.

- Can be unscrewed with a drill with left rotation and a construction drill with reverse. A drill with a thin diameter drills a hole in the head of the element. Then a drill of a smaller size is taken compared to the diameter of the damaged bolt. The drill is inserted into the drill and set to inverse rotation. The speed of the drill should be low and the pressure strong. When the element is pressed firmly, the drill will screw into it and pull it out.

Hex head screw diagram.

A bolt or hex screw can become damaged at any time. Various available tools can help in its repair, but the use of special tools may be required, without which it is impossible to unscrew the hex head of the damaged element.

Therefore, it is important to know all currently available methods for repairing this element. The hexagon is found in various types of indoor water mixers and in car spare parts. At the moment, these bolts are considered quite convenient fasteners, so they are widespread and found in many mechanisms.

Their use is advisable where a reliable power connection is required. This type of fastener is perfectly adapted to high loads and significant physical pressure. These bolts are especially often used in industries such as construction and mechanical engineering.

If we turn to the process of creating a hexagon, it becomes clear that the process of their manufacture is long and quite labor-intensive. These bolts are made from steel wire rod, which then softens after being in a hot oven for a long time. Then the wire rod is placed in a sulfuric acid solution for some time to completely remove rust particles. After being washed with water and treated with phosphates, the steel becomes resistant to rust and is then sent to be formed into a hex head element.

In the process of creating these products, many people are involved, providing the Russian market with modern, high-quality fasteners.

Wide application of steel hexagon

The areas of application of hexagons are quite different depending on the method of production of this type of metal.

A calibrated hexagon is needed for the production of high-precision parts and mechanisms, often in areas such as aircraft manufacturing, mechanical engineering, etc. A hot-rolled hexagon is very convenient as a workpiece for hot stamping using the rolling method on forging rolls, as well as for hot volumetric forging on gas and compressed metal materials and crank hot-stamping presses.

Areas of application of hexagonal rolled metal:

- Mechanical engineering;

- Construction sector;

- Shipbuilding and aircraft construction;

- Production of medical equipment;

- Furniture industry;

- Manufacturing of food equipment;

- Mining industry.

Steel hexagon has found its application in many areas of industry, but most often it is used in construction. Hexagonal rolled metal can be used as composite metal structures, frames, load-bearing elements, decorative structures and fences.

Purpose and application

The purpose of using this tool is to tighten (unscrew) screws, self-tapping screws, confirms that have a hexagonal recess. The key is used in many industries - in auto repair, furniture assembly, plastic windows, bicycles and motorcycles, and household appliances. The use of such a device as an imbus wrench is limited only by the area of application of the corresponding screws, and today they are used in almost all branches of human activity.

Structurally, the tool is a hexagonal rod bent in the shape of the letter G. The working end is, most often, the shorter part, although in hard-to-reach places the bolts are sometimes unscrewed or clamped with the long side of the hexagon. Also, for working in hard-to-reach places, a spherical tip is made on the long arm of the tool, which makes it possible to work with screws located at an angle.

In the production of an imbus key, tool steel, chrome vanadium and chrome molybdenum alloys are used. The keys are made not only in the form of the usual L-shaped tool, but also with a T-shaped handle, in the form of heads or bits for screwdrivers. There is a wide variety - a common feature is the use of an internal hex socket in the screw heads.

Features of operation

The hexagon is used for mounting (dismantling) fasteners that have a hexagonal contact area in the form of a recess. For effective and long service, the internal hexagons of the object must completely coincide with the working surface of the key. This will avoid damage to the key and the unscrewed (screwed) element.

Read also: Motor overload protection

Due to their exceptional maintainability, hexagons will serve more than one cycle of work. If the edges of the key begin to wear off, just go over them with a file and it is ready for use again. In cases where this technique does not help, the erased part of the key is simply cut off, leaving a new edge with clear edges.

How to use a hexagon

Unscrewing the fasteners with a hexagon is quite simple.

The main thing is to follow simple safety precautions and avoid striking the key or screwdriver in order to create greater leverage.

Step by step steps include:

Read also: How to properly sharpen a knife with your own hands

1. Selection of a hexagon corresponding to the type and size of the fastener.

2. Inserting one side of the hexagon into the internal hole of the part so that it occupies the entire depth.

It is better to enter the L-shaped form with the short side, but if necessary, the long side can be used.

3. Applying a load to the tool and gradually increasing it until the torque is reached.

The same should be done when twisting elements.

The instructions are suitable for both external bolts and internally slotted parts.

Steel grades and range of stainless hexagons

The range of our company offers stainless hexagons containing nickel grades 14Х17Н2, 08Х18Н10 (AISI304) and 12Х18Н10Т (AISI 321) and without the addition of nickel grades 12Х13, 20Х13, 30Х13, 40Х13, which are in great demand and popularity among consumers. We are able to supply hexagonal rolled products to individual orders, made from various corrosion-resistant grades of alloy and high-alloy steel. The quality of calibrated hexagonal rolled products is h11. Hexagons with a small diameter are supplied in so-called coils. The length value is classified into measured, unmeasured and multiple of measured. The diameter is easily determined by the circle inscribed with a hexagon.

Scope of application of hex keys.

A hex or imbus key is a metal rod bent in the shape of the letter “L”, respectively, with a hexagonal section at the tip. It is used for mounting and dismantling fasteners that have a hexagonal slot, respectively.

Hex keys come in two types:

- with standard tip;

- with a ball at the end of the key.

A wrench with a ball allows you to work at an angle of up to 30 degrees, and after a complete turn there is no need to rearrange it - this significantly saves time when doing any work related to removing or installing fasteners. It’s worth making a reservation right away: it doesn’t make sense to buy only one hex key. It is more practical and economical to purchase a set of hex keys of different sizes - you can rest assured that they will all come in handy.

Bottom line

If you implement these instructions as carefully as possible, the hexagonal gazebo for your dacha will become a favorite place for relaxing in the fresh air. You can also watch the video in this article, in which you will see the nuances on how to make a hexagonal gazebo with your own hands.

Currently, a hexagon is one of the most indispensable tools in the process of carrying out certain repair work. Many modern bolts are equipped with heads of this particular type, so it is simply not possible to unscrew them with a regular open-end wrench. Not every person has a hexagon at home. If you urgently need it, then the question arises, how to unscrew the bolt if the tool is not available. You can use various improvised means instead of a hexagon, but this is not always convenient. It's better to go a little different way. We will talk further about how to make a hexagon yourself.

Hexagons are used for loosening and tightening bolts when repairing and assembling furniture.

How to choose the right hexagon

If you choose a good set of hexagons, you can provide yourself with the right tools for all occasions: from car repairs to assembling furniture at home.

In order not to get lost in the wide selection of offers varying in price and composition, you should remember the basic rules:

1. For frequent professional use, you should choose a set consisting of at least 12 types of hexagons.

This is convenient and will save time on shopping.

In everyday life, 3-5 tools are enough.

You can purchase them individually, based on your personal needs, or in a small set at a reduced price.

2. Hexagons made of special tool steel or chrome vanadium are considered the most durable.

They will last for many years and will not deform.

3. Don’t skimp on choosing a manufacturer.

Cheap Chinese tools easily spoil the equipment and furniture with which they are used and break themselves.

Technological features in the production of hexagonal rolled products.

The production of hexagonal rolled products requires assembly lines or fully automated complexes capable of performing basic and a number of auxiliary technological operations. Currently, 350 and 450 rolling mills are widely used for the production of hexagons.

Technological requirements for production equipment:

- Possibility of transferring a rolled metal billet from one caliber to another.

- Possibility of transporting workpieces from warehouses to rolling mill rolls and heat treatment furnaces.

- Turning, branding and marking of finished hexagonal rolled products.

- Possibility of transporting finished products to warehouses, operations for straightening and packaging of finished hexagons.

Rolling mills 350 and 450 are medium-grade equipment. Such equipment can be used to roll products made of high-quality metal. The rolls of rolling mills have a working diameter from 300 to 450 mm, which makes it possible to produce products of the appropriate cross-section. The working stands of rolling mills are installed in a sequential order, or in the form of steps in 2-3 lines. This design makes it possible to produce hexagonal rolled products from billets weighing from 1.2 to 1.4 tons. Over the course of a year, the rolling mill allows the production of approximately 1 thousand tons of finished steel.

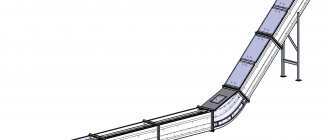

Standard layout of 350 semi-continuous rolling mill:

- The design includes 14 working cages. They are installed in 3 lines arranged in series, while the lines are parallel to each other.

- 3 production lines. The lines consist of rollers located in horizontal and vertical planes. The largest number of rolls is installed in the first line of the rolling mill.

- Scales for weighing workpieces. They are installed on a special roller conveyor (roller table).

- Heating furnaces for heat treatment of workpieces.

- Lever-crank shears for cutting steel workpieces to an acceptable size and weight. The operation of cutting the workpieces is performed before the first working stand.

- Shlepper conveyors move steel blanks between rolling lines. The workpiece transportation speed is approximately 15 m/s.

- Circular saw for cutting hexagon bars to a given length after the rolling process.

- Double-sided refrigeration unit for cooling hexagonal rolled products.

After cooling, the finished product is sent for final heat treatment, then cooled and transported to warehouses.

If calibration of hexagonal rolled products is required, then the technological operation can be performed using two standard methods:

- Method using rough gauges.

- Option using profiling pre-finishing gauges (3 pcs).

How to choose a set of hex keys?

The online store catalog offers sets of hex keys in a variety of configurations, of varying quality and cost. Which one is better to choose? If you are not an avid motorist and buy furniture or appliances once every three years, then a set of 12 keys is of no use to you. You can limit yourself to a set of three or five tools. But they must be of high quality, preferably made of tool steel or chrome vanadium alloy.

Also keep in mind that hex splines also come in different types; most often you have to deal with a regular hexagonal section or a star section. In order not to spoil equipment and tools, it is better to have on hand keys suitable for each option.

And the last point is the manufacturer. Tools from a well-known brand are much more expensive than the Chinese “no name”. But you can’t argue with the quality. Some people believe that if all the equipment is still assembled in China, then it can be repaired using Chinese-made keys. This is not the case, as you will quickly see. And as a result, you will pay not twice, but three times - first for a cheap analogue, then for damaged equipment, and finally for a new high-quality set of hex keys. Therefore, it is better not to make dubious savings and immediately purchase a decent product.

The hexagon is used to work with fasteners whose heads have a hexagon-shaped recess.

This is a tool with a tip that has 6 edges and can be made into several plumbing tools.

Read also: Sprocket chains for chain drives

Most often during repair and construction work, a wrench and a screwdriver are used.

They come in different forms, but often have the same purpose.

Hex screwdrivers and keys should be in every home, not to mention people who professionally repair furniture, cars, and equipment.