After purchasing an automatic washing machine, there remains a small “trifle” - connecting it correctly to the water supply. There are two ways - call a plumber or do everything yourself. We recommend choosing the last option, since there is nothing difficult in this work that a man could not handle.

It is necessary to select the necessary equipment - a tap and install it in a convenient place on the water pipe. You will also need thread seals and gaskets.

Faucet tee for washing machine without compensator

Experts recommend:

- if you have steel pipes and you do not want to weld an additional outlet, install the faucet on the outlet to the toilet cistern;

- in a metal-plastic or plastic pipe, you can choose any suitable place on the pipeline.

Below we will look at which taps are used to connect a washing machine to the water supply and how the process itself occurs.

Importance of using a tap

Using the tap that connects the washing machine to the water supply, you can turn off the water if unforeseen circumstances occur. These include breakdowns of equipment, which can lead to leaks. The so-called water hammer carries even more danger. It can cause defects in the elastic hose. The result will be a large-scale flood, which will also affect the neighbors.

To prevent this situation, the equipment must be connected through a tap. This part should be located in a visible place so that it can be quickly accessed if necessary. If a breakdown occurs, this will give you the opportunity to gain a few minutes, which will play a key role in protecting against flooding.

Connection to hot water supply

There are models of automatic washing machines that have a double connection to the water supply: not only to cold, but also to hot water. Most often this is equipment from Japanese or American brands. This solution allows you to save electricity, which is used to heat water in the washing machine. However, in practice in Russian realities, models of this type rarely cope with increased load.

The fact is that this technique is very demanding on the quality of the incoming hot water. In centralized heating systems, the water is usually not clean, which leads to rapid filter clogging, equipment breakdowns, etc. In addition, the quality of washing may be completely unsatisfactory. In some cases, rust stains and other contaminants appeared on washed laundry, and cases of damage to delicate fabrics were also observed.

In conditions of individual water supply, the water is usually much cleaner. However, even in this case, before purchasing a washing machine, you should still conduct a thorough analysis of the water and assess its condition. You may need to improve your existing cleaning system to prevent breakdowns of expensive appliances.

Device classification

The range of products presented in modern stores is pleasingly diverse. Among the products, the most popular types can be distinguished. These are the taps for connecting the washing machine to the water supply:

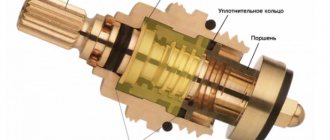

- Multi-turn. By moving the plate, they block the water.

- Ball. They can be turned on and off by moving a miniature ball located in the housing. They have a whole list of positive qualities. These include tightness, the ability to quickly shut off water due to a quick response, simplicity of design, due to which the operation of the products does not cause problems.

These are special cutting devices, the additional advantage of which is their miniature size, so even in conditions of limited space they can be safely used.

Ball models

There are several types of ball cutters. One of them is the pass-through mechanism. It has outlets located on both sides. This feature makes it possible to shut off the water by dividing it into two branches. These devices can be mounted on separate pipes that go from a common riser to any technical device. They can be used for insertion.

Continuous ball valves are often used to connect a washing machine, but they are compatible with other plumbing equipment. For example, they are often used as a connecting element for a tank in a bathroom.

Tee and corner elements

Another design option is a tee. Its design features correspond to its name. It has 3 inputs and outputs. One of these holes is necessary to shut off the water, the other 2 combine the water supply elements into a single one.

Such a faucet for a washing machine, connected to the water supply, is called a three-way faucet. It can be used to connect washing machines and dishwashers to the water supply. When this element is activated, water supply can be carried out autonomously in relation to several units at the same time. Similar parts may differ regarding:

- forms;

- size;

- configurations.

When they are installed in a water pipe, it is possible to combine these elements with a mixer and other important devices. A simple flow-through tap cannot cope with this task, as it has inappropriate design parameters.

The corner option best matches the properties of the pass-through fitting. With its help, you can divide the outlet pipe into several separate branches, fixed at right angles. Such products can be used to install washing equipment located non-standardly. They are also suitable for arranging bathrooms. This is an indispensable component when equipment has to be connected to a water pipe fixed to the wall. Making a direct withdrawal in such a situation is very problematic.

Any category of cranes includes a standard set of elements:

- fixing nuts;

- O-rings;

- rotary handles with which you can access the water or turn it off as needed.

The last component is mounted using a locking nut on the housing.

Purpose of taps for a washing machine

The faucet for the washing machine is a recommended condition for a safe connection. This means that you can connect the washing machine to the water supply through a simple outlet, especially since the latest models of washing machines have an “aqua-stop” function and independently shut off the water supply outside of washing. Why would there be an additional valve on the water pipe in such a system?

The faucet for the washing machine at the inlet performs the following functions:

- Protects equipment from water hammer, which is not uncommon in the central network. When you are not washing, keep the tap closed, cutting off the washing machine from the central water supply.

- Serves as an emergency device to shut off water in the event of a machine breakdown or a leak in the inlet hose.

- Makes it possible to safely disconnect the device from communications and, for example, change equipment to a new one or move the machine to another location.

- Will serve as protection against sudden leaks in your absence. A closed valve will allow you to safely leave the house without fear of flooding the apartment and neighbors.

Note! An additional tap will not be superfluous for a machine with the “aquastop” function. Household appliances tend to break down, and a shut-off valve is a simple and reliable device with a long service life.

Tips for choosing

The location where the washing equipment is located is the main criterion when choosing a faucet. Corner parts are more suitable for small apartments. They allow you to reduce the space required for connection. If there is a need to connect several plumbing fixtures at the same time, it is better to purchase a three-way tap. A pass-through version of a ball valve would be appropriate if you already have an outlet for a washing machine.

The material from which products are made is not the least important. Brass components are more expensive than silumin ones, but they pay for their price due to their long service life and the ability to withstand significant loads.

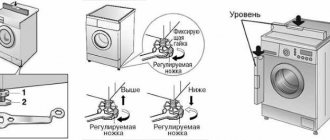

The next parameter worthy of attention is the diameter of the device. It must match the dimensions of the water pipes. You should also pay attention to the features of the carving. Size is important, as is its presence from the inside or outside. It also happens that carving is done independently by a home craftsman. When purchasing a crane, they also look at the angle of rotation. If, when closing the valve, it is directed towards the wall and touches it, it becomes difficult to use.

Tee for connecting the washing machine to the water supply

When buying a new washing machine or moving, you are faced with the task of connecting the device to the water supply. For this purpose, a tap called a tee is most often used.

Purpose

The idea that a tee tap for a washing machine is not so important appears in many people’s minds. Such users are most likely unaware of the concept of water hammer in water pipes, as a result of which both metal and metal-plastic pipes can separate at the seam. And if the inlet hose is connected directly to the water supply, there is a high risk that it will break due to such a water hammer, which will lead to water flows in the apartment.

Using a tee tap will save you from the need to redo repairs both in your apartment and in the neighbors below. And it is the tee that is especially convenient, as it allows you to connect several household appliances into the water supply at once, for example, a dishwasher and washing machine.

Types of cranes

The following can be used to connect a washing machine:

- Tees or straight-through taps. They are used for tapping into pipelines.

- Angle taps. They are chosen if you need to connect equipment to a separate branch.

Each type of these valves is valve, ball or straight-through. The differences lie in the method of shutting off the water in these taps. In addition, they may differ in the material from which they are made (usually brass or silumin).

Which one is better to install?

You should first select a suitable crane based on your skills and financial capabilities. The choice of faucet type should be based on the purchase budget, and not on the location of the washing machine.

The most economical and simplest is the walk-through valve, since its installation does not require special devices. By connecting such a tap to the water supply hose, the washing machine can be connected to a faucet, washbasin, water heater (to the pipe supplying water to the heater tank) or even to a drain tank (both after the hose and before it)

When choosing a straight-through valve, it is important to pay attention to the direction of its lever so that it does not rest against the wall and is easy to get to.

To connect the tee, you need to prepare a gas wrench and a set of keys. Also, for work you will need FUM tape, which must be screwed onto the thread. After tightening the connection using a gas wrench, you need to check its tightness. Installing a tee on old pipes is not recommended.

If you are going to install an angle valve, you should purchase additional pipe. You will also need a special tee that is installed in sections of the pipe. In general, installing an angle tap is the same as connecting a tee tap, that is, you need to use FUM tape and wrap it around the thread. Then the valve is screwed into the pipe, and the hose from the machine is connected to it. Next, the connection is tightened with a gas wrench.

Methods for connecting to the water supply

Metal pipe

The easiest way is to connect the machine to a place where there is already a tee for a faucet, toilet or dishwasher. Having disconnected the hose of the device, another tee tap is installed in its place. The previously connected plumbing fixtures and the faucet for the washing machine are inserted into its outputs.

If a tee has not been installed on the pipe before and you do not have the opportunity to use a “vampire”, you need to make an insert. After cutting out part of the line, you will have to make a thread, and then connect the tee.

Metal-plastic pipe

To install a tee on plastic pipes, a special tool and the correct selection of a tee with fitting elbows that connect to metal-plastic pipes are required. Using special scissors, it is necessary to perform high-quality crimping of the bends. If you don’t have such scissors and you haven’t worked with metal-plastic pipes before, it’s better to invite a specialist to connect the machine.

Alternatives

Instead of a tee tap, you may prefer to install a tee fitting. After cutting the pipe, such a fitting is installed between its sections, and then a pipe is inserted into its free hole, which goes to the washing machine. This is both a simple and inexpensive method, but it cannot be called very reliable. Fitting seals wear out over time, causing leaks.

Also, the tee valve can be replaced with a regular ball valve. Its reliability is as high as that of a specialized crane, while the cost is much lower.

List of tools and materials

To connect the unit to the water supply, it is not enough to find a valve of a suitable configuration. Tools are also needed. Their list should include:

- Adjustable wrench. It is required for installation work, tightening nuts and connecting pipes.

- Calibrator. A necessary tool for working with plastic pipes. It makes it possible to adjust the screen when installing it on a pipe cut-in.

- Lerka. It can be replaced with any similar tool that allows you to cut threads.

- Screwdriver, file, drill. All this is necessary for work on arranging holes and other manipulations.

- Scissors for plastic. Instead, you can take a grinder, which is suitable for working with elements made of plastic and metal.

The washing machine must include a double hose. It will also have to be used during work. The length of the product should be slightly longer than necessary. This will make it possible to get a small margin during the rearrangement. When a hose has to be purchased specifically for these purposes, it is recommended to give preference to models with wire reinforcement. They will best withstand the pressure inside the pipes.

A filter must be installed on the threaded part of the tap. It is designed for water purification. It is fixed to the outlet of the water pipe. This element is small in size and improves the quality of the liquid used. This reduces the risk of lime deposits forming. When water rich in minerals is used, several filters can be used simultaneously.

When planning to install plumbing parts, you cannot do without sealing rings and FUM tape. In addition, you will need winding and spare bolts. This set will allow you to secure the faucet tightly and, therefore, reliably. It is necessary to select a suitable connection option, taking into account the characteristics of the room and the area where plumbing fixtures are installed.

What will be needed for installation?

When installing a faucet, you need to have a whole set of tools on hand. By preparing everything in advance, you won’t have to be distracted from your work. So, when connecting you will need:

- adjustable wrench. The device is necessary for installation, namely fixing the pipes, tightening the nuts;

- calibrator Will be needed to “adjust” the dimensions of the tap and pipe;

- die (popularly lerka). Necessary for “cutting” threads;

- screwdriver, Phillips and slotted;

- drill and file;

- scissors for cutting polymers;

- Bulgarian. Required if the shut-off device cuts into the pipe.

In addition to these tools, a double hose will be needed. It sometimes comes complete with the washing machine, or is purchased separately. It is better that its length is slightly longer than required. Due to this, there will be a small reserve that will be “useful” when rearranging equipment.

It is better to install a filter element in front of the shut-off valve. By using a small mesh, you can improve the quality and soften the water. All this minimizes the risk of scale formation on the internal parts of the machine.

It is possible to install several filters at once in front of the shut-off valve, for example, separately for water purification and softening.

In addition, it is important not to forget to prepare sealing rings, winding, a couple of spare bolts, and FUM tape. Without these devices, it is impossible to secure the tap and ensure a tight connection. Before starting work, you should consider which connection option will be optimal, taking into account the configuration of the room and the placement of plumbing.

Installation of the flow element

There are various faucet connection diagrams available for DIY. One such option is to install a flow element. Before starting any manipulations, you must turn off the cold water supply.

A tee and a regular tap will need to be installed. The remaining liquid is drained from the pipe. It will interfere with the future work process, so you should get rid of it. The easiest way is to install it on a separate branch of the pipe. The package usually includes a threaded bushing onto which you can screw a faucet with a two-outlet system. It is connected to the filter. This element is attached to the inlet hose.

An angle valve can be installed using the same algorithm as a flow valve. The difference lies only in the design features of these products. It is necessary to control the location of the valve. It should be comfortable for users. At the end of all actions, you should inspect the fasteners to determine if there are any leaks in them. If water drops appear, the connecting nodes must be re-secured.

Connection

To correctly and reliably connect the washing machine to the water supply, it is not enough to limit yourself to choosing a good valve. Certain tools are required, and the order of correct connection for a particular crane model is also important.

Tools

Minimum set, without which you cannot work:

- A wrench with an adjustable mechanism, it will be needed for installation: pipes and pipes, nuts.

- Plastic pipe calibrator. It will be needed to adjust the faucet when installing it onto a water pipe.

- A thread cutter or similar tool that can be used for similar work.

- Drill, file, screwdriver. Needed for drilling holes and other functions.

- Plastic pipe cutters or a grinder for inserting a tap into a plastic or metal drainage system.

In addition, a double hose will be needed; it is usually sold complete with the automatic machine or purchased separately. It is better that the size of this part is a little larger than what is needed: this will give a margin of length, which will be needed if you suddenly need to move it to another place.

adjustable wrench

When purchasing a special hose, it is advisable to choose a part with wire reinforcement, which will make it possible to withstand pressure drops, which happens in a watercourse system.

The cleaning filter is installed on the thread of the tap, which is connected to the pipe outlet. This element makes water of higher quality, therefore reducing the possibility of the appearance of films and the release of mineral salts.

The aqueous composition can have many impurities, so it is permissible to use several filter systems at the same time.

To securely connect the faucet and ensure the tightness of this unit, you will need:

- seal rings;

- winding;

- tape made of thin polyethylene film (or FUM - sealing tape);

- spare bolts.

You cannot do without these elements when working with plumbing installation. It is worth thinking about the most profitable connection option, taking into account the characteristics of the room and the location of plumbing fixtures.

pipe filter

Methods

The most commonly used connection options can be easily done at home, using certain tools and a small number of accessories.

No. 1. Installation of the flow element

- First, the cold water is turned off, this is done with a tap located on the riser. Then water drops drain from the pipes; they will interfere with subsequent actions.

- The easiest way is to install a flow valve on a separate branch of the pipe. In such a case, there is a threaded bushing; a tap with a two-outlet system is attached to it, which is connected to the filter. This part is attached to the inlet hose.

After completing all these manipulations, you need to check the fasteners for the possibility of leaks. If water is visible, then all connecting nodes will need to be redone and additional gaskets installed.

Do you turn off the water tap after washing?

Oh yes! No.

Method No. 2. Installation of an end valve

A special part of the water supply can be connected to the washing unit. In this case, you can connect the end valve using a tee (mortise clamp).

- It is carefully screwed to the pipe, the guide sleeve should be outward.

- Then holes are drilled in the pipe; they are used to connect to a clamp or part of the pipe where the faucet is supposed to be installed.

- A thread is cut at the bottom; it must match in size and shape with the grooves that are made on the tee. From the outside, the thread is wrapped with a sealant (FUM tape) or flax, then the tap must be screwed onto the outer pipe.

- A hose is attached to the other end of the tap; it comes complete with the washing machine or can be purchased separately. The opposite end of the hose is inserted into a special hole, it is on the other side of the washing machine. Be sure to remove the latch from it, which is put on during transportation.

The assembled device must be tested for the possibility of leaks. Typically, the angled end of the hose is connected to the washing machine, and the straight end is connected to the water supply. This method is more optimal, since the washing machine is often placed against the wall.

No. 3. Installation of a tap with pipe insertion

It is much more difficult to mount the faucet directly to the pipe, since you have to cut out the fragment.

Expert opinion

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

Ask a Question

In plastic pipelines this is done very simply - with polymer pipe scissors. Much more serious effort will be required to complete such an operation if you have to deal with a metal pipeline. Here you need to use a grinder.

- The size of the cutout area is determined by adding the length of the tap and the size of the filter. Then an incision is made, and a thread is made on the ends of the pipes; it should be the same in appearance as the one already on the tap.

- Then a filter is installed, it will protect the car from impurities, which are abundant in the water coming from the pipes. Then a tap is installed to regulate the pressure. The mounting nuts are removed from the part, which are used to connect to the pipe.

- When installation is done on a polymer structure, at the beginning of work this part is expanded using a calibrator.

- The joints are secured with tightening rings. The tap compartment, which is closed, is connected to the machine inlet hose. Then the nuts are tightened with an adjustable wrench. It is very important to fix it well, since a loosely screwed or twisted bolt can cause damage and leaks will occur.

- The joints are tightly sealed with O-rings; they are sold together with the tap or filter. You can use FUM tape, flax or a similar product. Then connect the machine to the sewer.

The final step: monitoring the operation of the assembled mechanism, as this helps to identify all the shortcomings of the assembly.

gas adjustable wrench

End valve installation

Sometimes a special type of water supply is connected to the washing machine, which allows you to connect the end valve using a mortise clamp. This element is also called a tee. It is screwed to the pipe so that the surface of the guide sleeve is located outside.

Holes are installed in the pipes through which the pipes are connected directly to the clamp. This is where the crane will be installed later. At the ends of the pipe, a threaded pattern is applied that matches the grooves on the tee. The shooting from the outside is closed with a seal, the role of which is played by FUM tape. You can use flax instead. Following this, screw the tap onto the outer pipe.

Next, you need to attach the hose to the opposite end of the tap. It usually lies close to the washing machine. If it is not there, you will have to purchase this product. Before use, the transport valve located on the surface must be removed.

Once the structure is assembled, you should check for leaks. In most cases, the corner end of the hose is connected to the equipment. Its straight end must be connected to the water supply system. This solution is more comfortable, since the washing unit is usually placed near the wall.

Sewerage

There are also several ways to connect the washing machine drain hose to the sewer system.

On the edge of the bathtub or sink

The simplest solution is to hang the hose fixed in the standard fasteners on the edge of the kitchen sink or bathtub. The obvious disadvantage of this solution is that the plumbing fixture cannot be used during washing.

The simplest solution is to attach the drain hose to the edge of the bathtub.

But frequent draining of hot water with detergent dissolved in it guarantees the absence of blockages: in 4 years of living in a service apartment with just such a scheme for draining water from a washing machine, I have never encountered sewage problems.

Tee under siphon

The drain hose can be directed into a tee installed in the sewer socket at the connection with the siphon of any plumbing fixture. Installing a tee in the case of a prefabricated plastic sewer takes no more than a couple of minutes.

A couple of nuances:

- The connection between the hose and the tee must be tight. Otherwise, sewer odors may enter the apartment through the gap between them;

All drain connections to the sewer system must be sealed. Otherwise, the sewer aromas will spoil your appetite.

- Use a skew tee with the side outlet pointing upward. Even if the connection is depressurized, the wastewater will flow into the sewer by gravity.

Connecting the drain hose to the oblique tee between the sink siphon and the comb.

Tee in comb

The most civilized solution is a separate tee for connecting a washing machine, embedded in the sewer comb (indoor sewer system). In this case, you can safely use a straight tee.

I strongly recommend extending its upper outlet with a pipe at least 40-45 cm long: some washing machines do not have a shut-off valve between the tank and the drain hose, and if the hose is lowered too low, water can pour out of the tank by gravity.

The most correct scheme for connecting to the sewer is with a separate insert into the comb and a water seal.

Pipe insertion

You can install the tap directly on the pipe, but this option is considered labor-intensive. It requires cutting out the area. Such work will not seem very difficult if the elements are made of plastic. Special scissors can handle this. Labor costs will increase if the pipeline is made of metal. In this case, you will have to take a grinder. To determine the size of the area that needs to be cut, you should add up the dimensions of the filter and the length of the tap. Next, you can arrange the incision. You will also need threads at the ends of the pipes. It should have the same parameters as the grooves on the tap.

The next stage is filter installation . It will protect the design of washing equipment from foreign impurities, which are often found in tap water. Next, install a tap for water supply. For this purpose, remove the mounting nuts used to connect to the pipe. If the structure is made of plastic, before proceeding, the part must be expanded with a calibrator.

Installation of a tap with insertion is advisable when metal-plastic or polymer elements were used to produce the pipeline. Such a unit can be placed under the sink or in another place convenient for use. The joints must be secured using tension rings.

The inlet hose is connected to the tap compartment. After this, all that remains is to tighten all the existing nuts with an adjustable wrench. The clamping force during such work is especially important. If the bolt is not tightened well enough, the structure may be damaged. The same can be said about the situation when the fixing elements are overtightened. This may cause leakage.

O-rings are used for sealing. They are usually included with the filter or faucet. Flax fibers can also cope with this task. Checking the finished structure is the final stage of the work.

Device selection criteria

When choosing a faucet for your washing machine, pay attention to the following points:

- Does the fitting correspond to the declared characteristics (is it a fake). To protect yourself from counterfeit goods, use trusted retail chains and ask for documents for the goods.

- Does the type of thread on the fitting (internal or external) match the thread on the pipe.

- Does the diameter of the fitting correspond to the size of the home wiring?

- Is there enough space to install a pass-through device or will a corner housing be required?

- Consider the location of its installation. It is important here that when turning its handle does not rest against the wall, plumbing fixtures or furniture.

If there is not enough room for the lever, then go for a butterfly faucet or ask the seller for a faucet that has a lever that turns the other way.

Note! The valve handle should be easy to grip with wet or slippery (for example, soapy) hands. This will allow you to quickly turn off the water in the event of an accident, even if you are not quite ready for this.

Specific options

Sometimes the key is connected in non-standard ways. They have to be resorted to when classical methods do not provide the required level of convenience.

The installation option on a mixer is attractive due to its accessibility and simplicity. But it cannot be called ideal, since this scheme has a number of disadvantages. The finished structure does not have a very aesthetic appearance. In addition, it is difficult to place an additional valve in this position.

By placing the tap in this way, you have to deal with a decrease in the performance characteristics of the mixer. This is due to an increase in loads on it, which leads, in turn, to a decrease in the service life of the element. Using both a mixer and a screen is problematic if these two devices are combined. Experts admit the possible use of this solution in practice, but only as a temporary option. Installation on older model faucets requires caution.

The connection procedure in such a situation will be accompanied by numerous difficulties. It is problematic in terms of time and financial costs. If the modification contains the Aqua-Stop system, you can refuse to connect it from the tap. These models have magnetic valves installed at the ends of the inlet hose that regulate the water level.

Additional connection options

Separately, it is also possible to highlight non-standard methods of connecting a tap. They are used when conventional options are not possible or such options are more necessary.

No. 1. Installing a tap on a mixer

This type is often used in practice, as people like it because it is simple and accessible. But it cannot be considered too convenient, since this option has many negative sides.

This position of the tap has a bad effect on the mixer. The latter is subjected to very high loads, and this greatly reduces the service life of the mechanism. And the combination of two devices at once makes it difficult to use both the tap and the mixer.

According to experts, it is permissible to use such a solution only for a while, and you definitely need to think about how to properly connect the washing machine.

You need to be careful if you want to install a faucet on old faucets. But this operation will require a complex procedure that will cost a lot of time and money.

Expert opinion

I work in the household appliance repair industry. Extensive experience in restoring washing machines and dishwashers.

Ask a Question

But if it is necessary to use this particular connection option, it is good to immediately replace the old mixer with a new one.

Method No. 2. Installation on old pipes

Buildings from many years ago (especially Stalinist ones) are distinguished by a metal (most often cast iron) water supply network. In such cases, the ends of the pipes are damaged by rust, and this makes installation work difficult.

This installation complexity can be solved as follows:

- The ends of the pipes are processed with files. The ends of the elements are aligned, so the hose is laid next to the pipe.

- An extension cord is installed, at one end it is hidden by damaged ends. On the other edge, this part is mounted with a reinforced hose with a gasket.

You must be sure of the integrity of the assembly and protect the pipes from subsequent damage, for example, paint them with paint that protects against rust. But it’s better to change the pipes right away, and connecting other devices will not create difficulties.

Video

Method number 3. Double connection

There are washing machines, usually of Japanese and American production, with the ability to connect them directly to hot and cold water flow.

This type of SMA greatly saves electricity consumption, because there is no need to heat water, like the most common types of machines.

These washing machines are not very widely used due to the poor composition of hot water: it contains a lot of sediment, so there is a high risk of damage to parts and poor quality of washing clothes.

Manipulations with old pipes

The water supply network in old houses is often made of metal. This is usually cast iron. In this situation, entire areas of pipes may be affected by corrosion, which makes further installation difficult. There are several methods to overcome this problem.

You can use files to run along the edges of the pipes. Thanks to this procedure, the end areas of the parts are aligned. It is possible to lay the hose in close proximity to the pipe.

Another solution is to place an extension cord. At one of its ends you can hide the end areas that are damaged due to corrosion, and on the opposite edge you can mount a firmly fixed hose with a gasket.

https://youtu.be/j6JtNhNt4iwhttps://youtu.be/uyP9oaRcDsc

_