Beton-House.com

Website about concrete: construction, characteristics, design. We combine the experience of professionals and private craftsmen in one place

Set of drills of different diameters

Concrete is the most versatile material used in home construction. Therefore, there are often cases when it is necessary to make holes in the concrete surface when laying cables or wires, installing equipment and furniture.

This cannot be done with a regular drill due to the high strength of the material. Only special concrete drills or drills can provide the required result. The article will tell you the types of tools, their features and methods of use.

Tool selection criteria

Tool sizes by diameter and length

To make the right choice of which drills to drill concrete with, you must first determine the volume and type of work to be performed.

To carry out small repair operations in your home, it is enough to use diamond drills with a diameter of 6 - 10 mm. If you need to hang a picture, it is better to take thinner tools with a diameter of 3 mm to 5.5 mm.

The diameter of the drill affects the depth of the mounting hole:

Dependence of diameter on drill length

According to GOSTs, all tools are marked, indicating the diameter and length, which helps to choose without error the size of the drill for a concrete screw to make a hole on a specific surface.

For example:

- Drill 6×110 mm. This is the most versatile and indispensable tool when making repairs in your homes;

- Drill 8×600 mm. Such long tools are used to drill deep holes;

- Drills 12×200 mm and 12×460 mm are used when it is necessary to drill holes for fastening furniture and laying electrical cables;

- Drill 24×460 mm. This drill is quite large in size and is often used when installing water supply and heating systems.

These are the main characteristics when choosing a drill. To learn in detail what types of tools there are for drilling and drilling holes in concrete, and how to choose the right ones for a particular case, you should watch the video in this article. Particular attention should be paid to the manufacturer.

Best concrete drill sets

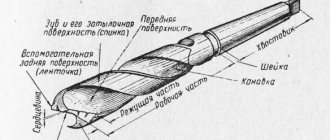

Such drills differ from similar products for other work in the soldering on the tip and the angle between the cutting edges. The width of the soldered plate exceeds the diameter of the drill itself. Products can be made in the form of a cone, cylinder or crown.

DeWALT 6956

A set of a well-known American company that produces its products in various countries around the world, including China. The set includes five drills of different diameters: 4,5,6,8,10 mm. Convenient plastic packaging allows you to comfortably carry the tool to your place of work and store it on a shelf in a workshop or garage.

Pros of the set:

- Fast and high-quality drilling of concrete and brick products.

- The cylindrical end of the shank is easy to clamp.

- Great working resource.

- The set contains the most popular sizes for work.

- The price is quite reasonable for the excellent quality of the drills.

Cons of the set:

- Not detected.

Vira 550105

The set is the fruit of a partnership between a Russian company and a Chinese manufacturer. This set contains twist drills, which are most often used in work. Their diameters are: 4, 5, 6, 8 and 10 mm. This consumable tool can be used to drill concrete, brick, stone - a hard steel alloy copes with such work without problems.

Pros of the set:

- Convenient bright packaging.

- Cylindrical end shape, convenient for clamping.

- Compact packaging dimensions: 166x59x12 mm.

- Light weight: 160 g.

- provide high-quality drilling and do not break under intense load.

Cons of the set:

- Not detected.

Makita D-05175

The Japanese company's consumables are packaged in an easy-to-carry box. Information about each drill included in the set is printed on the package body, which allows you to accurately select the required consumable tool. Carbide tips allow you to work with such durable materials as stone, brick, concrete.

Pros of the set:

- The set includes drills of various diameters: 4, 5, 6, 8, 10 mm.

- Compact packaging dimensions: 155x57x12 mm.

- Minimum weight: 157 g.

- Classic shank end, cylindrical, which is suitable for different drilling tools.

Cons of the set:

- The lack of proper control in production leads to the production of crooked drills, especially 6 mm products.

- Comments are made about the poor presentation: traces of rust are visible on the instrument.

Review of popular brands of tools for drilling holes in concrete

Drills used for concrete work are produced by foreign and domestic manufacturers. The cost of the instrument depends on the popularity of the brand.

How to choose the right drill bit for concrete?

Tip: When purchasing a tool, you should keep in mind that the higher the price of the product, the higher its quality and longer service life.

Good and durable tools are produced by foreign and Russian manufacturers. The best concrete drills are presented in the table:

| Manufacturer | Tool Features |

| High quality, durable and wear-resistant drills are tipped with carbide, retaining their properties even under prolonged loads that are accompanied by heat generation. Each drill is sandblasted and coated with titanium nitride, which increases their wear resistance. They are characterized by high elasticity and are resistant to bending and impact loads. A special sharpening of the solder makes it easier to insert the drill into concrete, and a spiral groove removes construction dust from the hole. |

| Rennbohr | High-quality metal is used to make the drill, and special processing protects the product from damage by corrosion. It has high strength and wear resistance, reliable protection against deformation. Retains its original shape over a long period of use. |

| Metabo | High quality, hard tipped, durable concrete drill bits. They have special heat resistance, are very durable, and have special grooves for quick removal of drilling waste. |

| Usually produced in a set of eight drills, of different diameters from 3 to 10 mm, packaged in a cardboard box. High-quality tool steel is used for production, and special processing protects against corrosion. Has high strength and wear resistance. It is not subject to deformation during frequent and long periods of operation. The U-shaped spiral on the tools helps to effectively remove dust when drilling a hole. The cylindrical shank securely secures the drill in the equipment chuck. |

| Tools with a four-spiral shape. This significantly reduces the time and labor required to remove concrete residue from a hole. |

| Tool Feature:

|

| The presence of a pobedite tip allows you to drill concrete and other building materials. The best option is to work in electric impact drills. |

| Anchor | They have an optimal price-quality ratio and a long service life. Products are made in China. They are equipped with durable carbide plates that are not destroyed even if the drill hits steel reinforcement when drilling concrete. However, you cannot drill through reinforcement with this drill. But when purchasing such a tool, you need to pay attention to the soldering of carbide plates - they must be even. |

| Used for rotary impact drilling. Peculiarities:

|

Advice: Which drills are best to use for concrete, everyone decides for themselves, based on their material capabilities. But it is always worth remembering that more budget options may be a fake, which can be immediately recognized when drilling concrete. Therefore, which drills are best to purchase, you should consult the seller.

The best metal drills

Metal drills can be twist, step or milling. They are made of high-speed steel and have a special sharpening. As a rule, the range of applications of such a tool depends on its angle.

Graff GMSD430

4.9

★★★★★

editorial assessment

95%

buyers recommend this product

The drill is made of high-quality high-speed steel of increased hardness. Fourteen steps with a pitch of 2 mm make it possible to produce holes with a diameter of 4 to 30 millimeters without replacing equipment. Each level is marked accordingly to make drill selection easier. The number of available sizes is 14.

The special tip point allows you to quickly get started. For more reliable fixation in a self-clamping or jaw chuck, the shank has a triangular design.

Advantages:

- high strength;

- size markings;

- a large number of steps;

- neat work;

- secure fit.

Flaws:

- heaviness.

Graff GMSD430 is suitable for making holes in sheet metal. A universal choice for both home and professional use.

Bosch PointTeQ 2.608.577.174

4.9

★★★★★

editorial assessment

94%

buyers recommend this product

The main feature of the PointTeQ drill is its self-centering tip, which ensures easy and smooth drilling. The two cutting edges remain sharp for a long time, guaranteeing neat holes.

The length of the working part is 87 millimeters, the diameter is 10 mm. The oxide coating of the spiral removes chips more effectively and provides additional protection of the metal from external factors. The tool is made from high-speed steel, which is resistant to wear and heavy mechanical load.

Advantages:

- strength;

- neat drilling;

- long service life;

- oxide coating;

- low heat emission.

Flaws:

- short drill length.

Bosch PointTeQ is used for making blind and through holes in non-ferrous metals, steel, cast iron. A reliable solution for mounting in a drill stand or hand drill.

Stayer 29660-6-20-8

4.8

★★★★★

editorial assessment

90%

buyers recommend this product

The equipment is made of high-quality high-speed steel and has a triangular shank with grooves, which allows you to transmit maximum torque. The special geometry of the drill guarantees accurate holes of various diameters.

The length of the tool is 75 millimeters, standard sizes of steps are 6-20 mm. To prevent jamming during operation, cross-shaped points are made on the cutting edge.

Advantages:

- durable metal;

- accurate drilling of various diameters;

- cross point;

- secure fit.

Flaws:

- high price.

Drill Stayer 29660-6-20-8 is suitable for precision work with sheet metal.

Granite 165078

4.7

★★★★★

editorial assessment

84%

buyers recommend this product

The model is made of high-speed steel and is durable and fracture-resistant. The self-centering tip reduces the chance of the drill bit drifting, ensuring clean holes.

The length of the main part is 102 millimeters, diameter - 7.5 mm. For reliability and smooth insertion into the material, the main surfaces of the tool are ground on all sides.

Advantages:

- high strength and durability;

- secure fit;

- neat drilling.

Flaws:

- heats up quickly.

Drill Granit 165078 is designed for making through and blind holes in workpieces made of steel, cast iron, bronze, and aluminum.

READ ALSO

18 Best Drilling Machines

Drilling holes

The process of drilling a hole in concrete with an electric drill

The instructions for carrying out the work are quite simple:

- Working tools are carefully selected. With a hammer drill, due to the transverse runout, the hole is slightly larger in diameter; it is better to purchase a drill of a smaller diameter. A diamond bit cuts through concrete with minimal tolerances;

- The surface is marked for drilling holes;

- To clearly position the tool in the center of the hole, it is better to mark the starting point with a concrete punch or bolt;

- The tool is installed in a pre-designated recess and a hole is drilled in the concrete using a hammer drill;

Tip: When working with a rotary hammer or impact drill, a lot of dust is generated. Therefore, when drilling holes, you should use safety glasses, gloves and a respirator.

- Pressing with great force on the handle of the hammer drill, you gradually need to move deeper into the concrete;

- When drilling a sufficiently deep socket with a low-power impact drill, it is necessary to use several techniques, periodically cooling the drill;

- For large holes, you first need to go through the center of the intended hole with a drill of a smaller diameter, and with a more powerful one, expand the cavity to the desired size;

- Upon completion of processing, the cutting edges of the tool are inspected;

- If necessary, the drill is sharpened.

Best Wood Drill Sets

Special drills are used to work with wood. They differ in type: they can be ring and feather, screw and milling. There are also Forstner drills and a countersink. They are used for various types of work with wooden material. Let's name the best sets of similar drills.

DeWALT 4535

A set of screw drills allows you to work with any hard wood material. Vanadium and chromium additives provide long-term wear resistance to this consumable material and also improve cutting properties. The ground surface increases the precision of processing and the cleanliness of the hole edges.

Pros of the set:

- The set contains the most popular sizes of drilling products: 4,5,6,8,10 mm.

- Affordable price.

- Convenient packaging.

Cons of the set:

- Products produced in the Asian region are uncentered and crooked.

Ryobi RAK07SB 5132002252

Such drills from Japanese manufacturers are used for drilling holes in thin wood material, for example, in chipboard. The set includes 7 pieces with a diameter from 10 to 32 mm. The shank of the products has a hexagonal shape, which ensures reliable fixation in the drilling tool.

Pros of the set:

- Small, easy to use, kit dimensions: 275x250x55 mm.

- Universal use: can be used for plasterboard and plastic work.

- The point located in the center ensures precision drilling.

- Convenient case with product diameter markings.

Cons of the set:

- The curvature of most drills causes beating to be felt during operation.

- Poor sharpening quality.

- The cutting edge quickly becomes dull.

BOSCH Robust Line 2.607.010.533

The use of high-chromium and high-vanadium CV steel with anti-corrosion coating by German manufacturers guarantees the durability of the products even under intense loads. These screw drills can be used to drill holes in various types of wood. The set includes 8 pieces of the most popular sizes: 3×30, 4×40, 5×45, 6×50, 7×60, 8×65, 9×70 and 10×75 mm.

Pros of the set:

- Reliable packaging made of impact-resistant plastic.

- Improved sharpening quality of cutting edges.

- Convenient fixation of the shank in the equipment.

- Long product life.

Cons of the set:

- Unreliable fixation of the consumable tool in the open case.

Drill sharpening

Drill cutting edge

Tip: When starting to make holes in a concrete wall, it is necessary not only to choose a high-quality tool, but also to use it correctly.

In this case, you need effective preparation of the drill, which consists of sharpening it. You can do this yourself on a sharpener with a corundum whetstone.

The operating technology is similar to restoring the cutting edge of any similar tools, but taking into account some nuances:

- Severe overheating of the surfacing should not be allowed. Exposure to high temperatures reduces the adhesion of the winch and the steel base, which reduces the strength of the connection;

- If the moment was missed and the drill got hot, it takes enough time for it to cool down so that the process occurs slowly. It is forbidden to immerse the instrument in water: due to temperature changes, cracks will appear on it;

- The drill is sharpened along a cone, or along a helical surface. In the first case, no additional devices are required;

- When sharpening to a conical shape, the edges should meet exactly in the center of the drill. If the intersection of the edges shifts: the tool will be pulled to the side during operation, and one of the edges will become blunt much faster;

- It is better to use screw sharpening when working on foam or aerated concrete, and the working part of the tool should be sharpened on a special sharpening machine.

Some useful tips when working with a drill

To drill a concrete surface with your own hands without any problems, you should follow the advice of experts.

Some of them can be found below:

- Before you start working on concrete, you should stock up on drills for different materials, including metal. This is because concrete drills are only used for drilling holes in concrete, ceramic, stone and other hard materials. But often, when entering concrete, the drill encounters metal reinforcement. This requires the use of a metal drill, which temporarily replaces the concrete tool used to drill through the reinforcement and then put the old one back;

- During operation, it is necessary to constantly monitor the temperature of the tool. Every 15 seconds of continuous drilling, you need to pause to cool the drill, but only naturally, without the use of water or other liquid;

- If, when entering concrete, the drill rests on a hard stone, it is better to use a punch, crush the stone, and then continue working with the same tool;

- If it is necessary to make a hole in the ceiling or load-bearing wall, it is better to replace the impact drill with a hammer drill;

- If drilling ceramics, use a concrete drill, but turn off the impact drill mode to prevent splitting of the tiles;

- A dull drill can be sharpened using a grinder by installing a diamond disc on it. If you purchase high-quality expensive tools for work, they will not need to be sharpened.

Tips on what and how to choose drills, concrete drills, and how to use them are useful for both beginners and experienced craftsmen. Drilling concrete is quite difficult, so it is better to first take into account all the recommendations of specialists and choose the right working tool.