Purpose and principle of operation of the winch

The winch is used in many branches of human activity.

This is a special mechanism designed to lift a load vertically or move it horizontally by transmitting force from the drum drive to a flexible traction element, for example, a cable or chain.

Depending on the type of winch, it can be used to perform the following tasks:

- Move the car. Here the mechanism is most often used to pull a vehicle to some static object, in cases where the car is not able to move independently, for example, “sat down” in the sand. Using a winch, the vehicle can pull itself up or pull up other vehicles. In general, a winch installed on any vehicle, especially one designed for off-road driving, including a snowmobile and ATV, is used to free stuck equipment.

- Lifting a load is the most obvious way to use the mechanism. So winches are the basis of lifting systems of various cranes, including truck and tower ones. Car enthusiasts and craftsmen also buy special hand winches for garages as an alternative to hoists. By the way, the hoists themselves, as well as the crane beams, which are found in almost every large workshop, are also built on the basis of a winch mechanism.

- On the water, winches are used as part of the anchoring and mooring devices of both small boats and huge ships.

It should immediately be noted that despite the similar principle of operation, each type of winch is designed to perform a very specific, limited job.

The simplest version is installed on a well to lower and raise a bucket of water.

Exploitation

Instructions for the operation of lifting mechanisms are given by the manufacturer in the passport or operating manual for each specific product.

General maintenance instructions include periodically checking and tightening threaded connections, lubricating rubbing components and parts, checking cables and rigging.

When operating lifting devices, certain safety precautions must be observed:

- comply with general safety standards when working with lifting mechanisms;

- before use, inspect and check all components of the unit, paying special attention to the cable or chain;

- for stationary winches or hoists, the fastening elements are checked;

- overloads exceeding the nominal (certificate) values must not be allowed;

- It is strictly forbidden to use winches and hoists with a faulty brake;

- do not unwind the rope until the last turn;

- When using an electric drive, the electric motor is connected only to the electrical network corresponding to the passport data; the electric drive cannot be connected bypassing the standard protection circuits.

When operating lifting mechanisms, special attention is paid to the correct slinging of the load. The material, quantity and points of slinging are determined based on the shape and weight of the load.

Guarantee

Each manufacturer indicates the terms of the warranty in the product passport. The warranty does not apply to consumables and products with mechanical damage. The warranty period for lifting mechanisms is from 12 months.

Device and characteristics

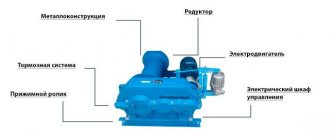

A classic winch consists of a rigid frame with a support or suspension, on which the main movable drum for winding the cable is mounted.

It is driven by an electric or manual drive, using a drum or worm gear.

Manual drive involves the use of human muscular strength, and therefore the work occurs through the rotation of a snare drum that engages with a large main drum, or through the rocking movements of a special lever with a ratchet mechanism.

The reduction ratio of some winches can reach 300:1 or more, and the design itself is nothing more than a transmission with a specific gear ratio, similar to a car.

This means that for one revolution of the main drum it is necessary to turn the drive drum 300 times, thereby reducing the applied force.

Double reduction is achieved by adding a second speed to the design, or by using a moving block.

The vast majority of winches have a brake, which can be:

- Maneuvering (maneuverable) – keeps the transmission from spontaneous rotation.

- Safety – keeps the drum from spontaneous rotation. This kind of brake is also called a locking or stopper brake.

If everything is clear with manual models, then electric ones are equipped with a control panel connected to the electrics of the winch itself with a flexible cable.

NOTE:

There are radio controlled options.

Material

During operation, individual winch components can experience enormous loads, and therefore only durable metal is used in production.

So, for example, in the manufacture of a drum, SCh 15-32 cast iron or welded steel is used, gears and gears of the gearbox are made of cast iron or steel (grade 30 or 40), casting is used.

For gear shafts, steel 35 and 40 is used.

Housings can also be made of aluminum.

Dimensions and weight

Depending on the purpose, the size and weight of the winch vary widely.

The average household model has a length of 546 mm, is equipped with a drum with a diameter of 64 mm and a length of 226 mm, on which 27 meters of 9 mm cable are wound.

The weight of the structure in this case is about 24.7 kg.

Household winches can, in principle, have the following dimensions:

- Overall dimensions LxWxH (mm): 180 – 640 x 74 – 260 x 128 – 240.

- Cable parameters: diameter 4 – 36 mm, length 8 – 32 m.

- Drum parameters: length 68 – 320 mm, diameter 36 – 180 mm.

Characteristics of the drum and types of cable

The cable is the traction element of the winch.

The material used to make it directly depends on the purpose of the structure.

Based on the objectives, the following can be used:

- Steel cable does not require special care, has a relatively low cost, however, over time it inevitably begins to burst, therefore, its reliability decreases.

Attention!

At the moment of breakage, a stretched steel cable can, without exaggeration, seriously injure.

- The rope is safer, lighter and thinner than the previous version, made of synthetic material, has high strength and durability. These are polyester, Kevlar, Vectran wicker products with and without a core, with impressive wear resistance, but requiring careful handling and constant care.

Instead of a cable, some winches use chains and sling tape.

The latter is also made of synthetic materials; its difference from rope lies in the cross-sectional shape and width, reaching 150 mm or more.

One of the characteristics of a winch, on the basis of which a specific product is selected, is the rope capacity of the drum.

It depends on the size and height of the sides of the latter.

Rope capacity indicates how long a cable can be wound given its specific diameter.

There are models that can use a rope of almost infinite length in their work, since instead of a drum, the design provides a pulley with several grooves.

Engine characteristics

To increase operating speed, load capacity and, in principle, automation of the process, winches can be equipped with one of the following types of drive:

- Electric - compared to the manual version, it is capable of winding a rope at a speed of up to several meters per second. The load capacity depends on the power of the electric motor, and this parameter, depending on the model, averages 0.5 - 4 kW. At the same time, cargo winches of tower cranes are equipped with a motor whose power can reach 30 kW and higher.

- Pneumatic - used mainly in places with a flammable environment, for example, in oil fields, in mines. Such models belong to the highest category equipment. Average power 6 – 10 kW.

There are also hydraulic traction and crane winches that are connected to the hydraulic network, for example, tractors are able to work under water due to their tightness.

Load capacity and tractive effort

For winches, tractive effort and lifting capacity have the same meaning, since in this case they actually mean the same thing, although in essence they represent different characteristics.

These parameters indicate the force with which the drive mechanism is capable of pulling a rope with a load, as well as the maximum weight load on the device.

So, for example, 2 tons of traction force indicates that the mechanism is capable of moving a maximum of 2-ton loads.

If you drag an object, then the winch is also counteracted by friction, which means that some reserve is required in terms of traction force.

The traction force can be doubled if you use a special power unit.

Malfunctions

Winches are very reliable devices, but malfunctions occur during operation:

- damage to the traction element - a damaged cable or chain must be replaced;

- jamming of the gear transmission - shift of the shafts due to loosening of the bolted connections, the bolted connections need to be tightened and locked;

- increasing the required force on the lever or handle - check the condition of the lubricant and, if it is missing, lubricate the parts;

- strong noise in the gearbox - check the condition of the lubricant, wash and lubricate the gearbox.

Malfunctions when using an electrically driven device:

- the electric motor does not start , a possible reason is that the circuit breaker in the protection circuit has tripped, the voltage in the network is low, or the contactor coil is faulty;

- when the remote control is turned off, the electric motor continues to operate - sticking of the magnetic system of the contactor, sticking of the limit switches;

- low voltage - check the cross-section of the supply cable, the voltage at the input panel;

- current or thermal protection is triggered - first eliminate the possibility of overloading the drive, check the elements of the electrical circuit for burning.

- the electric motor hums, but does not rotate under load - the motor operates on two phases (if three-phase), in the case of a hum in a single-phase motor (applies to three-phase motors) - the bearing may be worn out, as a result, locking (jamming) occurs under load;

- strong heating of the brake pads - check the uniform fit of the pads, the clamping and, if necessary, adjust;

- spontaneous lowering of the load - the malfunction is caused by weak clamping of the brake pads or their oiliness. The surface of the pads is washed and the clamping is adjusted;

- the noise of the electromagnetic brake is caused by the gap between the armature and the electromagnet core, and is eliminated by adjusting the gap;

Minor repairs and maintenance are performed directly during operation of the winch or hoist. In case of a serious malfunction that requires disassembling the gearbox, brake mechanism or electric drive, it is better to contact a specialized organization.

Repairs to the electrical part of the device are carried out only by a specialist with the appropriate electrical safety clearance group.

Replacement of loaded parts should only be carried out with parts supplied by the device manufacturer.

GOST

For different types of winches, technical conditions have been developed that are included in specific GOSTs:

- GOST 7014-74 - for manual single-drum models, the pulling force of which is in the range of 12.5 - 80 kN, excluding options for lifting people, crane and wall. Currently cancelled, and replaced by TU 22-4929-81.

- GOST R 52218-2004 – for tunneling options.

- GOST 12617-78 – for ship cargo models.

- GOST 15035-80 – for underground scraper winches.

Marking

The marking of the winch, as a rule, contains its maximum pulling force, as well as its units of measurement (S, U, LB, and so on).

Therefore, the 16800LB has a towing capacity of 7620 kg, since 1 lb = 0.454 kg.

Underground scraper winches are manufactured in the following versions:

- 2C is a two-drum model with a coaxial arrangement of drums and motor.

- 2SK – the previous version, but for the potash industry.

- 2P - Two drums and a motor are located parallel to each other.

- 3C – coaxial arrangement of three drums and the engine.

In this case, the standard designation indicates the standard size, modernization (letters), export version and this standard.

Certificates

Winches are subject to certification to confirm that their safety and quality meet established standards.

The following certificates are issued for different types of products:

• TR TS 010/2011 “On the safety of machinery and equipment” – for mechanical models.

• For electromechanical options - additionally TR TS 020/2011 “Electromagnetic compatibility of technical devices” and TR TS 004/2011 “On the safety of low-voltage equipment”.

Winch Manufacturers

Currently, many Western and CIS manufacturers present their products on the market. The range and features of the products of some of them are presented below.

DENZEL

DENZEL is a German brand of hand and power tools. The lifting equipment of this brand is represented by cable hoists with electric drive with a lifting capacity of up to 1 ton and a lifting height of up to 12 m.

The kit includes fastenings for fixing to the pipe. For horizontal movement, an electrically driven carriage is available for installation on an I-beam.

Einhell

Einhell is a German tool manufacturer. The company produces cable hoists with electric drives with a nominal value of up to 1000 kg and a cable length of 11.5 m.

The kit includes fastenings for installation on steel beams. The control panel is protected by a silicone casing that prevents the ingress of dust and moisture.

FIT

Fit is a manufacturer of electric, pneumatic and hand tools. Lifting equipment of this brand is presented:

- manual lever winches with a lifting capacity of up to 4 tons and a cable of up to 3 m;

- drum winch with manual drive with a lifting capacity of 1t and a cable of 9.5m

Hand winches are offered in a reinforced version - with two symmetrical gears. For greater convenience and safety, the stopper is moved closer to the lever.

JET

Jet is an international concern producing machine tools, hand tools, and lifting equipment. The range of lifting equipment includes:

- manual cable hoists with a lifting capacity of up to 10t and a lifting height of up to 12m;

- manual lever hoists with a load capacity of up to 3 tons and a lifting height of up to 12 m;

- electric hoists with a load capacity of up to 400/800 kg and a lifting height of up to 18/9 m;

- lever winches with a lifting capacity of up to 3 tons;

- electric winch with a lifting capacity of 250 kg and a lifting height of up to 60 m;

- tourist winch with electric drive with a traction force of 450 kg and a cable of up to 4.5 m

Some winches are not supplied with a rope and must be purchased separately. Lever winches have a telescopic lever design with a shear pin that functions as an overload safety device.

The company offers additional equipment: electrically driven carriages for electric hoists, movable carriages, clamps for fixing the hoist on an I-beam.

Kraftool

Kraftool is a German brand of professional hand and construction tools. The company produces manual chain hoists. The range includes mechanisms with a nominal value from 1 to 5 tons and a lifting height of up to 5 m.

The hoists of this company are made of high-quality carbon steel, the lifting parts are made of tool alloy steel. The products of this company are distinguished by compact dimensions and light weight. The self-return locking mechanism ensures high operational reliability.

Prorab

Prorab is a Russian brand representing electrical and construction tools. The company offers under its brand hoists with electric drive up to 1t, lifting height up to 6m and operating speed 4m/min.

Sorokin

Sorokin is a Russian tool manufacturer, specializing in equipment for car service. The company mass-produces several types of lifting equipment, covering the entire range of lifting capacities.

The range includes manual winches:

- drum up to 1.3t and cable length up to 15m.

- lever ones up to 3t and cable length up to 1m.

- traction capacity up to 5.4t and cable length up to 20m.

The brand also represents a line of hoists and hoists:

- lever hoists up to 9t and height up to 1.5m;

- chain hoists up to 20t and height up to 3m;

- mobile chain hoists up to 10t and height up to 3m (the chain hoist is combined with a carriage for installation on an I-beam);

- hoists with electric drive up to 5t and lifting height up to 15m.

In addition, automobile winches are produced designed for:

- for SUVs with a carrying capacity of up to 7.7 tons;

- for installation on ATVs with a lifting capacity of up to 2 tons;

- hydraulic electric winches for tow trucks with a lifting capacity of up to 9 tons.

The products of this manufacturer are made from high-quality materials, which ensures reliability and durability. The design allows you to replace standard cables or chains with traction elements of increased length.

Some models use textile tape as a traction element. In addition to the main units, the line includes additional accessories: consoles, blocks, slings, ropes and chains.

ZUBR

ZUBR is another Russian brand. In the segment of lifting equipment, the range is quite wide. A stationary winch with a manual drive up to 900 kg, and lever automobile winches with a lifting capacity of 2 and 4 tons are commercially produced.

Among the hoists, mechanisms are available with a chain drive up to 5 tons and a lifting height of up to 12 m and with a lever drive up to 5 tons and a lifting height of up to 1.5 m. The lifting mechanisms of this company are simple in design and reliable in operation.

The key to their durability is the quality of the materials used - all parts are made of high-quality carbon steel, and the chains are made of hardened tool steel.

The gear ratio is optimally selected, which ensures efficient operation with little force on the traction chain. Advertising from sponsors: // // //

Types of winches and their prices

Depending on the drive used in the operation, winches are:

Lever (manual)

A universal solution, since it does not require any energy sources other than the operator’s muscular strength.

Another name is a mechanical winch, which, by the way, is the only one that can be angular.

This means that it is based on a lever mechanism with a ratchet.

During operation, the operator does not rotate the drum, but pumps the lever, which transmits force to the required unit of the lifting unit.

The design allows you to work in limited space, provides a significant gain in effort, but loses in speed.

Approximate price – 3 – 5 thousand rubles.

There are options that are much more expensive.

Electrical

It is based on an electric motor that can be powered either from a 220 or 360 volt AC supply or from a low voltage DC source.

Due to this, a specially designed electric winch is often installed on cars.

The advantage of such a drive is that all the work is done by the electric motor, however, the disadvantage lies in its dependence on energy.

Price – from 5 thousand rubles.

Hydraulic

They are built using a hydraulic motor, the operation of which is ensured by the pressure of the connected hydraulic system.

Such models are installed mainly on special equipment, such as a tow truck or tractor, but are also found on passenger cars.

The connection is made to the hydraulic system, individual hydraulic pump or power steering.

Price – from 40 thousand rubles.

Pneumatic

They operate from compressed air and are respectively connected to a pneumatic system.

Notable for the fact that they can be used near explosive and fire hazardous substances.

The approximate price is 180 thousand rubles, depending on the characteristics.

Gasoline

Ideal for use in the field.

These are portable models, usually of compact size.

Compared to electric options, they are not used as often, but they work up to 4 times faster.

According to the type of winch force transmission mechanism, there are:

Drums

The most common among manual models.

During operation, the cable is wound onto the drum by rotating the handle.

They are used for simple tasks, as they increase the traction force by no more than 2 times.

The cost is approximately 1.5 - 4 thousand rubles.

Worm

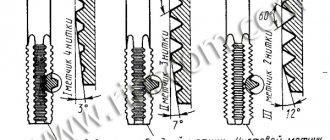

They differ in that the drum with the cable rotates due to the transmission of force through an Archimedes screw.

The main advantage is their miniature size, which is why such models are also called mini-winches.

Among the disadvantages, it should be noted that there is quite noticeable friction between individual components, as well as the need to exert significant effort if we are talking about a manual device.

Planetary

The design includes a planetary gearbox, which allows for large gear ratios while having a small number of gear units.

In other words, such models are compact, but at the same time powerful and load-carrying.

Gear

The transmission of rotation from the drive occurs through a series of gears or gears, which can be combined into a full-fledged gearbox.

The system requires lubrication during operation.

According to the type of traction mechanism, winches are divided into:

Cable (rope)

A simple and compact mechanism using steel cable or synthetic rope.

It is used, as a rule, in mid- and entry-level systems, since it is difficult to achieve serious lifting capacity with ropes.

Tape (belt)

As a rule, this is a manual drum version with a lifting height of up to 10 m.

Chain

They have a high load capacity due to the strength of the chain, however, such models are characterized by heavy weight, since the chain itself is quite massive.

According to their purpose, winches can be divided into 2 main types:

Traction

They act as a traction mechanism during loading and unloading and other work, and therefore all kinds of lifting devices are equipped with similar devices.

Such winches are not separately suitable for lifting loads, but are used, for example, when moving various trolleys, pulling cars and similar work.

They have a small cable reserve, but a decent operating speed.

Installation (construction)

Designed for lifting various loads at various industrial and construction sites.

They are mounted on a frame, have a long cable length and a low drum rotation speed.

The following types of winches are classified as special, that is, they are designed to perform specific tasks in specific conditions:

Elevator

They look like a small crane with a short boom.

Designed for lowering and lifting people on elevators, which is where the name comes from.

These models are also used in bunkers, mines and other objects.

It is marked “LE”, the number after the letters indicates the maximum permissible load capacity, for example: LE-150.

Price range 100-200t.r.

Shunting

They are used in railside warehouses for the movement of railway cars, thereby replacing diesel locomotives.

There are single-drum and double-drum ones, they work on electric or pneumatic.

Freight

Actually, any winch designed for lifting and lowering a load, that is, moving it vertically.

A striking example is hoist.

Garage

A small-sized option that is permanently attached to a horizontal beam.

The load capacity does not exceed 2 tons, and the cable length, as a rule, is no more than 2.5 m.

Winches with floor-to-ceiling support

Designed to lift loads to an average height of 60 m.

Load capacity often does not exceed 300 kg.

This construction winch is installed on a floor-to-ceiling spacer stand or in a window opening.

The cost of the electric version is approximately 100 thousand rubles.

Scraper

They are used in underground mining for the delivery of rock, as well as in the storage of bulk materials in open-pit mining.

Automotive

They are attached to the car body and are used to pull out stuck cars.

In addition to the drives described above, cardan power transmission is used, that is, the winch is connected to the power take-off.

They are distinguished by unpretentiousness, reliability and power.

An option often used by true off-road enthusiasts is a high-speed winch with several electric motors and a rope winding speed of up to 50 m/min.

The cheapest model will cost about 8 thousand rubles, and the average price is about 30 thousand.

Tunneling

Mine option for hanging communications and equipment in the shaft.

Aviation

They are actually used when loading and unloading aircraft; they are removable equipment.

Skidding

A mounted version for a tractor, designed for transporting fallen logs.

Skip

For moving along an inclined skip bridge.

Motor winches

A gasoline version, which, in addition to direct functions, is capable of performing soil cultivation when installing special trailed equipment.

Price from 19 thousand rubles.

Shipping also has its own winches:

Anchor

Actually for releasing and raising the anchor, often with an electric drive.

Boat

For careful transportation of water craft to storage areas.

Price – from 6 thousand rubles.

Mooring

For retrieving the mooring line at a fixed speed, regardless of the load.

Functions

Functionally, both devices are designed to move goods. However, there is some specification.

Hoists are mainly designed for lifting and holding objects. They can also be used for horizontal movement. In this case, the hoist is attached to a special carriage moving along an I-beam.

In this design, the lifting mechanism is called a hoist. The trolley drive in this case can be mechanical or electric.

Winches are used to move loads in any direction. Functionally, the following groups are distinguished:

- Traction. Designed for lifting or moving loads;

- Shunting. They are used when it is necessary to move freight cars in rail warehouses;

- Auxiliary and drilling. Specialized units for lifting equipment to drilling sites from receiving bridges, working with casing pipes;

- Scraper. Used to move parts of rocks during mining.

Stationary winch with manual drive

If you have a welding machine and an angle grinder, the device can be easily made quickly. Main components of the product:

- frame made of profile pipe 20×20 mm;

- drum made of 3 mm sheet metal, hubs made of the same material;

- shaft;

- 6 bushings 200 mm long from tubes with a diameter of 14 mm;

- lever, cable and carabiner.

This design can be easily converted into a winch driven by an electric motor or any other engine. You will have to find two sprockets with different numbers of teeth. The drive from the gearbox on the motorcycle and the driven one on the wheel will do. You will also need a chain of the appropriate pitch.

They start by making the frame, for which they cut rectangular pipes and form the ends at 45°. Lay out the parts on the table and grab them pointwise in the corners. After checking the perpendicularity and dimensions, the seams are welded. If it is planned to install a motor, make a metal base with cut grooves and secure it. Clean it with a grinder, sand it, cover it with a primer, then two layers of enamel.

For the drum, cut out 2 identical circles of 300 mm in diameter. Drill holes:

- for mounting hubs - 4 pieces;

- in the center - under the shaft;

- stepping back 70–80 mm - for bushings.

The hubs are fixed with bolts, the drum disks are connected with studs. Tube bushings are mounted on them between the circles. Secure with nuts and locknuts. The structure is mounted on a shaft, which is threaded into the holes of the sheet metal cheeks. On one side from the outside there is a place for the drive handle, on the other, if provided, there is a large sprocket. A chain is then put on it, which goes to the engine. To reduce the friction force, use bearings of a suitable diameter.

One end of the steel rope is fixed to the shaft and wound. A simple design has emerged that can move loads horizontally. If it is necessary to lift a weight, a manual hoist is additionally used or a cable is thrown over a block. The winch is also installed on vehicles.

Do-it-yourself manual winch: 7 stages of manufacturing the device

Winches are a very convenient device for lifting loads, which is why they are widely used among car enthusiasts.

Since the cost of special equipment is quite high, a do-it-yourself manual winch will be the best option for motorists who prefer the best price-quality ratio.

Also, using an individual layout, you can create a unique winch that will combine convenience and high load capacity. Compact homemade devices can be installed on any part of the car, which makes the mechanism a universal assistant for repairs and long-distance trips.

Purpose of winches

The winch is one of the oldest mechanisms that man invented and used in his activities to facilitate the movement of heavy objects. The traction force created by the physical strength of a person or animal is transmitted through a rope, chain, cable or other flexible element from the drive drum to the load that needs to be moved.

In a winch, the drum drive can be manual, electric, from an internal combustion engine, from a steam engine, or hydraulic. Most often, a winch is used to lift a load vertically. But sometimes using this mechanism it is convenient to move weights horizontally (for example, a car).

If the winch is firmly installed on the car, then with its help you can independently free yourself from a hole, from a swamp, or climb a mountain. If the stuck car does not have a standard winch, then any other one must be firmly secured to the ground and the problems that have arisen must be solved.

Winch on a car PHOTO: motorsguide.ru

Gearbox selection

The next problem is the choice of gearbox. Any 220 V electric winch with your own hands must contain a mechanism that will transmit rotation with a large traction force. There are the following types of gearboxes:

- Worm drives transmit rotation at an angle of 90 degrees and do not require braking devices, as they have good self-braking properties.

- They are not used for winches due to the complexity of the perpendicular arrangement of the main drive and secondary shafts.

- Cylindrical, are one or more pairs of gears in one plane, meshed. Rotation is transferred from the smaller wheel to the larger one. They have high reliability, but less tractive effort. Convenient for use when constructing homemade winches.

Worm gear – high degree of reliability

Many mechanisms of this type, which have a large load capacity, provide for control of the speed of the cable. Thanks to this, you can change the intensity of the exerted physical effort. A manual worm winch can have a variety of mounting options.

This device is easy to use and highly reliable. Using this element, designed for load-bearing capacity, it is possible to carry out installation, repair and construction work. In this case, the winch will have a high level of safety during operation.

It should have a comfortable handle, and the worm gearbox can provide an excellent ability to hold the load.

How to make different types of winches

In order to take on the development and manufacture of a winch with your own hands, you must be able to work with plumbing tools, welding equipment, electrical appliances and machines.

Homemade winches are created for a specific car. They best meet the needs of the owner, are much cheaper than purchased ones, have high maintainability, are easy to maintain, and are more compact.

One of the most popular options for a homemade winch is created from bicycle parts.

To manufacture this device, you will need the following components: bicycle chain, rear axle, bushing, sprocket, strip of sheet steel 6-8 mm thick, steel cable, carabiner, cable block, hook.

The tools you will need are a grinder, a drill or drilling machine, a screwdriver, a welding machine, a vice, taps, a hammer, a core and something else.

The ratchet, which is needed as a safety device against spontaneous reverse rotation of the drum, is made from a bushing.

Homemade ratchet from a bicycle hub PHOTO: usamodelkina.ru A body is made from a steel strip into which the hub with the ratchet is inserted. The main part of the winch is ready.

Device with ratchet assembly PHOTO: usamodelkina.ru