Operating principle of a deep concrete vibrator

Internal concrete vibrators are used on all construction sites. They rid the solution of excess air and moisture. The device creates high-frequency vibrations, under the influence of which the mixture becomes homogeneous and its porosity decreases. When pouring, the mold is completely filled, there are no air voids.

The unit consists of a motor with a shaft and a vibrating tip. It can be purchased at a hardware store, but it is easy to make yourself. You will need a high-quality tool on the basis of which the unit is created.

The operating principle of the device is based on the rotation of the working surface at high speed under the action of a power tool; rotational movements are converted into vibrations. Vibration causes the mortar to move, causing air to rise and be removed from the solution.

Making a vibrator with your own hands from a hammer drill

It’s easy to make a vibrator for concrete with your own hands, using a hammer drill as a basis, the power of which should be at least 1.5 kW. The engine speed plays an important role:

- coarse-grained solution - more than 3,500 rpm;

- medium-grained - up to 9 thousand rpm:

- mixture of fine fractions - 10-20 thousand rpm.

The attachment for the work is a regular peak, a broken drill or something similar. It will rest against the prepared formwork. Adhesion is ensured using a steel washer with a diameter of 5-7 cm.

The concrete vibrator should be started after all parts have been firmly fixed and connections have been checked.

To process mortar at shallow depths, the bayonet method is used. It is necessary to weld an additional one to the main nozzle. The length of the bayonet must correspond to the depth of the mold being processed. The nozzle is pressed against the bottom and moved as needed.

If the length of the vibrating bayonet does not allow processing the entire volume of the mixture, pouring is done in layers.

Special attachments (vibrating heads) with a mounted shaft are available for sale. It is easy to attach it to the original tool and get started.

To do this, the hexagon output of the internal flexible shaft is attached to the unit with a suitable adapter. A metal ring located at the end of a rubber hose must be connected to the tool. Three holes should be made for short screws that will secure the shell to the head of the hammer drill.

Making your own vibrator from a drill

To make an individual vibrator for concrete, you can use a drill with a power of 1 kW or more. A special nozzle with an eccentric and a steel tip is made from a piece of stainless steel tube with a diameter of 30-40 mm and a length of 40-60 mm.

Vibration and movement of the mechanism will be provided by the internal rod. To make it, a metal plate 15-20 mm long is welded to a metal pin 125-150 mm long. The elements are combined with each other. A through eyelet for the wire is drilled at the end of the core.

Rotation of the core is ensured by two bearings, the inner diameter of which will allow the end of the rod to be tightly placed inside. They must be of high quality: steel with a high carbon content, since they will bear the main load. It is important to protect these elements from dust and dirt.

The pin is inserted into the tube, secured at both ends with bearings, and trimmed if necessary: it should protrude 5-10 mm on each side. In order to completely close the torque, a sleeve of a suitable size is placed on one end of the pin.

The eccentric shaft is made of dense rubber or flexible plastic pipe, an internal pin that can bend and change shape. The shaft combines the drill with the attachment. A tube is placed on top: with a margin of 4-5 cm on each side.

A concrete vibrator works by vibrations caused by a rotating rod. One side of it is put on the sleeve, the other rests against the core with a through hole. Then the parts are combined. To thoroughly secure the connection, the bushing must fill the bearing to the stop.

Final stage

To finally complete the work on the tool you need:

- pull the hose onto the bushing;

- compress the tube with clamps with a diameter of 5-6 cm;

- Install the tip guard.

So, to pour the foundation yourself, you can make a concrete vibrator with your own hands. It is convenient to make it using a hammer drill, drill or other tool with a motor of sufficient power. It is important to know that a unit longer than a meter is inconvenient to operate alone. When making a tool, it is necessary to securely fasten all joints, since the concrete mixture puts significant pressure on the tool and resists vibrations.

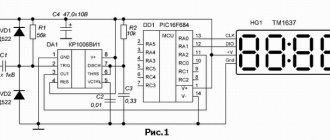

Vibrating table on an electromagnet

Having become interested in the topic of making paving slabs at home, having read the forums and watched a lot on YouTube about a rather delicate tool, namely a vibrating table, the basis for making them is a motor with an eccentric, I was not satisfied with this design.

It carries parasitic vibrations of horizontal components of vibrations. Besides, people are not able to pay 5-6 rubles for a vibrator. The price for this equipment, IMHO, is deliberately overstated, despite the assertions that the impregnation of the windings, bearings, housing, all these components took place in normal Soviet production and were quite affordable in price, but today they have turned into space nanotechnology and began to cost accordingly, well, okay, flag them in your hands. My attention was drawn to electromagnetic vibrators. It’s very strange, having so many patents for the above-mentioned device and not having finished products on the market, it struck me. Having become familiar with the production of similar devices from foreign friends. A certain device was born that claimed simplicity of design, mechanical stability, and repeatability of the design, of course, with certain metal-loving skills. Yes, I’ll make a reservation that the topic of a vibrating table based on a vibration pump has been studied, and the baby is not satisfied with the design of the rigid fastening of the components between the frame and the table cover; this is a completely different principle for obtaining vibration; we will not consider it. And so we have a certain structure in which the main component is an electromagnet, in other words, a coil of a certain transformer, which creates some mechanical vibrations of a core that has mass, such as an eccentric in the exciter that causes the table top suspended on springs to oscillate. The coil of our vibrator is connected to the circuit of a home AC network of 50 hertz through a diode; the half-cycle component in the coil will be 2 times lower and amount to 25 hertz. Our heavy core is suspended on springs and together makes up the oscillatory system of our table. The idea really overwhelmed me and a certain device was born which was manufactured, assembled and tested and proved to be a device with quite good data. For the first topic I will post a photo of the design. In the sequel I will tell you how and what to make this device from. I want you not to pay extra money for fairly simple devices that help us live and survive more accurately. To be continued . Happy holiday to all border guards. demony wrote: The coil of our vibrator is connected to the circuit of the home AC network of 50 hertz through a diode, the half-cycle component in the coil will be 2 times lower and amount to 25 hertz.

No, with a diode the main vibration frequency will be 50 Hz (if nonlinear mechanical chatter and frequency conversion do not occur when operating in shock mode), and without a diode the frequency will be doubled 100 Hz. When working with a diode, the winding must be selected for a higher voltage (with a greater number of turns, almost twice as it works with permanent magnetization) than when working without a diode. The armature of the electromagnet can be alternately and symmetrically pulled by two electromagnets in different directions, turning on their windings through diodes so that they operate in different half-cycles (this symmetry is good for a network (especially for a weak one) and the spring stiffness can be selected as you like)

How to make a concrete vibrator from a hammer drill

If you plan to pour a reinforced concrete foundation or wall, then in such situations you cannot do without such an important tool as a vibrator. The main purpose of such a tool is to remove air cavities and improve the properties of the solution. Using a vibrator, you can make the mixture homogeneous and also remove air and moisture from it, increasing the efficiency of the work performed. A vibrator belongs to the category of those tools that are not used very often. In order not to buy such a tool when carrying out one-time construction work, you can make a vibrator for concrete with your own hands from a hammer drill. Let's find out how to do this in more detail.

Design and operating principle

The purpose of a tool such as a vibrator is to change the consistency of the concrete mass to a more dense one, which is necessary to increase strength. The operating principle of the device is based on the fact that the tool creates high-frequency pulses, as a result of which the consistency of the concrete mass seeps between the smallest particles.

A construction vibrator allows you to solve the following problems:

- The process of removing moisture and air from the mixture is carried out.

- Increasing the strength of concrete by filling voids with concrete mass.

- Increasing the degree of fluidity and homogeneity of the mass.

- Acceleration of the hardening process by removing moisture.

- Increasing the durability of a concrete structure.

- Uniform filling of the form.

The design of the vibrator is based on elements such as a shaft with a motor, a vibrating tip, and a special mechanism for creating impulses. The operation of the device is based on the fact that one end of the rod is placed directly into the concrete mass, which has already been poured into the mold. When the nozzle is immersed, the electric motor starts, which generates pulses. These impulses are transmitted to the tip, resulting in vibrations of the concrete mass, and it fills all cavities and voids. The tip can be immersed to different depths of the poured concrete mass, which is one of the significant advantages.

Application area of the device

Construction vibrators, or they are also called deep vibrators, are used primarily in construction. The main work that cannot be done without the device in question is pouring the foundation. If the foundation layer is relatively small, then you can do without special devices, but if you need to make the foundation as high quality and reliable as possible, then you will definitely need to use a concrete vibrator.

Deep vibrators allow you to dissolve a large volume of solution, increasing its fluidity, and thereby filling the mold more efficiently. The structure of a foundation or wall made of concrete, poured using a tool, is stronger and more durable than structures without the use of this special unit.

It is important to know! If a foundation of great depth is being poured without using a vibrator, then such work should be carried out in stages, which will require a considerable amount of time.

In addition to construction, the units in question are used in the following areas and industries:

- energy;

- industry;

- mechanical engineering;

- road construction;

- Agriculture.

Using this tool, not only concrete mixtures are compacted, but also bulk materials. Its use in most areas and industries can significantly increase the efficiency of mechanized work. You can make a vibrator for concrete yourself if you have a hammer drill or drill on your farm. Let’s take a closer look at how to make such a device to make your life easier.

DIY vibrator from a hammer drill

To make a vibrator for concrete from a hammer drill, you will need to use a peak or take a steel pin. An important condition when constructing a device such as a vibrator from a hammer drill is the use of reinforcing bars of the required length. This is necessary in order to know that the product can effectively penetrate the thickness of concrete.

It is important to know! The best option for making a vibrator is to use a steel tube, which must be welded to an old drill shank or other attachment from a hammer drill.

If it is necessary to vibrate concrete mixtures that are poured horizontally, for example, formwork, then the tool must be installed in such a way that the nozzle forms an angle with the horizon. To create such a slight slope or angle, they resort to using a steel washer of the appropriate diameter installed on wooden formwork. The hammer drill attachment is installed into the resulting structure, after which the tool is started for a few minutes. The procedure is repeated in different parts of the concrete base several times.

To ensure efficient operation, it is necessary to use a hammer drill with a power of at least 1.5 kW.

Recommendations for use

If there is a need to construct concrete structures in a one-time form, then it makes no sense to purchase a factory-made vibrator. You can do without it by making a homemade tool from a hammer drill.

To summarize, it should be noted that the tool in question plays an important role when performing various concrete pouring jobs. The effectiveness of this tool is simply priceless, since before the invention of the device it was necessary to use steel wire.

Vibration mechanism

The vibration mechanism of a vibrating plate, or vibration exciter, can have two design options:

- unbalanced, which is a rotor unbalanced relative to the axis of rotation;

- planetary, using the energy of moving elements that move along special closed paths.

Making a planetary mechanism at home is impractical, since it is difficult both to create and to maintain. It is difficult to make an unbalanced vibrator, and the magnitude of the driving force is the same in both cases, so the choice is obvious.

The eccentric rotor is mechanically connected to the engine via a drive belt. To do this, pulleys located in the same vertical plane are installed on both elements. With their help, you can adjust the gear ratio and change the vibration frequency of the installation.

How to make your own submersible vibrator for concrete

To evenly distribute concrete and completely fill the formwork, builders use special devices - vibrators. Air bubbles in the mixture contribute to corrosion of the reinforcement; the moisture that accumulates in them in winter turns into ice, expands and causes cracks to appear. Therefore, the use of compaction tools is a necessity. Additional benefits: increased fluidity of the solution and reduced hardening time.

There are two types - surface and submersible. The former are used only when pouring screeds of small thickness, the latter are compacted not only on the surface, but throughout the entire depth. If the device is needed for a small amount of work, then you don’t have to buy it, but make it yourself from improvised tools.

Deep vibrator device

- Drive (220 V). When manufacturing on your own, it is used as: a single-phase electric motor with a power of 0.75-2 kW and a rotation speed of 1500-3000 rpm; a drill with a power of 1 kW or a hammer drill with a power of 1.5 kW.

- Flexible hose up to 7 m long with a shaft inside. This part supplies torque from the electric motor. To make it, they usually use a sewer cleaning spring (plumbing cable), which can be purchased at a plumbing store.

- Working tip (mace). This is an elongated cylindrical part with an eccentric inside, due to the movement of which vibration is transmitted. The mace is made from a pipe made of stainless steel. Other metals are not suitable due to low strength or susceptibility to corrosion.

Operating principle

The operation of a vibrating plate is based on the use of a rotating shaft with an eccentric, which generates strong vibration. The shaft is mounted on a massive metal base, which with its weight acts on the soil, compacting it due to its weight.

On the same base, a motor is installed, which is necessary to drive the eccentric shaft into rotation. To control the structure and give the installation the desired direction, a long handle is installed.

There are several types of vibrating plates:

By weight they are divided into:

- light (up to 75 kg);

- universal (from 75 to 90 kg);

- medium-heavy (from 90 to 140 kg);

- heavy (140-200 kg or more).

There are also different ways to move the vibrating plate:

- upright, capable of moving only forward and requiring a platform of sufficient size to turn around;

- reversible, capable of moving both forward and backward, which makes them more convenient in conditions of limited space.

Lightweight and versatile vibrating plates are used for compacting paths, paving slabs, and landscaping work. During construction and foundation work, medium-heavy and heavy-duty installations are required that provide maximum compaction combined with high productivity.

Important! The weight of a vibrating plate created at home should not be too large, otherwise it will be difficult to move it and there will be a danger for the worker servicing the installation.