Methods for unscrewing bolts, screws, screws with licked edges

If the usual method fails to unscrew the fasteners whose edges have licked off, you can use one of several proven options.

Gas key

This method is used when unscrewing bolts, since they have a protruding head that you can grab onto. For this:

- Clean the bolt head.

- Lubricate the joint with kerosene or diesel fuel, a liquid like WD-40 works well, and leave for 15–20 minutes.

- Unscrew the bolt. They do this with a gas wrench. With its help, a lot of force is created and it is possible to grip even a round head well.

The disadvantage of this method is that it is not always possible to get a gas wrench to the desired bolt.

Cutting new edges

If the bolt is large, then using a grinder you can cut new edges on it. It is enough to make only 4 of them and use a smaller key to unscrew the bolt. You can cut new edges on a bolt with a file, but this is more difficult and takes longer. You can make a cut on the head of a screw or screw using a hacksaw or grinder.

You can make a deeper cut on the head of a screw or screw for a screwdriver.

Hammer and chisel or impact screwdriver

This option is more suitable for licked nuts or fairly large screws. The chisel is pressed against the head of the fastening element and, hitting it with a hammer, the screw or nut is gradually turned. Small screws or screws can be removed using an impact driver and a hammer. After loosening the fastening, the work is done with a regular screwdriver.

An impact screwdriver can be used to unscrew small screws or screws with licked slots.

Band or piece of rubber

In this case, use a small part of a medical tourniquet or a piece of thick rubber. The selected material is placed on top of the head of the screw or screw, after which it is pressed with a screwdriver and gradually turned. The presence of rubber will help increase friction and solve the problem.

The harness is placed between the screwdriver and the head of the screw or screw.

Extractor

An extractor is a special tool that is used to unscrew screws, bolts or screws with licked or broken heads.

Extractor - a tool for unscrewing screws, bolts or screws with licked or broken heads

The order of its application:

- Using a thin drill, a small hole is made in the head. In some cases, the extractor can simply be driven into the licked screw slot.

- Select an extractor of the required diameter. Drive or screw it into the prepared hole. This depends on whether a regular or screw tool is used.

- Unscrew the bolt.

Video: unscrewing a licked screw using an extractor

Regular or left hand drill

Left-handed drills with counterclockwise rotation are available for sale. They improve tool centering and reduce the load on the drill, which gives higher productivity and drilling accuracy. By inserting such a tool into a drill, you can unscrew a screw or screw with a licked head. If you don’t have a left-handed drill, you can try to drill out the stuck fasteners using a regular one. In this case, you need to take a drill whose diameter is smaller than the diameter of the bolt or screw

You must act carefully so that you do not have to cut threads for new fasteners later.

The drill bit should have a diameter smaller than that of the problem bolt

Glue

A nut of the appropriate diameter is fixed to the head of the problematic screw or screw using epoxy glue or glue called “cold welding”. After the glue secures it securely, use a wrench to turn the nut and unscrew the screw or screw together with it.

Using glue, fix the nut to the licked head, and then unscrew the screw together with it.

Welding

If you have a welding machine nearby, you can fix a new nut on the head of a bolt or screw by welding it. After this you can immediately unscrew it.

A new nut can be welded to a problematic bolt or screw.

Solder and soldering iron

If you need to unscrew a small screw or cog, use a soldering iron and solder:

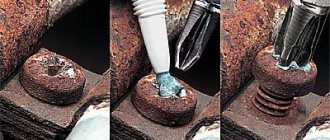

- Heated solder is dripped onto the head of the fastener with licked edges.

- While the tin has not hardened, insert a screwdriver into it and wait a few minutes.

- Unscrew the problematic screw and clean the solder tip of the screwdriver.

Lubricate the thread

Sticky fasteners must be lubricated with penetrating lubricant. | Photo: electro-shema.ru.

Rusty bolts and nuts, which have been sitting tightly in place for years, very often “grow” with threads to the mating part. In this case, a product that will lubricate the threads will come in handy. The first thing that comes to mind is the famous WD-40. You can also use kerosene. But it is worth knowing that if “vedeha” does not help, then no “chemistry” will help.

Effective ways to unscrew a rusty bolt or nut?

If we consider more effective ways to combat rust, it is worth highlighting the following methods.

Heat.

From the physics course we know that metal tends to expand as temperature increases. This feature can be used to solve the problem.

To unscrew a rusty nut, warm it up thoroughly, and then immediately try to unscrew it.

It is important to act quickly here so that the metal product does not have time to cool down. The essence of the manipulation is that due to uneven heating, the rust is deformed and has less restraining force

Heating can be carried out in any available way. This could be a gas burner, a candle, a lighter, or even a soldering iron.

You can also use a blowtorch or other device.

When using this technique, be careful and remember the contraindications. In particular, heating is not recommended if wood or paintwork products are located in the joint area.

In this case, the part will be damaged and you will have to spend money on replacing it.

Tapping.

You can unscrew a rusty nut or bolt using the traditional method - by tapping around the perimeter of the part.

Mechanical impact on each side allows for greater deformation, which contributes to the scattering of rust.

While tapping, be careful not to damage the edges of the nut. Otherwise, the task of unscrewing will become more difficult.

Twist.

You can also go the other way. First, tighten the nut (bolt) with maximum force, and then try to rock the connection and dislodge the rust layer in this way.

If the manipulation is successful, unscrewing the nut or bolt will not be difficult.

Wax cup (difficult, not practical, but possible).

This technique cannot be called popular, but in terms of effectiveness it is in no way behind its “competitors”.

The algorithm of actions is simple. Make a cup-shaped shape from plasticine or wax so that its sides are above the level of the nut (about 2-3 mm).

Then dilute the sulfuric acid, pour the liquid into the prepared cup and add a little zinc. This chemical combination provides a galvanic effect and the ability to unscrew the part.

Destruction.

If none of the above methods produces results, and the upper part is broken or severely deformed, there is another solution - breaking the bolt and drilling it out of the vehicle part.

Here, to complete the work you will need a hand or electric tool, as well as a set of drills of a suitable diameter.

Before drilling, place the drill bit in the center of the bolt and hit it with a hammer. This is necessary to deepen the product in the central part to a certain depth.

First, work in small increments and make sure that the drill enters exactly in the central part (tilts to the left and right are prohibited).

Start with a small diameter drill and then move on to a larger piece.

When choosing a drill, pay attention to two criteria - price and country of origin. Please note that high quality products cannot be cheap, because they are made from hardened steel and sharpened in a certain way.

Please note that high quality products cannot be cheap, because they are made from hardened steel and sharpened in a certain way.

At the same time, special drills do an excellent job with aluminum, cast iron and other materials (including brittle ones).

To ensure correct drilling, use special lubricants, which can solve several problems at once - protect the drill from strong heat, cool the metal and lubricate the drilling elements. As a result, the whole process becomes easier.

Chemical

Now we will consider methods for those who do not rely on the help of physics, but want to solve the problem with the help of chemistry. Your laboratory should have: kerosene, white spirit, acidified sulfuric acid, zinc, plasticine, hammer, water, sandpaper, wrench, chisel.

Attributes of the chemical method for unscrewing the nut

Process.

We moisten the nut and bolt with kerosene (experienced people recommend making a mixture of White Spirit and kerosene), applying a swab to them, it doesn’t matter whether it’s cotton or gauze. After some time - from an hour to a day, and with repeated attempts, you may find that the hub nut can be easily unscrewed. But even here you cannot do without force: at a minimum, you will probably have to work with sandpaper to clean the parts from rust. If even after this things don’t work, you should help with a hammer: tap it on the edges of the hub nut.

If in this case you are not successful, make a small container out of plasticine, secure the hub nut on top, pour water with sulfuric acid into it, and put zinc in the container. A chemical reaction begins that does a very good job of removing rust. Usually a day is enough for even advanced corrosion to go away from a part. Finish the job with a wrench. But this method is valid only in the case when the reason is that the nut is tightly stuck and/or rusted, and if it was simply tightened, neglecting the required tightening torque (to “be sure”), then you just need to tighten it.

What is the result..

As you can see, unscrewing the hub nut is not an easy task, but it can be solved

Please note that the first step is to try to preserve the hub nut by using penetrating fluids such as Vedeshka. Physical efforts to twist the hub should be moderate

And, of course, you should refrain from strong blows and heating with a torch, as methods that can render not only the nut, but also the bearing unusable.

Penetrating fluids and lubricants

Even at the dawn of the automotive industry, mechanics were faced with the problem of soured bolts and nuts, but at that time there were no special fluids to eliminate this problem. And then car enthusiasts began to use improvised means. You can always find brake fluid or antifreeze in every garage or car trunk. They contain glycols, which have high penetrating ability and destroy rust. Kerosene and white spirit also have similar properties. In addition, the oiliness of kerosene, in addition to destroying rust, helps to lubricate the thread, which will facilitate further unscrewing.

Technology does not stand still, so today there are many special penetrating liquids and lubricants that make it easier to unscrew bolts and nuts that seem to be soured. They contain aliphatic hydrocarbons , which destroy rust and other harmful formations.

Such liquids are sold in aerosol cans in the form of a spray, which significantly accelerates their penetration into the threaded joint. The most famous of them is the universal lubricant WD-40. It has been used by car enthusiasts all over the planet for decades. There are, of course, more inexpensive analogues, for example, Unisma or the domestic “ Liquid Key ”, but in terms of reliability and effectiveness they remain far behind the original.

How to unscrew a soured bolt using penetrating fluid or lubricant:

- Pour penetrating liquid liberally into the threaded connection. You can also dampen a rag with it and place it on the thread.

- Then you need to wait 30-40 minutes for the chemicals to break down the rust and free the bolt.

- Then you need to fill the connection with lubricant and let it pass along the threads into the connection.

- Then you need to try to unscrew the bolt.

- You can also pre-tap the threaded connection to completely destroy the rust.

- If you still need to make an effort to unscrew the bolt, you should repeat the procedure again.

Unscrewing a stuck bolt using heat

If the penetrating liquid does not help to unscrew the soured bolt, or it simply is not at hand, you can use another option - heating the threaded connection. This is a more labor-intensive but effective solution. This method is also used if the connection was fixed with a special thread sealant.

First you need to choose which tool will produce the heating - a gas burner or an industrial hair dryer. The second option is more convenient, since the threaded connection needs to be heated to a certain temperature, but in the absence of a powerful industrial hair dryer, the burner will cope with this problem.

The threaded connection must be heated to 230C, since at a higher temperature it can be soldered, and this will only increase problems. Then you need to give it time to cool naturally, since artificial methods can lead to deformation of the metal. As a result of heating, the metal elements expand, thereby destroying the rust on the threads and increasing the gap between the bolt and the nut. The final effect can be achieved only after several heating/cooling cycles. After this, you need to refill the threaded connection with lubricant and try to unscrew the soured bolt.

Read also: Longitudinal twisting machine

It should be remembered that if, after heating and lubricating, you still have to make a lot of effort to unscrew the bolt or nut, then you need to repeat the process again, and not use force. Forceful methods can only make the situation worse.

The problem of stuck fasteners is familiar to many car enthusiasts. When exposed to moisture, bolts, nuts and screws rust, and unscrewing them becomes very difficult. But no matter how “complicated” the bolt is, professional car mechanics know what to do, because they can disassemble even the most problematic parts.

Cases when it is difficult to unscrew a bolt

Threaded connections have the unpleasant property of losing their mobility over time. To avoid this, the fasteners to be connected are made of different metals, for example, steel and brass. Or the mating pair is made of stainless steel. But that rarely happens.

Basically, steel fasteners are used in mechanisms, units and metal structures. If it is in a humid environment, then over time corrosion processes begin, significantly complicating dismantling when the need arises. There may be several reasons why hardware (metal products) do not want to unscrew.

Edges torn off

During assembly, each fastener must be tightened with a certain force - sufficient to ensure the strength of the connection. By applying excessive force, you can break the threads of small-sized products - from M3 to M12.

This is no longer a problem for larger fasteners, so many men tighten the bolts and nuts with maximum force. This is bad for any hardware. When the time comes to disassemble the connection, parts damaged during assembly can greatly complicate the task: a screw or screw with a twisted spline, a bolt or nut with torn edges.

Most often, a hexagon turns an open-end wrench, which has only two working planes. Therefore, if possible, you should always use a spanner, socket or special tool.

But if the edges have already been “licked”, they do not always help. The tool rotates, but the fasteners remain in place.

Rusted nut

Corrosion processes always lead to the appearance of rust, which tends to swell and increase in size. As a result, the thread jams. Unscrewing a rusty nut becomes problematic. Auto mechanics, mechanics, and craftsmen working at home face this problem.

In addition, the nut can rust not only in the thread area, but also in the area where it contacts the product. Sometimes even the puck doesn't help. The connection becomes monolithic over time. It takes a lot of work to take it apart.

The bolt has become stuck over time

There is often a situation where fasteners on mechanisms last for years before disassembly. During this time, it manages to stick so strongly to the body of the structure that the strength of the connection can be compared with a welded one. The most difficult to unscrew in these situations are the hardware that is exposed to heat.

Car enthusiasts and car service mechanics know how difficult it is to unscrew the exhaust tract fasteners on a muffler or resonator. Sometimes any means of moving a stuck bolt are powerless. All that remains is to destroy the connection using one of the mechanical methods.

METHOD #1: Drill

How it works: can be used instead of a screwdriver if the latter does not cope with the task. Let's say it just doesn't have enough power. The drill will obviously be more powerful. We clamp the required bit into the drill holders and, pressing firmly on the tool so that the contact is maximum, so as not to lick the slots, we press the treasured button.

Why it didn’t work: the advantage of this method is convenience. Minus - the power may not be enough to remove rust from the turns of a bolt or nut.

How to unscrew a hex or sprocket head bolt

In the automotive industry and other equipment, hex tool bolts are often used. How to turn out a torn cap that has broken edges:

- Make a horizontal notch on the head with a grinder or file. In this case, a strong screwdriver is used to unscrew the broken screw.

- Using a special TORX sprocket, which is driven into the head. The nozzle is selected in size, slightly larger than the torn cap, for a strong connection between the walls.

- A set of extractors that can be purchased at a hardware store. Before using the extractor, a hole is drilled with a drill in the base of the bolt, then the extractor is inserted, and the screw is removed with pliers or a special clamp.

- Using a left-handed drill with a slightly smaller hole diameter. Work with the tool is carried out in reverse mode, with this method it is possible to damage the thread.

How to unscrew a bolt with torn edges manually

Broken nuts are more difficult to unscrew, since during work there is a possibility of damage to the threads. The simplest way is to use chemicals; the surfaces are cleaned and treated with the product for 15 minutes. If the edges are torn off, it is impossible to use a wrench or socket. In such cases, a chisel is used to destroy the main part of the nut, then removed and replaced with a new nut.

How to remove a bolt if the head has broken off

A broken head of the structure can cause a lot of trouble during work. How to act in such a difficult situation without resorting to using a serious tool. If the element is small, it is possible to make a notch with a grinder, the recess of which will allow the use of a screwdriver with sharp edges. To perform more complex work, you will need an extractor, drill and reamer. The base of the threaded connection is drilled exactly in the middle, after making the hole, the tool is screwed in counterclockwise.

https://youtube.com/watch?v=PoJ4X-xN2i4

When performing sequential actions, unscrewing a damaged structural element will not be difficult even for those who are encountering this problem for the first time. It is necessary to correctly assess the situation and use a good quality tool for a productive result.

How to drill out a broken bolt

A drill made of high-quality material is used for the work. The size must be selected in accordance with the torn edges; the diameter of the drill should not be larger than the hole. A high-quality drill has a higher price, but its use eliminates rapid wear and the possibility of breakage during operation.

You should use the tool slowly, and before completing the task, correctly assess the situation. It is necessary to monitor the position of the tool during operation; drilling is carried out strictly in the center, without deviations in different directions.

METHOD #3: Hacksaw

How it works: if the bolt head has become unusable, there is a very slim chance that you will still be able to cope with it using more or less improvised means. You can use a hacksaw to cut a slot on the head of the bolt and try to turn it with a screwdriver. The screwdriver should have a large handle for maximum possible torque.

Why it didn’t work: the chance that this option will help is 20 percent. In the remaining 80% of cases, the bolt will be completely broken. Oh, yes, another option is not suitable for all types of bolts. If the head fits flush with the surface, you won't succeed.

Self-tapping screws with stripped splines (asterisk)

If overheated screws are unscrewed/twisted a couple of times, their edges lose their sharpness, the screwdriver turns, but the screw itself remains in place. If it “sits” in wood, plaster, chipboard or other similar, not too hard materials, you can put a thin elastic band (for example, for hair) under the screwdriver. Due to the elastic force, a tighter fit is achieved to the remaining edges, which helps to move the self-tapping screw from its place. Other methods are more “traumatic”:

- Cut grooves inside the “licked” funnel using a flat-head screwdriver and unscrew. This method is quite dangerous: if the walls of the “funnel” are too thin, there is a chance that the screw head will simply crumble from the effort. All that remains is a screw that cannot be unscrewed. It’s already difficult to unscrew such a self-tapping screw

- Drill and unscrew using a small diameter extractor.

- Take a chisel and grind it to the size of the cap. Place it on the cap, hitting it well with a hammer a couple of times. A new cap is formed and, at the same time, existing rust may crumble (if the screw is stuck in the iron). Using the same chisel, try to move the stubborn screw from its place. To make the process easier, you can drop oil on wood or WD40 on metal.

- Drill out the material around the cap, take a tube with an internal diameter slightly larger than the diameter of the cap, and put it on the cap. Pour glue inside. When the glue hardens, unscrew the tube.

Unscrew the self-tapping screw with torn edges (cross)

The remains of a bolt or stud without a head can be unscrewed as follows: cut a left-hand thread in the remaining body, drip “moment” glue, screw in the left-hand tap, and leave for an hour. Apply some oil to the main thread and leave for an hour. When the glue sets, unscrew it. If the remains of a self-tapping screw are stuck in the wood, it is easier to seal this hole and install another fastener nearby.

How to unscrew a hex without a key

Other ways to unscrew a bolt without a hexagon are as follows:

- If the size of the bolt is not too small, you can use a chisel or an ordinary hammer: they strike at an angle in the direction of unscrewing the fastener.

- Method using a spanner or gas wrench.

- If you have a problem with how to unscrew a “licked” hexagon, you can use a wrench with an attachment. The bolted connection is unscrewed using a hammer mechanism.

- Method of using welding: a small amount of metal with a nut or any piece of reinforcement is welded to the fastener, with the help of which it is then unscrewed.

- The extreme measure for unscrewing hex hardware with an internal axis is to completely dismantle the fastener, when cuts are made with a hammer and the fastener is disassembled.

Saw

Sometimes it is simply impossible to unscrew it without destroying the bolt. | Photo: ngo.tech-obzor.com.

When repairing a car, it often happens that the use of non-destructive methods does not give results. In this case, there is only one thing left to do: remove the problematic nut or bolt. There are many different methods here: from a chisel and a hacksaw to a grinder and a special tool - a “nut splitter”. In any case, no matter what is done, part of the fasteners will be hopelessly damaged.

Unscrewing a rusty bolt or nut can be quite nerve-wracking.

Read also: Colors of phase wires according to new rules

A person who has never faced the problem of how to unscrew a rusty, soured bolt or a tightly stuck nut cannot even convey how much time, effort and nerves this sometimes seemingly futile task can take. Sometimes you just give up, and the only way out seems to be the “grinder”, which allows you to resolve the issue, albeit radically, but quickly. But often even she is not able to help and threatens only to aggravate the situation, creating problems of a different kind.

So is it possible to unscrew a problematic bolt or rusty nut without resorting to emergency measures? Car enthusiasts know this issue best. They are the ones who most often encounter similar situations and can give practical advice by sharing successful experiences and recipes from their own arsenal of remedies. Let's look at the available options.

Methods for unscrewing bolts, screws, screws with licked edges

If the usual method fails to unscrew the fasteners whose edges have licked off, you can use one of several proven options.

Gas key

This method is used when unscrewing bolts, since they have a protruding head that you can grab onto. For this:

- Clean the bolt head.

- Lubricate the joint with kerosene or diesel fuel, a liquid like WD-40 works well, and leave for 15–20 minutes.

- Unscrew the bolt. They do this with a gas wrench. With its help, a lot of force is created and it is possible to grip even a round head well.

The disadvantage of this method is that it is not always possible to get a gas wrench to the desired bolt.

Cutting new edges

If the bolt is large, then using a grinder you can cut new edges on it. It is enough to make only 4 of them and use a smaller key to unscrew the bolt. You can cut new edges on a bolt with a file, but this is more difficult and takes longer. You can make a cut on the head of a screw or screw using a hacksaw or grinder.

Hammer and chisel or impact screwdriver

This option is more suitable for licked nuts or fairly large screws. The chisel is pressed against the head of the fastening element and, hitting it with a hammer, the screw or nut is gradually turned. Small screws or screws can be removed using an impact driver and a hammer. After loosening the fastening, the work is done with a regular screwdriver.

Band or piece of rubber

In this case, use a small part of a medical tourniquet or a piece of thick rubber. The selected material is placed on top of the head of the screw or screw, after which it is pressed with a screwdriver and gradually turned. The presence of rubber will help increase friction and solve the problem.

Extractor

An extractor is a special tool that is used to unscrew screws, bolts or screws with licked or broken heads.

The order of its application:

- Using a thin drill, a small hole is made in the head. In some cases, the extractor can simply be driven into the licked screw slot.

- Select an extractor of the required diameter. Drive or screw it into the prepared hole. This depends on whether a regular or screw tool is used.

- Unscrew the bolt.

Video: unscrewing a licked screw using an extractor

Regular or left hand drill

Left-handed drills with counterclockwise rotation are available for sale. They improve tool centering and reduce the load on the drill, which gives higher productivity and drilling accuracy. By inserting such a tool into a drill, you can unscrew a screw or screw with a licked head. If you don’t have a left-handed drill, you can try to drill out the stuck fasteners using a regular one. In this case, you need to take a drill whose diameter is smaller than the diameter of the bolt or screw

You must act carefully so that you do not have to cut threads for new fasteners later.

A nut of the appropriate diameter is fixed to the head of the problematic screw or screw using epoxy glue or glue called “cold welding”. After the glue secures it securely, use a wrench to turn the nut and unscrew the screw or screw together with it.

Welding

If you have a welding machine nearby, you can fix a new nut on the head of a bolt or screw by welding it. After this you can immediately unscrew it.

Solder and soldering iron

If you need to unscrew a small screw or cog, use a soldering iron and solder:

- Heated solder is dripped onto the head of the fastener with licked edges.

- While the tin has not hardened, insert a screwdriver into it and wait a few minutes.

METHOD #5: percussion instrument

How it works: An impact drill looks like a regular drill, but it can not only unscrew bolts, but also work as an impact tool. In our case, the impact action can weaken corrosion, paint trapped between the coils, etc.

Why it didn't work: This method was overheard on a garage forum. The downside is that the bolt heads may suffer during shock loads and become unusable. This is usually what happens.

Step-by-step instructions for unscrewing a bolt

The methods presented below will help solve the problem of unscrewing fasteners for various types of damage.

With damaged edges

The experience of specialists will tell you how to unscrew bolts with torn edges. To do this, several effective methods are used at once. The speed of work is affected by the location of the fasteners, the availability of the necessary tools and the availability of hardware. It is recommended to use each of the following methods in turn until the damaged hardware is completely dismantled:

- Using a sharp chisel. This method is only applicable when a large bolt has broken. Access to fasteners will be a significant argument. To remove a part with a broken edge, you will need a chisel and a hammer. You need to attach a chisel to the head of the bolt tangentially and hit it with a hammer. This approach can be called the simplest. But such actions are not suitable in all cases.

- A more effective method is to use an adjustable key. If there is free access to the hardware, a universal key will most likely be able to tear the element out of place. The principle of operation is to use special notches that are located on the working surface. The key securely clamps the head and allows you to unscrew the smallest bolts. A prerequisite is that the adjustable key must be new.

- A spanner wrench may also be a necessary accessory. Sockets for unscrewing bolts with torn edges quite often cope with the most difficult cases. The key profile should consist of 12 edges, and inside there should be an asterisk socket. The head should be one size smaller than the bolt. The part is carefully placed on the fastener using a hammer and the hardware begins to unscrew.

- Hacksaw for metal. The device allows you to cut a recess for further unscrewing of the hardware using a flat-head screwdriver. In this case, the depth should be 25% less than the height of the hardware head.

- Using a grinder or a file, you can make new edges for a smaller key size. Using an open-end wrench, you can make only 2 faces parallel to each other.

- The backup option is to use a welding machine. In this case, an additional nut must be welded to the bolt.

Thread damage

A common problem is thread damage. As a result, the bolt rotates in the seat and is not removed outward. There is a proven way to unscrew a bolt with broken threads. Use a flathead screwdriver to lift the fastener. To do this, a screwdriver is placed between the head of the hardware and the base, after which the fastening element is lifted up with force. Then you need to start unscrewing until it is completely removed from the seat.

Experts also recommend pushing the fastener from the reverse side, provided that the hole is through the sample. If it is not possible to dismantle the nut due to a broken thread, this place is cut off with a grinder.

Asterisk and hexagon

Fastening materials with asterisk heads, as well as hexagons, have become widespread. Such hardware is reliable and easy to use. However, such parts can also fail.

If the edges are damaged, you need to proceed in the same way as in the case of simple bolts. The only difference is that dismantling is carried out using special keys with characteristic shaped edges - hexagon or asterisk.

For a screwdriver

If access is limited, you can make a notch on the bolt. A chisel or grinder will come to the rescue. Having made a cut, they try to unscrew the hardware with a screwdriver. If this method does not bring the desired result, place the screwdriver at an angle and hit the handle with a hammer. Before unscrewing the torn bolts, it is recommended to apply a lubricant. The applied force must be in a counterclockwise direction.

Detailed video on how to unscrew damaged bolts:

Why is a rusty bolt or nut difficult to unscrew?

Any metal fastener inevitably undergoes corrosion and rust over time. The process is accelerated if the bolts and nuts are often exposed to aggressive environments:

- contact with water;

- interaction with chemicals, including detergents;

- street dirt, dust, caustic salts - they accelerate the corrosion process.

Despite special protective coatings against rust, if the surface of the fastener has been even slightly damaged, then over time the process of destruction is inevitable.

After some time, the rusted bolt must be removed and replaced, but a problem often arises - it will not unscrew. Due to the oxidative processes of the metal, rust grows on fasteners and parts and the surfaces “grab” together. If this process develops at the location of the bolt thread, then the situation becomes even more difficult.

The problem of rusted bolts and nuts

It is important to remember that the fasteners in question are made of metal. This means that the bolt and nut are susceptible to corrosion.

Products used in cars are resistant to moisture, rain, fog or snow. All this can become a catalyst for the formation of rust and problems with twisting products.

No less difficult is created by sand, salt or chemical compounds that are sprinkled on the road surface in winter.

Special reagents have a negative effect on body metal and accelerate the formation of rust on the threaded elements of the car.

As for sand, it carries certain risks at any time of the year - winter and summer.

Small grains of sand hitting a metal surface leave microcracks on it, which only accelerates the corrosion process and complicates the maintenance process for the car owner.

Another risk factor is the vehicle’s cooling system, which may lose its seal during operation.

If water is flooded inside, if a leak occurs, it gets into the joints and accelerates the process of scale formation and problems with unscrewing.

No matter how the car owner protects the car, each of the listed factors has a negative impact.

That is why it is important to know how to unscrew a rusty nut or bolt without creating additional problems for yourself (for example, damaging adjacent and expensive elements of the vehicle)