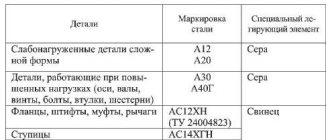

Group A steels are classified as structural carbon steels of ordinary quality, but, most often, endowed with increased machinability. Strictly regulated mechanical characteristics and properties play a role here against the background of relative freedom in terms of the chemical composition of the metal. As a rule, steel A is used to create components and entire structures without initially undergoing forging, stamping or other hot or heat treatment. As a result, hot-rolled steel grade A always retains its original properties.

Steel A12 and A20

The most popular materials of this class are considered to be alloys A12 and A20, which are actually analogues of each other. These are structural materials of increased machinability, characterized by low cost and high manufacturability. This alloy is supplied to industrial enterprises in the following form (in accordance with GOST):

- GOST 1414-75, GOST 2879-2006, GOST 2590-2006, GOST 2591-2006 – long and shaped rolled products

- GOST 1414-75 and GOST 14955-77 – silver and ground rods.

- GOST 8559-75, GOST 1414-75, GOST 8560-78 – calibrated rods

Automatic steel marking

According to the regulatory requirements of GOST 1414-75, it is designated with a capital letter A, which indicates that this material is recommended for use for processing using automatic machines. After the letter A there is usually a number that indicates the total carbon concentration (units of measurement are hundredths of a percent). If the material contains any additional additives (manganese, selenium, chromium or lead), then this is also indicated in the name of the material according to the GOST nomenclature.

Main grades of automatic steel

| Brand | Additional impurities (besides phosphorus and sulfur) | The main parts that are made from this alloy |

| A11 | None | Bolts, nuts, chains, forks for automotive clutch mechanisms |

| A12 | None | Axles, shafts, bolts, screws, nuts and various small items of complex shape that require precise processing |

| A20 | None | Small parts of various machines and mechanisms of complex shape that require precise processing |

| A30 | None | Parts of complex shapes and sizes, various hardware (these can be screws, bolts, nuts, rings, gears, etc.) |

| A35 | None | Various parts of circular or complex shapes that require precise processing on automatic machines (gears, screws, bolts, rings, chains, etc.) |

| A35E | Selenium | Matrices and bandages |

| AS14HGN | Lead, manganese, chromium, nickel, silicon | Various automotive parts (bushings, shafts, gears) |

| AS19ХGN | Lead, manganese, chromium, nickel, silicon | Gear transmission mechanisms |

| AS35G2 | Manganese, nickel, silicon; in small quantities - copper, chromium, lead | Oil pump rollers |

| AC40X | Chromium + in small quantities - lead, copper, nickel | Axle rings for passenger cars |

Mechanical and physical properties of A12 steel

The hardness of this alloy is HB 10-1 = 160 MPa. The material is flake-sensitive and therefore requires strict adherence to smelting technology. However, it is not prone to temper brittleness and is not used as part of welded structures. The basic mechanical and physical properties of A12 steel can be found here:

Steel 12ХН3А - definition of steel grade, GOST, material characteristics

Steel grade - 12ХН3А

Standard - GOST 4543

Substitute - 12ХН2, 20ХН3А, 25ХГТ, 12Х2Н4А, 20ХНР

Steel 12ХН3А

contains an average of 0.12% carbon,

X

- indicates the chromium content in steel is approximately 1%,

H3

- indicates the nickel content in steel is about 3%, the letter

A

at the end of the brand means that the steel belongs to the high-quality category.

Steel 12ХН3А is used for the manufacture of large critical parts. Steel products are subjected to carburization followed by heat treatment; sometimes this steel is used for non-cemented parts. Steel with high strength, toughness and hardenability.

Gears, axles, shafts, worms, claw couplings, piston pins and other parts are made from steel 12ХН3А

| Mass fraction of basic chemical elements, % | ||||

| C - carbon | Si - silicon | Mn - manganese | Cr - chromium | Ni - nickel |

| 0,09-0,16 | 0,17-0,37 | 0,30-0,60 | 0,60-0,90 | 2,75-3,15 |

| Temperature of critical points, °C | |||

| Ac1 | Ac3 | Ar1 | Ar3 |

| 715 | 773 | 659 | 726 |

| Technological properties | |

| Forging | Forging temperature, °C: beginning 1220, end 800. Sections up to 100 mm are cooled in air, sections 101-300 mm are cooled in a pit. |

| Weldability | Limited weldability. Welding methods: manual arc welding, automatic arc welding, resistance welding. |

| Machinability | In the hot-rolled state at HB 183-187 and σв = 590 MPa: Kv hard alloy = 1.25 Kv high-speed steel = 0.95 |

| Flock sensitivity | Sensitive |

| Tendency to temper brittleness | Inclined |

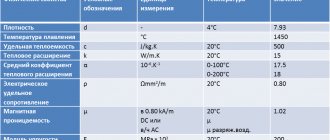

| Physical properties | Test temperature, °C | |||||||||

| 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | |

| Modulus of normal elasticity E, GPa | 200 | — | — | — | — | — | — | — | — | — |

| Modulus of elasticity under torsional shear G, GPa | — | — | — | — | — | — | — | — | — | — |

| Density ρn, kg/m3 | 7850 | 7830 | 7800 | 7760 | 7720 | 7680 | 7640 | — | — | — |

| Thermal conductivity coefficient λ W/(m*K) | — | 31 | — | — | 26 | — | — | — | — | — |

| Electrical resistivity ρ, nOhm*m | — | — | — | — | — | — | — | — | — | — |

| 20-100 | 20-200 | 20-300 | 20-400 | 20-500 | 20-600 | 20-700 | 20-800 | 20-900 | 20-1000 | |

| Linear expansion coefficient α*106, K-1 | 11,8 | 13,0 | 14,0 | 14,7 | 15,3 | 15,6 | — | — | — | — |

| Specific heat capacity c, J/(kg*K) | — | — | — | 528 | 540 | 565 | — | — | — | — |

tekhnar.ru

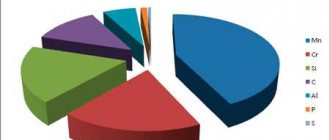

Chemical composition of the alloy

The number 12 in the brand designation traditionally indicates the average percentage of carbon, expressed in hundredths of a percent. The chemical composition of A12 steel is the following set of elements:

- C – 0.08-0.16%

- Mn – 0.7-1.1%

- Si – 0.15-0.35%

- P – 0.08-0.15%

- S – 0.08-0.2%

- Cu – no more than 0.25%

Calibrated rolled structural steel with high machinability by cutting GOST 1414-75

| Catalog/roll calibrated st.A 12 GOST 1414-75 |

Calibrated rolled steel GOST 1414-75 A12, free-cut steel is made by cold rolling or drawing from hot rolled steel (roll).

Unlike long hot-rolled steel, calibrated rolled free-cut steel has more accurate cross-sectional dimensions and metal surface quality. These qualities allow it to be used for processing on high-performance automatic lathes, as well as for cold stamping on cold heading equipment. High precision and surface quality make it possible to significantly reduce metal consumption during further processing. Calibrated rolled products GOST 1414-75 from structural steel with high machinability by cutting the use of automatic steel in the form of a circle, hexagon: in mechanical engineering, in the automotive industry.

Rolled products calibrated GOST 1414. Steel grades and chemical composition.

| Steel groups | steel grade | Content of chemical elements, % | ||||||

| C | Si | Mn | Cr | Pb | S | P | ||

| Carbon sulfur | A11 A12 A20 A30 | 0,07-0,15 0,08-0,16 0,17-0,24 0,27-0,35 | no more than 0.10 0.15-0.35 0.15-0.35 0,15-0,35 | 0,80-1,20 0,70-1,10 0,70-1,00 0,70-1,00 | — — — — | — — — — | 0,15-0,25 0,08-0,2 0,08-0,15 0,08-0,15 | no more than 0.10 0.08-0.015 no more than 0.06 no more than 0.06 |

| Sulfide-manganese lead containing | AC14 | 0,10-0,17 | no more than 0.12 | 1,0-1,30 | — | 0,15-0,30 | 0,15-0,30 | no more than 0.10 |

Mechanical properties of rolled products

| steel grade | Size, mm | Type of processing | Yield strength N/mm2(kgf/mm2) | Temporary tensile strength N/mm2 (kgf/mm2) | Relative extension, % | Relative narrowing, % | Hardness | |

| imprint diameter, mm, not less | NV, no more | |||||||

| A11 | all sizes | calibers | 309(40) | 490(50) | 10 | — | 4,2 | 207 |

| A12 | 30 or less | calibers carbon deposits. | — | 510(52) | 7 | — | 4,1 | 217 |

| A12 | over 30 | calibers carbon deposits. | — | 460(47) | 7 | — | 4,1 | 217 |

| A20 | all sizes | calibers carbon deposits. | — | 530(54) | 7 | — | 4,1 | 217 |

| A30 | all sizes | calibers carbon deposits. | — | 540(55) | 6 | — | 4,05 | 223 |

| A40G | all sizes | calibers annealed | — | 590(60) | 17 | — | 4,0 | 229 |

| AC14 | all sizes | calibers carbon deposits. | 390(40) | 490(50) | 10 | — | 4,20 | 207 |

Acceptable surface defects

| Surface quality group | Quality | Acceptable surface defects | The greatest depth of defects |

| A | h9 | Individual minor risks of mechanical origin | Established by agreement between the manufacturer and the consumer |

| h10 | maximum deviations | ||

| B | h10 | Individual small risks of mechanical origin, scale residues, fingerprints, rippling, shallow stripping, traces of abrasive cleaning | Limit deviations |

| h11 | |||

| h12 | |||

| IN | h10 | Isolated small risks of mechanical origin, scale residues, fingerprints, rippling, shallow stripping, traces of abrasive stripping, individual small rolled out and loosened bubbles and dirt (hairs) | Limit deviations |

| h11 | |||

| IN | h12 | Isolated small risks of mechanical origin, scale residues, fingerprints, rippling, shallow stripping, traces of abrasive stripping, individual small rolled out and loosened bubbles and dirt (hairs) | Limit deviations for quality h12 |

| Limit deviations for quality h11 |

Calibration (calibrated rolled products) is used for the manufacture of critical parts in the automotive and mechanical engineering industries.

Calibrated rolled products have the highest possible dimensional accuracy and high technical characteristics of surface quality; rolled products are produced in sizes from 4 to 16 mm - in coils, in sizes from 5 to 65 mm - in rods from steel grades A12 (carbon, sulfur).

Due to the increased sulfur content in the range of 0.08-0.20%, the machinability of rolled products by cutting is improved. Temporary tensile strength depending on steel grades from 460 to 510 N/sq.mm

How to buy calibrated rolled steel GOST 1414-75 st.A 12 at low prices:

- fill out the simple “Place an order” form at the top of the page;

- call on the phone +7;

- send your application by email;

Terms of sale:

- Sales of metal products wholesale and retail;

- Cashless payment by transferring funds from a bank account;

- Possibility of deferred payments;

- Free consultations from our specialists;

- We provide packaging services according to customer requirements;

- We are ready to produce products of any complexity to order according to customer drawings.

Delivery terms:

- Products are delivered from the warehouse based on availability;

- If necessary, we can provide a storage service;

- We are ready to provide a discount on delivery according to the terms of partnership programs of transport companies;

- Possibility of self-pickup of goods from warehouses.

Guarantees:

- All products are certified and released after technological control;

- Hardware, fasteners, ropes, mesh, wire, electrodes and other metal products comply with GOST and TU;

- Possibility of returning goods in accordance with the legislation of the Russian Federation;

Delivery within the Russian Federation: Moscow, St. Petersburg, Arkhangelsk, Astrakhan, Barnaul, Belgorod, Bryansk, Vladimir, Volgograd, Vologda, Voronezh, Yekaterinburg, Ivanovo, Izhevsk, Yoshkar-Ola, Kazan, Kaluga, Kirov, Kostroma, Krasnodar, Kurgan, Kursk, Lipetsk, Omsk, Orenburg, Penza, Perm, Pskov, Rostov-on-Don, Ryazan, Samara, Saransk, Saratov, Sevastopol, Simferopol, Smolensk, Stavropol, Tambov, Tver, Tomsk, Tula, Tyumen, Ulyanovsk, Ufa, Chelyabinsk, Yaroslavl, etc.

The information presented on this website contains a catalog of reference information on more than 3,000 types of metal products, is for informational purposes only, and can be used in various areas of enterprise activity.

Application of grade A steels

A12 (A20) steel is widely used in the creation of industrial equipment: bushings, rollers and axles are cast from it, and gears and gears are made from it. In general, this material is excellent for the manufacture of small bolts, screws and other small parts - complex shapes, lightly loaded, intended for processing using automatic machines. A rather important characteristic of the alloy can be considered its compliance with increased requirements for the dimensional accuracy of the resulting parts and the quality of their surfaces. In other words, this steel is a material with increased machinability.