Rolling of various types of metals is considered a popular technological operation that is performed at metalworking enterprises. The most popular areas where this technology is used are construction and repairs. You can make rollers for sheet metal yourself. However, to do this, you need to become familiar with the operating principle of this equipment, its design, strengths and weaknesses.

Rollers for sheet metal bending

Where is it used?

This type of metal deformation is used for processing and production of various products. For example, when preparing finished products for stamping or as primary processing. Not only sheet metal or alloys are subject to rolling, but also pipes, rods, profiles, polymer materials made from rubber compounds, plastics or plastics. After rolling or cold stamping, the structure of the material becomes more dense, and its technical characteristics are significantly improved. Depending on the type and settings of the machine, during processing, products are obtained in the form of:

- cylinder;

- oval;

- cone;

- square.

Rolling equipment is used today to produce a wide range of products for various fields and fields of activity:

- cylindrical shells;

- composite panels;

- wide band saws;

- channels for air conditioners;

- profiled metal corners;

- decorative building elements.

Rolling is necessary not only for the manufacture of new products, but also for various preliminary, additional and subsequent types of processing of metal and composites - compaction, squeezing or flattening of workpieces. Using rolling equipment, the surface of the workpieces acquires a uniform gloss, unevenness and roughness are removed, and the material becomes the same thickness over the entire plane. Considering that the workpieces can have different shapes and configurations, to create the required design, the sheet is fed in one of three directions.

- Transverse – when rolling long elements of open rolled pipe.

- Longitudinal – for processing short elements and open pipe blanks.

- Screw - for the production of products that do not require subsequent welding of the joint.

Thanks to the development of modern technologies, the rolling method is used both in enterprises and at home using miniature compact hand-held machines and special tools. In this case, you can make the equipment yourself with your own hands. In production workshops, professional large-sized equipment with an electric or hydraulic drive is used for rolling materials.

Principle of operation

Shaft location

First, you should familiarize yourself with the basic rules for processing grain crops using this equipment. A correctly selected operating mode will significantly reduce costs and achieve optimal processing quality. To do this, you need to study the characteristics of a specific model.

The roller machine must be part of the equipment complex. Before bulk material enters for processing, it must be properly prepared - cleared of debris and dried. Only after this, through a special feed line, does it enter the roller machine for grinding. This usually happens using a screw conveyor.

Stages of material processing using rollers.

- The optimal operating mode of the machine is established. This refers to the speed of rotation of the shafts, as well as determining the angle between their surfaces. During processing, these parameters may change if required by the production process;

- Connecting the feed auger and supplying bulk material;

- The grain enters the feed unit. Through it it flows to the distribution bar. With its help, the material is uniformly poured over the entire surface of the processing shafts.

- Grinding. Can be performed with one, two or three pairs of rollers. Some of them have a corrugated surface. Such models are intended for primary grinding. If it is necessary to improve the quality of processing, use shafts with corrugations of small height. But at the same time they are located much more often than in the primary block.

- The final stage is unloading the finished material.

To ensure maximum automation, the design includes mechanisms for monitoring the progress of work. With their help, the degree of grinding is regulated and excessive overload on the processing shafts is prevented. Additionally, there is a transparent window on the front of the machine for visual control of the process.

An important parameter is the frequency of arrangement and shape of the grooved shafts. They are often made wedge-shaped so that when the grains engage with each other, they are subjected to maximum pressure, and as a result, better grinding is performed.

BENDMAK

| Hand rollers CZ 46-10/0.8 | Working length 1050 mm | Metal thickness 0.8 mm | In stock | Sheet metal bending 68 436 q 1,915 BYN 326,980 KZT 60,600 KGS 378,248 AMD $778,659 € |

| Hand rollers CZ 56-10/1.0 | Working length 1050 mm | Metal thickness 1.0 mm | In stock | 72 583 q 2,031 BYN 346,794 KZT 64,273 KGS 401,168 AMD $826,699 € |

| Hand rollers CZ 56-12/0.8 | Working length 1250 mm | Metal thickness 0.8 mm | In stock | 96 519 q 2,701 BYN 461,158 KZT 85,468 KGS 533,463 AMD $1,098,930 € |

| Hand rollers C 46-10/0.8 | Working length 1050 mm | Metal thickness 0.8 mm | In stock | 89 433 q 2,502 BYN 427,302 KZT 79,193 KGS 494,299 AMD $1,017,862 € |

| Hand rollers C 56-10/1.0 | Working length 1050 mm | Metal thickness 1.0 mm | In stock | 97 901 q 2,739 BYN 467,761 KZT 86,692 KGS 541,102 AMD $1,114,944 € |

| Manual rollers CY 70-10/1.8 | Working length 1050 mm | Metal thickness 1.8 mm | Delivery in 60 days | 175 410 q 4,909 BYN 838,092 KZT 155,327 KGS 969,497 AMD $1,996 1,691 € |

| Hand rollers CY 90-10/3.3 | Working length 1050 mm | Metal thickness 3.3 mm | In stock | 215 763 q 6,038 BYN 1,030,894 KZT 191,060 KGS 1,192,529 AMD $2,455 2,080 € |

| Manual rollers CY 75-12/2.0 | Working length 1250 mm | Metal thickness 2.0 mm | In stock | 196 494 q 5,499 BYN 938,829 KZT 173,997 KGS 1,086,029 AMD $2,236 1,894 € |

| Hand rollers CY 90-12/3.0 | Working length 1250 mm | Metal thickness 3.0 mm | In stock | 228 033 q 6,381 BYN 1,089,519 KZT 201,925 KGS 1,260,346 AMD $2,595 2,199 € |

| Manual rollers CY 70-15/1.2 | Working length 1550 mm | Metal thickness 1.2 mm | In stock | 201,765 q 5,646 BYN 964,013 KZT 178,665 KGS 1,115,162 AMD $2,296 1,945 € |

| Hand rollers CY 90-15/2.5 | Working length 1550 mm | Metal thickness 2.5 mm | In stock | 245 574 q 6,872 BYN 1,173,328 KZT 217,458 KGS 1,357,296 AMD $2,795 2,368 € |

| Manual rollers CY 95-20/1.8 | Working length 2050 mm | Metal thickness 1.8 mm | Delivery in 60 days | 298 198 q 8,345 BYN 1,424,761 KZT 264,057 KGS 1,648,151 AMD $3,394 2,875 € |

Manufacturers

Rules for selecting and operating a metal laser engraver

The following manufacturers are especially popular:

- Metalmaster - models from this company stand out for their reliability and durability. They make it possible to work with metal sheets, fittings, and pipes. Well-known models are MSR 1215 and MSR 1315.

- Stalex is another well-known company whose equipment is valued by customers. It is used when processing sheets of different thicknesses. The housings of this equipment are made of durable steel grades that have an increased corrosion resistance.

- Anchor Corvette. Not suitable for mass production due to low reliability, but for a small workshop they are a good option.

At the same time, buyers highlight companies such as JET, PRINZING, SAHINLER, SCHWARTMANNS

It is important to consider the technical characteristics and capabilities of the equipment

Design Features

Rollers (they are also called) allow controlled plastic deformation of sheets made of metal. Operating on the rolling principle, such a device is equipped with several shafts, which, when a metal sheet or pipe passes between them, changes their configuration. Serial models of such sheet bending equipment and homemade rollers work on the same principle and, accordingly, have a similar design. Let's look at the main elements of the machine.

Device of manual three-roll rollers

Bed-base

This is a load-bearing element that ensures the stability of the rollers, as well as the correct relative position of all their components.

Two vertical support posts

In their bearing units, shafts are installed, of which there can be only two (two-roll machine), three (three-roll machine) or even four. In the design of most rollers equipped with three working bodies, the two lower rollers can change their position only in the horizontal plane, and the third, a thrust roller located on top, is also adjustable in height. In addition, the upper roller for removing the finished part is equipped with a quick tipping mechanism.

Upper pressure roller lifting mechanism

Rolls

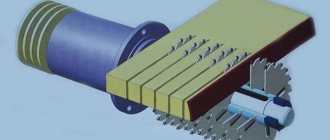

In the process of processing a sheet blank, the rolls must rotate, for which any one is equipped with a drive mechanism, which can be chain or gear. The operating scheme of these is such that only the lower rollers are driven into rotation, and the upper one, tightly pressed against the surface of the workpiece, rotates under the influence of friction forces.

Roll operation diagram

Manual

These are the simplest rollers, which are most often made by hand. To drive such devices, chain and gear drives can be used, the parameters of which should be selected depending on the characteristics of the material being processed. Hand rollers, taking into account the fact that significant physical effort is required to operate them, are used primarily for processing small workpieces.

Electrically driven

In terms of their performance, such rollers belong to the average category. Electrically driven three-roll rollers, due to the sufficiently high power of the drive mechanism, make it possible to process workpieces of considerable size.

Electromechanical rollers are often a modification of a manual machine to which a motor and control panel have been added.

Hydraulically driven

This is the most powerful of all rolling equipment on the market today. Due to the fact that the hydraulic drive with which such rollers are equipped allows their working bodies to act on the workpiece with great force, such a device can effectively process metal sheets of even very significant thickness.

Among industrial hydraulic rollers there are even such giants

The quality of processing performed on rollers is primarily influenced by the characteristics of the rollers. Since the rolls experience significant mechanical loads during operation, high-strength tool steel is used for their manufacture. In addition to the mechanical impact, when processing sheet blanks of considerable thickness, which are preheated to give them greater plasticity, the rollers also experience thermal impact. It should be noted that such an impact, which can be very significant, has a rather negative impact on the operational characteristics of the rolls.

Design and principle of operation

A roller machine consists of several key elements, after studying which its operating principle will become clear. These include:

- The supporting element, or as it is also called, the frame. Can be made of sheet steel or cast iron.

- Rollers, which can be from two to 4. During self-production, craftsmen recommend installing 3 rolls.

- Drive - electric or hydraulic (on manual models a handle is installed to control the rollers).

- Control Panel. Various sensors and a monitor are installed on CNC systems.

Working principle step by step:

- Initially, a sheet of metal is prepared that will be rolled. It should be smooth, without cracks or grooves. It is placed on two lower rollers. They are separated in different directions in advance.

- After this, the master lowers the third shaft towards the sheet in order to securely clamp it between the working parts.

- The lower rollers begin to rotate under the influence of a drive or human manual force. The sheet is moving. As it begins to move, it begins to bend around the rollers.

Gradually, the metal blank passes through all the working parts according to the given configurations until the product of the required shape is obtained.

CNC rollers in production

Mechanism design and operating principle

The main part of both factory-made and self-made roller machines is considered to be a heavy bed, which acts as a base. It is usually made of cast iron or thick steel sheet. The machine body, which includes from two to nine rolls, is attached to this powerful frame.

In some devices, these rollers are also equipped with a special groove, which makes it possible to bend not only metal sheets, but also use them for rolling pipes and rods.

Rollers are:

- Metal polished.

- Rubberized.

The technological capabilities of a roller mill are determined by its design features, in particular:

- sheet metal width;

- the diameters of the rollers, on which the radius of the part being manufactured directly depends;

- the thickness of the metal itself;

- distance between shafts (maximum measured);

- production of cone-shaped elements.

In addition to the above, there are many more factors that determine the performance of rolling machines and the ease of use.

Pipes are produced quite simply on a rolling machine:

- First of all, the prepared metal sheet is clamped with a special handle between the shafts (middle and outer);

- After this, using the third roller, the workpiece is pressed against it;

- Then the specialist starts the electric motor, or rotates the rollers with his own hands.

The whole process of work consists in the fact that the metal sheet, passing at a designated speed through the shafts, is bent under the required shafts.

To make pipes from a gutter with your own hands, it will be enough to purchase a roller machine for manual work. But the need for this type of purchase will disappear if you make such a device with your own hands.

Sheet metal rolling machine

The main component of the machine are rollers or rollers, which directly bend the metal sheet. There can be two, three or four of them, one of which is the main one, and the rest, rotating, carry out the rolling process. Three- and four-roll machines are more popular. The greater the number of rolls, the thicker the metal that can be deformed, and the productivity of such machines is almost twice as high. Four-roll machines have high rolling precision.

As a rule, most enterprises use three-roll bending machines with asymmetrically located rollers. In such machines, the lower and upper rolls are driven and for proper operation they are adjusted with a gap that is equal to the thickness of the metal or less, so that it does not slip during operation. Adjustment occurs by lowering or raising the lower shaft.

Types of machines

Professional machine ZM2

To achieve the required processing quality, it is necessary to correctly determine the machine model. This applies only to factory models, since homemade ones in most cases do not meet modern technological requirements.

After determining the required technical and operational characteristics, you can begin to select equipment. Often they try to purchase domestic machines, since they are reliable, and most importantly, they have the ability to purchase components. This is one of the determining parameters, since downtime of the production line in the event of emergency situations should be minimal.

Types of roller machines for grain processing of domestic production:

- flour milling They are used for high-quality grinding of grain crops or similar bulk materials. The most common models are A1-BZ-ZN and A1-BKhN. They are distinguished by the quality of the final product and have a maximum degree of automation;

- grinding machines. They are designed for secondary product processing and are used as additional equipment in production lines. The most popular and widespread is the ZM roller machine, which has a fairly high productivity rate.

The difference between these types of equipment lies in the quality of processing. Therefore, you should study in detail all the technological and operational parameters of a particular model. Usually, in addition to the roller machines, several more units are installed. With their help, optimal results are achieved.

For optimal grinding performance, it is recommended to install a detacher after the roller mill. This is a shock-erasing device.

Kinds

Hand rollers are used very often; they can be found even in the most ordinary home workshops. Such devices can be used to produce ventilation parts and other pipelines. Most often, hand rollers are used for single jobs, but the same tool is also used in industry. They allow you to significantly save on electricity bills. The main characteristics are:

- insignificant variety of metal processing options;

- the ability to perform various processing schemes without additional preparation;

- mandatory mechanical forces of the operator during operation;

- relatively low productivity;

- unsuitability for full-fledged conveyor production.

But for sheet metal of large thickness, that is, for sheets 3 mm and thicker, it is much easier to use electromechanical rollers. With this technique it is possible to produce gutters, pipes and cones on a large scale. Finished products are assembled from the structures obtained using such equipment. Sometimes fully finished small-sized products are made on electromechanical rollers. The main applications are:

- rapid bending of the sheet to the required radius;

- formation of stiffening ribs and recesses on blanks for pipes;

- preparing places where pipes will be connected;

- initial processing and defect detection of metal.

Very heavy work can be done on hydraulic rollers. They are often used to:

- compressors and their parts;

- billboards;

- tanks for liquids, gases and solids.

The thickness of workpieces processed using hydraulic equipment ranges from 3 to 70 mm. Their width varies from 1500 to 3000 mm. The drive in each machine is strictly individual. A three-roll rolling machine is much simpler, and some models of this kind can even be created independently. But such equipment is also supplied by various companies specializing in metalworking equipment. There are options with manual and electromechanical drive.

Cone rolling can be performed on almost any type of three-roll roller. But still, for this work, professionals advise using more advanced four-roll equipment.

Three-roll rollers are presented in the video below.

Main types of rollers and their purpose

Rolling machines in the modern world are very often found in many enterprises producing metal products. You can easily make such a device at home with your own hands. Using this mechanism, a specialist can make parts of various shapes from a metal sheet - cylindrical, oval or conical.

Rolling devices, which are now produced on an industrial scale, are capable of processing sheets of various types of steel, as well as copper, aluminum, brass, and cast iron.

There are three categories of rolling devices:

- Manual machine for rolling sheet metal. This type of device is manufactured in two versions: floor-mounted (when the flaring machine is installed on a stand), and desktop (when the unit is mounted on a workbench). To work on this type of manual rolling machine, you will have to put in a lot of physical effort, although the undoubted advantage is ease of operation and a very simple design, which allows you to preserve the reliability of the device for a long period of time.

- Electromechanical rolling machine. A device of this type has a gearbox in its components. It allows you to significantly increase the efficiency of such a unit. An electromechanical machine is used in industrial production to process metal sheets and to slightly change the configuration of rolled pipe.

- Roller machine with hydraulic drive. This type of machine is one of the most powerful and is very often used in enterprises of various fields. Compared to manual and electromechanical machines, it has many more working mechanisms in its design. These devices make the device more powerful. This type of equipment can bend even the thickest metal sheets (up to 8mm) without any problems.

Advantages of manual rollers:

- compactness of the device;

- low weight;

- good mobility;

- electrical efficiency;

- relatively low cost.

Types of sheet metal rollers

Sheet-leveling machines for working with metal workpieces can be different, the scope of their application depends on the technical characteristics and the range of tasks expected to be solved:

- the dimensions and diameter of the shafts depend on the type of structure, depending on this the radius of the possible bend will change;

- the length of the shafts determines the width of the workpiece that can be worked with at one time;

- the drive determines the thickness of the products suitable for processing.

Much will depend on the design features of the machines.

Machines are divided among themselves depending on technological capabilities and technical characteristics. Machines for working with metal can be divided into several main categories:

- two-roll;

- three-roll;

- four-roll.

The first type is the simplest. Their design is based on two working shafts and a rigid frame; the shafts are located parallel to each other. The one on top is always half the size. It is preferable to use steel as a material for it.

The workpiece is pressed by the lower shaft and scrolled, which gives the product the desired shape. The possibilities of bending metal are formed depending on the nature of the rotation of the shafts, which is why two identical machines can differ from each other in terms of efficiency. The machine is adjusted mechanically, so the radius of the product can be set in advance.

The second type can be divided into symmetrical and asymmetrical. The work involves the principle of rolling a workpiece sheet around one of the shafts, which is the main one in the design.

Electromechanical machines with three shafts are sometimes called power machines; they are more massive in design and have a higher tensile strength, unlike a manual drive. Such equipment can be used to manufacture products on an industrial scale. For home workshops, such designs are suitable for processing copper or aluminum up to 4 mm thick.

Four-roll rolling machines are designed with one more shaft at the very bottom, which makes bending the metal easier. This is the type of machine most often used for industrial processing. Here, the thickness of the blanks can reach 75 mm, the shape can be simple or geometrically complex - both can be accurately reproduced in the same way.

This is a professional tool for working with metal in every way.

Main technical parameters

An example of a homemade design

Often this type of equipment is used not only to complete large food processing plants, but also in farms and private households. In this case, simple models are used. Therefore, the choice of a specific type of machine and its characteristics should be approached with particular care. This is especially true for homemade equipment.

At the first stage, a performance indicator is determined. It indicates how much material the roller mill can process per unit of time. In this case, the quality of grinding is taken into account. Then you should find out the degree of automation of the process. This mainly relates to the configuration of the unit for loading and removing processed grain.

To select equipment, it is necessary to take into account the following characteristics:

- dimensions and weight. They determine the possibility of installing the machine in the workroom;

- type of loading block and its location in the structure. It is usually located at the top of the structure. It is important to decide on the configuration of the feed neck - it must fit the feed auger. Otherwise, you need to purchase or make an adapter;

- roller parameters. First of all, this is their diameter, length and quantity. It is also necessary to pay attention to the complexity of their replacement and configuration;

- power of the power plant;

- number of revolutions of the working rollers. To optimize the workflow, this parameter must be varied depending on the desired grinding result and processing speed.

For each model, the manufacturer sets requirements for the quality of the source material. The degree of its preliminary purification, humidity and specific gravity are taken into account. Therefore, the preparatory stage is no less important than the grinding process.

Typically the clearance range between rollers is 0.1 to 5mm. This is determined by the type of grain crops being processed, as well as the required quality of grinding.

Which rollers to choose?

Twin rollers

| Twin rollers have two shafts located one above the other. As a rule, the upper shaft is made of durable steel and has a small cross-sectional diameter. The lower shaft has a significantly larger diameter and is made of steel coated with a flexible elastic material (polyurethane, rubber). In this case, the diameter of the resulting pipe depends on the pressing force of the two shafts during rolling. The advantage of such rollers is the absence of straight untreated areas along the edges of the workpiece (without preliminary bending and trimming the edges). |

Three-roll rollers

Three-shaft rollers are the most common machines due to their variety of sizes, mature technology, and lower cost. They allow the production of pipes of various shapes, cones, gutters.

According to the relative position of the shafts, such rollers are divided into several types:

| Symmetrical shaft arrangement These rollers have a simple design and low price. The disadvantage is the inability to bend the edges of the workpiece. | Symmetrical adjustable shaft arrangement With this design, straight sections along the edges of the workpiece are minimized, so that the resulting pipes have an ideal shape. | Asymmetrical shaft arrangement With an asymmetrical shaft arrangement, there are practically no straight sections along the edges of the workpiece, so the quality of the pipes is comparable to the products of a four-roll machine. |

Recommendations for making a rolling machine

To make a roller bender yourself, you need to prepare tools, consumables, find drawings on the Internet, and carry out assembly according to the instructions provided.

Required tools, consumables:

- Metal sheets.

- Channels, corners, profiles.

- Welding machine.

- Grinder, drill.

- Pipes as rollers.

- Gears, chain, bearings.

- Springs for making the clamping mechanism of the upper roller.

The amount of consumables is calculated according to the drawing. You can find ready-made sketches on the Internet. They indicate the dimensions, location of the main parts, and the direction of rotation of the working parts.

Step by step assembly:

- Using a welding machine, weld the base (frame) from metal sheets. Clean the welding seams and treat them with an anti-corrosion compound.

- Use channels to make side posts that are welded onto the frame.

- Make a housing from metal profiles to house the belt drive and gears. To make this mechanism, you can use a chain or sprockets from a bicycle.

- The shafts must be installed in the bearing holes. Before final fastening, check the parallelism of the working parts.

- Attach the handle to rotate the shafts.

Before finally fastening all the elements of a homemade machine together, you need to check it in action. During test rolling, it is necessary to accurately set the chain tension. Do not forget to lubricate the bearings with oil during operation. Self-assembled rollers that will be installed in a cold garage or workshop without heating must be coated with protective paint to avoid rust.

Selection and justification of the design diagram of the machine

Operating principle of the roller machine

Plate bending rollers differ in the following parameters:

- By the number of work rolls: they can be three or four rolls (installations with a large number of rolls are rare).

- According to the layout of the rolls. There are mechanisms whose roll axes are located symmetrically and asymmetrically to the transverse axis.

- According to the method of fixing the rolls in the frame - on rolling or sliding bearings.

- By type of drive - from manual rollers to those driven by AC and (less often) DC motors.

The question - how to make rollers that will be designed for sheet metal - should begin with the development of technical specifications. It should be taken into account that the manual drive is effective when bending products with a thickness of no more than 0.8...1.2 mm, and with a width of no more than 500...800 mm, otherwise the drive handle will have to be made very long. This is not only inconvenient, but will also lead to an increase in the size of the production area where the unit is supposed to be installed.

For the same reason, a three-roll design should be preferred to a four-roll design - the complexity of manufacturing will increase, and the user will not receive any visible benefits. Moreover, there is no point in making rollers with an even larger number of rolls (for example, seven-roll versions are needed when it is necessary to perform radius bending of sheet products with diameters from 1500...1600 mm).

A more complex issue is the symmetry of the roll arrangement in three-roll rollers. The symmetrical scheme (in which the rolls are arranged in an equilateral triangle: the pressure roller is on top, and the working rollers are on the bottom) is structurally simpler and more technologically advanced to manufacture. However, after processing on such equipment, the front and rear edges of the workpiece at a certain distance (about half from the interaxial one) will remain straight and will require a repeated deformation cycle. If the rollers are intended to produce thick-sheet products, mainly of the type of cylinders with curved edges, then an asymmetrical machine will have to be manufactured.

Which rollers to choose?

Twin rollers

| Twin rollers have two shafts located one above the other. As a rule, the upper shaft is made of durable steel and has a small cross-sectional diameter. The lower shaft has a significantly larger diameter and is made of steel coated with a flexible elastic material (polyurethane, rubber). In this case, the diameter of the resulting pipe depends on the pressing force of the two shafts during rolling. The advantage of such rollers is the absence of straight untreated areas along the edges of the workpiece (without preliminary bending and trimming the edges). |

Three-roll rollers

Three-shaft rollers are the most common machines due to their variety of sizes, mature technology, and lower cost. They allow the production of pipes of various shapes, cones, gutters.

According to the relative position of the shafts, such rollers are divided into several types:

| Symmetrical shaft arrangement These rollers have a simple design and low price. The disadvantage is the inability to bend the edges of the workpiece. | Symmetrical adjustable shaft arrangement With this design, straight sections along the edges of the workpiece are minimized, so that the resulting pipes have an ideal shape. | Asymmetrical shaft arrangement With an asymmetrical shaft arrangement, there are practically no straight sections along the edges of the workpiece, so the quality of the pipes is comparable to the products of a four-roll machine. |

Four-roll rollers

| Four-roll rolling machines are the most convenient, productive and accurate. They are often equipped with a CNC controller and have an electric drive for pressing the bending shafts. Such machines make it possible to obtain pipes with very high bending quality along the entire length without remaining straight sections along the edges, which is especially critical during subsequent seam butt welding of pipes. In addition, the fourth shaft allows for quick centering of the sheet, acting as a stop. |

Double-roll hydraulic rollers MG2R series

The MG2R series twin-roll bending machines are specialized for the serial production of thin-walled cylinders and pipes. These German twin-roll rollers have small overall dimensions and a convenient control panel.

The upper steel roll exerts pressure on the polyurethane-coated lower roll. The springing of the polyurethane shell of the lower roll presses on the sheet and gives it shape.

After bending is completed, the upper roll is retracted by a hydraulic drive, the stop for the lower roll is folded back and the pipe is conveniently removed from the machine.

The diameter of the upper roller is selected in accordance with the requirements for the resulting diameter. The diameter of the resulting pipe can be changed by changing the upper roller or using special insert pipes.

The basic package of the roller machine includes:

-rigid steel welded construction, high-strength body

-the machine is completely maintenance-free

-direct hydraulic drive of rolls

-electronic overload protection system

-control panel with digital display and joystick to control the rotation and lowering of the top roll

-emergency stop button of the machine;

-manual adjustment of the pressure limiter using the steering wheel

-hardened top roll to hardness 53-55 HRC

-bottom roller coated with polyurethane

-hydraulic folding stop for convenient pipe removal

-the machine is equipped with a removable table for quick and accurate installation of workpieces at an angle

Possible additional options:

-digital display for rotation speed and pressure of the upper roll

-CNC system for full automation

-support for large workpieces and sheets

-devices for removing finished pipes

-replaceable forming rolls for different diameters

-feeding table with drive and automatic sheet positioning

-vacuum lift for automatic loading of the feeding table

Specifications:

| Model | Working length mm | Thickness sheet mm | Ø diameter upper roll, mm | Ø diameter lower roll, mm | Engine kW | Weight kg | Dimensions mm |

| MG2R05 | 550 | 1.2 | 80 | 220 | 4.0 | 950 | 1.840×850×1.240 |

| MG2R07 | 750 | 1.2 | 90 | 220 | 5.5 | 1.600 | 2.034×850×1.240 |

| MG2R10 | 1.050 | 1.2 | 100 | 300 | 5.5 | 1.700 | 2.340×1.000×1.240 |

| MG2R12 | 1.250 | 1.2 | 110 | 300 | 5.5 | 1.850 | 2.540×1.000×1.240 |

| MG2R10HD | 1.050 | 4.0 | 140 | 300 | 7.5 | 1.950 | 2.500×1.000×1.300 |

| MG2R15HD | 1.550 | 4.0 | 150 | 300 | 7.5 | 2.150 | 3.000×1.000×1.300 |

| MG2R20HD | 2.050 | 4.0 | 160 | 300 | 7.5 | 2.400 | 3.500×1.000×1.300 |

These rolling machines are an example of reliability and productivity. Today there is a program agreed with the manufacturer, according to which the price for Hezinger 2-roll rollers is extremely attractive.