Compressor oils are specialized mineral or synthetic lubricants that ensure correct operation of the compressor and increase the service life of the equipment several times. They are purchased taking into account a number of parameters. One of the main ones is density. What is this indicator, how is it measured and what is it used for?

Characteristics

The properties of the lubricant are regulated by GOST 9243-75.

According to the document, the viscosity at 100 degrees Celsius ranges from 18 to 22 mm2/s.

Viscosity index (VI) not lower than 95.

The oil has a low percentage of ash content (below 0.01%), sulfur content (not higher than 1%), coking capacity (below 1%). Characterized by high antioxidant properties with no acid number.

The product does not contain:

- water;

- solvents;

- mechanical impurities;

- dissolved alkalis and acids.

The ignition temperature in an open container is +260°C, and the freezing point in the cold is -15°C, which indicates that the lubricant is quite frost-resistant and can withstand high, but not extremely high temperatures.

How and in what units is compressor oil density measured?

Oil density is calculated at a certain temperature. The average is +20 degrees Celsius. To calculate, you need to take the temperature indicator and subtract the average value from it. The resulting difference is then multiplied by the temperature correction. Current temperature corrections are displayed in GOST 9243-75. It remains to subtract the resulting product from the density parameter, which is displayed in the technical characteristics of each specific brand of compressor oil.

Density is measured in kg/m3. Average indicators, which depend on the brand and the viscosity of a particular compressor oil, range from 885 to 905 kg/m3.

Scope of application

Chainsaw oil: when to use synthetics

In GOST 17479.4-87, lubricant I-40A is designated “I-G-A-68”. This GOST regulates the purpose, scope, presence or absence of additives and kinematic viscosity of lubricating fluids.

The first letter - “I” - denotes that it belongs to industrial, rather than transport, lubricants, which means the possibility of use in stationary units, where operating conditions are milder than in automobiles and motorcycles. This division made it possible to create lubricants that are cheaper to produce, which, at the same time, will fully meet the requirements for lubricants in industry.

The second letter, “G,” defines “I-G-A-68” as “intended for use in hydraulic systems,” which distinguishes it from other types of lubricants intended for bearings, guides or heavily loaded components.

The letter “A” in the abbreviation indicates the absence of specialized (anti-corrosion, anti-oxidation, etc.) additives in the composition. Thus, I-40A does not have increased protection against oxidation or corrosion.

The number “68” at the end of the abbreviation means it belongs to the 68th kinematic viscosity class, according to which the oil viscosity at a temperature of 40°C should be in the range of 61-75mm2/s. This parameter is especially important if you plan to replace your oil with an analogue: the viscosity of the lubricant must correspond to the operating conditions (high for heavily loaded low-speed mechanisms, low for high-speed lightly loaded components). Typically, viscosity requirements are indicated in the equipment data sheet.

Thus, I-40A oils are intended for use as a lubricating or hydraulic fluid in medium-loaded mechanisms, including:

- industrial machines, presses, automated lines;

- construction and road equipment;

- obtaining specialized lubricants by adding additives and oils with intermediate viscosity values.

Also, I-40A industrial oils can be used to replace more expensive lubricants if their properties are suitable for the planned operating conditions

We list the points that you must pay attention to when choosing I-40 as a lubricant for your equipment.

- There are no special requirements for anti-oxidation, anti-corrosion and other special properties of the oil.

Due to the fact that I-40A does not contain anti-wear, adhesive, extreme pressure and other additives, it does not have increased protective properties against corrosion or oxidation. In severe operating conditions, it is recommended to use lubricants with additives that improve the required characteristics. - The operating temperature corresponds to the operating temperature of the oil.

Lubricating fluid I-40A fully retains its performance qualities at temperatures from -5 to +70°C. At a lower temperature, thickening and viscosity increase, and at a temperature of -15°C, the lubricant freezes. When the temperature rises above 70°C, the viscosity decreases, and when the temperature exceeds 200°C, the oil may ignite. - The viscosity of I-40A meets the equipment specifications.

The technical passport of machine tools and other industrial equipment for each unit must indicate the permissible viscosity of the lubricant, taking into account the expected loads and operating conditions. It is imperative to adhere to them to avoid premature wear or breakdown of equipment.

Compressor oils: what they are, their application, types and brands

Compressor oils are a special material for lubricating parts and elements of compressors to prevent premature failure and, as a result, equipment deterioration. The application of compressor oils is especially important at low temperatures, in the winter season, because the lower the temperature, the greater the load on the equipment, and therefore the higher the likelihood of damage.

Types of oils for compressors

Depending on the application and equipment, compressor oils are divided into three types:

- Oils for piston and screw compressors, commonly found in industrial machinery and vehicles. Since in this case the oil has direct contact with the gas, the oil should be selected depending on the properties and characteristics of the gas itself.

- For turbocompressor installations. In this area, more viscous and stable materials are often used, such as Tp-22B or Kp-8S

- For refrigeration compressors. In this case, special lubricants are also required, designed specifically for direct contact with the refrigerant and resistant to changes in temperature and pressure.

By using good compressor oil in your equipment, you can significantly increase its service life.

Compressor oil selection

The operation of all equipment depends on the quality and reliability of the lubricant. If you take the choice of compressor lubricant seriously, you can greatly reduce the risk of premature equipment failure. A good oil should perform three main functions:

1) lubrication of installation elements to reduce friction;

2) increasing the level of tightness in mechanisms;

3) engine cooling (especially important when working directly with compressed gas, since the risk of overheating increases significantly).

How to choose a truly high-quality compressor oil that is suitable for you? The main indicators of this oil are:

– Low degree of evaporation;

– Chemical neutrality with respect to gases in the compressor and refrigerants (for refrigeration units);

– Resistance to high temperature changes (acceptable flash point 192-270 degrees Celsius)

– Oil viscosity is acceptable in the region of 7-30 mm2 at a temperature of 100 degrees Celsius.

General operating principles

In order for compressor oil to provide reliable protection of the device from damage, you should know the basic rules for its use:

1) In order not to make a mistake with the class of the required oil, you should carefully study the instructions, which, as a rule, are included with the compressor itself.

2) As a rule, half the required amount of the substance should be added to the compressor, and the other half to the dryer (receiver / accumulator). Thus, the residual lubricant will be evenly distributed throughout the compressor.

3) To avoid damage to the compressor, called “oil shock,” which may occur when turning on after filling with oil, the compressor shaft should be rotated about 10 times.

4) After filling is complete, you need to wait about an hour for the oil to settle, after which you can turn on the equipment.

5) If you do not count the time spent on work, the best option would be to regularly change the oil twice a year.

Famous brands and companies:

The choice of compressor oil is a responsible thing, because it affects the final quality of equipment operation. Therefore, it is better to overpay once again, but choose a reliable manufacturer. An excellent option is Corena, an oil from the British-Dutch company Shell, which has been operating on the market for more than a hundred years and has managed to earn the highest reputation for itself. ShellCorena lubricating oil will allow the compressor to operate even in the most difficult conditions. Also, MobilRarus and TotalDacnis are very good manufacturers.

Oil I-50 - manufacturers and analogues

Industrial oil i-40a

The most popular industrial oils on the Russian market are those from domestic producers: Lukoil, Rosneft, Gazpromneft. Their products are characterized by stable performance properties and fully comply with GOST requirements. At the same time, its cost is lower than that of foreign analogues.

I-50 lubricants of less well-known brands are cheaper. However, before purchasing, you need to make sure that the characteristics of the oil comply with GOST - in the cheap segment there is a greater chance of purchasing a low-quality product. A good solution may be to buy a small amount of oil and test its performance before purchasing a large amount.

Compressor oil KS-19P

Chainsaw oil

PURPOSE AND DESCRIPTION OF KS-19P OIL

Oil KS-19P

Designed for lubrication of medium and high pressure piston compressors, blowers and rotary compressors used in various industries and transport, where the equipment manufacturer specifies the use of oil of this viscosity class. Also recommended for single-stage and multi-stage compressors compressing air and/or other oil-insoluble gases. The use of unique base oils ensures high performance characteristics of the product.

ADVANTAGES OF KS-19P OIL

contains an antioxidant additive that helps minimize the formation of oil deposits in compressor discharge lines

has good thermal stability, which guarantees long-term and efficient performance of the oil

high auto-ignition temperature ensures safe operation of compressors

oil acts as a sealing medium (seals the compression chamber), lubricates cylinders and valves, protects parts from corrosion

APPROVALS / CONFORMITY OF OIL KS-19P

TU 38.401-58-243-99.

PHYSICO-CHEMICAL CHARACTERISTICS OF KS-19P OIL

| Indicator name | Norm |

| Kinematic viscosity at 100C, mm2/s: | 24,1 |

| Viscosity index | 90 |

| Flash point in an open crucible, C | 260 |

| Pour point, C | -15 |

| Acid number, mg KOH/g | ots. |

| Ash content, % | 0,003 |

| Coking rate, % | 0,39 |

| Mass fraction of sulfur, % | 0,4 |

| Stability against oxidation: - sediment after oxidation, % wt. — acid number of oxidized oil, mg KOH/g | 0,002 0,2 |

| Density, at 20 C, g/cm3 | 0,894 |

| Color on the CNT colorimeter, units. CST | 4,0 |

Produced by OJSC Gazpromneft-ONPZ, 644040, Russia, Omsk, Gubkin Ave., 1 according to TU 38.401-58-243-99 Produced by order of LLC Gazpromneft-SM OJSC Slavneft-YANOS, 150023, Russia, Yaroslavl, Moskovsky Avenue, 130, according to TU 38.401-58-243-99. The above data is typical of the product obtained within normal manufacturing tolerances and does not constitute specifications. The information is for reference only and is subject to change without notice.

Standard packaging: 216.5 l barrels.

Product status: permanent stock item Availability in warehouse: yes Quantity: >> 52

Call | Request a call back | write us a letter

Compressor oils: technical features

Compressors are complex production mechanisms, without which it is impossible to imagine any enterprise. The most common applications for compressor units are: air conditioning, refrigeration and compressed air production. Compressed air is one of the energy sources that can ensure the operation of control systems and equipment on an industrial scale.

The durability, safety and correct operation of compressors depend in particular on the lubricants used. One of the main features of compressor oils is their stable viscosity properties. The viscosity level of compressor oils varies in the range of 7-30 mm2/s at 100°C, the ignition level on average is +190...+275 °C.

To ensure uninterrupted operation of compressors, oils must have the following performance characteristics:

- ensuring thermal stability;

- preventing the formation of coke-like oil deposits;

- ensuring stable viscosity;

- maintaining tightness (minimizing gaps);

- ensuring lubrication of friction pairs;

- cooling of pump elements during operation.

A competent choice of compressor oils can increase the service life of units.

According to the classification of the USSR State Mining and Technical Supervision, in Russia today there are 4 groups of compressor oils.

- Group I. The first group includes compressor oils operating under moderate load conditions. They are used in equipment that compresses air and other oil-insoluble gases at a discharge temperature of less than +160 °C.

- Group II. The operating conditions of oils belonging to this group are similar to the operating conditions of oils from group I, with the exception of the discharge temperature, which can reach +180 °C.

- III group. Oils of this group are intended for compressors operating under high load conditions, at discharge temperatures up to +200 °C.

- IV group. This includes compressor oils that operate exclusively under severe operating conditions, at high pressure and discharge temperatures above +200 °C.

The oils of each group have a certain set of properties that are important to consider when selecting a given lubricant for a particular type of compressor equipment.

Compressor oils are divided into two types: oils for piston compressors and oils for screw compressors.

In piston-type compressor units, the rubbing elements of the structure are lubricated. These include the crankshaft, bearings and piston and cylinder. Compressor oils are in direct contact with compressed air, which can cause oil oxidation, carbon formation and a decrease in viscosity. Therefore, higher demands are placed on lubricants for this type of compressor.

Screw-type compressors are divided into two types: oil-free and oil-injected. Oil injection units provide a high compression ratio and are therefore highly efficient and reliable. In such compressors, only bearings and screw surfaces are lubricated, between which an oil film is formed. Since oils can become very hot at high compression ratios, when choosing an oil you need to remember the flash point indicator.

It is necessary to read the symbols on the oil label as follows: the letter “K” means a specific type of product, in this case “compressor oil”. The group to which the oil belongs is indicated by the number I, II, III or IV. This is followed by the kinematic viscosity at 100 °C.

In order for compressor equipment to serve for many years, you need to remember a few simple rules:

- it is necessary to use only recommended brands of oils or their analogues;

- Do not mix oils of different brands;

- During the oil change procedure, it is necessary to flush the oil systems.

Correct use of lubricants ensures trouble-free and long-term operation of the compressor. Any violations of the lubrication regime, for example, the use of low-quality or inappropriate lubricant, cause decomposition and complete loss of the working properties of compressor oils.

Classification of compressor oils and their scope

All modern compressors are divided into two main types, differing in their design and operating features. These include:

- Volumetric. In such equipment, the distilled gaseous substance is sucked into the working chamber, compressed and thrown out under pressure by the forward-return movement of the piston system;

- Dynamic. The compression of the medium they distill is carried out using turbine mechanisms. The intake gas is accelerated by the turbine rotors, after which it suddenly slows down, causing it to be dynamically compressed.

In volumetric piston compressors, oil provides lubrication of moving parts - piston group, valves, bearings. Traditionally, such models use mineral oil that meets international certificates DIN-51506-VGL, VDL. The viscosity class for them corresponds to ISO/VG standards from 68 to 150. In positive displacement rotary or screw compressors, the moving parts are lubricated using an oil bath. As a result, the oil is constantly mixed with the forced air, heating to a temperature of about 90-100ºC.

At the outlet of the compressor chamber, a filter device is installed that separates the oil from the gaseous substance. Therefore, for use in rotary and screw compressors, oils with increased deaeration and demulsification characteristics are used.

Special requirements are also imposed on increased anti-corrosion properties and the maximum amount of deposits during operation. Most manufacturers of such equipment provide instructions in the accompanying instructions regarding the selection of a suitable lubricant.

In dynamic modifications of compressor units, lubrication is provided through a forced supply circuit: gears, shaft seals, bearings. It is recommended to use the same type of oil for the compressor operating mechanism and its drive system. It is recommended to use special turbine oils of the following grades in dynamic installations that comply with the ISO/DP-6521 standard:

- DIN-51-515 TDL-32;

- TDL-46;

- TDL-68;

- TDL-EP with extreme pressure additives.

Conventional motor oils are classified according to their flash point.

Compressor lubricants are divided, unlike motor lubricants, according to the temperature of the pumped substance.

In Russia, along with the international classification of compressor oils, the domestic classification adopted by Gostekhnadzor back in Soviet times is still often used.

According to it, all compressor oils are divided into 4 groups:

- Lubricant intended for operation under moderate loads. The temperature of the discharge gas does not exceed 160ºC.

- The second group is intended for operation under moderate loads, but with a discharge gas temperature of up to 180 degrees.

- Compressor lubricant of the third group is designed for mechanisms operating under increased loads and temperatures up to 200ºC.

- The last group includes oils intended for operation in extremely difficult conditions, with increased pressure and temperatures up to 200ºC.

Each group has a special list of operational and technical properties that must be taken into account when choosing the type of oil for the compressor.

It should be noted that foreign manufacturers have not developed a unified classification for operating temperature, and each large company uses its own standards.

Classification of compressor oils

According to operating conditions:

- first group.

This includes compressor oils designed to operate under moderate loads. Used at discharge temperatures up to +160 ˚С; - second group

. It has the same performance characteristics as the previous one, with the exception of the discharge temperature, which can reach +180 ˚С; - third group

. Oils in this category are intended for equipment operating under high loads. Discharge temperature – up to +200 ˚С; - fourth group

. This includes compressor oils operating under particularly difficult conditions under very high loads. The discharge temperature can exceed +200 ˚C.

By equipment type

:

- for piston compressors

. In such equipment, the movement mechanism and the cylinder are lubricated by spraying oil. The main objective is to reduce wear, friction, protect against corrosion and seal the compression chambers. The oil comes into direct contact with compressed air, so high demands are placed on it. Oil for piston compressors has good oxidation resistance and does not form carbon deposits when heated. In addition, it maintains the required viscosity over a wide temperature range; - for screw compressors

. In them, oil performs the functions of lubrication, sealing and cooling. Due to the fact that the rubbing parts heat up during operation, the ignition temperature of the compressor oil should not be lower than +180 ˚С. Oils for screw equipment increase its wear resistance and have soft extreme pressure properties.

Application of KS 19 oil

- compressor units for compressing gases and clean air (piston and rotary);

- can operate in both single-stage and multi-stage units (even without intermediate gas cooling);

- blowers in which direct contact of gas and lubricant occurs.

Information High performance characteristics make it possible to use KS 19 in units without checking factory tolerances for consumables.

In addition to its main area of application, this lubricant (mostly used up) is used in forge shops for hardening metal products. This popularity among blacksmiths is due to the purity of the product (more precisely, the small amount of additives).

What is the main feature of compressor lubricant?

KS oil is used if compressed gas does not dissolve in the lubricant. The substance has a special composition, which was developed taking into account the operating characteristics of the compressor. When creating the product, we took into account the fact that if the substance gets into the compressed air, it will not be possible to separate the piston system from the drive. Without observing this point, the lubricant cannot fully perform its declared functions, which is why many compressor developers make similar demands on these products

In turn, oil refineries pay a lot of attention to the production of high-quality lubricants

Why do you need a compressor?

In order to supply compressed air or other gases under high pressure, devices are needed that help compress the gas entering them to small volumes. At the same time, they must be compact, small-sized and mobile. These devices are called compressors. Their use is very wide in various fields, for example, in car services and in the renovation of apartments, offices and building facades. The lightest and most compact devices are used in everyday life to perform various types of work around the house and in the garden.

Types of compressors.

For these purposes, you can use cheap oil-free compressors, but their service life is limited, since parts wear out very quickly without oil. For car services and companies performing repair or construction work, more reliable oil devices are suitable, but their price will be more expensive. But their use will last longer than those without the use of lubricant. In industrial conditions, compressors are installed with large dimensions and high power, using KS 19 oil to improve performance characteristics.

When using a compressor, it is very important that the electricity flows without interruption and there must be a constant voltage. For this purpose, it is better to purchase a stabilizer that keeps the current constant

Then the device will operate without interruption, and the wear of compressor parts will occur more slowly. The efficiency of a unit that uses oil lubrication is much higher than the efficiency of a device that does not have lubrication. Since oil-free appliances are unstable at high and low temperatures.

In the modern world, with the help of this device you can inflate car tires and any rubber products, paint a fence or walls, and do many other useful things. Since electricity is now very expensive, many manufacturers are thinking about how to make repairs cheaper than the cost of using electric tools. It turned out that tools powered by compressed air use much less energy, while their use is much easier in terms of labor costs.

Why does the compressor foam or eject oil?

In a screw compressor, the oil foams if it is incorrectly selected, if foreign impurities enter, or if different brands are mixed. In a piston engine it foams for the same reasons, and also when the breather is clogged or the piston is worn out.

The screw compressor spits oil into the air filter due to a malfunction of the valves (unload, suction, minimum pressure). A particularly strong release of lubricant occurs during a sudden stop or emergency shutdown of the engine.

To look for an answer to the question of why oil is being released from a piston compressor, you need to start by checking its level (if it is too high, drain the excess). Other reasons why oil is thrown out of the compressor are: excess pressure in the crankcase, improper installation or a stuck oil scraper ring.

Piston compressor:

throws oil through the breather when its hole is clogged, the air filter is clogged, the intake and/or exhaust valves are faulty, or the cylinder-piston group (CPG) is worn out;

- spits oil if it has low viscosity or is filled above the permissible level, accumulates in the receiver due to a malfunction of the separator;

- drives oil into the air system when the capacity of the air filter or intake pipe decreases, or the CPG wears out.

If the compressor sends oil into the receiver, this may be due to crankcase overfilling or damage to the oil scraper ring.

Compressor oil KS 19

Oil selection table depending on weather conditions.

As mentioned earlier, oil compressors last longer and work better. Therefore, if you are planning work that requires the use of pneumatic tools or compressed air under pressure, then it makes sense to purchase this device. Moreover, their price category is affordable even for an ordinary individual. In order for the unit to operate smoothly, it is necessary to pour compressor oil into the device, then all rubbing parts will be lubricated and cooled even at high temperatures.

Winter is an extreme season for the compressor, because the load on it increases several times

Therefore, maintenance of the unit must be carried out with special care and attention. To do this, you need to choose the right lubricant

Just like in a car engine, oil has multiple functions. Its main purpose is to minimize friction of the moving parts of the compressor; it also cools and lubricates all internal parts of the device. Since the entire mechanism heats up greatly when the compressor operates, high temperatures do not contribute to long and fruitful operation. The device can easily burn out and fail. Therefore, the lubricant must be selected taking into account all the above requirements.

Compressor oil KS 19 is an ideal option for any type of similar devices, especially piston or rotor types. Such devices typically use high or medium pressure to release air or gas. Its characteristics fully meet all the requirements for lubricants of this kind, and the price is more than affordable. Any oily liquid is a product of crude oil refining, and KS 19 is no exception. For oils of this type, there are GOST standards, which are then used to certify the product.

Stages of oil production.

The process of obtaining this oil product is quite automated and the output will be high-quality lubricant. To obtain it, crude oil is used, with an average static content of sulfur and paraffin, which is distilled and purified many times. Since oil is made from petroleum, it is called mineral oil. After all these operations, the technical characteristics of KS 19 allow it to be used at not very high temperatures ranging from 120° to 160°. At higher temperatures, the oil loses its quality and the compressor will wear out quickly.

This lubricant is universal; its capabilities are limited only by high temperatures. It is used in almost all industries where oil compressors are used: chemical, automotive, construction. Since the oil is not synthetic, there are restrictions on its use, for example, high temperatures or use of the unit in extreme conditions, where the load on it is greater than standard. In such cases, it is better to use synthetic or semi-synthetic lubricants, which, on the contrary, behave better under any increased loads than during normal operation.

The main technical characteristics of any oil are viscosity and the limiting ignition temperature at which the liquid itself can ignite.

This lubricant can be used both for industrial multi-stage units and for single-stage simple units that can be used at home for personal needs. In any case, KS 19 will behave equally professionally, performing all its functions at the proper level when working.

Compressor oils

Compressor oils are a special type of lubricants that prevent premature wear of industrial compressor parts. During the operation of compressors, the oil comes into contact with compressed gas at elevated temperatures, so the key characteristics of the lubricant are the ignition temperature, viscosity and evaporation coefficient.

Technical characteristics of I-50A according to GOST 20799-88

The composition, technical characteristics and performance qualities of industrial oils are regulated by GOST 20799-88. According to GOST, I-50A grade oils must have the following properties.

| Indicator name | Standard according to GOST |

| 1. Kinematic viscosity at 40 °C, mm/s | 90-110 |

| 2. Acid number mg KOH per 1 g of oil, no more | 0,05 |

| 3. Ash content, %, no more | 0,005 |

| 4. Mass fraction of sulfur in oils from sulfurous petroleums, %, no more | 1,1 |

| 5. Content of mechanical impurities | — |

| 6. Water content | — |

| 7. Density at 20 °C, kg/m, no more | 910 |

| 8. Pour point °C, not higher | -15 |

| 9. Color on the CNT colorimeter, CNT units, no more | 4,5 |

| 10. Flash point determined in an open crucible, °C, not lower | 225 |

| 11. Stability against oxidation: | |

| 0,4 | |

| 3 | |

| 12. Solvent content in selectively refined oils | |

| 13. Content of water-soluble acids and alkalis in alkaline refined oils | — |

Documentation

Compressor oils

Depending

on the areas of application and requirements, compressor oils are divided into classes:

— for piston and rotary compressors,

— for turbocompressor machines,

- for refrigeration compressors.

Oils for piston and rotary compressors

M

Oils of this class are widely used for lubricating compressors used in various industries and transport. In reciprocating and rotary compressors, the lubricating oil is in direct contact with the high-temperature compressed gas. The composition and properties of the gas largely determine the requirements for the oil and its performance.

IN

In piston compressors, oils are used to lubricate cylinders and valves, and also as a sealing medium to seal the compression chamber. The parts of the movement mechanism are usually lubricated with industrial oils. In compressors with a single lubrication system for cylinders and the movement mechanism, only compressor oils are used.

IN

in accordance with the rules approved by the State Gortechnadzor of the USSR (“Rules for the design and safe operation of stationary compressor units, air ducts and gas pipelines” dated December 7, 1971), the air temperature after each compression stage of air compressors should not be higher than 170 ° C for general industrial compressors and higher 180 °C for compressors for process purposes. Under such conditions, the main operational property of oils that ensures long-lasting, efficient and safe operation of compressors is their thermal-oxidative stability and the ability to prevent or minimize the formation of coke-like oil deposits in compressor discharge lines. The main cause of fires that occur in oil-lubricated compressors is the formation of solid products of the breakdown and compaction of the oil during its operation, sometimes similar to engine deposits called carbon deposits. The requirements for the thermal stability of compressor oils increase depending on the compressor discharge temperature.

P

In relation to compressor machines, viscosity is one of the main performance characteristics of the oil. Energy losses due to friction, wear of friction surfaces of parts, sealing of piston rings, compressor startup time, and temperature of friction surfaces depend on viscosity.

ABOUT

The formation of coke deposits depends on the thermal stability of the oil as well as its viscosity. Lower viscosity oil moves faster through the compressor discharge path and forms less deposits in the discharge system. In accordance with the safety regulations for the operation of stationary air compressors (ISO 5388 standard) for oil-lubricated compressors, coke deposits must be promptly removed. The frequency of checks and cleaning time depend on the quality of the oil, but the thickness of the deposit layer between cleanings should not exceed 3 mm at an effective pressure of less than 1 MPa, 2 mm at a pressure of 1-3 MPa and 1 mm at a pressure of 3-5 MPa. It should be borne in mind that the existing opinion about the connection between the flash point of an oil and its safe operation is incorrect. A high flash point does not guarantee greater safety for their use compared to oils with a lower flash point. For piston compressors, the auto-ignition temperature of compressor oils is more important, which is higher for distillate oils with a low flash point than for residual high-viscosity oils.

ABOUT

The designations of domestic compressor oils are established in accordance with their unified range developed in the 80s. According to the classification, oils are divided into groups:

first

— for compressors operating under moderate conditions, compressing air and other oil-insoluble gases at a discharge temperature below 160 ° C;

second

- Same. at a discharge temperature below 180 °C;

third

— for compressors operating in difficult conditions with discharge temperatures below 200 °C;

fourth

— for high-pressure compressors operating under particularly difficult conditions with discharge temperatures above 200 °C.

IN

In accordance with the classification of oils, they are marked as follows. The letter “K” means it belongs to compressor oils. The oil group is indicated by the number after “K”, with the exception of the first group. Then after the hyphen there is a number corresponding to the kinematic viscosity at 100 °C.

P

examples of designations: oil K-12 - compressor, belongs to the first group of classification, viscosity 12 mm-'/s at 100 ° C;

TO

4-20 - compressor oil, belongs to the fourth classification group, with a viscosity of 20 mmV at 100 °C.

X

The characteristics of compressor oils are given in the table:

Characteristics of compressor oils

| Indicators | Oils without additives | Oils with additives | |||||||||||

| K-19 | KS-19 | Kp-8S | K3-10 | K3-10N | KS-19P | K3-20 | K4-20 | K2-220 | K2-24 | ||||

| Kinematic viscosity, mm2/s, at temperature: 100°С | 17-21 | 18-22 | 6,5-9 | 8,8-10,5 | 9-13 | 18-24 | 17-23 | 19,5-22 | 18-21 | 21-25 | |||

| 40 °C | — | — | 41,4-50,6 | 73,7-96,2 | 76-130 | — | 206-336 | 240-310 | 220-310 | — | |||

| Viscosity index, not less | — | 92 | 95 | 90 | 90 | 85 | 80 | 85 | 82 | 82 | |||

| Acid number, mg KOH/g | 0,04 | 0,02 | 0,05 | 0,2 | 0,2 | 0,03 | 0,5 | — | 0,4 | 0,35 | |||

| Temperature, °C: flashes in an open crucible, not lower | 245 | 260 | 200 | 205 | 205 | 260 | 250 | 225 | 230 | 270 | |||

| hardening, not higher | -5 | -15 | -15 | -10 | -30 | -15 | -15 | -15 | -10 | -10 | |||

| Content, % (wt. fraction), no more than: water-soluble acids and alkalis | Absence | — | — | — | Absence | — | — | — | — | ||||

| mechanical impurities | 0,07 | Absence | 0,07 | 0,02 | Absence | ||||||||

| water | Absence | Footprints | Absence | Footprints | Absence | ||||||||

| sulfur | 0,3 | 1,0 | 0,5 | 0,65 | 0,65 | 1,0 | 0,35 | 0,6 | 0,5 | 0,5 | |||

| selective solvents | — | Absence | — | — | Absence | — | Absence | — | — | ||||

| Coking rate, %, no more | 0,5 | 0,5 | 0,05 | 0,2 | 0,2 | 0,45 | 0,45 | — | 0,45 | 0,45 | |||

| Ash content, %, no more | 0,01 | 0,005 | 0,005 | 0,005* | 0,005* | 0,005 | 0,12 | 0,5-0,8 | 0,06 | 0,06 | |||

| Stability against oxidation, no more than: sediment, % (wt. fraction) | 0,015 | Absence | 0,02 | — | — | Absence | — | — | — | — | |||

| acid number, mg KOH/g | — | 0,5 | 0,2 | — | — | 0,5 | — | — | — | — | |||

| increase in coking capacity, % | — | — | — | 1,5** | 1,5** | — | 2,0** | — | 3,0** | 2,0** | |||

| evaporation losses, % | — | — | — | 15** | 15** | — | — | — | 20** | — | |||

| Color, units CNT, no more | — | 7,0 | 2,5 | 6,5 | 6,5 | 7,0 | 7,5 | — | 7,5 | 7,5 | |||

| Corrosion: on steel plates | You are living | — | — | Withstands | — | You are living | — | — | — | ||||

| on lead plates, g/cm2, no more | — | 10 | — | — | — | — | — | 10 | — | — | |||

| on copper plates | — | — | You are living | — | — | You are living | — | — | Withstands | ||||

| on steel rods | — | — | Absence | — | — | — | — | Absence | — | — | |||

| Density, kg/dm3 | — | 905 | 885 | 900 | 900 | 905 | 900 | 900 | 905 | 900 | |||

| * The indicator is normalized for base oil. ** Stability determined according to ISO 6617 method. Note. Oxidation conditions when determining stability according to the GOST 981-75 method: Oil | Temperature, °C | Duration, h | Oxygen consumption, ml/min | ||||||||||

| K-19, KS-19 and KC-19p | 120 | 14 | 200 | ||||||||||

| Kp-8S | 150 | 25 | 50 | ||||||||||

Compressor oils without additives

Oil K-19

(GOST 1861-73) are produced from low-sulfur oils by selective purification. Designed for lubrication of medium and high pressure piston compressors in technological installations where low sulfur content oils are required.

Oil KS-19

(GOST 9243-75) are produced from sulfurous paraffinic oils by selective purification. Designed for lubrication of medium and high pressure piston compressors.

Compressor oils with additives

Oil KS-19p

(TU 38.4011055-97) are produced from sulfurous paraffinic oils by selective purification. Contains the antioxidant additive ionol. Designed for lubrication of medium and high pressure piston compressors.

Oil K3-10

(TU 38.401724-88) are produced from a mixture of low-sulfur oils using the method of selective purification. Contains a composition of additives that reduce the formation of carbon deposits in the compressor discharge line, as well as improve antioxidant, anti-corrosion, lubricating and anti-foam properties. Designed for lubrication of piston compressors with discharge temperatures up to 200 °C, as well as rotary compressors.

Oil K3-10N

(TU 38.401905-92) are produced using the same technology as KZ-10 oil. Contains an additional additive that lowers the pour point. Has improved starting properties at low ambient temperatures. The scope is the same as KZ-10 oils.

Oil K2-24

(TU 38.401-58-43-92) are produced from a mixture of Volgograd and low-sulfur West Siberian oils using the method of selective purification. Contains an additive that improves antioxidant and anti-wear properties. Used for lubrication of multi-stage high-pressure piston compressors, including compressors of air separation units.

Oil K3-20

(TU 38.401700-88) are produced from low-sulfur oils by selective purification. Contains a composition of additives that reduce coke formation in the compressor discharge line, as well as improve lubrication and anti-foam properties. Designed for lubrication of heat-stressed high-pressure piston compressors.

Oil K4-20

(TU 38.101759-78) are produced from low-sulfur oils by selective purification. Contains additives that improve lubricating, dispersing and anti-foaming properties, as well as increasing thermal stability. Designed for lubrication of high-pressure piston ship air compressors with a single lubrication system for the cylinders and the movement mechanism.

Oil K2-220

(TU 38.401-58-90-94) are produced from a mixture of Volgograd and Shaim oils using the method of selective purification. Contains additives that improve antioxidant, anti-wear and anti-foam properties. Designed for use in heat-stressed air compressors.

Oils for turbochargers

D

For the lubrication of centrifugal and turbocompressor machines, turbine oils are mainly used, among which the most common oils for this purpose are Tp-22S and Tp-22B. In turbochargers paired with highly loaded gearboxes, operating conditions often dictate the use of a more viscous, specially developed compressor oil Kp-8S (TU 38.1011296-90). In cases where high resistance to sediment formation and good antioxidant stability are required from the oil, Tp-22B and Kp-8S oils should be used in compressors. The advantages of these oils over Tp-22S oil are especially pronounced when they operate in compressors pumping ammonia. Based on the results of laboratory studies and operational tests of oils on domestically produced turbocompressors and imported supplies from the All-Russian Scientific Research Institute of NP and the Scientific Research Institute of Turbocompressors (Kazan), limiting quality indicators have been developed, the excess of which negatively affects the condition of friction units and the operation of compressors:

| Index | Maximum allowed value |

| Acid number, mg KOH/g | 0,2 |

| Mass fraction, %: water | 0,05 |

| sediment insoluble in gasoline solvent* | 0,05 |

| Deviation of kinematic viscosity from the viscosity of fresh oil, % | ± 15 |

| *Determined according to GOST 981-75 with an acid number of more than 0.1 mg KOH/g. | |

Oils for compressors of refrigeration machines

Compressor oils for refrigeration machines are subject to specific requirements due to the continuous contact of the lubricant with the refrigerant, as well as constant changes in temperature and pressure of the medium. For refrigeration compressors, it is recommended to use mineral and synthetic oils with a fairly low pour point and high chemical stability. Chemical stability is generally understood as the tendency of oils to interact with refrigerants based on halogenated fatty hydrocarbons at elevated temperatures and pressures. The most important performance characteristics of refrigeration oils are their ability to mutually dissolve with refrigerants (see figure below), as well as the temperature at which paraffin flakes fall out of solutions. The flocculation temperature in the R-12 freon solution is for oil: HF12-16 - minus 50, XA-30 - minus 40, XC-40 - minus 55°C.

N

It is also necessary to control the aggressiveness of refrigerant-oil mixtures towards metals and other materials used in refrigeration machines.

D

For compressors of refrigeration machines, oils of the XA and HF series are used in accordance with GOST 5546-86:

XA-30

— a mixture of distillate and residual petroleum oils;

HF12-16

— petroleum oil with an antioxidant additive;

HF22-24

— petroleum thickened oil;

HF22S-16

— synthetic oil with antioxidant additive.

TO

In addition to oils in accordance with GOST 5546-86, for compressors of refrigeration machines operating in the temperature range -50...+150 °C, you can use synthetic oil

VNIINP XS-40

(TU 38.101763 - 78), and for industrial freon refrigeration machines - petroleum oil

XM- 35

(TU 38.1011158-88).

Characteristics of oils for refrigeration compressors

| Indicators | XM-35 | XA-30 | HF12-16 | HF22-24 | HF22S-16 | XC-40 |

| Kinematic viscosity, mm2/s, at temperature: 20°С | — | <=150 | >=17 | — | — | — |

| 50 °C | 32-37 | 28-32 | >=16 | 25,4-28,4 | >=16 | 37-42 |

| Acid number, mg KOH/g | 0,03 | 0,05 | 0,02 | 0,04 | 0,35 | 0,02 |

| Temperature, °C: flash in an open crucible, not lower | 190 | 185 | 174 | 130 | 225 | 200 |

| hardening, no higher | -37 | -38 | -42 | -55 | -58 | -45 |

| Ash content, %, no more | 0,005 | 0,004 | — | — | — | 0,02 |

| Stability against oxidation, no more than: sediment, %, (wt. fraction) | — | 0,02 | 0,005 | — | 0,02 | — |

| acid number, mg KOH/g | — | 0,5 | 0,04 | — | 0,4 | — |

| Color, units CNT, no more | — | — | 1,0 | — | — | — |

| Corrosion: on copper plates | They are holding out | |||||

| on steel plates | — | Absence | — | — | Absence | |

| Notes 1. For oil HF12-16, the temperature of flocculation with freon 12 is not higher than -50 °C. 2. For all oils, the content of water-soluble acids and alkalis, mechanical impurities and water is absent. | ||||||

Description

KS-19 is made only from natural raw materials - oil. According to a unified classification, it is classified in the first group of compressor oils.

Its performance characteristics make it possible to use it in all types of compressors, regardless of the compressed gases used.

The approvals meet the requirements for work in high and medium pressure installations.

Liquid marking meaning:

- “K” - compressor;

- “C” denotes the sour crude oil from which the lubricant is produced.

- 19 - average viscosity at 100°C (in mm/s2).

The peculiarity of the product is the minimum of additional elements in the composition. For example, no anti-friction additives are added because the base is sufficient to effectively reduce friction. But there is an anti-corrosion additive in the oil.

Features of compressor oil

The technical characteristics that compressor oil must have are a low tendency to self-ignition, foaming and low volatility. One of the mandatory requirements for a lubricant is its viscosity: not lower than seven units. It’s worth noting right away that regular motor oil is definitely not suitable for a piston compressor - it creates a fire hazard and harms the proper operation of the equipment. The operating temperature of the substance is also important: as a rule, it depends on the season, but there are also universal oils that must be refilled regularly, after a certain period of operation of the compressor.

Oil for piston compressor equipment should, first of all, be recommended by the manufacturers of the units themselves. Compliance of the substance with the compressor model is a guarantee that the device will accept it perfectly and will work properly. At the same time, piston units are very demanding: the equipment is characterized by high compression temperatures (up to 150 degrees Celsius), pressures of up to 20 bar, condensation formation even at low loads, and fine dust entering the compressor if the mechanism is installed incorrectly.

There are several types of compressor oils:

Composition and performance characteristics

To ensure trouble-free operation and long service life of the mechanisms, the lubricant must meet the following requirements:

- Ensure temperature stability by effectively cooling the moving internal components of the compressor;

- Prevent the formation of coke-like deposits during oil heating;

- Have a stable viscosity indicator over a wide range of operating temperatures;

- Maintain the tightness of the joints of the parts, filling all the gaps;

- It is good to lubricate rubbing parts to avoid abrasion and overheating.

To achieve the above requirements, compressor oils have the following performance and technical characteristics:

- The viscosity coefficient at t = 100ºC varies in the range from 7 to 30 centistokes;

- Low degree of evaporation, including at elevated operating temperatures;

- Ability to perform its functions at high temperatures of mechanism components and pumped substances. According to the requirements of technical standards, the ignition temperature of compressor lubricant should be from 190 to 270ºC;

- Chemical neutrality. It must not react with the pumped gases. When used in refrigeration units, compressor oil must be inert towards refrigerants.

Based on their composition, compressor oils are divided into mineral-based varieties. These are either pure mineral oils or have a certain percentage of additives that provide anti-corrosion properties, oxidative stability, and increase the service life of fuels and lubricants.

In recent years, synthetic and semi-synthetic oils made from hydrotreated or essential oils have become widespread. Their main advantage compared to mineral oil is their improved technical characteristics. This concerns the fluidity rate, the lower solidification threshold, and the ability to work for a long time in particularly difficult conditions.

Hydraulic oil standards and designations

If we take all the applicable standards for these oils, we mainly focus on DIN, this is what describes the requirements for all hydraulic oils from the point of view of control by Germany.

They are given the abbreviation N. These are ordinary mineral oils without additives. It is not possible to find these oils on the market, since they operate at a pressure of 150 atm. That is, this is a rather unstable hydraulics designed for relatively low pressures.

In modern systems it can oxidize and lose its properties. HL series oils. These are mineral oils with anti-corrosion and antioxidant additives, which are designed for pressures of up to 250 atm, but the temperature of the oil in volume is up to 90 degrees.

HLP series oils

These are already top requirements for oils. Operates at pressure within 250 atm. and oil temperature above 90 degrees. This is just for those systems on which you can boil a kettle. The HVLP series oils stand out. The letter "V" stands for viscosity. These are oils with high low-temperature and high-temperature properties. They have improved viscosity stability. But if we take without taking into account external temperatures, then the applicability is the same compared to the previous one.

To work with pressures above 250 atm, special hydraulic oils are produced for special requirements. Please note that sometimes tolerances are marked with ISO tolerances, so don’t be alarmed if you don’t find it in stock. Liqui Moly oils are marked according to DIN.

Production

The use of a synthetic base for the manufacture of KS-19 is excluded by GOST requirements.

During processing by hydrotreating, sulfur content is reduced simultaneously with the proportion of oxygen-containing compounds, which provides the lubricant with minimal oxidation.

The base is brought to the required viscosity, then the required minimum of additives is added. Let's summarize

KS-19 oil has the required kinematic viscosity, high temperature stability with a low degree of self-ignition. It has a number of advantages, which are confirmed both by tests and by the experience of users of compressor devices - domestic and industrial.

What makes the lubricant accessible to all categories of consumers is not only the optimal price, but also the variety of liquid pouring options.

It is possible to replace KS-19 with MS-20 oil.

Specialists in the supply departments of enterprises are offered draft KS-19 in any required quantities. And for everyday use, the oil is sold in cans and bottles of various sizes, which gives convenience and freedom of choice.

DVR NEOLINE X-COP 9100S

Fugicar FC8 mirror-on-board computer

Black Size – gel for penis enlargement

Previous

Compressor oil KS-19

Application

A compressor is a device widely used in car repair and maintenance, and in interior and exterior construction and repair work.

The compressor can be oil-based or oil-free, but the latter loses in service life, moreover, due to rapid wear of parts.

The oil engine must be lubricated regularly, changing the used fluid, just like in a car engine.

Compressor oil KS-19 is a universal substance that is used in all areas:

- construction;

- chemical industry;

- car service organizations;

- housekeeping (care of equipment purchased for personal needs);

- other areas of application of compressors.

The lubricant equally effectively protects parts of complex multi-stage devices in production and simple single-stage devices in everyday life from corrosion and excessive friction. The price of the product is also quite affordable for both successful companies and household consumers.

There are only two restrictions on the use of KS-19 - high temperatures and extreme loads. Only under such conditions is it preferable to use synthetic oils designed for the appropriate operating mode.

Differences in classification and method of application

If motor oil is simply classified by ignition or flash point, then compressor technical fluids are divided by discharge temperature.

The liquids or gases that the compressor pumps have an inlet and outlet temperature. There are 4 groups for lubricants (domestic classification):

- Simple operation: up to 160°C.

- Moderate mode (the most common) – up to 180°C.

- Severe duty: for powerful pumping stations, continuous operation and (or) variable loads - up to 200°C.

- Extreme mode: particularly difficult conditions, emergency systems, installation of compressors in unfavorable environments - over 200°C.

The difficulty of selection lies in the fact that, unlike motor oils, compressor manufacturers have not developed uniform compatibility rules, such as SAE, ACEA, or API.

For example, foreign manufacturers of technical fluids for piston pumping units are guided by the VCL DIN 51 506 classification. And screw compressors are serviced with oils that meet a different standard: ISO/DP 6521.

Properties of Total compressor oil, proper selection for equipment - video

There is nothing wrong with this, but it is difficult for the compressor user to select consumables. If you cannot find a compatible product, you have to buy exactly the type (and often the brand) of compressor oil that is indicated in the documentation.

If you have a domestic compressor, you can safely follow GOST 1861-73. It installs two main types of consumables:

- K-12 – distillate oil, with the addition of a depressant additive in a volume of 1/100. It is possible to replace the base with a mixture of residual and distillate oil (by analogy with synthetics and semi-synthetics). The domestic development of AzNII is used as an additive.

- K-19 is a composition based on 100% residual oil, with the addition of additives (similar to mineral oil).

As an example, we can give the classification of imported analogues:

Shell synthetic compressor oil:

The illustration shows a table of compatibility with ISO operating conditions, while other manufacturers use the same standard in their own way.

There is another option for the applicability of standards: DIN 51506 and ISO 6743/3 with additional information. It is similar to the Shell format, but with its own characteristics. Imported oils may use additives or be produced without them.

Let's look at the temperature classification option from the manufacturer Klüber Lubrication.

The range of compatibility is wider than according to Russian GOST, and there are fewer groups. This indicates some unification. However, the same Klüber Lubrication introduces its own standards for compressor oils, for compatibility with other manufacturers, comparative tables will be required.

The following classification option: compatibility for Russian GOST for temperature and operating conditions:

- K19 (KS19) - the lubricant is free of sulfur compounds. Designed for operation with medium and high pressure loads of the pumped material.

- K2-24, K3-20, K4-20 – oils are used in compressors with the ability to connect the pumped material and lubricant. No filter is required, the consumable is high quality and neutral. Does not change characteristics at high pressure. Contains universal additives for severe operating conditions.

- K3-10 (10N) is a high-temperature lubricant that does not change parameters at air mixture temperatures up to 200°C. For stabilization, compressor oil contains a complex of high-temperature and antioxidant additives.

Advantages of KS 19

Mineral compressor oil KS 19 has a number of advantages compared to other similar lubricants.

Comparison of mineral and synthetic oil

- The auto-ignition temperature at which the product evaporates is very high and is at least 400°. This guarantees stable operation throughout the entire period of operation.

- The oil contains a patented additive that has antioxidant properties, which protects internal parts from corrosion and helps remove oil formations on the walls and rotating parts of the compressor.

- When the unit is operating, the chamber where the incoming air or gas is compressed is sealed with oil, which allows the device to operate as efficiently as possible, without passing or losing even small volumes of gas.

- It has excellent lubricating characteristics, in which cylinders, rotors and valves receive additional protection from overheating and friction.

- Throughout the entire period of operation, it does not change its temperature properties, that is, there is thermal stability. This has the best effect on the operation of the compressor and the oil poured into it as a whole.

This lubricant is easy to purchase in all specialized stores, especially since the industry offers different bottlings. For example, if you need to purchase large volumes for industrial production, then it is best to buy KS 19 for bottling. If you need small or medium volumes, you can buy bottles or canisters of different sizes, which is very convenient. The price of KS 19 oil corresponds to the standard price for this type of lubricant and is not overpriced.

Hydraulic systems

If we talk about modern hydraulic systems, every day manufacturers of hydraulic systems are trying to increase productivity and reduce the size of their units, but to achieve this goal there is only one option: to increase the pressure in the system as much as possible. As a result, the temperature rises. It is under these conditions that hydraulics, in comparison with mechanics and pneumatics, shows all its best properties. An undeniable plus is the smooth operation of the main body of the entire hydraulic system.

Excellent temperature stability and excellent performance at extremely high temperatures. But such work imposes severe demands on oils. The first thing you need to pay attention to is oxidizing properties. Since modern systems operate at high volumetric temperatures. That is, our hydraulics heat up like motor oil.

What hydraulics to use: properties

Therefore, you need an oil that is very resistant to oxidation. This approach will also help save us from the cost of new hydraulic system parts. In second place are anti-foam properties. There are situations when air accidentally gets into an actively working unit, especially when it comes to the oil drain tank. If the oil has low anti-foaming properties, then this unsettled substance will successfully reach the hydraulic working area.

This can cause something similar to an air brake problem. At first, our reaction slows down, that is, we press the pedal to the floor, but nothing happens. If an air bubble enters, we bring the working unit into proper condition, but then the pressure will increase due to the fact that many bubbles will appear. It turns out that we are not using hydraulics smoothly, but are crumbling the component.

Oils should immediately reject gas bubbles entering the system.

Anti-wear properties of oils

The forces in modern hydraulic systems have doubled or tenfold. Therefore, anti-wear properties are very important for modern hydraulic oils.

Filterability. It is engaged in helping the oil overcome the thin pores of the filter, throwing all contaminants onto them while minimally losing speed. Viscosity-temperature properties. The better the stability of these properties, the easier it is for the hydraulic drive. Even in warm-up mode, the system will operate adequately at the output. If we talk about water, then at high pressure it will remain liquid and then it will boil.

Cavitation may form, as in the example with water vapor. There are also special requirements, for example, demulsifying properties, that is, maintaining the performance of the engine oil when a small amount of water gets in contact with it.

It turns out that the hydraulics will take in water until its volume exceeds the limit. but basically the demulsifying properties are put at the forefront.

Anti-corrosion properties. When corrosion occurs, the cleanliness of the surface will be compromised. It will destroy the seals.

Technical characteristics and operational properties of compressor oils.

According to GOST 12.1.007, the hazard class of compressor oils for harmful effects on the human body:

- in liquid state – 4th;

- when oil mist forms – 3rd.

The heat of combustion of compressor oil is about 40 MJ/kg, therefore, in accordance with VNTP 4-89, premises in which air compressors are used are classified as V/D in terms of explosion and fire hazard (if a unit of equipment contains more or less 60 kg of oil ).

To improve the performance properties of mineral compressor oils, antioxidant, anti-corrosion, anti-foam, detergent and other additives are introduced into their composition. The characteristics of different types of oils are given in Table 1.

Table 1

| Indicators | Oils without additives | Oils with additives | ||||||||

| K-19 | KS-19 | Kp-8S | K3-10 | K3-10N | KS-19P | K3-20 | K4-20 | K2-220 | K2-24 | |

| Kinematic viscosity, mm2/s, at temperature: 100°C | 17-21 | 18-22 | 6,5-9 | 8,8-10,5 | 9-13 | 18-24 | 17-23 | 19,5-22 | 18-21 | 21-25 |

| 40 °C | — | — | 41,4-50,6 | 73,7-96,2 | 76-130 | — | 206-336 | 240-310 | 220-310 | — |

| Viscosity index, not less | — | 92 | 95 | 90 | 90 | 85 | 80 | 85 | 82 | 82 |

| Acid number, mg KOH/g | 0,04 | 0,02 | 0,05 | 0,2 | 0,2 | 0,03 | 0,5 | — | 0,4 | 0,35 |

| Temperature, °C: flash in an open crucible, not lower | 245 | 260 | 200 | 205 | 205 | 260 | 250 | 225 | 230 | 270 |

| hardening, no higher | -5 | -15 | -15 | -10 | -30 | -15 | -15 | -15 | -10 | -10 |

| Content, % (wt. fraction), no more than: water-soluble acids and alkalis | Absence | — | — | — | Absence | — | — | — | — | |

| mechanical impurities | 0,07 | Absence | 0,07 | 0,02 | Absence | |||||

| water | Absence | Footprints | Absence | Footprints | Absence | |||||

| sulfur | 0,3 | 1,0 | 0,5 | 0,65 | 0,65 | 1,0 | 0,35 | 0,6 | 0,5 | 0,5 |

| selective solvents | — | Absence | — | — | Absence | — | Absence | — | — | |

| Coking rate, %, no more | 0,5 | 0,5 | 0,05 | 0,2 | 0,2 | 0,45 | 0,45 | — | 0,45 | 0,45 |

| Ash content, %, no more | 0,01 | 0,005 | 0,005 | 0,005 * | 0,005 * | 0,005 | 0,12 | 0,5-0,8 | 0,06 | 0,06 |

| Stability against oxidation, no more than: sediment, % (wt. fraction) | 0,015 | Absence | 0,02 | — | — | Absence | — | — | — | — |

| acid number, mg KOH/g | — | 0,5 | 0,2 | — | — | 0,5 | — | — | — | — |

| increase in coking capacity, % | — | — | — | 1,5 ** | 1,5 ** | — | 2,0 ** | — | 3,0 ** | 2,0 ** |

| evaporation losses, % | — | — | — | 15 ** | 15 ** | — | — | — | 20 ** | — |

| Color, units CNT, no more | — | 7,0 | 2,5 | 6,5 | 6,5 | 7,0 | 7,5 | — | 7,5 | 7,5 |

| Corrosion: on steel plates | Withstands | — | — | Withstands | — | Withstands | — | — | — | |

| on lead plates, g/cm2, no more | — | 10 | — | — | — | — | — | 10 | — | — |

| on copper plates | — | — | Withstands | — | — | Withstands | — | — | Withstands | |

| on steel rods | — | — | Absence | — | — | — | — | Absence | — | — |

| Density, kg/dm3 | — | 905 | 885 | 900 | 900 | 905 | 900 | 900 | 905 | 900 |

| * The indicator is normalized for base oil. ** Stability determined according to ISO 6617 method. |

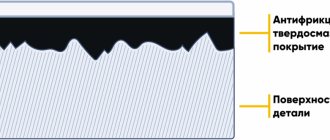

Density and viscosity of compressor oil with temperature changes

With an increase/decrease in temperature, the viscosity and density of compressor oil decrease/increase (Fig. 1), which can cause a deterioration in its lubricating and sealing properties/difficulties in starting equipment in the cold season.

Fig.1

For highly loaded equipment, the required viscosity of the lubricant is calculated using the formula:

υp = υα p

where υp and υ are dynamic viscosity at operating (p) and atmospheric (0) pressure; α is a constant coefficient for a specific brand.

The density of the oil at temperature t can be quickly determined in a simple way: multiply the difference between it and +20 °C by the temperature correction (Table 2), subtract/add the resulting product from the density value at +20 °C (indicated in the technical specifications), if t above/below +20 °C.

table 2

| Density at 20 °C | Temperature correction per 1 °C | Density at 20 °C | Temperature correction per 1 °C |

| 0,6500–0,6590 | 0,000962 | 0,8300–0,8399 | 0,000725 |

| 0,6600–0,6690 | 0,000949 | 0,8400–0,8499 | 0,000712 |

| 0,6700–0,6790 | 0,000936 | 0,8500–0,8599 | 0,000699 |

| 0,6800–0,6890 | 0,000925 | 0,8600–0,8699 | 0,000686 |

| 0,6900–0,6999 | 0,000910 | 0,8700–0,8799 | 0,000673 |

| 0,7000–0,7099 | 0,000897 | 0,8800–0,8899 | 0,000660 |

| 0,7100–0,7199 | 0,000884 | 0,8900–0,8999 | 0,000647 |

| 0,7200–0,7299 | 0,000870 | 0,9000–0,9099 | 0,000633 |

| 0,7300–0,7399 | 0,000857 | 0,9100–0,9199 | 0,000620 |

| 0,7400–0,7499 | 0,000844 | 0,9200–0,9299 | 0,000607 |

| 0,7500–0,7599 | 0,000831 | 0,9300–0,9399 | 0,000594 |

| 0,7600–0,7699 | 0,000818 | 0,9400–0,9499 | 0,000581 |

| 0,7700–0,7799 | 0,000805 | 0,9500–0,9599 | 0,000567 |

| 0,7800–0,7899 | 0,000792 | 0,9600–0,9699 | 0,000554 |

| 0,7900–0,7999 | 0,000778 | 0,9700–0,9799 | 0,000541 |

| 0,8000–0,8099 | 0,000765 | 0,9800–0,9899 | 0,000528 |

| 0,8100–0,8199 | 0,000752 | 0,9900–1,0000 | 0,000515 |

| 0,8200–0,8299 | 0,000738 |

Specifications

| indicators | k-19 | ks-19 | kp-8s | k3-10 | k3-10n | ks-19p | k3-20 | k4-20 | k2-24 |

| kinematic viscosity, mm 2/s, at temperature: | |||||||||

| 100 °C | 17-21 | 18-22 | 6,5-9 | 8,8-10,5 | 9-13 | 18-24 | 17-23 | 19,5-22 | 21-25 |

| 40 °C | – | – | 41,4-50,6 | 73,7-96,2 | 76-130 | – | 209-336 | 240-310 | – |

| viscosity index, not less | – | 92 | 95 | 90 | 90 | 85 | 80 | 85 | 82 |

| acid number, mg con/g, no more | 0,04 | 0,02 | 0,05 | 0,2 | 0,2 | 0,03 | 0,5 | – | 0,35 |

| flashes in an open crucible, not lower | 245 | 260 | 200 | 205 | 205 | 260 | 250 | 225 | 270 |

| hardening, no higher | -5 | -15 | -15 | -10 | -30 | -15 | -15 | -15 | -10 |

| content, % (mass fraction), no more | |||||||||

| water-soluble acids and alkalis | absence | – | – | – | ots. | – | – | – | |

| mechanical impurities | 0,07 | absence | 0,07 | 0,02 | ots. | ||||

| water | absence | footprints | absence | footprints | ots. | ||||

| sulfur | 0,3 | 1,0 | 0,5 | 0,65 | 0,65 | 1,0 | 0,35 | 0,6 | 0,5 |

| selective solvents | – | absence | – | – | ots. | – | ots. | – | |

| coking capacity, %, no more | 0,5 | 0,5 | 0,05 | 0,2 | 0,2 | 0,45 | 0,45 | – | 0,5 |

| ash content, %, no more | 0,01 | 0,005 | 0,005 | 0,005* | 0,005* | 0,005 | 0,12 | 0,5-0,8 | 0,6 |

| stability against oxidation, no more | |||||||||

| sediment, % (mass fraction) | 0,015 | absence | 0,02 | – | – | ots. | – | – | – |

| acid number, mg con/g | – | 0,5 | 0,2 | – | – | 0,5 | – | – | – |

| increase in coking capacity, % | – | – | – | 1,5** | 1,5** | – | 2,0** | – | 2,0** |

| evaporation losses, % | – | – | – | 15** | 15** | – | – | – | – |

| color, units tsnt, no more | – | 7,0 | 2,5 | 6,5 | 6,5 | 7,0 | 7,5 | – | 7,5 |

| corrosion: | |||||||||

| on steel plates | vyd. | – | – | withstands | – | vyd. | – | – | |

| on lead plates, g/cm 2, no more | – | 10 | – | – | – | – | – | 10 | – |

| on copper plates | – | – | vyd. | – | – | vyd. | – | – | vyd. |

| on steel rods | – | – | ots. | – | – | – | – | ots. | – |

| density at 20 °C, kg/m 3, no more | – | 905 | 885 | 900 | 900 | 905 | 900 | 900 | 900 |

Methods for obtaining meat liquid

The oil product is obtained after automated oil processing. The production process uses crude oil containing sulfur and paraffin. It is carefully distilled and undergoes lengthy purification. As a result, we get high-quality mineral lubricant, which can be used at temperatures from 120 to 160 degrees. It is not recommended to use at very high temperatures, as this will cause rapid wear of the device.

This lubricant is a truly universal product, but is limited only by temperature limits. It is actively used in the chemical, automotive and construction industries. But if your engine constantly operates in intense and extreme conditions, then synthetic lubricants that are well adapted to this operating mode are best suited.

It is necessary to comply with technical requirements and not exceed the temperature limit to prevent fire.

Compressor oil: what is the difference from motor oil

A fairly common question is what is the difference between motor oil and special compressor oil. In general, we can say that synthetic compressor oil belongs to motor oils. This is due to the fact that both versions are used in difficult operating conditions: changes in load, temperature and many other parameters.

It is not recommended to use conventional oils for a screw compressor for a number of reasons, among which we note slightly different performance characteristics.

In addition, mineral oil for internal combustion engines has the worst properties. This is due to the fact that they do not tolerate overheating and are characterized by worse performance characteristics in comparison with synthetic versions.

The above information determines that synthetic motor oils can be used for compressors, but only in case of short-term operation. If the device operates constantly, then attention should be paid to special lubricants that have more attractive properties.