LLC SO "PRESSMASH" produces and sells open-type crank presses. The equipment is designed for processing sheet metal using the cold stamping method. The following operations can be performed on open crank presses:

- flexible,

- pruning,

- hole punching,

- shallow hood,

- cutting down and a number of other actions.

The functionality of this equipment allows the production of parts of various shapes - from simple plates and disks to stepped shafts. Stamping equipment allows you to give workpieces a certain shape. An open crank press is one of the most popular categories of equipment used in metalworking.

FOUNDATION REQUIREMENTS

Crank presses can arrive at the site either in full factory readiness, mothballed, or as separate elements (assembly elements - drawers). Our company’s specialists pay special attention to the stage of transporting the press or its parts from the manufacturer’s premises to the installation site. This process is divided into several technological stages: delivery of equipment by the plant, loading onto transport, unloading and temporary storage until the final installation of the press on the foundation. During each stage, the condition of the equipment is monitored to ensure there is no damage; the completion of the work is recorded in acts with the obligatory signatures of specialists from both the parties handing over and receiving the equipment.

Taking into account the weight and size parameters of crank presses and the specifics of the work they perform, special attention, even before installing these units, is paid to the installation of the foundation for them, which is made of high-grade reinforced concrete with mandatory control of the geometry of the press attachment points. If the site already has a foundation for a crank press, or if the work on its construction was carried out by another organization, specialists will carry out a set of works to check it, and, if necessary, laboratory tests of the foundation material for compliance with the declared strength characteristics.

Types of stamping technologies

The stamping process of processing blanks can be carried out using the hot or cold method. These technological varieties involve the use of special equipment and the use of certain metal processing conditions.

Cold stamping is one of the types of stamping

The hot stamping method processes workpieces that are preheated in special devices to a given temperature. Hot stamping is necessary when there is not enough equipment power to process a cold alloy. Heating devices can be electric or plasma ovens. This method requires accurate calculation of the parameters of the finished part, taking into account the shrinkage of the metal during the cooling process.

In cold stamping, parts are formed due to the mechanical pressure of the elements of the stamping press. Cold stamping is considered a more common method of metal processing. It does not require additional equipment, complex calculations or mechanical modification of parts. Thanks to this method, the strength properties of the material increase. The resulting products are distinguished by high surface quality and precision.

This is interesting: Radial drilling machine 2M55: characteristics and documentation

PREPARATORY STAGE OF WORK

The specificity of the work and the weight and size characteristics of crank presses impose increased responsibility on the preparatory stage of installation, dismantling and rigging of this type of equipment. In order to avoid unwanted problems and unforeseen expenses in the future, it is necessary at the initial stage to study the product passport in detail, to ensure the quality of the unit, the absence of damage during transportation, as well as during its storage immediately before installation. No less attention is paid to studying the plan of an industrial building in which it is planned to carry out work on the installation or dismantling of a crank press, collecting information about the available capacities and the measures necessary for carrying out the work, as well as drawing up as-built documentation for the installation of the press or PPR for the installation of the press. Only after the parties have signed a comprehensive package of documents can the installation, dismantling or rigging of the crank press begin.

WORK EXPERIENCE

Our company has unique experience in carrying out installation and dismantling of crank presses. One of our company’s projects consisted of moving a press operating in the USA to one of the Russian industrial enterprises. Accordingly, the complex of works for this project (enlarged) included: dismantling the press, loading components and assemblies first onto automobile and then onto sea transport, acceptance of equipment at the port of arrival, unloading of equipment onto automobile transport, acceptance of equipment at the installation site, installation press and, finally, commissioning and final acceptance of equipment.

By ordering a service for installation, dismantling, rigging or overhaul of crank presses from our company, you are guaranteed to receive a high-quality service and save yourself from the need to eliminate the consequences of a negligent or unprofessional attitude to the matter. In the case of complex and large units such as crank presses, these consequences can be of a serious financial nature.

Overview of IPONMAC presses and their characteristics

| Model series | KD 23D | HL41 | PG41 |

| Nominal force, t | 10-80 | 40-315 | 40-315 |

| Opening height/clearance, mm | 130-280 | 800-1600 | 800-1600 |

| Table/bottom plate size, mm | up to 520*860 | up to 1400*1200 | up to 1400*1200 |

| Drive power, kW | 1,1-7,5 | 5,5-30 | 5,5-30 |

| Weight, kg | 600-5280 | 3000-36000 | 3-36000 |

The meanings of the first two digits in the designations of crank presses:

rice. 1. Classification and designation of mechanical presses

- K14 - open press (C - type), single-crank, single-action, single-column, with a movable table

- K21 - open press (C - type), single-crank, single-action, two-post, with a fixed table

- K23 - open press (C - type), single-crank, single-action, two-post, with a fixed table, tiltable

- K30, K31 - open press (C - type), double-crank, simple action

- K25..K27 - closed press (H - type), single-crank, simple action

- K55 - closed press (H - type), single-crank, double-acting

- K35..K37 - closed press (H - type), two-crank, single action

- K60..K65 - closed press (H - type), double-crank, double-acting

- K40..K45 - closed press (H - type), four-crank, simple action

- K70..K75 - closed press (H - type), four-crank, double-acting

- K19 - hole punching press

- K01 - coordinate-turret press

- I13 – press brake

Types of technological operations

Technological operations with metal sheets are separating and forming.

Separation stamping operations are performed on equipment equipped with special tools. As a result, a certain part is separated from the workpiece along a straight line or a given contour. The separation of part of the sheet occurs in the following processes:

- Segment _ To perform this action, the equipment is equipped with disk, vibration devices or guillotine shears.

- Trimming . This operation separates the extreme parts of the resulting product.

- Punching . Holes of various configurations are created in a metal sheet using a stamp.

- Felling . A shaped part with a closed contour is obtained from the workpiece.

Form-changing operations are intended to create a product with different parameters and dimensions without mechanical destruction. The following types of these operations are distinguished:

- Beading. The contour of the workpiece or the internal holes are exposed to the stamp to form beads of certain sizes.

- Hood. This operation is a type of volumetric stamping, in which a spatial element is obtained from a flat material.

- Crimping To narrow the ends of a hollow workpiece, a stamp with a conical-type matrix having a narrowing working area is used.

- Flexible. As a result of the operation, the curvature of the surface changes by bending the metal and deforming the workpiece.

- Molding is a change in the shape of individual sections by reducing the thickness of the part without disturbing the external contour of the product.

- Puklyovka. Connecting two plates with a stamp without using additional elements.

GENERAL PROVISIONS

has a full range of technical approvals to perform work related to installation, dismantling, as well as major repairs of crank presses. If the necessary technical documentation is missing, our specialists are able to quickly restore or re-develop it. not only carries out installation, dismantling, rigging and repair of press equipment, but also offers its subsequent warranty maintenance service. has permits for all types of work, for all operations with industrial equipment. In addition, he is a member of the SRO. The timing and cost of repair work that we offer to clients are 100 percent reasonable, realistic and competitive.

Features of open and closed dies

Closed stamping

Stamping equipment can be equipped with open or closed dies. In an open die, excess metal flows into a burr or flash that performs a specific function. The main disadvantages of this technology are: loss of alloy due to flash, reduction in product quality due to cut fibers when removing burrs.

Closed dies are used to produce simple shaped products. This flash-free technology is characterized by metal savings, no costs for cutting burrs, and high product quality due to all-round compression. Metal fibers are not cut. The closed die processing method is used for low-plasticity alloys. The main disadvantages are: the need for precise dosage of the alloy, the complex design of the die.

In modern manufacturing, stamping is primarily a preparatory operation that allows the production of parts for both electronics and aircraft or watercraft. The resulting products are subsequently subjected to welding, cutting, riveting and other processing methods depending on the technological process.

Related video: Sheet stamping

This is interesting: Types and characteristics of welding inverters

Values of the main parameter in the designation of presses:

Table 1. Designation of the main parameter of the press

| Press designation | Press force, kN | Press designation | Press force, kN | Press designation | Press force, kN | Press designation | Press force, kN |

| 14 | 25 kN | 20 | 100 kN | 30 | 1000 kN | 40 | 10000 kN |

| 15 | 31.5 kN | 21 | 125 kN | 31 | 1250 kN | 41 | 12500 kN |

| 16 | 40 kN | 22 | 160 kN | 32 | 1600 kN | 42 | 16000 kN |

| 18 | 63 kN | 23 | 200 kN | 33 | 2000 kN | 43 | 20000 kN |

| 24 | 250 kN | 34 | 2500 kN | 44 | 25000 kN | ||

| 25 | 315 kN | 35 | 3150 kN | 45 | 31500 kN | ||

| 26 | 400 kN | 36 | 4000 kN | 46 | 40000 kN | ||

| 28 | 630 kN | 38 | 6300 kN | 48 | 63000 kN |

Example of designation of mechanical presses:

- KD2122 - 160 kN, single-crank open press (C type), simple action, two-post with a fixed table

- KD2124 - 250 kN, single-crank open press (C type), simple action, two-post with a fixed table

- KD2126 - 400 kN, single-crank open press (C type), simple action, two-post with a fixed table

- KD2128 - 630 kN, single-crank open press (C type), simple action, two-post with a fixed table

- K2130 - 1000 kN, single-crank open press (C - type), simple action, two-post with a fixed table

Example of hydraulic press designation:

- P6320B - 100 kN, single-column press with correct pressing

- P6328B - 630 kN, single-column press with correct pressing

- P6330 - 1000 kN, single-column press with correct pressing

- P6334 - 2500 kN, single-column press with correct pressing

rice. 3. Single-acting open single-crank presses with a force of up to 630 kN

- a - non-tilting single-post with a movable table and a horn of the KD14 type

- b - the same with the horn installed;

- c - non-tiltable two-post with a fixed table, type KD21

- g — tilting two-column presses with a fixed table, type KD23

Operating principle and design of various types of presses

metal stamping workshop

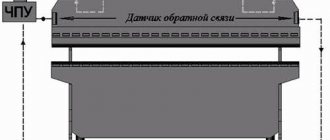

Any standard stamping machine consists of the following main components: motor, transmission, actuator. The transmission and motor together make up the "drive". The main characteristic of the drive is the type of connection between the engine and the actuator: mechanical or non-rigid (liquid, gas, steam). Working parts of the press: rollers, slider, cross-beams, rollers, women.

Crank press

The machine drive rotates, the movement on the slide is converted to reciprocating.

Under the influence of this movement, the metal is processed using a stamp. All machine parts are made of durable steel and equipped with stiffeners. The movement of the slider occurs according to a strict schedule. The force on the slide reaches 8 thousand tons. Crank forging plants make it possible to speed up, simplify and reduce the cost of production of parts, saving up to 30% of rolled stock. All crank machines are divided into simple, double and triple action. The crank press is capable of performing the following types of work:

- stamping in open and closed dies;

- burr formation;

- extrusion;

- firmware;

- combined processing.

A mechanical press acts on the material with an impact, while a hydraulic press, applying less force, gets a greater effect. Therefore, the latter are used for the manufacture of large products with thick walls.

Hydraulic presses

Hydraulic Press

Capable of stamping surfaces, pressing and forging metal products. They are also used for recycling metal waste. The operation of the machine is based on increasing the force of pressure on the metal many times. The press consists of two communicating cylinders with water, between which a pipe passes. Pistons are installed in the cylinders. The operating principle of the press is based on Pascal's law.

Radial forging apparatus

Processes metal using the hot method. The blank enters the heating module, which operates on the induction principle. Here it is heated, when the metal becomes sufficiently pliable, it is fed through a conveyor to a gripping mechanism, which feeds the workpiece directly into the processing zone. Forging or stamping is carried out with strikers; during the process, the workpiece rotates all the time, due to which it is processed evenly on all sides. The press is powered by an electric motor connected by a V-belt drive to the shafts. They are placed vertically and direct movement to the connecting rod and striker, between which the slider is installed. To ensure that all movements of the mechanism are synchronous, there are copying drums. The blank holder is rotated by an electric motor through worm gears. The spring clutch slows down the movement at the right moments.

Electromagnetic press

This is the latest development, which is just beginning to be used in industry. The working body of the machine is the core of an electromagnet, which moves under the influence of an electromagnetic field. The core moves the slider or die, the springs return the slider to its original position. Such machines are characterized by high productivity and efficiency. Today, there are models with a small amplitude of movement of the working body - 10 mm and a force of no more than 2.5 tons.

Operation of a roughing stamping machine in the video: