Description

Multi-saw wood sawing machines are devices adapted for the production of finished lumber, that is, for producing various blades, as well as for making cuts and milling. They can be equipped with one or two working shafts, as well as mechanized feeding of workpieces. They are usually characterized by high processing accuracy.

This equipment, depending on the type and power, works in various large industries and small workshops.

The main difference between such machines and sawmills is that the sawmill does not have the same precision of operation as a multi-saw. This device uses band or circular saws. A frame-type machine with band saws is more expensive than a machine with circular saws. But sharpening its discs is more expensive.

Design and principle of operation of multi-rip machines

Let's look at the main working mechanisms of this woodworking machine.

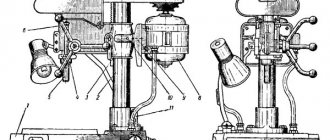

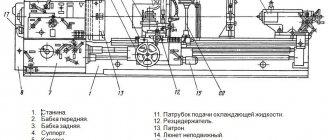

Bed – contains the main components of this equipment.

Power unit - produces rotational or reciprocating movement of saws processing material. In addition, it drives the workpiece feed unit.

Cutting element - includes 1 or more shafts on which saw blades are mounted.

The principle of operation of the multi-rip machine

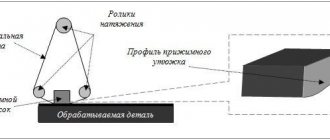

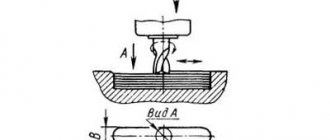

The principle of installing saws for cutting boards to size

Circular saw packages

The mechanism that feeds the workpiece. The larger the workpiece for cutting, the correspondingly more powerful this unit should be.

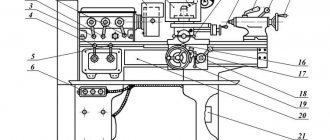

Also, this equipment is usually equipped with 6 shafts: four feed and two receiving shafts. A claw protection is installed on the hole through which the workpiece is fed (it is necessary to exclude the possibility of causing harm to the health of the operator and the workpiece flying out of the machine), and at the exit there is a special protective curtain. To ensure safety, the disk shaft is covered with a platform with slots for cutting tools. The arrangement of the equipment in this way prevents the penetration of various large sawing waste into the sawdust container. In addition, it is possible to connect chip ejectors if necessary.

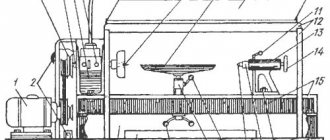

Multi-rip saw SDM-160

The essence of the operation of multi-rip machines is the horizontal feeding of workpieces. They are rigidly clamped by rollers to fix them in the upper and lower parts. The cut is made by rotating the saw part of the machine where the cutting tool is located. The workpiece feed speed is about 30-70 m/min.

It is also possible to make such equipment with your own hands if you feel confident in yourself and your abilities. A multi-saw made independently can be used for processing various edges, longitudinal sawing of wood and many other operations.

Specifications

Among the main technical parameters of multi-saws are:

- workpiece dimensions;

- number of saws installed;

- feed speed;

- workpiece cutting speed;

- saw diameter;

- greatest distance between saws;

- power;

- dimensions of the equipment itself;

- weight.

Now let's look at some basic parameters in more detail.

The maximum dimensions of the material that can be processed allow us to determine the permissible dimensions of the workpiece.

The number of saws installed on the equipment shows the maximum number of boards and blades obtained per pass of the workpiece through the cutting device of the machine.

The feed and cutting speed of the workpiece with a multi-rip machine greatly affects the productivity of the machine and production as a whole.

The diameter of the saws determines the depth of the cut in the workpiece.

By the distance between the saws you can understand how wide the processed lumber will be.

We advise you to carefully select a multi-blade machine, taking into account the parameters described above depending on the required volume of work, operating conditions and production tasks.

Installed saws