Metal cutting is one of the most popular and widespread methods of processing such material. In this case, it is mandatory to use special tools that provide the ability to cut sheet metal, since it is unrealistic to do this without the use of additional devices.

Cutting technology consists in the fact that a workpiece made of a particular material is exposed to the cutting edge of a tool. The sharp cutting edge of the tool moves along the surface of the metal, cutting it. During this process, the cut layer undergoes plastic deformation.

Metal cutting at home

Sheet metal cutting

The main tools for cutting at home are cutters, discs, and drills. The use of such tools makes it possible to give the part the required shape, polish the metal surface, bringing it to the required dimensions.

When using such methods, a knife or other machine acts on the surface of the metal. In this case, it is very important that its cutter has a higher hardness than the workpiece, otherwise no cutting will occur.

The most common method of cutting metal in a home workshop is mechanical cutting. This method of processing the material is quite economical and can provide a very smooth edge to the workpiece. Its only drawback is that it usually only allows for straight-line cutting of metal.

How to make roller shears for cutting sheet metal with your own hands

Metal cutting is one of the most popular and widespread methods of processing such material. In this case, it is mandatory to use special tools that provide the ability to cut sheet metal, since it is unrealistic to do this without the use of additional devices.

Cutting technology consists in the fact that a workpiece made of a particular material is exposed to the cutting edge of a tool. The sharp cutting edge of the tool moves along the surface of the metal, cutting it. During this process, the cut layer undergoes plastic deformation.

Roller knives for metal

Very often in the modern metalworking industry, roller knives are used for cutting sheet metal. The operation of such a tool consists of the work of its two main elements - cutting discs. Rotating in different directions, these roller discs are pressed into the material, cutting it. Due to the friction of the metal and the knives among themselves, the workpiece moves along the tool.

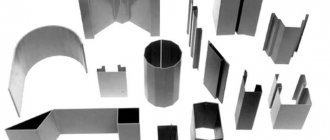

The most common are roller knives for metal, which consist of two rollers. This tool has two rotating disks - lower and upper. Nowadays there are three types of knives:

- with parallel position;

- with one inclined;

- with several slopes.

The first group of such cutting tools is mainly intended for cutting material into strips.

The second group is intended for cutting metal into strips, as well as for round and ring workpieces.

The third group is mainly used for cutting annular, round and curved workpieces with a small radius.

All of these knives are well suited for quickly cutting sheet metal. In this case, the cut edge of the material does not require any additional processing.

Homemade roller knives

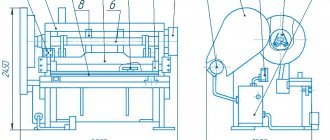

Design of a homemade roller knife

The cost of even the simplest models of roller knives is now very high. Therefore, it makes sense to purchase such a tool only if such processing of sheet metal will be carried out very often. Otherwise, for one-time or periodic use, such a purchase will not justify itself from a financial point of view.

In such a case, the more correct solution would be to try to make such a tool with your own hands.

There can be a lot of designs of roller knives, so making a knife yourself will not be difficult. But the main part of the tool - the cutting knives - must be made of the highest quality and durable alloy, the strength of which exceeds the material being cut. Otherwise, the quality of the cut edge will be very low and additional processing will be required.

Usually, even in factory models of roller knives, the resource is within 25 km of sheet metal 0.5 millimeters thick. If you cut sheet metal with greater thickness, then the service life of the tool will decrease. But after this, the rollers can be sharpened, as a result of which the tool will be ready for use again.

As for the service life of homemade roller knives, it directly depends on the quality of the material from which the cutting parts of the machine are made.

Making roller tools

To work you will need:

- two ball bearings (204 or 205, or others), the same size - an optional condition;

- steel pipe for the handle;

- corner (40-60 mm, approximate length - 300-400 mm);

- fasteners - bolts, nuts, washers, etc.;

- tools: grinder, drill, welding machine.

The whole process looks like this:

- A part of the required dimensions is cut out from the corner. On both ball bearings, the edge is ground off at an acute angle.

- A hole is drilled in the corner piece to secure the bearing. To fix it, use a bolt with a countersunk head and a washer, which provides the required pressure to the corner shelf.

- The future knife is attached so that its edge protrudes beyond the edge of the corner by one or two millimeters. To be able to adjust, the washer is placed on the inside. The bolt head is recessed into the base of the profile. If this is not possible, then the groove is made in a workbench.

- The second element is cut off from the profile; it is half as long as the first, on which the bearing is already attached. Using a grinder, a piece is cut out of it, pointed on one side. At its end part, after drilling a hole, fix the second future knife.

- The new workpiece is welded to the large element so that the upper and lower bearings are in close contact, and the distance from the outer race to the base flange is about 1 mm.

- The last stage is welding the handle, which is pre-bent in a way that is convenient for the master.

The produced cutting tool will be able to cut metal sheets whose thickness is a maximum of 0.5 mm. Since wear of the edge of ball bearings is an inevitable evil during operation, it is necessary to provide a device for their convenient, precise adjustment.

A do-it-yourself roller knife for sheet metal is a good way to significantly simplify work, reduce time for processing material, minimize the number of defects, the amount of debris, and also avoid lengthy physical “exercises.” Therefore, the described mechanism, made independently, is not only beneficial in terms of economy, it is an ideal replacement for both metal shears and an industrial guillotine.

Since what is written with a pen does not always allow a thorough understanding of all stages of work, it is quite difficult to present a clear picture without an auxiliary video. It is this that describes the whole process that is located here:

What can knives be made from?

Roller blade made of bearings

In the case of making such a tool yourself, the main problem is to choose the appropriate material that will cut metal workpieces.

So, if it is necessary to cut not the most durable sheet metal - aluminum, galvanized steel, etc., a good solution would be to use ordinary bearings, the ends of which must first be sharpened.

To cut such knives into metal, one of the rollers, the drive one, must be installed on a handle with which you can press the knives to the material. After this, all that remains is to pull the metal, holding the handle of the homemade machine pressed to the base.

The larger the diameter of the bearings, the higher the cutting speed of such a hand tool.

Thus, now you can find many designs of homemade roller cutting shears. The most difficult thing is to find parts that can be used as knives. To make it more convenient to use a do-it-yourself machine, it can be additionally equipped with guides that will allow you to cut the workpiece smoothly.

In this case, the finished tool, if necessary, can be installed on any metalworking equipment, for example, on a sheet bending machine.

What can a knife be made from?

The options can be very different; here you need to pay attention to what exactly you plan to cut. So, if it is not the most durable sheet steel in its structure, including aluminum, galvanized metal and other similar materials, the most ordinary bearings will be a completely suitable solution. True, for this you will have to pre-sharpen their ends.

To carry out cutting, one of the rollers, the one that will play the role of a drive, is installed on the handle, due to which the knife will be pressed to the metal. Please note that the larger the diameter of the bearings, the faster the material can be cut.

In order for the cutting process to take place with maximum comfort and accuracy, the device can be additionally equipped with guides - this will not be particularly difficult, but it is guaranteed to serve you well in the future.

The resulting tool is quite versatile and can be used in conjunction with a wide variety of metalworking equipment, including sheet metal bending machines, which can also be made independently at home.

Review and comparison of factory models

| Knife model | Trim Cutter 3017 | RNK 098A | for LBM machine |

| Cutting thickness, mm | 0,7 | 1 | 0,8 |

| Weight, kg | 4 | 1,11 | 7,92 |

| Dimensions, mm | 220*180*260 | 180*150*200 | 460*250*300 |

| Price, rub | 27163 | 39390 | 21019 |

Trim Cutter 3017

RNK 098A

for LBM machine