Originally from Sweden

The history of the discovery of metal was born in Sweden. In the middle of the 18th century, the Swedish chemist A.F. Kronstedt suggested that different substances are hidden under the name Molybdaena. After a series of experiments K.V. Scheele (also a Swede) obtained "Wasserbleyerde", a special white earth, and gave it the name molybdic acid.

And in 1782 P.Ya. Gjelm (also a Swede, of course) received a kinglet made from molybdic acid.

Gjelm was happy:

“I am glad that we now have the metal – molybdenum!”

Metal properties

Molybdenum, Molybdaenum (Mo) is element number 42, located in the sixth group of the 5th period of the periodic table. It is classified as a transition metal.

Some characteristics of the element:

- density 10.2 g/cm³;

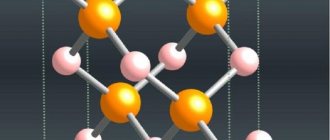

- crystal lattice body-centered, cubic;

- melting point 2623°C;

- paramagnetic;

- hardness on the Mohs scale 4.5.

Chemical properties are largely determined by oxidation states: +2, +3, +4, +5, +6 (the last is the most stable).

The metal practically does not react with hydrogen and nitrogen.

Under normal conditions, molybdenum does not react with air gases. It begins to oxidize when heated above 400°C.

When exposed to reducing agents in a slightly acidic environment, it forms molybdenum blues. These substances are used as dyes (for example, in silk dyeing).

| Properties of the atom | |

| Name, symbol, number | Molybdenum / Molybdaenum (Mo), 42 |

| Atomic mass (molar mass) | 95.96(2)[1] a. e.m. (g/mol) |

| Electronic configuration | [Kr] 4d5 5s1 |

| Atomic radius | 139 pm |

| Chemical properties | |

| Covalent radius | 130 pm |

| Ion radius | (+6e) 62 (+4e) 70 pm |

| Electronegativity | 2.16 (Pauling scale) |

| Electrode potential | −0,2 |

| Oxidation states | 6, 5, 4, 3, 2 |

| Ionization energy (first electron) | 684.8 (7.10) kJ/mol (eV) |

| Thermodynamic properties of a simple substance | |

| Density (at normal conditions) | 10.22 g/cm³ |

| Melting temperature | 2623 °C |

| Boiling temperature | 4885K |

| Ud. heat of fusion | 28 kJ/mol |

| Ud. heat of vaporization | ~590 kJ/mol |

| Molar heat capacity | 23.93[2] J/(K mol) |

| Molar volume | 9.4 cm³/mol |

| Crystal lattice of a simple substance | |

| Lattice structure | cubic body-centered |

| Lattice parameters | 3.147 Å |

| Debye temperature | 450 K |

| Other characteristics | |

| Thermal conductivity | (300 K) 138 W/(m K) |

| CAS number | 7439-98-7 |

We recommend: RHENIUM - the last of the stable isotopes

New technologies

Properties of molybdenum

Molybdenum, like tungsten, in D.I. Mendeleev’s periodic table of elements is located in group VI, but in the 5th period. The hexavalent state is most characteristic of it, although compounds in which molybdenum has other valences are known. Its serial number is 42; atomic mass 95.95; density at room temperature 10200 kg/m3. Molybdenum is a refractory metal and is a transition element. It melts at 2620±10°C and boils at approximately 4800°C.

Molybdenum and its alloys are also distinguished by a high modulus of elasticity, a low temperature coefficient of expansion, good heat resistance, and a small thermal neutron capture cross section. The electrical conductivity of molybdenum is lower than that of copper, but higher than that of iron. In terms of mechanical strength, it is somewhat inferior to tungsten, but is easier to process under pressure.

Physical and mechanical properties of molybdenum

| Property | Molybdenum |

| Atomic number | 42 |

| Atomic mass | 95,94 |

| Unit cell parameter, nm | 0,3147 |

| Atomic diameter, nm | 0,272 |

| Density at 20°C, g/cm3 | 10,2 |

| Melting point, °C | 2610 |

| Boiling point, °C | 5687 |

| Heat of fusion, kJ/mol: | 28 |

| Heat of evaporation, kJ/mol: | 590 |

| Molar volume, cm³/mol: | 9,4 |

| Specific heat capacity, J/(g•K) | 0,256 |

| Thermal conductivity, W/(m•K) | 142 |

| Linear expansion coefficient, 10-6 K-1 | 4,9 |

| Electrical resistance, µOhm•cm | 5,7 |

| Young's modulus, GPa | 336,3 |

| Shear modulus, GPa | 122 |

| Poisson's ratio | 0,3 |

| Hardness, HB | 125 |

| Spark color | Short yellow intermittent beam of sparks |

| Group of metals | Refractory metal |

Chemical properties of molybdenum

| Property | Molybdenum |

| Covalent radius: | 130 pm |

| Ion radius: | (+6e) 62 (+4e) 70 pm |

| Electronegativity (according to Pauling): | 2,16 |

| Electrode potential: | 0 |

| Oxidation states: | 6, 5, 4, 3, 2 |

Advantages / disadvantages of molybdenum

Advantages:

has a high melting point, and therefore heat resistance;

because the density of molybdenum (10200 kg/m3) is almost two times less than the density of tungsten (19300 kg/m3), then molybdenum-based alloys have significantly greater specific strength (at temperatures below 1370 °C);

molybdenum has a high modulus of elasticity;

low temperature coefficient of expansion;

has good heat resistance;

small cross section for thermal neutron capture;

Molybdenum is characterized by high corrosion resistance. This metal is stable in most alkaline solutions, as well as in sulfuric, hydrochloric and hydrofluoric acids at different temperatures and concentrations.

Flaws:

molybdenum has low potassium content;

high fragility of welds;

low plasticity at low temperatures;

Strengthening of molybdenum by cold hardening can be used only up to 700-800 °C; at higher temperatures, softening occurs due to return.

Applications of molybdenum

Molybdenum is used as an alloying additive to various alloys, including high-quality steels. Molybdenum and molybdenum alloys are used in parts that operate for a long time in vacuum up to 1800°C (in rocket nozzles and in electric vacuum devices), as a structural material in nuclear power reactors, for the manufacture of equipment operating in aggressive environments. Molybdenum wire and molybdenum tape are used for the manufacture of high-temperature furnaces and electric current inputs in light bulbs.

Molybdenum and its alloys are refractory materials. For the manufacture of shells for the warheads of missiles and aircraft, refractory metals and alloys based on them are used in two versions. In one embodiment, these metals serve only as heat shields, which are separated from the main structural material by thermal insulation. In the second case, refractory metals and their alloys serve as the main structural materials. Molybdenum ranks second after tungsten and its alloys in terms of strength properties. However, in terms of specific strength at temperatures below 1350-1450°C, molybdenum and its alloys take first place. Thus, molybdenum and niobium and their alloys, which have greater specific strength up to 1370°C compared to tantalum, tungsten and alloys based on them, are most widely used for the manufacture of skins and frame elements of missiles and supersonic aircraft.

Molybdenum is used to make honeycomb panels of spacecraft, heat exchangers, shells of rockets and capsules returning to earth, heat shields, wing edge skins and stabilizers in supersonic aircraft. Some parts of ramjet and turbojet engines (turbine blades, tail skirts, nozzle flaps, rocket engine nozzles, control surfaces in rockets with solid fuel) operate under very difficult conditions. At the same time, the material requires not only high resistance to oxidation and gas erosion, but also high long-term strength and impact resistance. At temperatures below 1370°C, molybdenum and its alloys are used to manufacture these parts.

Molybdenum is a promising material for equipment operating in sulfuric, hydrochloric and phosphoric acids. Due to the high stability of molybdenum in molten glass, it is widely used in the glass industry, in particular for the manufacture of electrodes for glass melting. At present, molds and cores of machines for injection molding of aluminum, zinc and copper alloys are made from molybdepo alloys. The high strength and hardness of molybdenum alloys at elevated temperatures have led to their use as a tool in the hot forming of steels and alloys (piercing mill mandrels, dies, press dies).

Molybdenum significantly improves the properties of steels. The addition of molybdenum significantly increases their hardenability. Small additions of Mo (0.15-0.8%) to structural steels increase their strength, toughness and corrosion resistance so much that they are used in the manufacture of the most critical parts and products. To increase hardness, molybdenum is introduced into alloys of cobalt and chromium (stellites), which are used for surfacing the edges of parts made of ordinary steel subject to wear (abrasion). It is also part of a number of heat-resistant and acid-resistant alloys based on nickel, cobalt and chromium.

In its pure form, molybdenum is used in the form of tape or wire as heating elements for electric furnaces operating in a hydrogen atmosphere at temperatures up to 1600°C. Molybdenum wire and tin are widely used in the electronics industry and X-ray engineering for the manufacture of various parts of electron tubes, X-ray tubes and other vacuum devices.

Molybdenum compounds - sulfide, oxides, molybdates - are catalysts for chemical reactions, pigments for dyes, and components of glazes. Also, molybdenum as a microadditive is included in fertilizers. Molybdenum hexafluoride is used when applying molybdenum metal to various materials. MoSi2 is used as a solid high-temperature lubricant. Pure single-crystal molybdenum is used to produce mirrors for high-power gas-dynamic lasers. Molybdenum telluride is a very good thermoelectric material for the production of thermoelectric generators (thermo-emf with 780 μV/K). Molybdenum trioxide (molybdenum anhydride) is widely used as a positive electrode in lithium power sources.

Chemical compounds of molybdenum are also used. MoS2 disulfide and molybdenum diselenide MoSe2 are used as a lubricant for rubbing parts operating at temperatures from -45 to +400°C. In the paint and varnish and light industries, a number of Mo chemical compounds are used as pigments for the production of paints and varnishes and for dyeing fabrics and furs.

| Grades of molybdenum and alloysStandard | Brand | The basis % | DR. % | Avg. impurity content. and landings % no more |

| WIRE: OST11 021.004-76, | ||||

| TU48-19-203-76, TU11-77 Yae0.021.122TU, | ||||

| TU11-77 Yae0.021.123TU | MCH | Mo basic | Al+Fe-0.018. Fe-0.009. Ca+Mg-0.005. Ni-0.005. Si-0.014. C-0.005. | |

| ROD: TU11-77YaeO.O21.O57TU. | ||||

| TU48-19-203-76, TU48-19-247-77 | ||||

| PLUSCHENKA: TU11 Yae0.021.016.-75 | MCH | Mo basic | According to statistics data K-0.0100. Ca+Mg-0.0030. Al+Fe-0.014. | |

| Ni-0.0030. Si-0.003. W-0.2000. C-0.300. | ||||

| O-0.1000. N-0.0030. H-0.0005. | ||||

| MC BILLETS: TU48-19-88-78, TU48-19-250-77. STRIPES: TU11-77 YaeO.021.055, TU48-19-315-80, TU48-19-272-77, | ||||

| GOST 5.1820-73. FOIL: TU48-19-245-76. PIPES: TU48-19-251-77. | ||||

| WIRE FOR LIGHT SOURCES GOST 27266-87 | MCH | Mo 99.96 | The amount of impurities is 0.04. | |

| ROD: TU11-77 Yae0.021.057TU, | ||||

| TU48-19-203-76, TU48-19-247-77 | ||||

| PLUSCHENKA: TU11 YaeO.02 1.016-75. | MChVP | Mo basic | According to statistics data K-0.0100. Ca+Mg-0.0030. Al+Fe-0.014. | |

| Ni-0.0030. Si-0.003. W-0.2000. | ||||

| C-0.300. O-0.1000. N-0.0030. H-0.0005. | ||||

| MChVP BILLETS: TU48-19-88-78, TU48-19-250-77. STRIPES: TU11-77 YaeO.021.055, TU48-19-315-80, GOST 5.1820-73. | ||||

| FOIL: TU48-19-245-76. PIPES: TU48-19-251-77. | ||||

| STRIPES: TU48-19-272-77 | MChVP | Mo basic | Ti-0.007 | |

| B 0.005-0.025 | Fe+A1-0.018 Ca+Mg-0.005. Ni-0.005. Si-0.014. C-0.003. N-0.005. O-0.005. N-0.0008. | |||

Content of refractory metals in compounds, %

| Formula | Connection name | Molecular weight | % |

| MoCl5 | Molybdenum pentachloride | 273,24 | 35,12 |

| MoO2 | Molybdenum dioxide | 127,95 | 74,99 |

| Mo03 | Molybdenum anhydride | 143,95 | 66,66 |

| MoS2 | Molybdenum disulfide | 160,08 | 59,94 |

| MoSi2 | Molybdenum disilicyl | 152,12 | 63,07 |

| MoCl | Molybdenum chloride | 131,39 | 73,02 |

| MoF6 | Molybdenum fluoride | 209,94 | 45,7 |

Refractory Metal Standards

GOSTs and specifications for molybdenum

| Mo | GOST 17434-72 | SHEETS. RODS. FORGINGS FROM M-MP POWDER | |

| Mo | GOST 18905-73 | Molybdenum wire. Assortment | |

| Mo | GOST 25442-82 | Annealed molybdenum strips for deep drawing. | |

| Mo | GOST 27266-87 | Molybdenum wire for light sources МЧ, МК, МРН. | |

| Mo | GOST 4759-91 | Ferromolybdenum. Technical requirements and delivery conditions (ISO 5452-80) | |

| Mo | GOST 5.1820-73 | Molybdenum strips | |

| Mo | OST1 90022-71 | Molybdenum wrought alloys | |

| Mo | OST11 021.004-76 | MOLYBDENUM WIRE DDYA IET. OTU MCH, MRN, MK, MS | |

| Mo | SuO,021,001TU TU11-80 | MOLYBDENUM STANDS MCH, MRN, MK, MS | |

| Mo | SuO, 021,118TU | MOLYBDENUM CARBIDED WIRE FROM WIRE. TU48-9-47-66 AND ANNEALED IN HYDROGEN | |

| Mo | SuO,021,141TU TU11-77 | MOLYBDENUM BILLETS, UNGRINDED MCH, MK, MRN | |

Production, deposits

Molybdenum is a rare metal. In nature, its presence in its pure form is impossible.

Almost two dozen molybdenum-containing minerals are known:

| Mineral | Ore-forming metal content |

| Molybdenite | 57-60% |

| Ferrimolybdite | 40-60% |

| Will command | 48% |

| Wulfenite | 27–46% |

| Zeirigit | Up to 24% |

Other molybdenum-containing ores (chillagite, comosite, kechlinite, jordisite and others) are not of interest for industrial use.

Significant metal deposits belong to:

- USA;

- Chile;

- Canada;

- Kazakhstan;

- Peru;

- China.

The ranking of molybdenum ore production is headed by China, the USA is in second place by a wide margin, and Chile is in third place.

The State Balance of Mineral Reserves of the Russian Federation lists 34 molybdenum deposits.

The origin of molybdenum ores is from skarn, greisen, and hydrothermal deposits.

The content of rare metal in the earth's crust is only 0.02%. But it is necessary for the existence of humans as a biological species. But there is suspiciously a lot of molybdenum in space. Red giants are especially rich in it - old stars, for which “everything is in the past.”

How to get Molybdaenum

The production of molybdenum can be divided into several stages:

- The ore is enriched using the flotation method. As a result, molybdenum concentrates are obtained, there are three grades of them.

- Production from MoO3 concentrates, so-called. “cinder”, pure molybdenum anhydride is isolated from the cinder by sublimation or chemical processing. Product purity is at least 99.975%.

- Molybdenum powder with a grain size of 0.5-2 microns is obtained by reducing the anhydride with hydrogen.

| Molybdenum grades | Peculiarities |

| MCh, MChVP | Metal without additives |

| MRN | There are no additives, but there are impurities |

| MK | Contains silica-alkali additive |

| CM | Additive - zirconium and/or titanium |

| MR | Rhenium alloy |

| MV | Tungsten alloy |

Molybdenum Products

The industry produces a wide variety of products. The most common are molybdenum wire, molybdenum rods, molybdenum powder, rod, sheet.

Molybdenum rods, as well as wire and tape, are used for the manufacture of heaters for high-temperature electric furnaces. In addition, rods are used for the manufacture of bushings for electric vacuum devices. The wire has found application in the production of high-temperature thermocouples, incandescent lamps, receiving-amplifier and generator lamps, and X-ray tubes. The sheets are used as a structural material for the production of products in the aviation and space industries. Molybdenum powder acts as an alloying additive to various steels and alloys. It is also the starting material for the production of compact molybdenum.

Pros and cons of metal

The properties of molybdenum dictate its good and bad sides.

| Advantages | Flaws |

| High specific strength | Welds are very fragile |

| High modulus of elasticity | Low ductility at low temperatures |

| Excellent heat resistance | Low potassium |

| Great corrosion resistance | Hardening by hardening is possible at temperatures up to 800°C |

| Low coefficient of expansion when heated |

Molybdenum tube

Physical properties of molybdenum:

| 400 | Physical properties | |

| 401 | Density* | 10.28 g/cm3 (at 20 °C and other standard conditions, state of matter – solid), 9.33 g/cm3 (at melting point 2623 °C and other standard conditions, state of matter – liquid) |

| 402 | Melting temperature* | 2623 °C (2896 K, 4753 °F) |

| 403 | Boiling temperature* | 4639 °C (4912 K, 8382 °F) |

| 404 | Sublimation temperature | |

| 405 | Decomposition temperature | |

| 406 | Self-ignition temperature of a gas-air mixture | |

| 407 | Specific heat of fusion (enthalpy of fusion ΔHpl)* | 37.48 kJ/mol |

| 408 | Specific heat of evaporation (enthalpy of boiling ΔHboiling)* | 598 kJ/mol |

| 409 | Specific heat capacity at constant pressure | 0.251 J/g K (at 25 °C), 0.272 J/g K (at 0-100 °C) |

| 410 | Molar heat capacity* | 24.06 J/(K mol) |

| 411 | Molar volume | 9.4 cm³/mol |

| 412 | Thermal conductivity | 138 W/(mK) (at standard conditions), 138 W/(mK) (at 300 K) |

| 413 | Thermal expansion coefficient | 4.8 µm/(MK) (at 25 °C) |

| 414 | Thermal diffusivity coefficient | |

| 415 | Critical temperature | |

| 416 | Critical pressure | |

| 417 | Critical Density | |

| 418 | Triple point | |

| 419 | Vapor pressure (mmHg) | |

| 420 | Vapor pressure (Pa) | |

| 421 | Standard enthalpy of formation ΔH | |

| 422 | Standard Gibbs energy of formation ΔG | |

| 423 | Standard entropy of matter S | |

| 424 | Standard molar heat capacity Cp | |

| 425 | Enthalpy of dissociation ΔHdiss | |

| 426 | The dielectric constant | |

| 427 | Magnetic type | |

| 428 | Curie point | |

| 429 | Volume magnetic susceptibility | |

| 430 | Specific magnetic susceptibility | |

| 431 | Molar magnetic susceptibility | |

| 432 | Electric type | |

| 433 | Electrical conductivity in the solid phase | |

| 434 | Electrical resistivity | |

| 435 | Superconductivity at temperature | |

| 436 | Critical magnetic field of superconductivity destruction | |

| 437 | Prohibited area | |

| 438 | Charge carrier concentration | |

| 439 | Mohs hardness | |

| 440 | Brinell hardness | |

| 441 | Vickers hardness | |

| 442 | Sound speed | |

| 443 | Surface tension | |

| 444 | Dynamic viscosity of gases and liquids | |

| 445 | Explosive concentrations of gas-air mixture, % volume | |

| 446 | Explosive concentrations of a mixture of gas and oxygen, % volume | |

| 446 | Ultimate tensile strength | |

| 447 | Yield strength | |

| 448 | Elongation limit | |

| 449 | Young's modulus | |

| 450 | Shear modulus | |

| 451 | Bulk modulus of elasticity | |

| 452 | Poisson's ratio | |

| 453 | Refractive index |

Application: from light bulb to rocket

- Most molybdenum products are consumed by radio electronics.

- The use of metal in rocket technology is increasing: for lining reentry rockets and capsules, in rocket engine nozzles, in solid fuel rockets.

- Molybdenum wire is used for the production of thermocouples, incandescent lamps, and heaters for high-temperature electric furnaces.

- Molybdenum tapes and wires are in demand in the lighting industry; they are used to make electrodes for melting glass.

- The use of molybdenum and its alloys is widespread in nuclear energy, in the production of cooling pipelines, and shells of fuel assemblies.

- More than 2/3 of the produced metal is used in metallurgy, as an alloying additive to steel.

- Molybdenum sulfide is an excellent high-temperature lubricant for parts, it is used to coat bullets, and it is used in the production of ceramics as an additive to clay (to produce blue or red colors).

We recommend: SILVER - lunar metal against any evil spirits

Metal forming is simpler than similar processing of tungsten.

Production

Molybdenum deposits and its production by country

| A country | Deposits (thousand tons) | 2001 | 2002 | 2003 | 2004 | 2005 | 2006 | 2007 | 2014 |

| USA | 2700 | 37,6 | 32,3 | 29,9 | 41,5 | 58,0 | 59,8 | 59,4 | 68,2 |

| China | 3000 | 28,2 | 30,33 | 32,22 | 29,0 | 40,0 | 43,94 | 46,0 | 103,0 |

| Chile | 1905 | 33,5 | 29,5 | 33,4 | 41,48 | 47,75 | 43,28 | 41,1 | 48,8 |

| Peru | 850 | 8,35 | 8,32 | 9,63 | 9,6 | 17,32 | 17,21 | 17,25 | 17,0 |

| Canada | 95 | 8,56 | 7,95 | 8,89 | 5,7 | 7,91 | 7,27 | 8,0 | 9,7 |

| Russia | 360 | 3,93 | 4,29 | 3,57 | 3,11 | 3,84 | 3,94 | 4,16 | 4,8 |

| Mexico | 135 | 5,52 | 3,43 | 3,52 | 3,7 | 4,25 | 2,52 | 4,0 | 14,4 |

| Armenia | 635 | 3,4 | 3,6 | 3,5 | 3,0 | 2,75 | 3,0 | 3,0 | 7,1 |

| Iran | 120 | 2,6 | 2,4 | 2,4 | 1,5 | 2,0 | 2,0 | 2,5 | 4,0 |

| Mongolia | 294 | 1,42 | 1,59 | 1,6 | 1,7 | 1,19 | 1,2 | 1,5 | 2,0 |

| Uzbekistan | 203 | 0,58 | 0,5 | 0,5 | 0,5 | 0,57 | 0,6 | 0,5 | 0,5 |

| Bulgaria | 10 | 0,4 | 0,4 | 0,2 | 0,2 | 0,2 | 0,4 | 0,4 | ? |

| Kazakhstan | 130 | 0,09 | 0,05 | 0,05 | 0,23 | 0,23 | 0,25 | 0,4 | — |

| Kyrgyzstan | 100 | 0,25 | 0,25 | 0,25 | 0,25 | 0,25 | 0,25 | 0,25 | ? |

| Others | 1002 | — | — | — | — | — | — | — | — |

| Total | 11539 | 134,4 | 124,91 | 129,63 | 141,47 | 186,26 | 185,66 | 188,71 |

Genetic groups and industrial types of deposits

1. Contact-metasomatic (skarns).

2. Hydrothermal.

A. High temperature (greisen). B. Medium temperature. A. quartz-molybdenite. b. quartz-sphalerite-galena-molybdenite. V. quartz-chalcopyrite-molybdenite (porphyry copper ores). pitchblende-molybdenite.