Rules for using a jigsaw

An electric jigsaw is widely used for straight and curved cuts. Used for cutting laminate, parquet boards, chipboard, plastic, plexiglass, metal, tiles and ceramic tiles. The quality of the cut depends not only on the experience of the master, but also on the technique. Sawing activities should be carried out on a special sawing and cutting table, which can be built independently or purchased ready-made in specialized stores. The workplace should have fairly good lighting.

To cut freely with a jigsaw, you need to install the tool so that its cutting part is in contact with the surface of the material. After turning on the jigsaw, the file must be moved smoothly, without force or pressure along the marking.

To cut parallel to the edge, use a guide bar, which is installed against the edge. When cutting, the tool skid must always be parallel to the tire.

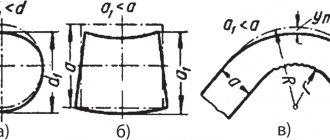

Bevel cutting is done using a tool skid, which is set at the desired angle. To make a bevel cut, the ski screws must be slightly loosened and set at an angle, after which they should be tightened well and the cut begins. For beginners, it is recommended to cut at an angle using a guide rail or ruler.

To cut out an oval and a circle, a persistent compass is used, which is installed in the center on the working surface. The cutting procedure begins from the edge, then you should smoothly move the jigsaw along the markings.

You can cut oval or round holes using a circle cutter. First you need to drill a hole, the diameter of which should be 2 cm larger than the width of the working file. Then you need to install the circle cutter, then install the file in the hole and start sawing. The circle cutter in this case will serve as a compass.

It is recommended to make longitudinal cuts using a metal support bar, which serves as a limiter. One side of the support bar will always move along the face of the work material. Cutting at an angle should be done extremely carefully. It is recommended to set the support sole to a certain degree.

To improve the movement of the tool along the working surface, it is better to use a special metal pad for the support leg.

Features of sawing

An electric jigsaw easily copes with straight-line sawing. Also, using the tool, you can make various cuts at an angle and cut an oval or circle in the workpiece. Each type of cut has its own characteristics.

Round and oval elements

The outline of the figure is applied to the prepared canvas. After this, using a drill, a hole is made in the workpiece into which the cutting element of the jigsaw is installed.

The cutting process begins and ends at the hole made. If you drill several holes, then a circle or oval can be cut out in parts.

Straight-line

An electric jigsaw is the easiest to handle this type of cut. Markings are made on the canvas along which the tool is smoothly guided.

For straight cutting of material, you can set the highest speed. It is recommended to secure the workpiece before starting work.

At an angle

Such cutting of the material is carried out by first installing the sole at the required degree of slope. After fixing the required angle, the same actions are performed as for straight cutting.

Sawing with a jigsaw at an angle

Safety regulations

Safety rules must be followed not only by beginners, but also by experienced professionals. Compliance with safety precautions will not only prevent injuries, but also facilitate the work process, as well as increase productivity and quality of work.

- Working with a jigsaw begins with a careful inspection of the tool to ensure the serviceability of the tool and the integrity of the power cable.

- Do not touch a moving part of the tool with your hands in an attempt to check its rigidity and tightness of installation while the power cord is plugged in.

- Work should be done with gloves and safety glasses.

- It is prohibited to carry out sawing work while intoxicated.

- All work with an electric jigsaw must be performed in a dry room.

- Before cutting, the working material should be securely fixed on the workbench. The immobility of the material will increase productivity and improve the quality of the cut.

- During the cutting process, no effort should be made to increase the speed. By pushing the tool forward, you risk breaking the saw, and this can cause irreparable damage to your health. During the cutting process, the tool itself must pave the way, smoothly moving forward. The master’s task is to set and maintain the desired direction.

- It is forbidden to use a dull file for cutting. A file with dull teeth reduces the cutting speed and deforms the front and back surfaces of the material. Moreover, a dull file increases the load on the electric drive, which leads to premature failure of the tool.

- Upon completion of work, the tool must be thoroughly cleaned and blown with air. It is recommended to store the tool in a dry place.

Compliance with the above rules will help to avoid injuries when working with an electric jigsaw and will increase the service life of the tool.

General rules and operating features

The quality of cutting products with both a manual and electric jigsaw depends on its correct use. Each type of tool has its own operational characteristics that should be taken into account during the work process.

Hand jigsaw

There are several points to consider when cutting material with a simple jigsaw:

- All movements of the tool must be vertical. The jigsaw should be held straight, otherwise the saw will quickly deteriorate, and the cutting process itself will be somewhat delayed. Movements are performed in only two directions - up and down.

- Do not press hard on the tool. Excessive force can significantly reduce the quality of the cut. You need to lower the jigsaw with gentle and light pressure, and when lifting it, it is recommended to be completely free.

- When cutting out a design, only the blade is rotated. The jigsaw should remain in its original position. In this case, it is necessary to hold the tool with one hand, and with the other to ensure the rotation of the material according to the intended sketch.

Do not press too hard on the hand jigsaw.

It is recommended to place the cutting blade at the edge of the cut line. This will ensure the accuracy of cutting curly lines.

Electrically controlled jigsaw

Using a jigsaw requires compliance with its own rules, which will help you cut the material efficiently:

- To put the tool into action, you need to connect it to the network and press the start button.

- Always press the support plate against the material while cutting. This will allow you to cut the canvas exactly along the intended line.

- The support bar must always be perpendicular to the material being processed. Incorrect placement of the guide sole can lead to damage to the product and the cutting element itself.

- When cutting the fabric into shapes, you should use a minimum of effort. Any excessive pressure on the tool can damage the workpiece.

- If it is necessary to make cuts at an angle, you must first adjust the support sole.

- When working with an electric jigsaw, you should take short breaks of ten minutes every half hour. This action will help protect the device from overheating and will greatly extend its service life.

When using an electric tool for the first time, you should set the speed to low. This will allow you to feel how the jigsaw works and get used to it.

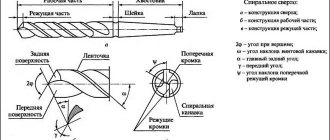

Types and mode of operation of files

The quality of work depends on the correctly selected cutting part for cutting various types of material. Files differ in shape and layout, have different heights and tooth directions. When choosing a jigsaw file, you must be guided by the following rules:

- For a straight cut, a saw blade is used, the blade of which is characterized as the widest. For a curved cut or a rounded cut, a file is used, the blade of which is characterized as medium.

- A clean, straight cut of wood material is performed using a standard saw, the teeth of which are of medium size and directed upward. The length of the file depends on the thickness of the material. If the quality of the cut does not matter, then for regular cutting you can turn on the pendulum movement, which will increase the speed of the jigsaw. For rough cutting of hard materials, it is recommended to use attachments with a wide blade and a large tooth.

- For rough cuts and uneven cuts, saw blades with large teeth are used. Cutting thick wood material should be done in two steps. When cutting, the tool should be held firmly, since when working with thick material, vibration and recoil increase as a result of the saw hitting the work surface.

- For cutting chipboard and laminated surfaces, it is recommended to use a saw with a reverse cut. This file does not leave chips on the front side of the material. If a fine-tooth attachment is used for cutting, the work must be performed strictly on the back side of the sawing material. Both methods can be performed at maximum tool speed.

- Straight cutting of metal is performed with a special file with a fine tooth. Externally, the cutting blade is similar to a standard hand hacksaw for metal. This type of saw is distinguished by the fact that it produces a clean cut without defects. However, when cutting other materials, the cutting speed is significantly reduced, which leads to rapid heating of the tool. Experienced craftsmen recommend using a sheet of plywood when cutting thin sheet metal. The plywood is placed on the work surface in advance, securely attached to the table, and thin sheet metal is laid on top of it. This cutting method will prevent tearing and deformation of the workpiece.

- Experts prefer to work with wood using a saw whose teeth are directed downward; such a file does not deform the surface of the sawn material. To avoid damaging the front side of the material surface, the cut should be made from the back side. Making a regular straight cut with a saw whose teeth point down requires experience, as there is increased kickback and high vibration during operation.

- For cutting tiles and ceramic tiles, a non-standard file is used, namely a file without teeth. Cutting tiles using a jigsaw is performed extremely rarely, due to the high consumption of material. Used only in cases where curved cuts are required.

- Plastic and plexiglass are sawed with a saw with small teeth downwards. The blade blade is medium. To perform an even cut, it is advisable to turn off the pendulum stroke. Cutting must be done at medium frequency. In order to avoid overheating of the saw and tool, it is necessary to use cooling. The speed should correspond to 30–40% of the maximum possible speed of the tool.

Features of preparing a jigsaw for work

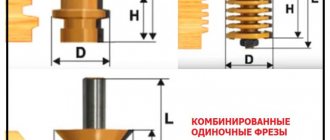

Choosing a file. One of the main parameters of high-quality sawing is a correctly selected file. For each material, a corresponding type of cutting tool is provided:

- If you need to make a straight cut in wood, you should choose a blade with medium (or large) teeth. This saw can be used to cut parquet, laminate, and boards. It is better to use files with a wide blade. On some models of saws you can see a special icon - clean for wood - this is how manufacturers mark products for wood processing. They are easier to manage without expending excessive effort. The soft start function will help ensure an even cut - the engine accelerates gradually, without jerking;

- For metal, it is better to take a narrow saw with fine teeth. The thickness of the cut in metal is usually from 3 to 5 mm. The most durable alloys and stainless steel are easier to cut with a blade with the finest teeth. And for durable plastics and non-ferrous metals, you can choose a larger tooth size. Files for such operations are marked with the inscription - for metal;

- Ceramics or tiles are treated with a toothless cloth. Instead, the file is coated with an abrasive compound, most often diamond coating. The tool carefully rounds the edges and makes a straight cut. It's not difficult to recognize the painting. In addition to the absence of teeth, the side surface has a marker - special for ceramics;

- The easiest way to perform figured sawing is to use a narrow and thin file with a fine tooth. This blade is not clamped during turning operations, which contributes to accurate, error-free cutting. The Hitachi CJ65V3 is considered one of the best tools for shape cutting - this jigsaw can even handle carved furniture.

Read also: How to test a battery

How to insert a file into a jigsaw. Properly securing the file is necessary not only for accurate cutting, but also to prevent injuries during work. Jigsaws are available with different types of saw blade mounts:

- Kolodochnoye. The most commonly used type of clamp. The blade is inserted into the block and clamped until it stops with two screws. The screws must be tightened carefully, avoiding distortion of the file. Replacing a dull blade is just as simple - loosen the screws, pull out the file, and insert a new one in its place.

- Screw. In such devices, the file is placed in a clamp and tightened with one screw. The canvas changes quickly and effortlessly. The main thing in installation is to check the angle of the inserted saw. Experts recommend not tightening the screw to the limit - this will lead to excessive vibration of the blade.

- Quick-clamping. Not universal. This fastening is used only for a certain type of files. In addition, users have complaints about the reliability of the file’s fixation. Installation and replacement of the blade is carried out as follows: the lever on the clamp is pulled out, the dull blade is pulled out, a new one is inserted, it snaps into place, the lever returns to its place.

Safety precautions when working with a jigsaw

Using a jigsaw you can make fast, precise, even, rectangular and linear cuts. You can work with a jigsaw on horizontal, vertical surfaces and even suspended. An electric jigsaw cuts wood, plastic and even iron. With skillful handling, it can make shaped cutouts in multi-layer plywood and chipboard, for which a manual jigsaw is often used, which is much more difficult and difficult to work with.

The jigsaw has several modes for adjusting the oscillation speed of the saw blade: the minimum frequency for sawing steel, followed by non-ferrous metals, ceramics, chipboard, the fastest speed is used for wood.

Files with large teeth are used for coarse cuts, fine ones for narrower and thinner ones. Narrow blades are made for curved cutting and cutting out various shapes. Metal blades have the finest teeth.

At a high frequency of vibration of the saw, the speed of work increases, but then the file heats up more; at a low frequency, the operating time increases and the wear of the parts of the tool itself increases. To correctly select the optimal combination, a special plate is attached to the instrument body, which will help you choose the right mode. But it should be remembered that the device is electric and there are safety rules when working with a jigsaw that must be strictly followed.

How to work with a jigsaw: features and rules

When making straight cuts or sawing circular holes, it is important to choose the right mode. Both the quality of cutting and the safety of the tool itself depend on this. Experienced craftsmen intuitively feel the operation of the tool, but there are basic recommendations for working with various materials.

Working with wood. It seems obvious to many craftsmen how to work with a jigsaw on wood. But there are nuances. For example, for soft wood, it is more advisable to cut at high speed. The denser and harder the wood, the lower the speed of movement of the saw should be. The pendulum stroke of the 1st stage should be connected when working with workpieces more than 3 cm, and if the thickness of the board is more than 5 cm, then it is better to switch to the 2nd stage and higher. For example, the GRAPHITE 58G061 model in pendulum mode can handle boards up to 65 mm.

Interesting fact: many models of jigsaws, for example, Sparky TH 60E, are equipped with a pendulum function. This function allows the file to move not only up and down, but also slightly to the sides. Multi-stage pendulum movement is used only for straight cutting, for large workpieces or large volumes of cutting, when productivity is needed, but the cleanliness of the cut can be neglected. The speed of sawing operations in pendulum mode increases significantly with a slight loss of quality.

Metal cutting. Metal cutting is carried out at low speed without the use of a pendulum mechanism. To improve the quality of the cut and reduce the load on the tool, it is recommended to supply a special composition to the cutting line - water mixed with machine oil. In addition, it is imperative to pause while working to cool the tool. The Makita JV0600K has proven itself to be excellent for such operations - you can connect a vacuum cleaner to it to collect sawdust.

Cutting plastic. The difficulty of sawing plastic and similar materials, such as plexiglass or textolite, lies in the fragility of the materials being processed. Despite their low hardness, they can become deformed, crack or chip. Therefore, it is better to saw them slowly, using a fine-toothed file.

Working with other materials . A household jigsaw is often used for cutting or rounding tiles and ceramic tiles. Its strength is low, so the processing speed must be set low, avoiding shock loads.

In any case, when trying to cut a material whose “behavior” is unknown, you need to take into account its strength, thickness and hardness. To understand how best to set up a jigsaw for this material, you need to try different modes on non-critical areas of the workpiece, and the operation of different files.

Here you can see the key parameters of jigsaws from leading companies:

Safety precautions when working with an electric jigsaw

It is necessary to distinguish the difference between work in production and in living conditions at home, the difference lies in the fact that in an enterprise for maintaining the health of an employee of the enterprise, specially appointed people are responsible - safety engineers, who for each type of work have drawn up a briefing outline which describes how to work with a tool. Special instructions are approved by the chief engineer and the head of the enterprise.

Types of instruction

The very first one, which is carried out upon entering a job, is an introductory one, which introduces the employee to the operating mode of the enterprise, compliance with personal hygiene conditions and daily routine, rights and responsibilities. The briefing is carried out against the signature of the instructed person in a special book.

The second is initial training at the workplace. This type includes specific labor safety requirements at the workplace where the future employee will perform tasks. This also includes electrical safety rules, fire safety, and evacuation rules.

The third is targeted training in safe work practices. The purpose of the briefing is to teach the employee how to work safely in the workplace. The instruction is conducted by an experienced master together with a mentor. After this, the student passes a skill test to an instructor or master, and with a positive assessment, he is allowed to work independently.

The fourth type of instruction is repeated; this type of instruction is carried out with employees to consolidate the skills and knowledge acquired during the initial instruction. Conducted once every 6 months.

The fifth was called unscheduled. It is carried out when legislative and legal acts are changed or put into effect that will affect the change in safety instructions, also if the enterprise has undergone a change in production technology, modernization or replacement of equipment.

Instructions and permission to work are recorded in special journals signed by the student employee.

Rice. 2. A visual poster on the types of instruction at the enterprise.

Safety precautions when working with a hand jigsaw

If the work is carried out on a personal basis, then it is enough to fulfill the requirements specified in the instructions for the product because Taking care of personal health rests with the owner of the instrument.

The rules include:

- Use the device only for its intended purpose;

- When working, it is necessary to use personal protective equipment: glasses, respirator, gloves;

- Carefully study the attached instructions on the features of working with the tool;

- In order to prevent hanging parts of clothing from touching moving parts of the device, clothing should fit snugly to the body;

- Do not try to speed up the advancement of the file with strong pressure on the device body;

- Monitor the integrity of the electrical cable; in case of damage to the protective insulation layer, insulate the damaged area;

- It is prohibited to turn on the jigsaw in a room with an explosive aggressive environment; when working with the tool, moisture in any form (any kind of precipitation, drops of water) must be prevented from entering the body;

- Avoid sudden changes in temperature (for example, when moving from an unheated room to a warm one in winter).

- It is prohibited to operate a jigsaw without a protective screen;

- The material intended for work must be securely fixed on a flat surface;

- Work on a faulty device: strong sparking under the electric brushes of the motor, extraneous noise, the smell of burnt insulation, cracks in the body, faulty fastening of the saw or start-up control buttons;

- Do not connect to a network with voltage fluctuations of more than 10%.

General cutting principles

Principle 1. All jigsaws produce uneven cuts. This is important to understand. The design of the tool itself implies several degrees of freedom of the saw, so it will not be possible to get a one hundred percent perfect cut, but following a few simple rules will reduce the number of “jambs” to a minimum:

- make no effort. Absolutely none. A slight pressure to the surface and setting the direction of movement is all that is needed for a clean cut. Yes, slowly, but efficiently;

- correct choice of stroke frequency. Each material has its own engine speed. Of course, you will have to select it experimentally, because the appropriate speed depends on many factors: the structure of the material, its thickness, the type of file installed, etc.;

- either speed or quality. Enabling the saw's pendulum feed mechanism speeds up the cut, but reduces the quality of the cut;

- only acute consumption. As soon as the cutting edge becomes slightly dull, the file begins to behave unpredictably. Therefore, if the teeth “sag”, change them urgently;

- temperature is everything to us. It is necessary to carefully monitor the temperature of the cutting surface and prevent it from overheating. Saw teeth are subject to severe wear precisely at moments of overheating, since the metal becomes softer and cannot adequately withstand the forces of friction.

The Achilles heel of most jigsaws is the pendulum system. It is its design that, in most cases, does not allow obtaining a cut strictly perpendicular to the surface. There are quite large gaps in the pendulum mechanism, which “lead” the file away from the vertical and the intended cutting line, when even slight forces are applied to the jigsaw. Only a few professional tools have a different pendulum system design (assembled directly in the gearbox) and cutting blade stabilization, which keep the saw blade in a strictly perpendicular position. To ensure a guaranteed perpendicular cut, the file should be as thick as possible (from 1.5 mm).

Principle 2. A jigsaw is just a saw drive. Its “bells and whistles” (number of pendulum feed stages, backlight, laser pointer, etc.) are not particularly important. A really important parameter is the power of the jigsaw. The type and thickness of the material that will be “too tough” for a jigsaw depends on it.

Principle 3. The file is the main violin in a duet with a jigsaw. There are a huge number of types and varieties of this instrument. And each one is “tailored” to a specific task or material. The quality of the final result depends on the correct choice of the type of cutting tool.

For example, for a shaped cut on a material, thin files are needed; for rough cutting of workpieces, files for rough cuts are suitable. To cut complex, intricate products, you will need files with two cutting edges. The front one produces the main cut, and the rear teeth cut the workpiece at small cutting radii, making the blade more maneuverable. In addition, the use of a double-sided blade allows you to move the jigsaw both forward and briefly backward. For example, when cutting out the outline of a maple leaf.

It is worth remembering that cutting blades for jigsaws are produced for different material thicknesses. There are files for cutting thick and thin material, differing from each other in their length. The size of some specimens can reach 250 mm, the main thing is that the power of the jigsaw is enough.

Principle 4. The thickness of the material of the workpiece to be cut must correspond to at least three teeth of the cutting blade. The thicker the workpiece, the larger the teeth should be on the saw. Compliance with this principle allows you to achieve the best result, since there is always room for sawdust to drain away from the cutting site, the groove does not become clogged and the process goes faster.

Principle 5. It's all about business. To obtain the most even, straight cut, do not neglect the auxiliary devices. A side stop, a guide rail or a jig made in haste will help guide the tool along the workpiece as evenly as possible, which will immediately affect the final result.

A piece of laminate or any other material with a smooth edge can serve as an excellent guide on which to rest the sole of the jigsaw. The main thing is to correctly align the supporting end and secure it securely.

Principles of correct operation

After a jigsaw is purchased, the master must learn how to use it. A jigsaw is a simple tool. But even a hammer - which is easier - can be used in different ways.

There is a rule that knows no exceptions: there are no bad tools, only misused tools.

When using a jigsaw, the master has “three degrees of freedom.” The master must:

- Choose the right equipment (file).

- Set the optimal pumping amplitude and motor rotation speed.

- Use the most appropriate working methods.

We can talk about each point for a long time, but we will try to highlight the main points.

Selection of equipment

A great variety of files are produced and sold. They differ in the type of steel from which they are made, the length and width of the blade, the shape and size of the tooth:

- The harder the material that needs to be sawed, the smaller the tooth on the selected file should be.

- For a curved cut, you need to choose a narrow file. For straight cuts - as wide as possible.

- The length is selected based on the thickness of the workpiece that needs to be cut.

Read also: Wood polish with wax

There are especially many different saws produced for working with wood. For quick cross cuts, choose a saw with large, set teeth. A large pitch allows you to cut very quickly, but it causes a lot of chips. For a clean cut, the tooth must be smaller.

Metal cutting files are very similar to a regular hacksaw blade for metal.

The files must be sharp. For important and large work, stock them in sufficient quantities.

Paging and speed

Pumping can significantly increase cutting speed. It is usually turned on when you need to quickly saw a large piece of wood straight. In other cases, it doesn’t really help and can even make work difficult or worsen the quality of the cut.

Figure cutting is done with paging completely disabled. It is impossible to give general recommendations here. You need to try different modes. The best solution is to first practice on some scraps of material.

Inexperienced craftsmen tend to work with a jigsaw immediately at maximum speed. It is not right.

When cutting plastics, the file can become very hot at high speed and the plastic will begin to melt. Not all metals like high speeds.

Start at low speed and increase it, carefully monitoring the result. If the quality of the cut deteriorates - the number of chips increases, the file overheats, etc. - reduce the speed of the file.

Working methods

As has been said many times, an electric jigsaw is a tool for many uses. However, the variety of situations comes down to just three cases: straight sawing, curved cutting and cutting holes.

Straight cut

This is the simplest case. Draw a line with a pencil and smoothly move the jigsaw along it. The built-in laser pointer will be more than useful here. Sometimes, for such work, a parallel stop, which is attached to the jigsaw frame, can be useful.

The saw blade speed can be set to maximum. Pumping will further increase cutting speed.

To maintain a straight line, you have to constantly “steer” the jigsaw. But even the most thorough “guidance” gives a mediocre result. In this type of work, a jigsaw is inferior to a circular saw in both cut quality and speed.

If straightness and evenness of the cut are critical to you, use a circular saw instead of a jigsaw.

Curvilinear cut

Such cuts are the native element of electric jigsaws. They were “born” for this.

The main secret of success is not to rush. Carefully mark the part. It is convenient to stick masking tape on the surface of the workpiece and draw lines with a pencil. Guide the jigsaw along the marking line, turning it slightly ahead. Small radius bends must be made especially slowly so that the forward movement for each saw stroke is minimal.

Cutting holes

This is one of those operations in which the jigsaw has no competitors. Typical examples: cutting a hole in a countertop to install a hob or sink, making a hole in a cabinet wall for an outlet, and thousands of other similar cases.

To cut a hole in a part, you first need to drill one or more “starter” holes using a drill. A jigsaw file is placed in them and the cut begins and ends in this hole.

If you have to cut a very large window, it is more convenient to cut it in parts.

Sawing at an angle to the surface of the part

All the cuts described above can be made not only perpendicular to the surface, but also at an arbitrary angle up to 45 degrees to the plane of the part. The need for such cuts arises, for example, if you need to connect two parts “on the mustache”.

How to cut metal

A special metal file must be used. Its feature is small teeth.

With thin or soft (aluminum, copper, etc.) metal, you can set the engine speed higher. For better gliding and reduction of friction forces in the cut, it is advisable to periodically add a few drops of oil.

When cutting sheet metal, to obtain an even cut, it is better to place a thin plywood backing underneath it. Cutting will become much more convenient, since the sheet of metal will not vibrate much.

To confidently cut metal parts, the power of the jigsaw should be as high as possible. The optimal value for cutting metal is above 750 W.

How to cut metal tiles

The main difficulty when sawing metal tiles is its complex profile. It is advisable to enclose a sheet of material between the bars on both sides of the cut. This will create the gap necessary for the saw to work and eliminate vibration of the material.

In order not to spoil the coating of the roofing sheet, it is better to wrap the sole of the jigsaw in soft material.

How to cut laminate

Cutting laminate flooring is not at all difficult. The main difficulty is represented by chips of the plastic surface that form at the edge of the cut. To prevent chipping of strips of laminate and other laminated materials (chipboard, fiberboard), you need a file whose teeth are directed downward from the jigsaw or a cutting blade with an equilateral tooth.

Important! When sawing thick workpieces with a saw with teeth directed towards the material, such a file is pushed away from the workpiece and strives to lift the jigsaw. You need to be extremely careful! An equilateral tooth does not have this disadvantage.

When making a cut with a regular blade for wood or chipboard, it is better to make the cut from the inside of the strip. In this case, the chips will “decorate” it, and the front side will remain untouched.