Basic shape cutting skills

The main tool for sawing wood is a hand jigsaw, consisting of an arc-shaped or U-shaped holder, a metal file stretched between its ends and a handle. Most files are flat and equipped with teeth on one side, but thread-like blades coated with diamond are also used.

Sawing with a jigsaw does not seem from the outside to be as complex and mysterious as, for example, welding. This is how it really is: the basic skills of figure cutting can be acquired in a few hours by ruining several plywood and saws.

Openwork cutting with a jigsaw

But to master the nuances of cutting wood with a jigsaw and start creating, it will take long evenings of honing the skill. Openwork sawing requires its craftsmen to have a precise eye, a steady hand and great patience.

How to saw and work with a jigsaw?

Today, a jigsaw is one of the most popular and in-demand tools. Not a single carpentry, furniture or educational workshop can do without it; it is a reliable assistant in any household. The jigsaw received such recognition due, first of all, to its versatility. It can be used for a wide range of jobs: from cutting firewood for the barbecue to cutting out various ornaments and making musical instruments.

Along with the jigsaw, the old manual jigsaw has not been forgotten. Although this tool has a narrower range of uses, it still enjoys some popularity, especially in school workshops and those who enjoy sawing wood and plastic. A hand jigsaw is suitable for processing small workpieces that need to be given precise shapes.

Features of working with a jigsaw

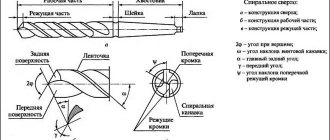

The design of a jigsaw is very different from its manual relative. The file is fixed only on one side, so it is several times thicker than a manual one; instead of a thin arc holder, there is a massive body with an electric motor and gearbox.

A jigsaw provides many times more productivity than a manual jigsaw for cutting, but you have to pay for it with more weight, strong vibration and reduced cutting accuracy when making curved cuts.

The unit allows you to quickly make cuts along a straight line or along a curved line with large radii.

The best result for artistic cutting with a jigsaw is obtained by combining a manual and electric document. Particularly fine details of the design and small radius roundings should, of course, be entrusted to a hand jigsaw.

An ordinary household or professional jigsaw is not very suitable for cutting. Its purpose is construction work, and cutting out complex designs with a jigsaw will lead to rapid fatigue due to the heavy weight and damage to the material.

Band jigsaw

However, there are also band jigsaws - in them the blade is clamped on both sides, the material rests on a massive wide work table and the arc of the holder from a manual jigsaw is visible in the design. With such a semi-professional device, you can achieve even greater cutting accuracy than with a hand tool. But this miracle unit costs accordingly.

Jigsaw: preparing the tool for work

The next section of our review is devoted to processing various materials using a jigsaw. This tool is more common than a hand jigsaw, it is more productive and has a wider range of applications.

First of all, make sure you have a comfortable and safe workplace. Remove unnecessary debris, prepare a clamp or vice with which you will secure the workpiece. You should also make sure that the electrical outlet, power cord and extension cord (if used) are in good working order. Inspect the body of the jigsaw, make sure there are no visible damage or faults in the insulation of the electric motor.

The selection of saw blade is important. There are a huge number of different types of jigsaw files available for sale, the choice of which is made depending on the material of the workpiece and the type of work performed. It should also be taken into account that the cutting performance and serviceability of a jigsaw largely depend on the serviceability and sharpness of the saw. Change blades in a timely manner, do not allow them to become excessively dull.

Before you begin, consider choosing the correct speed setting. Most jigsaws have a saw blade speed control. Choose a mode that will ensure not only high speed and accuracy of part processing, but also operator safety.

Bosch PST 900 PEL jigsaw in use

Body positioning

In every profession, for every typical operation, there is an optimal pose or set of poses from an ergonomic point of view. The working area is clearly visible in it, you don’t have to make unnecessary movements, sawing is convenient, and fatigue is minimal.

When cutting with a jigsaw, it is recommended to sit at a work table on a chair high enough so that your back does not bend. To unload the working hand, it is often rested with the elbow on the knee. This way your hand will be lighter and less tired. You just need to make sure that your knee doesn’t go numb. The work space should not be cluttered with scraps of material, tools and equipment not currently in use. A sketch of a drawing or an assembly drawing should be fixed in a vertical tablet at eye level.

Material for cutting - plywood

It is difficult to create a beautiful product from waste. The choice of material must be treated very carefully.

A plywood sheet for artistic cutting with a jigsaw must satisfy a number of conditions:

- The thickness of the sheet must correspond to the purpose. For artistic creativity, it is better to take a thin sheet (up to five millimeters), and for the production of figured furniture parts, a thickness of 1-2 centimeters is more suitable.

- The color of the plywood veneer is important if you are going to clear coat the piece. In the case of opaque paint or varnish, and stain treatment, the color is not important.

- Humidity can lead to frequent “bogging” and breakage of files. The material must be dried to 40-65%.

- Overall quality. If the plan is not to build a chicken coop, but to create artistic creativity, then the grade should be the highest or first.

- No knots or spots of a different color.

- No blisters, hollow or filled with resin.

- No veneer delamination.

Sufficient plywood thickness

As a test to determine the quality of plywood sizing, a narrow strip 1-2 cm wide is usually sawed off with a hand hacksaw. If it has not delaminated or crumbled, the plywood is suitable for sawing.

Tool for the job

You will need the following tools and consumables:

- Hand jigsaw. This is the artist's main tool

- An awl or drill with a 2-3 mm drill - for making initial holes when making closed contours.

- A set of files and needle files from pucker to velvet and sandpaper for smoothing edges.

- Electric jigsaw for preliminary cutting of material and making long cuts with slight curvature.

- Hand tools - pliers, hammer, mallet.

- Work table with vice, clamps. The table should be equipped with a cutting platform 20x30 cm, rectangular in shape with a cutout converging at an acute angle to a hole with a diameter of 3-5 cm.

- A pencil and a thin awl for transferring the sketch onto the material.

- A set of replacement files for jigsaws, for straight, curved and high-speed cutting.

- Many, many replacement files for a hand jigsaw.

Tools required for work

You will probably need twice as many files for a manual jigsaw - at the initial stage of training this will be the most consumable material.

Sawing technology

The cutting technology itself is not complicated, but in each operation you will need to acquire sufficient skill.

The process is divided into preparatory operations, main operations and final operations.

Preparation

The thoroughness of preparation largely determines the convenience of work and the quality of the final result.

So at this stage you should:

- Carefully inspect the selected piece of plywood and make sure there are no stains, knots, blisters or peeling veneer.

- Check the dryness of the material by making a test cut 1 centimeter from the edge

- Attach a sketch of the design to the plywood with tape or thumbtacks.

- At key points in the drawing, the beginnings and ends of lines, places of their intersections, etc. make punctures with a thin sharp awl.

- If the ornament is complex, then you can get confused in the jumble of dots. In this case, place carbon paper under the sketch and trace the outline of the drawing with a hard or medium pencil, transferring its lines onto the plywood.

- The areas to be removed after cutting should be immediately shaded on the plywood with a pencil to avoid confusion later.

Important! The pattern on the plywood sheet should be oriented so that most of the cuts are perpendicular to the direction of the grain of the face veneer sheet - this will make sawing easier.

Basic Operations

Upon completion of the preparatory operations, you can begin the actual cutting.

If you don’t have enough experience yet, then it’s better to start with simple drawings and outlines—for example, cut out a house with a window and a pipe from a child’s drawing. The battle of Chinese dragons is unlikely to succeed the first time.

Sawing on a jigsaw

First, you should cut out the outline of the future product, then you need to drill starting holes for the internal contours.

Important! It is better to drill all the holes in advance, since as you cut out part by part, the workpiece will lose strength and may break during drilling.

It is better to start mastering the skill with a simple operation - a straight cut. To do this you should:

- Insert a jigsaw file into the drilled starting hole. The teeth should be directed from the holder arc and towards the handle.

- Secure the blade with a screw from the side of the handle, tighten it so that it does not rattle when cutting, and tighten the second screw. The degree of tension is determined by bending the holder arc.

- Place the plywood on the platform, press it against it with your left hand and, moving the jigsaw up and down by the handle, begin cutting. As you move along the cutting line, feed the workpiece under the saw so that the jigsaw remains in place.

- To avoid straying from a straight line, you can place a guide bar on the workbench.

Cut out a few squares and rectangles to practice straight cutting.

The next operation that you need to master is a curved cut, or actually figured cutting:

- Secure the blade in the same way as in the case of a straight cut.

- Lay plywood with a clearly drawn outline on the work site.

- Start cutting with slow movements, feeding and turning the workpiece with your left hand so that the blade does not go beyond the boundaries of the contour line.

- If the cut deviates from the line, you should stop turning and lateral feeding and return the blade to the line with a short straight cut.

The first circle will most likely resemble a gear. Do not despair, only the genius of the Renaissance, the Florentine Giotto, could draw a perfect circle with one movement of his hand, and even Leonardo Da Vinci himself used a compass for this. On the fifth or sixth circle, your hand will become firmer, and the teeth on your gear will become completely invisible.

All elements of the drawing are performed in a similar way, including obtuse angles. Sharp corners are cut out with two cuts converging to the top, otherwise, most likely, the tip of the plywood at the top of the corner will break off and everything will have to start all over again.

Final operations

After all the elements of the design have been cut out, all edges should be processed first with a file, then with a needle file and, finally, with fine sandpaper. Even the most experienced craftsman cannot make the edges of all cuts perfectly smooth. During training, you will most likely have to wave a file and rustle with sandpaper quite a bit.

Next, in accordance with the type of finish you choose, the plywood is stained, painted or varnished. Varnishing is also a rather labor-intensive process; it makes sense to resort to it when your works leave the range of student crafts and begin to acquire aesthetic value.

Sawing with a jigsaw for beginners

Saturday, June 1, 2021

Until recently, schooling also included labor disciplines: girls learned handicraft and cooking skills, boys mastered working with various tools, including sawing with a jigsaw. Today, unfortunately, the school prefers to distance itself from teaching such useful things, so we are publishing material that will help everyone who wants to master the skills of handling a hand jigsaw.

Of course, beginners will not need an extensive set of tools and materials, but sawing with a jigsaw is a very exciting activity, so be prepared that at a minimum, the following things will be very useful to you in the future:

- actually, the jigsaw itself;

- a set of files for it;

- awl;

- regular and very fine file;

- hammer;

- screwdrivers;

- drill;

- vice;

- wire cutters;

- a small plane for processing flat surfaces;

- wood glue;

- sandpaper;

- tracing paper;

- small nails;

- copy paper.

When choosing a jigsaw, pay attention to the fact that the jaws of the clamps are well adjusted to one another, and that the threads are fully threaded. For thin and hard wood, as well as for very fine patterns, select files with small teeth; For soft wood and designs without small details, files with large teeth are suitable.

In order not to spend effort supporting the material with your hand while cutting, make a special stand. This will be a board 10 mm thick, with an acute-angled cutout at the end. The board needs to be screwed to the edge of the desktop. It is best to attach it to a small clamp, with which the stand is pressed against the table top. At the end of the work, the stand is removed.

Sawing requires precision in work

From the first stage of work, when you begin to transfer the drawing onto plywood, train yourself to be precise. To save the drawing for later cutting, place thin transparent paper (tracing paper) on it, then place plywood with carbon paper under the drawing and attach with thumbtacks so that it does not move.

After this, trace the contours of the drawing with a sharp-pointed hard pencil. Straight lines are best drawn using a ruler. Try to transfer onto plywood so that the longitudinal parts of the design lie along, and not across, the grain of the plywood. To save material, translate the drawings close to each other.

Remember: if you need to cut two identical patterns at once, transfer one pattern onto plywood, but under this piece of plywood, tack a second piece of plywood with small nails and cut both at once. By then separating these sheets, you will get identical drawings. It is necessary to connect two pieces of plywood in such a way that the nails do not fall under the jigsaw.

When you transfer the pattern onto the plywood, in the places where there will be holes in the pattern, use an awl to make holes not far from the contour line so that you can thread a file through them. First, the plywood is pierced on one side, then the hole is expanded on the other.

How to prepare a manual jigsaw for work

If the jigsaw does not have a tension screw (this also happens), then turn it with the bow down and lightly press the handle to slightly bend the tool into an arc, then the file is fixed in the lower and upper clamps sequentially.

The file is clamped evenly, without bending it at the ends, because in these places it often breaks. The teeth are positioned towards the handle - see picture below.

Sawing with a jigsaw

Sawing should begin not from the outer contour of the pattern, but from the inner pattern, since plywood that has not been sawn off from the edges is more convenient to hold with your hand. Now that you have learned how to insert the file into the jigsaw, pick it up again and release one end of the file from the top clamp.

Then, without releasing the machine, take the plywood and pass the freed end of the file through one of the holes punched in the plywood. The design should be on the top side of the plywood. Re-attach the file to its clamp. Then, holding the plywood with your left hand, carefully rotate it along with the jigsaw and place it on the stand.

When working with a jigsaw, remember: do not press on the file, do not rotate it, always keep the file in the same vertical plane and straight, without tilting. The right hand should calmly, gently and easily move the saw up and down, swinging in the elbow bend. The forward pressure should be as light as possible. With your left hand, hold the board you are cutting, feeding it forward and turning it so that the lines of the design gradually fit under the saw blade.

If you start sawing through any line of the pattern, then until you finish it, do not take your eyes off it, do not move in your chair.

If all these conditions are met, sawing will go smoothly and without unnecessary consumption of files. On sharp turns, slow down the feed of the board forward with your left hand so that the saw moves almost in one place until you have cut as far as necessary to turn.

When the internal cutting is completed, begin cutting out the external contours. Thin curls of the contours should be cut out at the narrowest point of the stand cutout.

The joints of parts, tenons, and grooves (holes for tenons) should be cut out with particular precision. It is best to make the tenons a little larger and the grooves a little smaller, so that later you can fit them tightly to each other.

Finishing parts

After cutting, each part has burrs that must be cleaned with small files. To make the part clean and smooth, it is necessary to grind the surfaces being processed. Sanding of the part must be done with sandpaper. The finer it is, the better and smoother the sanded surface of the part is obtained.

When sanding large surfaces, the sandpaper is stretched and secured with buttons on a flat and smooth wooden block so that there are no folds or wrinkles on the working side. Using smooth and even movements, with the lightest pressure, move this block along the surface to be sanded. The movements of the block should be directed along the grain of the wood. Grinding must be done carefully, especially if the part has complex shapes. If there are sawn holes in the part, then the burrs are removed with a file, and the ends are processed with a flat file.

The sanded parts are cleaned of dust with a brush, after which they are completely ready for assembly, if there is no need to paint them. Painting can be done with glue, oil and enamel paints, etching or staining, as well as other dyes.

Sawing out simple objects with a jigsaw

Towel rack

The hanger consists of two parts: the base, with which it is fixed to the wall, and the hook. The base and hook must be cut out of 5 mm plywood. To fasten the hook to the base, you need to cut a through groove along the thickness of the hook. The hook is inserted into the groove and glued with wood glue.

Chess

Cut out the required number of figures and stands for them from 5 mm plywood. Cut a rectangular hole in the center of each stand. Insert the chess piece into the hole in the stand so that the pieces are perpendicular to the base. Glue the figure to the stand with wood glue, after treating them with sandpaper. After the glue has dried, paint the shapes in the corresponding colors.

Ships

Quite interesting models include silhouettes of ships. From the drawing, carefully draw the outline of the ship and the corresponding base for it. Cut out the silhouette of the ship from 3 mm plywood, and cut out the base from a soft rock board. In the center of the board, make a cut with a hacksaw 2-3 mm deep. The width of the cut should be equal to the thickness of the plywood. The silhouette of the ship is fixed in the cut with glue.

Good luck with your jigsaw cutting experiments!

Tags: Useful practical skills

Safety precautions

To preserve people's health and material assets, it is necessary to follow safety rules when working.

- Use only proper tools. Before starting work, it is imperative to inspect it for mechanical damage and insulation damage.

- Do not try to saw with a broken blade, especially on a jigsaw. A cheap blade is not worth your injury and treatment.

- Personal protective equipment should be used: goggles or transparent face shield, gloves, respirator.

- When using a jigsaw, secure the workpiece with a clamp and hold the jigsaw firmly with both hands. If you can’t secure it, call an assistant, also providing him with personal protective equipment.

- When working with flammable liquids, the use of open flames and open electric heating devices within 5 meters of the work site is prohibited.

- The workplace should provide good ventilation and removal of dust and fumes from stains and paints.

Safety glasses are required even when sawing with a hand jigsaw, despite the low cutting speed and the absence of an electric drive. When a taut file breaks—as it inevitably does, even for an experienced craftsman—pieces can fly far enough to hit the eye.

What rules will protect against injury?

The mechanism seems harmless and simple only at first glance.

When performing any work, you must follow basic safety rules to avoid injury. There is work to be done

Safety rules when working with a jigsaw

with a sharp, metal part that hurts painfully, and on occasion will reach the bone. Before work, you need to inspect the jigsaw, check that the handle is firmly and firmly secured. If the fastening is broken during creative actions, the handle will fall off, but the hand will continue to move until it comes into contact with the metal pin. Which won't bring anything good.

A workbench or metalworking table must also be equipped with all special devices for safe work. Sometimes even a fall from a simple, unstable chair can cause injury and bone fractures.

The master always tries to take a closer look at his creation. This should not be done during work processes. If you lower your head too low, shavings will get into your eyes.

When a person gets used to a jigsaw and overcomes all the difficult moments, working with it becomes a real passion, and crafts become a source of pride. But a hobby can be combined with a source of income. Manual labor has always been valued much more than mechanical stamping.

- Related Posts

- How to choose a spray gun

- Grinding machine - how to choose

- Which electric jigsaw is better to choose - 2021 rating

« Previous entry

Which jigsaw to choose

In order for the hobby to bring joy and not to have to adjust and tighten something every five minutes, you should approach the choice of tool with all the attention and responsibility.

Despite the apparent simplicity of the design, a manual jigsaw has many nuances that must be taken into account when purchasing.

- Frame material. It is better to put aside the strip metal jigsaws. They are prone to twisting and distort the blade during cutting. A frame made of a metal tube does not have this drawback; it holds its shape perfectly and is also noticeably lighter.

- Lever. Be sure to check how firmly the handle is attached to the frame. If she constantly jumps off, the process will turn from pleasure into torture. Over time, sawing masters replace the cylindrical handle, turned on a lathe, with an individual one, carved from soft wood, taking into account the anatomical features of their hand.

- Clamps. Holding the saw securely during the cutting process is not only a matter of convenience, but also of safety. Good clamping areas are equipped with notch systems perpendicular to each other to ensure secure retention of the blade shanks.

- The wings of the clamps should have wide, high and comfortable ears. Avoid wing nuts stamped from sheet metal or replace them with tall wing nuts with the same threads.

Cutting technology

They begin sawing after securing the workpiece and applying markings. To do this, you need to turn on the jigsaw, set the maximum speed level and adjust the pendulum stroke by setting it to number 1.

You need to bring the file to the marking line, press the side of the platform against the guide and start working. When moving the jigsaw forward, you need to monitor the location of the platform. Do not deviate from the guide. When there are a few centimeters left to the end of the canvas, you need to carefully hold the free edge, avoiding breaking. At this point the process can be considered complete. To prevent the cut from turning out crooked, it is worth remembering a number of nuances:

- During operation, do not press too hard on the electric jigsaw, otherwise the file will break;

- when cutting a steel sheet, you need to choose a tool with maximum power and work at high speed - when heated, the steel softens and becomes more pliable;

- When processing plastic, laminate, organic glass or stainless steel, it is necessary to provide additional cooling for the file and periodically take breaks so that the tool has time to cool down;

- to prevent the plastic from melting during processing, it is necessary to set the minimum speed with a frequency of 1000 rpm;

- the figured cut will be smooth if you choose a narrow file with small teeth;

- After finishing the work, the electrical device should be cleaned of sawdust and placed in a special case.

Professional builders advise adhering to certain rules to help avoid mistakes that will not be easy to correct.

When choosing a file, you need to start from the material you are working with: plastic, thin or thick metal, plywood, solid wood. You should prepare in advance all additional items that may be needed during the cutting, marking and fastening process. Particular attention should be paid to fixing the material to the surface.

Note! To avoid defects, the canvas should be positioned face down.

It is best to try the sawing technique in advance and practice cutting with a jigsaw on unnecessary workpieces, because a crooked line will be difficult to correct. Safety precautions should not be neglected; you should use safety glasses and wear gloves when sawing.

If these recommendations are followed, the process of cutting parts should not be accompanied by unforeseen difficulties.

How to properly prepare a tool for use

The file in the frame should be clamped without distortions, strictly perpendicular to its ends, resting its back against the screws of the clamps. The saw teeth should be directed away from the frame. The blade should be stretched tightly so as to prevent vibration during operation. Craftsmen with sufficiently long and strong fingers squeeze the frame with their hand to do this. If this does not work, you can rest one end of the frame on the table, after which the lambs are tightened. To secure the fixation, you can slightly tighten the wings with pliers. At this moment you need to be careful not to damage the thread.

Securing the file in the jigsaw

The straightened frame ensures proper tension of the canvas. It is also unacceptable to overtighten the file. Increased voltage leads to rapid wear and failure. The ends of the blade should not protrude from the clamps by more than a couple of millimeters.

To make small parts, complex curved elements and sharp turns, thin files with fine teeth and a small pitch are used. They take turns better, leave a neat cut, and do not chip the plywood. For long straight cuts, take a wider blade with larger teeth. The accuracy and quality of the cut surface will be worse, but the speed will increase several times.

Working with a jigsaw: what you can do and how to work correctly

An electric jigsaw is widely used for working with sheet materials. It will be useful in repairs, carpentry or furniture workshops.

Using a jigsaw, you can cut soft wood , plastic , drywall , as well as complex materials such as ceramic tiles and metal .

Depending on the hardness and brittleness of the material, as well as the type of cut you want to achieve, the technique for working with a jigsaw will have some features. In this article we will talk about how to cut the most popular building materials.

Why do you need a jigsaw?

Most often, an electric jigsaw is used for making wood products. This tool is widely used in furniture production, where it is used to make elements and parts of various shapes.

choose the right consumables and cutting mode when working with an electric jigsaw , you can:

- make straight and curved cuts;

- cut circles without damaging the sheet;

- cut thin metal;

- make products from wood up to 10 cm thick (the Dnipro-M LE-110R jigsaw model cuts 11 cm bars );

- cut plastic;

- sawing ceramic and porcelain tiles.

Whether a power tool can work with a particular material will depend on the power and type of tool (household, semi-professional, professional). Not all electric jigsaws have additional functions, such as bevel cutting or the ability to connect additional elements and tools. To choose the right tool, read the article “How to choose a jigsaw.”

At the same time, you also need to select the right saw blades. The pitch of the teeth, their length, and material are taken into account.

Getting started: how to turn on the jigsaw and start cutting

- Working with an electric jigsaw begins with a visual inspection. The tool and power cord must not show any visible damage .

- Next, install the saw blade (it should always be removed before storage).

- Before you start working with a jigsaw, setup is carried out.

First of all, the frequency of movement of the nail file suitable for the material is selected. If you want to make an edge cut, you need to set the cutting angle. This is easy to do on Dnipro-M electric jigsaws thanks to the inclined sole. If the task allows, the pendulum stroke , and the amplitude of movement of the canvas is selected. - If necessary, a parallel stop or compass is installed to make holes in the workpiece.

- If your work generates a lot of dust, connect a vacuum cleaner.

How to cut sheet materials smoothly

The main purpose of a jigsaw is to obtain an even cut . It's the easiest way to do it.

The first step is to make markings that will serve as a guide during work. If the edge of the workpiece is smooth and you just need to make it smaller, use a rip fence . It is a T-shaped device that is attached to the sole of an electric jigsaw.

To reduce saw wear, a pendulum motion is activated. You need to move the jigsaw slowly, without jerking. Moving or jerking too quickly will have a negative effect on the cut line and additional processing (such as sanding) will be required.

How to make a curved cut

A curved cut, like a straight cut, starts with markings . You should definitely connect a vacuum cleaner or turn on the blower to remove debris from the markings.

Sawing out shaped products with a jigsaw is carried out without a pendulum stroke . A narrow blade with fine teeth is used, which makes it easy to change the direction of movement.

How to cut circles

Cutting a circle in a workpiece is one of the most difficult tasks for a beginner. But there is nothing incredible about it, since you can quickly learn how to work with a jigsaw correctly.

- Disable the pendulum stroke.

- Make the markings.

- Drill a hole for the saw blade.

- Install the stop compass and get to work.

You can make a compass with your own hands. To do this you will need a flat board and a self-tapping screw. The jigsaw is securely fixed to the block. Next, the required segment is measured (equal to the radius of the circle), and a self-tapping screw is screwed into the center, which will serve as the axis of rotation.

How to cut metal with a jigsaw

An electric jigsaw can serve as an alternative to a grinder in cases where you need to work with profiles, pipes, and sheet metal. It is this material that puts the highest load on the instrument and files. Be prepared for the fact that you will need to take breaks from work and often change consumables.

https://www.youtube.com/watch?v=n7KLT_n5aJA

The maximum thickness of metal that household and semi-professional jigsaws can work with is 10 mm.

Before cutting metal with a jigsaw, you need to select special saw blades .

A set of metal files Dnipro-M T 118 A are made of hard steel and are excellent for straight cuts. In order to reduce wear and prevent melting of the working part, use the pendulum function .

How to cut thin and thick wood

An electric jigsaw was created for working with wood, and therefore it is not at all strange that most of the work is carried out with this material. Moreover, with equal success you can cut:

- solid wood;

- lumber;

- pressed wood.

Depending on the thickness of the material, different blades are used. Moreover, they will differ not only in length, but in the frequency and size of the teeth. The thinner the material, the smaller and denser the teeth should be to each other .

To obtain a clean cut on thick wood, use saws with progressive teeth that gradually become smaller.

Source: https://dnipro-m.ua/news/7-primenenij-elektrolobzika-instruktsiya-ot-dnipro-m/

What to do if the file gets stuck

A file jam sometimes happens even to an experienced craftsman. Unfortunately, this is a common occurrence for beginners.

Wood file

We list the main causes of jamming and ways to eliminate them:

- Overheating of the canvas. It occurs during prolonged intensive work due to the friction of metal on wood (sometimes it can even produce smoke). You need to let the blade cool, reduce the sawing intensity, or select a file more suitable for the type and length of the cut. You can also wipe the file frequently with a damp cloth.

- Workpiece defects - foreign inclusions, knots, glue clots. Reduce speed or replace workpiece.

- Frame distortion. Occurs among beginners. Straighten the frame and carefully monitor its position.

- Clamping with almost separated strips of plywood for long cuts. The ends can be secured with a clamp or just a clothespin.

How to deal with chips

The frequency of occurrence and size of chips are determined by:

- quality of material;

- saw quality;

- correspondence of blade parameters to the material and type of cut;

- individual sawing technique.

There are several techniques to reduce the number and size of chips:

- If the plywood is of poor quality, you should take a saw with smaller teeth and cut faster.

- Use a file with a reverse or reverse arrangement of teeth.

- Cover the cutting line with masking tape or tape.

- Wet the back side of the plywood.

Transferring the diagram to a wooden piece

There are various ways to transfer sketches of designs for cutting with a jigsaw onto plywood:

- Prick the key points of the design with an awl and connect the holes on the plywood with a pencil. Suitable for the simplest drawings.

- Translate via carbon copy.

- Glue the sketch onto the plywood with double-sided tape or glue. After cutting, the remaining paper and glue are removed with sandpaper.

Scheme for cutting out a toy motorcycle