Features of sawing tiles with a jigsaw

The work area should be stable with a very level surface, and most of the tiles should be pressed tightly against it. A smaller section should be placed on the weight, even if it is specifically needed for installation. To reduce vibrations, it is better to fix the tiles with a couple of clamps with rubberized clamps. To avoid scratches, you can stick a piece of cardboard or plastic to the iron sole of the jigsaw with double-sided tape.

When the special saw blade is prepared and the tile is sufficiently moistened, you can safely begin processing it. Cutting tiles with a jigsaw has specific features, and is somewhat different from the usual wood, metal, plastic and other elastic materials. At first, you shouldn’t rush and try to speed up the leisurely cutting process by pressing on the jigsaw or increasing its speed, which should range from low to medium values. This approach will lead to the formation of severe chips, and strong pressing of the working tool can completely crack the tile. It’s not pleasant enough to waste valuable material, time and saw blade resources.

To reduce the likelihood of defects, it is recommended to cut the tiles at low speeds, while producing medium pressure sufficient to hold the working jigsaw on the mowing line and point it forward.

How effective is a jigsaw at cutting metal?

Let's start with the fact that an electric jigsaw is a very specific tool. Cutting metal with a jigsaw is significantly different from working with the same grinder. The performance level of a jigsaw is inferior to the potential of an angle grinder. But there is one big “but” in this comparison. The value of an electric jigsaw is not its performance. When cutting metal, it is important to consider that the jigsaw blade does not create scale and does not melt the cut line .

- Careful cutting is needed when taking metal samples for laboratory analysis .

- An electric jigsaw is used to saw damaged cars after an accident .

- It is advisable to use a jigsaw if the workplace is located close to a fuel and lubricants warehouse .

When cutting steel with a jigsaw, the thickness of the metal should not exceed 10 (mm). When cutting bronze, brass, copper or aluminum, the cutting depth can be increased to 30-40 (mm). Metal is cut at minimum speed, within 800-1000 (rpm). In this case, the power of a jigsaw for metal should exceed 500-600 (W).

Experts strongly recommend using a coolant when cutting metal with a jigsaw. Thanks to coolant, you can significantly extend the service life of the saw blade !

Saw blade selection

According to its structure, the canvas on the tile departs from our usual, traditional understanding of the file. It does not have teeth, and the role of the cutting element is played by a hard abrasive or diamond coating. The quality and speed of cutting with a similar nozzle depend on its grain size. The higher this indicator, the slower the cutting, but the higher-quality cutting line. A low grit value, on the contrary, increases the sawing speed, but causes more chips in the material. Grit is measured in micrometers (µm) and is usually indicated on the blade packaging.

How to cut tiles with a jigsaw: smoothly and without chips. Cutting tiles with a hand jigsaw

A fast jigsaw with relatively bulky saw blades is not always able to perform particularly delicate work or cuts with an internal contour. When you need to make a careful, jewelry cut with a complex pattern, a reliable hand tool comes to the rescue. Naturally, for these purposes you can use a jigsaw machine that works with the same thin files, but this equipment is quite expensive and it is not practical to obtain it for a small amount of work.

As you might guess, ordinary wood and metal files for a hand jigsaw will not be able to cut tiles. To perform a similar operation, you will need a special tungsten carbide string or a diamond-coated file.

The process of cutting the inflow with a manual jigsaw is one hundred percent similar to its electronic counterpart, except that it takes many times more time and effort. The tiles are soaked for a couple of hours, then fixed on a flat surface with clamps and, while cutting, occasionally moistened with water. We repeat once again that the speed of manual work is very leisurely, and it will take a fair amount of time even for a small figure. Before work, you should be aware of this and be patient in advance. To understand how to cut tiles with a jigsaw and estimate the pace of work, we recommend watching the following video.

How to cut circles

Cutting a circle in a workpiece is one of the most difficult tasks for a beginner. But there is nothing incredible about it, since you can quickly learn how to work with a jigsaw correctly.

- Disable the pendulum stroke.

- Make the markings.

- Drill a hole for the saw blade.

- Install the stop compass and get to work.

You can make a compass with your own hands. To do this you will need a flat board and a self-tapping screw. The jigsaw is securely fixed to the block. Next, the required segment is measured (equal to the radius of the circle), and a self-tapping screw is screwed into the center, which will serve as the axis of rotation.

What kind of files can be used to work with a jigsaw on metal?

There are times when you need to cut something iron, but the only power tool you have at hand is a jigsaw. This is not the best option, and not the worst either. The jigsaw is completely suitable for sawing metal.

But if you previously only had experience working with wood, you need to realize a very important thing: wood and metal are different materials in their own structure. This means that the approach to choosing tools and the cutting process itself is significantly different.

What blades does a jigsaw use?

There are 3 types of canvases:

- Serrated

- Abrasive

- With blade

In the traditional presentation, an electric jigsaw is equipped only with a toothed blade. But actually it is not. An electric jigsaw is often equipped with an abrasive blade as well as a blade.

Abrasive type blades work on the principle of a needle file or file. The blade-shaped blade is the same as a knife that is convenient for cutting rubber, plastic and other materials with a soft structure.

Of course, in the vast majority of cases, a jigsaw is used for cutting materials . To cut efficiently, the jigsaw is equipped with a serrated blade. For jigsaws, blades of increased thickness and improved strength are used.

How to properly cut metal with a jigsaw

Some power tool manufacturers do not advise working with metal parts if their thickness exceeds 5 mm. But there are also those that allow you to work with parts up to 10 mm wide. Everything depends on the reliability and properties of a particular model. Namely, from the property of the pendulum node.

Before starting the sawing work itself, it is necessary to carry out some preparation and set up the tool. For the correct jigsaw option, the pendulum pitch when cutting must be reduced to the first position or removed completely. So to speak, remove the beating of the pendulum. This is done in order to reduce wear on the jigsaw components and avoid dulling of the cutting surface of the saw.

It is not necessary to press hard on the jigsaw. You still won’t be able to cut faster, and the risk of damaging the tool increases. The speed of the jigsaw also should not be the highest. At high speed, you can overheat the cutting element, and this will lead to a decrease in the sharpness and hardness of the saw. Keep in mind that one file may not be enough for the whole job. Especially if you don't have enough experience. Always keep one or two spare parts in stock.

General information about the tool

A jigsaw is a saw whose cutting blade makes a reciprocating motion. Depending on the design, the tool performs from 200 to 3000 vibrations every minute, thereby cutting the metal workpiece.

A jigsaw, unlike most saws (hand saws, miter saws and others), is designed for figure cutting. Moreover, it is difficult for them to get a strictly straight cut line, but a curved one is easy. However, there are products for cutting at right angles. They are equipped with special guides and cost a little more than their analogues, while weighing down the structure.

Experts divide jigsaws for metal into groups according to a number of parameters, including:

- the need to use electricity;

- appointment;

- handle type.

In accordance with the last criterion, the tool is divided into two types:

- staple-shaped;

- mushroom-shaped.

The former allow you to hold the tool in one hand, which reduces the cutting accuracy, but expands the scope of use. The latter must be held with both hands, having previously fixed the part. This is inconvenient, but the accuracy of cutting the workpiece increases.

The type of handle allows us to classify only manual models. For electric ones, things are different. Next - in detail about other types of cutting tools.

Main types of metal files for jigsaws

Now let's move specifically to cutting tools. The fact that this blade is designed for working with metal will be indicated by the inscription on the file itself or on the packaging. Such products are marked with the inscriptions: “For Metal” or “For Metal,” depending on the manufacturer.

READ Chainsaw Ural Electron Starts and Stalls

By marking you can find out about the material from which the file is made. A commonly found steel is HSS. From the manufacturer's description it follows that this is high-speed steel.

BIM markings are found on some products. This is a designation of Bimetal, a hard cutting edge and a soft body of the blade. Two materials of different densities are joined by surfacing. The soft body of the blade prevents the brittle steel on the teeth from breaking.

The cutting tool differs in shape. Products with small milled wavy teeth are more popular. They give an even cut, with a slight twist if necessary. But such blades cut material 1–3 mm wide.

To cut parts with a larger width, there are special files with a set “tooth” and modified geometry. The so-called “progressive step”, in which the teeth grow from the jigsaw to the edge of the blade. Such models can cut parts up to 10 mm wide.

A saw with a set tooth can be used to process non-ferrous metals (such as aluminum, copper, brass) and hard wood. They can cut an iron profile (pipe or square) if the diameter does not exceed 30 mm and the wall thickness is 1.2 mm.

Don't be discouraged if it doesn't work out the first time. A little patience and attention - and you will succeed!

What to look for before purchasing

The most important thing is not to buy a professional model that will be used once a month, or a household model and try to work with it for 5 hours a day. Therefore, the user should pay attention not only to the power of the jigsaw. Below are some tips for choosing.

- The relationship between workpiece thickness and power. A manual household jigsaw cuts metal up to 4 mm thick, a professional jigsaw cuts metal up to 10-12 mm. It is desirable that both have a power of at least 500 W.

- Functional. Think about whether you should overpay for a tool with lighting, a blowing system, or a pendulum motion, if the device will be used for 1 hour per month? Wide possibilities are welcomed by professionals; an amateur can do without them.

- Possibility to adjust the frequency of saw movements. If the cutting blade can change speed, the tool is good for multiple metals (for example, steel, copper and aluminum). This is due to the fact that thick workpieces (5-10 mm) are cut at reduced speeds, otherwise the file may crack or become dull.

- Choosing a file. It is important to know the type of shank and the method of fastening the file (this is indicated in the technical data sheet of the product). Also, cutting blades are distinguished by their suitability for certain metals, which affects their parameters - pitch of teeth, their number, thickness of the removable element.

Types of processed material

The jigsaw can be used with the following types of materials:

- Wood species of different tree species and products made from it

- Metal – ferrous, stainless, non-ferrous and alloys thereof

- Polymers – all types of hard plastics, hardboard, cement-bonded particle boards

- Slate, glass, ceramics and many other substances

Clean cut

An operation such as cutting furniture panels or parquet boards requires a smooth and clear cut. Such tasks are done with the least productivity, but better, using blades for clean cutting that have:

- The teeth are at least three mm.

- Minor divorce.

Most of the files are cut by retraction, so the material is placed on the reverse side. To mark and cut from the face, you need a blade with a reverse tooth. They are not very comfortable to work with - in addition to maintaining the direction of the cut, they have to overcome the force of pushing out the tool.

Advice. A special saw with 2 rows of teeth allows you to cut panels laminated on both sides practically without chips.

Reading the markings

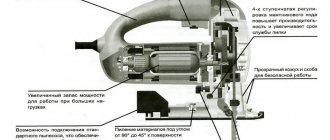

Diagram of the jigsaw device.

There are a huge number of reasons that influence the choice of cutting blade: the material that will be sawed, its thickness and density, the required cut quality, etc. In order not to make a mistake when purchasing, you should take into account the technical properties of the files, as well as the advantages and disadvantages of one or another model.

The first thing you need to pay attention to when choosing a file is the material from which it is made.

Table on the use of files.

- HCS. These files are classified as woodworking tools. They are made of high-carbon steel, which has ductility and elasticity. They can cut wood, chipboard, plywood and plastic. When choosing such a fabric, you should pay attention not to its hardness, but to its elasticity.

- H.S.S. Products made of hardened steel that can be used at high speeds. Used for processing strong materials, including metals of varying densities. Despite all its hardness, hardened steel is a rather brittle substance that must be handled very carefully.

- BIM. Bimetallic blades, which are made from the consistency of high-carbon and hardened steel, therefore they have all the advantages of the first two types. Depending on the shape and size of the teeth, they can be used for both wood and metal work.

- HIM. They are made from durable alloys, which is why they are characterized by the highest strength and rigidity. Mainly used for cutting clay tiles.

The color of the file can also indicate the material of production and purpose of the file:

- Snow-white (BIM) – for cutting wood and metal;

- Grayish (HCS or BIM) – for processing wood and materials based on it;

- Dove (BIM or HSS) – for cutting metal;

- Dark (HIM) - for performing special tasks (sawing clay tiles, strong steel, etc.).

Saw blades designed for working with wood are marked with HCS marks.

On the tail part of any jigsaw cutting blade there is a marking consisting of letters and numbers. The first letter is “T” or “U”, which indicates the type of attachment of the blade to the tool: T-shaped or U-shaped. It is followed by numbers indicating the length of the file:

- 1 – scanty fabric (up to 7.5 cm);

- 2 – standard cutting element (7.5-9.0 cm);

- 3 – extended file (9-15 cm);

- 7 – a long file (more than fifteen cm).

The longer the product, the more thick the workpiece can be sawed with it.

After the numbers there are again letters that indicate the size of the teeth:

- A – the smallest teeth (great for cutting laminate);

- B – larger teeth (used for processing wood, fiberboard, chipboard and plywood);

- C and D are the largest teeth used for pre-cutting.

Some manufacturers use two letters at the end instead of one (for example, T101BR). The 2nd letter means:

- O – for figure cutting;

- R – with reverse tooth (improves cut quality);

- F – bimetallic products (considered the strongest and most reliable);

- X – universal blade (it can cut both wood and metal);

- P – thick files (used for corner cutting).

Types of saw blade shanks.

When choosing a cutting blade for a jigsaw, you should know what material it will work with. This tool is capable of cutting not only wood and materials based on it (chipboard, fiberboard, plywood, etc.), but also plastic, slate, brick, metal and even tile. With all this, each material being processed has its own type of saw, with which the jigsaw will work with better efficiency. There are also universal cutting blades that are equally suitable for, for example, wood and metal.

Wood files. Depending on their purpose, such products are divided into two groups:

- For fast cutting;

- For a clean cut.

If you are faced with the task of sawing a huge amount of wood, spending a minimum of time, then a cutting blade with large teeth would be a good option.

READ How to Cut a Tabletop Without Chips Using a Jigsaw

The larger the teeth, the faster the cut. But as work speeds up, the cleanliness of the cut decreases, so here it is necessary to choose between speed and quality.

Canvas on laminate. When laying laminate, it is important that the cut does not have burrs. This can be achieved using the T101BR file, which is equipped with a reversible tooth. But if you don’t have this model at hand, and the laminate needs some sawing, you can get by with ordinary T101B blade. Only in this case, before work, it is recommended to cover the area of the intended cut with ordinary tape, which will protect the processed material from chips, burrs and other flaws.

Metal files. They have small teeth and a blue tail. If you will be working with metal three mm wide, buy a T118A file. It is also suitable for cutting plastic. For thicker material, it is recommended to use a T123X cutting blade, and for aluminum - T227D.

Files for tiles. They are marked T150RIFF or T130RIFF. Instead of teeth, their cutting part is carbide coating. You need to know that it is recommended to use a jigsaw for cutting tiles only in the latter cases, because the work will be slow and highly dusty.

A certain tooth shape is suitable for different tasks, which differs not only in the type of sharpening, but also in the method of setting:

- Milled set teeth. This blade is excellent for cutting wood. Divorce is carried out by analogy with an ordinary hand hacksaw. This allows the cut to expand slightly, thereby preventing overheating and jamming of the tool in the thickness of the wood.

- Milled teeth with wave setting. In this case, not a single, but a group setting is performed (for example, 4-6 teeth). Similar files are used for cutting metals.

- Ground teeth without setting. Balanced option for finishing cuts. This blade allows you to achieve the highest cutting properties in wood, laminate and plastic.

- Set teeth with grinding. This product is used for fast cutting, when no special requirements are put forward for the quality of the cut.

In order to choose the right file for an electronic jigsaw, you need to pay attention not only to the technical properties and labeling of the product, but also to the manufacturer. On the construction equipment market, cutting blades are presented in a wide range of European, Russian and Chinese models.

There is no single standard for alphanumeric marking of blades for jigsaws, but most manufacturers adhere to the European systematization from Bosch or indicate it in addition to their own designations.

Files are made from different grades of steel, which influence the purpose of the blades and are indicated by logos:

- CV (HCS) is a flexible alloy alloy for cutting wood, synthetic and wood-composite products.

- HSS is a strong high-speed steel for tough materials.

- BM (Bi-Metal) is a connection of the first two grades of steel that can withstand significant loads and is suitable for many operations.

- HM is a hard alloy for cutting tiles and building blocks.

The purpose of the canvas is also indicated by the following marks:

- Wood - soft lumber, fiber boards.

- Hardwood - hard wood, laminated panels.

- Inox - stainless steel.

- Alu - aluminum.

- Metal - tin, profiles and pipes.

- Plaster, fiber - fiberglass.

- Soft-material - rubber, polystyrene, carpets.

- Acrylic - plexiglass, polycarbonate.

From time to time there is an inscription on the file that specifies the type of work:

- Basic - standard blade for high-quality cutting;

- Speed - a saw with set teeth for fast cutting;

- Clean - blade without markings for a clean cut;

- Progressor - a saw with different teeth for cutting different materials;

- Flexible - flexible blade for cutting metal;

- Special - for cutting ceramics, plastic and other special work.

ᐅ Correct operation of an electric jigsaw

January 04, 2021

- Getting started: turning on and sawing

- Smooth cut of sheet material

- Shaped cutting with a jigsaw

- Sawing circles

- How to cut metal with an electric jigsaw?

- How to cut thin and thick wood?

- How to cut plastic?

- How to cut ceramic tiles?

- Safety precautions

- When the workpiece thickness is up to 30 mm, the pendulum mechanism is not used;

- When the workpiece thickness is from 30 to 50 mm, the pendulum mechanism switches to position I;

- When the workpiece thickness is over 50 mm, the pendulum mechanism switches to position II.

An electric jigsaw is widely used for working with sheet materials. It will be useful in repairs, carpentry or furniture workshops.

Using a jigsaw, you can cut soft and hard wood, plastic, drywall, as well as difficult materials such as ceramic tiles and metal.

Depending on the hardness and brittleness of the material, as well as the type of cut you want to achieve, the technique for working with a jigsaw will have some features. In this article we will talk about how to cut the most popular building materials.

Tool operating modes

It is no secret that the quality of the cut and the durability of the jigsaw largely depend on the correct choice of operating modes. And since most designs of modern jigsaws allow you to change the frequency of movement of the file and its transverse movement, it is these criteria that should be varied to achieve the most optimal result.

Wood sawing

Due to the fact that wood is a soft material, it is advisable to cut wood at high speeds (hardwoods are an exception).

Moreover, the use of the pendulum (transverse) stroke function in this case is justified only when working with thick wood materials.

And although the most optimal mode of the pendulum mechanism can be determined experimentally, power tool manufacturers still advise adhering to the following recommendations:

In general, it should be understood that the inclusion of the pendulum function, although it increases work productivity (cutting speed), at the same time significantly worsens the quality of the cut. Therefore, it is advisable not to use this mode when working with finishing materials such as laminate, parquet, furniture chipboard, etc.

Metal sawing

For many users, it may be a secret that you can cut metal products with a jigsaw. And all that is necessary for this is to install the appropriate equipment and follow the basic recommendations.

So, when working with metal, the pendulum mechanism should be turned off, and the speed of movement of the file should vary from 30 to 40% of the maximum

In this case, it is very important to provide the cutting area with an emulsion (water with machine oil) to extend the service life of the replaceable tool and reduce the mechanical loads on the drive part of the electrical equipment. In addition, it should be understood that metal cutting using a jigsaw is a rather labor-intensive and time-consuming task.

Therefore, during operation, it is necessary to periodically stop the tool to cool it.

Cutting plastic materials

A jigsaw is used with great success for sawing plastic, plexiglass, textolite and similar components. And although the listed positions are not distinguished by high hardness, nevertheless, in order to avoid their deformation (chips, melting), they should be cut off at low speeds using saws with fine teeth.

Tile processing

If it is necessary to form curved cuts on tiles, a jigsaw can also become an impeccable assistant. However, to achieve optimal performance, the following recommendations should be followed:

- When processing, the maximum area of the tile should lie on the table surface;

- The use of specialized interchangeable tools is mandatory;

- The saw stroke frequency should be below average, without turning on the pendulum.

How to make a curved cut

A curved cut, like a straight cut, starts with markings. You should definitely connect a vacuum cleaner or turn on the blower to remove debris from the markings. Sawing out shaped products with a jigsaw is carried out without a pendulum stroke. In this case, a narrow blade with fine teeth is used, which allows you to easily change the direction of movement.

We work with metal

Using a jigsaw, you can carefully trim the corners of a table or perform shaped cutting on an iron sheet.

Based on the density of the materials being cut and the technical abilities of jigsaws, we can highlight certain features of their use.

- The presence of a pendulum mechanism in jigsaws allows you to avoid unnecessary effort when cutting; increases cutting speed. The use of this mechanism is justified only in cases where there is no need for a clean or precise cut. Otherwise, the pendulum stroke must either be turned off or set to a low position. A better option for using a pendulum mechanism would be to cut soft wood, as well as foam, plastic, plywood, and chipboard.

- For sawing iron sheets or other hard materials, it is appropriate to use jigsaws with higher power. You also need to pay attention to the method of attaching the file - the cutting organ of the tool. Rigid fastening promotes a more confident cut.

- To perform household work, jigsaws with a power of two hundred eighty to 500 50 W are usually used with the effective power of the device in the range of 130-340 W. Even in household power tools, it is worth paying attention to the presence of electrical adjustment of the stroke frequency for different loads and materials. If there is adjustment, then even at low frequencies the instrument operates at full power, which has a beneficial effect on the speed and quality of work.

- When working with plastic, introducing high saw speeds can lead to the edges of the material being processed melting, worsening the appearance and quality of work.

At the same time, introducing huge speeds when cutting iron sheets is a more applicable option. In this case, as the steel heats up, it becomes softer and more flexible.

Shaped cutting of hard wood and other dense materials is also best done at high speed.

In any case, when choosing the speed of the cutting blade, it is necessary to take into account the need to obtain a finishing cut. If special precision and cleanliness are needed, then the speed of the saw is reduced.

In order to work perfectly with a jigsaw, it is important not to forget that each tool exists to perform a job specific to it. In other words, hammering nails with pliers can work too. But will it be great? As for power tools, using them for other purposes almost always leads to disastrous consequences.

- Let the tool, not you, do the work. Your task is simply to guide him in the appropriate direction. Do not press on the jigsaw. This advice will not only save your strength, but will also help you avoid unpleasant moments in the form of a bad cut, a broken saw, or something else more serious.

- To make long straight cuts, use blades with sufficient width. The large plane of the blade allows you to maintain a suitable cutting angle without any extra effort. Have several canvases in stock for different occasions.

READ How to saw a countertop for a sink

For finishing cuts, also use appropriate blades, for example Makita B10.

- If necessary, cut a narrow sheet of metal (less than one mm) and use a sheet of plywood as a backing. When working, beware of vibration by selecting a rational high-speed mode.

- When using low speeds for work, give the jigsaw a “rest” more often. This is due to the fact that at low speeds the air flow to the electric motor is small. Therefore, during long-term operation, overheating may occur.

- Follow all manufacturer's instructions for servicing your power tool. Carry out the necessary lubrication and cleaning; use and store the tool in appropriate conditions. Thanks to this, it will serve you for a long time.

- When working, secure the material with clamps. Some jigsaws can be used quite successfully with one hand; You can also work together with a partner. Despite this, material fixation plays a major role in achieving high-quality work.

- Use the pendulum mechanism when cutting wood along the grain. This helps to make a straight cut. The canvas will not be pulled to the side along the fibers of the material.

- Use personal protective equipment. Although many models of jigsaws are equipped with an attachment for connecting a vacuum cleaner or dust collector, this tool is still quite dusty. Dust accidentally getting into your eyes will not improve the quality of your work.

- Make the cut near the mowing line, not along it.

- When processing savory materials, place the front side down. At the same time, if the material is quite thick and you are not convinced that you can hold the saw perpendicular to the material, then turn the face upward and, if possible, put a special anti-friction pad on the sole.

The benefit is not only that it is easier to cut the material perfectly. When marking, you do not have to make allowances for the width of the cut.

For cutting zinc-coated profiles and sheet metal products, wave saw blades are used, similar in profile to blades for a hand saw. They are distinguished by small (up to one mm) teeth, deflected not through one, but in groups of 3–5 pieces.

For the same work, three blades are taken: for steel, aluminum and for non-ferrous alloys. If you have to cut metal infrequently, then one steel file will be enough, which is also suitable for ebonite and textolite.

In general, a jigsaw is not suitable for sawing metal: the tool is very loaded, and the process is slow. Faster, this is the last method, justified only from time to time, for example, when cutting sandwich panels with bimetallic saws with small cutters on the sides and large ones in the center.

How to cut sheet materials smoothly

The main purpose of a jigsaw is to obtain an even cut . It's the easiest way to do it.

The first step is to make markings that will serve as a guide during work. If the edge of the workpiece is smooth and you just need to make it smaller, use a rip fence . It is a T-shaped device that is attached to the sole of an electric jigsaw.

To reduce saw wear, a pendulum motion is activated. You need to move the jigsaw slowly, without jerking. Moving or jerking too quickly will have a negative effect on the cut line and additional processing (such as sanding) will be required.

Is it possible to cut metal with a jigsaw?

Marking of files

1st letter T or U. Type of fastening of the file.

This systematization is arbitrary and is not always followed, therefore the most reliable method for choosing a suitable file is to know its properties.

“T-shaped” shank, medium (2nd) file length, small tooth, finishing reverse cut. The processed material is plywood, chipboard, fiberboard, laminate, laminated wood, plexiglass, plastic.

From the above information it becomes clear that the determining factors when processing any material are:

- Selecting the right cutting tool

- Characteristics of the processed material

- Cutting depth

In other words, a saw for working with laminate can be used when sawing, for example, plywood. And the flip side is that using a cutting tool for boards, you can simply spoil not only the laminate being processed, but also quickly dull the file.

Depending on the need to use electricity, jigsaws come in two types. Mechanical is characterized by a conventional design of 3 main parts (handle, frame and file), lightness, and low price. The cutting element is fixed in the frame by means of two screw-shaped clamps that regulate the tension. If the blade sags, cutting the workpiece (especially iron) is unrealistic.

Polymer processing

Polymer materials - hardboard, textolite, various types of sheet plastic, plexiglass and others, are characterized by softness and low mechanical strength.

The conclusion is that the processing of products made from such material can be carried out at elevated cutting conditions.

But this worldview is wrong.

Due to its own weak strength parameters, plastic is characterized by the formation of chips and microcracks in the cut area, therefore the processing speed should not exceed average characteristics.

This causes an increase in frictional forces, which, in turn, are converted into thermal energy and begin to melt the workpiece.

Features of mechanical and electrical models

Depending on the need to use electricity, jigsaws come in two types. Mechanical ones are characterized by a simple design of three main elements (handle, frame and file), lightness, and low cost. The cutting element is fixed in the frame by means of two screw clamps that regulate the tension. If the blade sags, cutting the workpiece (especially metal) is impossible. Working with a mechanical jigsaw is simple, but time-consuming and energy-consuming. The maximum frequency of movements is 200-250 vibrations per minute, so such devices are considered ineffective today. However, to this day they are found in stores.

Example - KRAFTOOL 15606 with an oval frame depth of 165 mm. It makes it possible to cut large metal surfaces. For user convenience, there is a plastic handle with a ribbed surface (so that the device does not slip out of your hands), and durability of use is guaranteed by a tungsten carbide coated blade, which is very wear-resistant and durable. The cost of a mechanical jigsaw is from 700 rubles.

The situation is different with a jigsaw. The tool operates on mains or battery power, makes several thousand oscillations per minute, is compact, durable, and replacement metal files are available in hardware stores. Disadvantages include the weight of the product, noise during operation, and dependence on a power source (when operating network devices). However, the disadvantages pale in comparison with the advantages of modern models, which are discussed in detail in the next section.

In what cases is a precise cut needed?

Performing a technological operation for sawing or creating a figured cut implies the formation of a mowing line that corresponds to the task. In other words, the cut should be smooth with the smallest tolerances for deviation.

The following requirements are needed:

- Ensuring tight abutment of mating surfaces.

- Creating small gaps.

- Formation of the correct geometry of the structure from machined parts.

- Nice appearance of the mowing line cut and details in general.

T-shank

The name comes from a graphic resemblance to the letter T, another name is “cruciform”. Structurally, it has one stop. This type of shank is one of the most common. There is a variety with a double stop. Among the masters, a different name is used - “European type”.

Sources:

https://pro-instrument.com/ruchnoj/kak-pilit-metall-elektrolobzikom.html https://vseopilah.ru/lobziki/lobziki-stal/