Chainsaw chain problems

In addition to problems with the engine, the chainsaw may experience operational problems due to a malfunction of the cutting (sawing) unit, consisting of an oil pump, bar and saw chain.

There is no oil getting to the tire

Usually, if oil does not flow to the chainsaw chain, you need to check the channels through which oil is supplied to the tire and clean them of dirt. If the previous steps did not reveal the cause of the problem, then you will have to check the oil pump. To do this you need:

- remove part of the chainsaw casing;

- remove the coupling;

- unscrew the 3 screws and remove the cover hiding the pump;

- get to the worm gear gear that rotates the pump shaft.

If the thread on it is worn out, the shaft does not rotate, the pump does not work, and the chain is not lubricated. A worn gear needs to be replaced. You can also remove the oil pump itself and manually try to pump oil through it. If it does not pump, the pump should be replaced.

Chainsaw oil filter

Also, a lack of lubricant may be due to its leakage. You should check how tightly the pipes coming from the oil pump are connected. If the tightness is broken, the tubes are replaced with new ones.

The chain breaks

If the chain breaks while the chainsaw is running, this could happen when it hits a hard object, such as a nail. If the chain constantly breaks, then the reasons may be the following.

- Low quality of the metal from which the saw chain is made. It is necessary to buy gas cutter saws from reputable brands.

- Chain overheating due to poor lubrication. As a result, the saw overheats, the properties of the metal change, and it breaks under load. It is necessary to check the entire chainsaw lubrication system (discussed above).

You can also learn about the reasons for frequent circuit breaks from this video.

The chain doesn't turn

This nuisance often plagues inexperienced chainsaw owners. They forget to remove the brake after starting the engine. As a result, the chain does not spin, the brake system overheats, and the clutch mechanism fails. The problem is solved by removing the saw from the brake. If the clutch is not burnt out, you will notice the chain turning. Otherwise, the clutch mechanism will need to be replaced.

The chain gets dull quickly

Basically, the reason that the chain becomes dull quickly is the poor quality of the saw. Trying to save money on buying branded chains, chainsaw owners buy saws from unknown manufacturers, or, due to inexperience, purchase counterfeits of well-known brands. It is best to buy a cutting element for a gas cutter in company stores. Stihl saw chains are very popular among owners of this equipment.

The chain doesn't stop

If, when working with a chainsaw, you notice that the saw chain does not stop at the right moment, then this breakdown may have 2 options.

- The brake band is dirty. When operating the saw, dirt, sawdust, dust, etc. may get under the band. As a result, the brake mechanism becomes blocked and the chain does not stop when the gas is released. The problem is eliminated by cleaning this unit.

- The brake band is worn out. This element of the brake system needs to be replaced.

The chain is jammed

This happens when the drive or driven sprocket wears out. The chain usually starts to jam under load. But without load the saw can rotate. The photo below shows a worn chainsaw drive sprocket.

The next photo shows that the reason why the chain jams must be looked for at the location of the driven sprocket.

But what to do if the chainsaw is completely jammed, and all attempts to pull the starter are unsuccessful? This malfunction sometimes occurs on Chinese-made chainsaws. It is caused by the bolts that screw the engine to the plastic casing of the unit becoming loose due to vibration. These bolts are located directly under the flywheel (magneto). In the photo below, arrows show the location of the problem bolts.

As they unscrew, they begin to rub against the flywheel and can completely jam the chainsaw. The following photo shows the flywheel with some scuff marks from the bolts.

To fix the problem, you will need to remove the flywheel from the engine shaft and tighten the bolts.

The chainsaw cuts crookedly

This problem can occur if the chain is dull or improperly sharpened. This applies to a greater extent to new chainsaws. But if the tire is worn out, then even after replacing the chain you will notice that the saw is pulled to the side. Tire wear can be easily determined by placing it on a level table and applying a square to it, as shown in the following photo.

In this case, you can see that there is a gap of about 2 mm between the tire and the corner. It is because of this one-sided tire wear that the chainsaw cuts crookedly. The problem can only be solved by replacing the tire with a new one.

Preparing to use a chain saw

The peculiarity of electric saws is the location of the engine - longitudinal and transverse. It does not affect the operation in any way, but it does not affect the appearance and ease of use. Also, for a longitudinal arrangement, it is desirable to have a gearbox.

Saws come in circular and chain saws. The most popular models are with a chain, as they are much smaller in size and can be used in small farms.

Another feature of electric chain saws is the independence of price from the power of the tool. However, despite the fact that the saw is small and low-powered, it can cost the same as a powerful unit. This depends on the fact that the wiring cannot withstand heavy loads and may burn out. It is for cottages and small garden plots where the wiring is weak that small saws are created.

Electric chain saw Makita UC 3541 A: equipment

Saw assembly

The package includes a base with a motor, a bar and a chain. The preparation process consists of assembling the saw, i.e. put the chain on the bar. Here it is very important to properly tension the chain, since if the tension is weak, there will be sagging, which will consequently affect the work. The same operational problems will arise if the tension is too strong.

Run-in

It is not the electric motor that needs running-in, but the saw set. Preparatory actions that need to be carried out before work are mandatory.

- Starting is carried out only after adjusting the saw set: bar, chain and sprocket.

- Regular sharpening of the saw chain.

- Periodically check the lubricant level in the reservoir.

- Do not use the power saw during voltage surges, or install a stabilizer.

- Compliance with all safety rules when working with cutting garden tools.

Electric saw Champion 324N -18

The principle of operation of a chainsaw

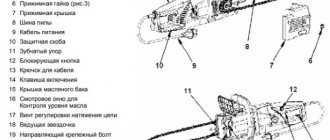

To understand the principle of operation of a chainsaw, you need to consider its structural components.

These include:

- an engine equipped with a crankshaft, cylinder and piston;

- manual starter - consists of a reel on which a cable is wound. To return the spring to its original position, a spring is provided in the mechanism;

- fuel system - includes a carburetor and fuel hoses;

- clutch - required for continuous connection between the engine and the sawing parts of the chainsaw;

- ignition - responsible for supplying the spark necessary to ignite the fuel mixture;

- saw set - consists of a bar and chain;

- lubrication system – necessary to supply oil to the headset;

- tension mechanism - required to adjust the chain on the bar.

The basis of the operation of a chainsaw is the operation of an engine that operates on a fuel mixture.

When the starter cable is pulled, the ignition system is activated, which generates a spark and transmits it to the cylinder. There, the fuel ignites and activates the piston, which in turn begins to rotate the crankshaft. He, through the clutch mechanism, causes the sawing bodies to rotate. An oil pump is responsible for the stable operation of the headset under conditions of increased friction and heating, which supplies lubricant to special grooves provided on the tire. From these, the oil is evenly distributed onto the chain. Thanks to this principle, the tire and chain can withstand increased loads and work in extreme conditions.

To stop the bar and chain in order to reduce the risk of injury to the operator, the gas saw is equipped with an inertia brake. It is triggered by a kickback caused by contact of the chain with a nail or wire.

Getting started with a power saw

Before starting the saw, check for oil. Very often, manufacturers supply equipment with an empty oil tank. Oil is a necessary component for smooth and long-term operation of the saw without breakdowns or abrasion of spare parts and parts. Also, do not forget to monitor the presence of oil while cutting, since the chain is automatically lubricated.

Electric chain saws

It is important to follow safety precautions when using a power saw. Before you start sawing logs or other materials, put on special clothing that provides good protection but does not restrict movement. Also take care of your senses of touch by wearing glasses, headphones and a mask to protect against loud noise, dust, wood chips and sawdust. It is also worth checking the readiness of the saw itself for sawing. First of all, test the brake operation, whether the bar and chain are installed correctly, whether the sprocket is secured, etc.

Try not to overload the saw and cut in short periods of a few minutes. If any malfunction occurs with the electric saw, disconnect the saw from the power supply, find out the cause of the failure and fix the problem.

Safety precautions when working with a chainsaw

When purchasing such a tool, you need to know how to use a chainsaw correctly. Occupational safety requires workers to use only working equipment. Therefore, operating a chainsaw requires:

- mandatory inspection before each launch;

- regular checking of the condition and configuration of the main components;

- timely addition of oil and regulation of chain tension;

- stopping work if a malfunction is detected in the chain brake and other critical parts and accessories.

You cannot make homemade changes to the design of the tool or use spare parts that are unsuitable for the model you are using. Some craftsmen talk about how to start a chainsaw without a starter. But they forget that its impeller is necessary to cool the motor, which will begin to overheat with the threat of failure.

You can operate a chainsaw only in special clothing, using special gloves, shoes with metal inserts, a helmet and eye protection. In this case, the tool is held with both hands with a straight back, without bending far forward and without lifting the saw above the shoulders. It is not recommended to place body parts in the cutting plane. Safety precautions prohibit moving with a chainsaw whose cutting chain rotates.

Practical work with a chainsaw when felling trees and cutting branches requires compliance with special rules to prevent worker injury from falling trunks. A kickback from a saw that hits an obstacle is especially dangerous. A lumberjack must not:

- fell trees in one cut;

- cut several branches at the same time;

- make a cut with the end of the tire;

- be in the area of a falling tree.

Tips and tricks for using an electric saw

Many experienced users of electric saws recommend installing a stabilizer that will protect the electric saw mechanism from power surges. Thus, you will protect yourself and your equipment from breakdowns, breakdowns and additional repair costs.

Electric chain saw Makita UC4041A

If, during operation, the electric saw does not gain a sufficient number of revolutions sufficient for comfortable cutting of wood, then it is necessary to replace the carbon brushes. The fact is that they wear out quickly and it is important to inspect the saw from time to time in order to identify the problem in time.

How to cut down a tree with a chainsaw

Now let's figure out how to cut down a tree with a chainsaw. The first thing you need to start with is cleaning the small growth around the trunk. This is a necessary procedure, because small branches not only interfere with access to the tree, but can also cause the operator to fall, which is quite dangerous given that the chainsaw is working.

Next, you need to decide on the direction of the felling. Determining the direction of felling a tree standing on a slope is not difficult, since it is almost always laid in the direction in which the center of gravity is shifted.

This is interesting: in order to fell a tree in the opposite direction from the slope, professional fellers use special heavy equipment or tie a cable to the top of the tree and use a winch to pull the trunk in the desired direction.

An upright tree can be felled in any direction, but it is worth considering the location of the branches. It is a little easier to fall the trunk in the direction with more branches than in the opposite direction.

At the next stage, a cut is made from the side of the felling direction. The cut is made in the form of a wedge. The depth of the cut should not exceed 1/3 of the diameter of the trunk, otherwise there is a risk that the tire will jam, because the trunk will weaken and tilt towards the cut. A properly executed cut should not cause the tree to tilt.

Next, a straight incision is made on the opposite side of the cut and 3-5 cm above it. The chainsaw should be directed in such a way that the direction of the felling on the chainsaw is directed towards the intended place where the trunk will fall. After this, using a wedge, fork or felling blade installed in the cut, the tree is helped to begin falling in the planned direction.

Below is a video on how to cut down a tree.

Features of electric saws

An electric chain saw has limits on the power of the electric motor, requires an extension cord to be connected to the mains, and makes a relatively small cut. But electric saws are cleaner than their gasoline counterparts, weigh less, do not require fuel, and start without any extra effort.

They are great for finishing or roofing work in confined spaces.

The chain saw is used wherever there is a large volume of sawing work:

- pruning branches on trees;

- carpentry;

- construction works;

- firewood preparation;

- dismantling of wooden buildings and structures.

Builders also often take an electric saw in addition to a gasoline one - for small volumes of work it is more convenient, and sometimes working conditions do not allow the use of a chainsaw.

When choosing any power tool, you must always know its design and types in order to choose the most optimal model.

There are control buttons on the body of the device, thanks to which you can start and stop the instrument. The mechanism begins to work with the help of a motor that drives the chain.

What should you do if you don’t have a chainsaw?

A chainsaw is the most effective tool for cutting down any trees.

If you don’t have one, you can use an ax and a hacksaw or a two-handed saw.

To make a cut, use a hacksaw to cut the trunk across the grain to 1/3 of the trunk diameter.

It is advisable to use a hacksaw with the largest and sharpest teeth possible.

Then the wood is cut down with an ax at an angle of 45 degrees, striking 2–4 cm above the cut. After this, the trunk is cut on the other side 3–5 cm higher (depending on the diameter - the thicker the trunk, the greater the difference).

If there is neither a hacksaw nor a two-handed saw, then all operations are performed using an ax - first they strike along the cut line, deepening the blade into the wood by 1-2 cm, then they chop from above at an angle of 45 degrees, forming a notch.

Some masters do the opposite, first striking at an angle, then cutting perpendicularly. Both methods are equally effective, so you can do what is more convenient in a given situation.

If at least part of the work is performed with the help of an ax, then it is necessary to secure the trunk with at least a rope under tension, and it is better to use a winch and springs. If you do not do this, the tree may fall in the other direction.

In addition, using an ax and a hacksaw or a two-handed saw, you should not cut down trees whose diameter exceeds 10 cm. Their trunk is too heavy, so due to strong blows it can go in the wrong direction and cause serious injury. Also, you cannot use an ax to cut down rotten and rotten trees; blows can cause branches to break off and cause a strong blow.

How to cut correctly with a chainsaw?

Working with a chainsaw is a dangerous activity, in which you need to think not only about your safety, but also about the people, objects, and structures around you. In the instructions, the manufacturer always indicates several rules and tips telling a novice operator how to operate a chainsaw. Before starting work, you must make sure that the equipment is in working order and that there is a sufficient amount of fuel and oil. It is necessary to inspect the object being cut, calculate the direction of felling, and clear the ground near the tree being processed at an angle of 45 degrees on all sides around the tree and on the sides of the direction of fall.

To cut correctly with a chainsaw, you need to take a stable position with your legs spread wide apart. The shoulder rests against the tree trunk, and try to make the guide cut as low as possible to make the task of felling easier and leave a small stump after work.

It is also important that the tree is not rotten, as it may not fall along the intended path.

Latest documents in the Database:

Occupational Safety and Health

Room ventilation logbook

Order to comply with the mask regime

Logbook for registration of work permits for gas hazardous work

Instructions for radiation safety when conducting X-ray flaw detection

Fire safety

Permission to extinguish fires in electrical installations

Fire drill schedule

Report on the results of fire training

Order on the actions of workers upon detection of a fire

electrical safety

Industrial instructions for electrical safety

Electrician's work instructions

Journal of work in electrical installations (example sample)

Instructions for the person responsible for electrical equipment

Tool Features

Hand-held power saws are widely used in production and at home.

In industrial settings where greater precision is required, cutting with a hand-held circular saw is mainly used. The household requires a tool with a wider specialization. A chain saw fits this criterion: it is an analogue of gasoline units, differing from them in lighter weight and the absence of exhaust gases during operation. As for power, it is quite enough to carry out a wide range of work on a personal plot. Important: An electric chain saw is a very dangerous device. To avoid injury or injury, strict adherence to safety rules when using a power chain saw is required.

Rules for operating a chainsaw

- Before starting work with a chainsaw, you need to make sure that the chain is well tensioned and not overtightened. Optimal tension assumes that the chain will not sag on the bar. If the chain is pulled too tight, the chain will have difficulty moving along the bar.

- Additionally, you need to make sure that the chain is well sharpened. If you cut with a dull chain, productivity will noticeably drop. A dull chain needs to be sharpened. Today, the industry offers a variety of sharpening tools. Among them there are both completely manual devices and electric ones. The chainsaw maintenance blog has a separate review on the topic: “How to sharpen a chain.”

- Before starting the chainsaw, you need to make sure that there is fuel in the gas tank and the oil sump is filled with lubricant. When refueling a chainsaw, you need to take into account that it is tedious to fill the tank not with pure gasoline, but with fuel with a small oil content. As a rule, chain saw manufacturers recommend adding 20 (ml) lubricant to 1 liter of gasoline.

- Don't forget about protective equipment. When working with a chainsaw, be sure to wear pants or overalls made of thick fabric, as well as a long-sleeved windbreaker. Of course, the fabric will not protect against the cutting chain. But thanks to a tight robe, you can significantly minimize the consequences of cuts. The fabric will wrap around the chain, quickly stopping it.

- It is imperative to protect your eyes, as when sawing wood, wood chips fly in all directions. For this reason, you need to wear translucent glasses when working with a chainsaw.

That's it, after the above precautions, you can safely start sawing wood. Working with a chainsaw is not at all difficult, the main thing is to adhere to safety precautions

Skills with chain saw tools develop very quickly. Soon you will be able to cut any wood efficiently, quickly and safely.

Reciprocating saws

Reciprocating electric saws use a thin file as a cutting blade. By design and purpose, this is an electric hacksaw that cuts through reciprocating movements. The speed of reciprocating electric saws can reach 3000-3500 strokes/min, the length of the cutting blade is 100-350 mm.

Reciprocating electric saws are used for cutting various materials; it is especially convenient to work with a reciprocating electric saw in hard-to-reach areas: hard and soft wood, aluminum, pipes, plastic, foam blocks and gas blocks, all kinds of profiles, fittings, drywall. A significant advantage of reciprocating saws is their high cutting accuracy, an order of magnitude higher than that of an electric chain saw.

When installing various attachments: files with different characteristics, abrasive attachments, metal brushes, the capabilities of the reciprocating saw are significantly expanded. Complete with additional accessories, a reciprocating electric saw can be used to grind, polish surfaces, and remove rust.

How to use a reciprocating saw

Experience is gained quite quickly, especially if you have skills in working with various electric saws. Thanks to the soft start, the saw starts working very softly and smoothly; you just need to guide its movement with light rocking movements up and down. Reciprocal movements back and forth remove sawdust.

How to cut down trees with a chainsaw (detailed description)

Following safety precautions when felling a tree is an important procedure. If you have never worked with a tool, you should first practice on branches and twigs.

Diagram of sawing thick wood with a chainsaw

The technology for felling large and small trunks has significant differences. The technology for felling large trees with a diameter exceeding 50 cm is as follows:

- On the falling side of the wood, you need to make a cut with a slope of 60 degrees. This slope is needed to direct its fall

- Once the bevel cut is made to ¾ or ½ of the trunk, a horizontal cut is made. It turns out a corner or wedge that should be pulled out. The resulting side cut is the direction in which the wood falls

- On the opposite side, horizontal sawing is done with a slight slope. This undercut is made slightly higher (3-5 cm) than the bottom cut from the side of the blade notch

- The undercut is made approximately to the middle of the trunk. The tree must remain horizontal

- A mallet or wedge is inserted into the resulting undercut, which will prevent tilting in the opposite direction.

- A light cut is carefully made from the side (in the area where the cut triangle is located), and you need to push the barrel with your hand to put it directly into the intended area

These cuts should be made on the trunk at waist level. Specialists immediately begin making cuts at the root, but this is very difficult and not safe. It is better to cut down the remaining part of the stump later, rather than the tool getting stuck inside the wood.

The process of sawing wood with a chainsaw

Starting a chainsaw

Having filled in the fuel mixture and lubricated the chain, you can proceed to the second stage - starting the chainsaw. The manufacturer's instructions will also come in handy here.

It briefly and clearly describes the main stages of this operation:

- Check the chain tension (pull the upper middle links). If they give in with some effort, this means that the chain is tensioned well enough. If the saw chain sags, then you need to use the tensioning mechanism and tighten it.

- We pull the chain along the tire. With normal tension it rotates easily. If you have over-tightened the chain, you need to loosen it a little. At the same time, we look at the position of the chain brake (the wide plastic shield next to the front handle). It must be turned on (pressed forward from the front handle by which the saw is held). At idle, when the engine warms up, we don't want the chain to rotate. That's why we put it on the brakes.

- Place the chainsaw on a level surface. We hold the front handle with our left hand. We place our right foot on the rear handle, turn on the ignition button, extend the throttle and sharply pull the starter handle several times. As soon as the engine gives the first “flash”, we close the throttle and again sharply pull out the starter handle until the engine starts.

- We turn off the chain brake, making sure that there are no foreign objects under the saw chain that it could pick up, and press the gas a couple of times to warm up the tool.

- Check the lubrication supply to the chain. To do this, bring the saw to any light object (sheet of paper, board, section of a stump). If a trace of oil appears on it, it means that enough lubricant is supplied to the chain.

The starting procedure described above is performed on a cold engine. If the saw has already been working for some time and has been turned off, then it is started using the starter handle without using the throttle.

How to cut down a thick tree with a chainsaw

There are several ways to cut down a thick tree and all of them require the use of special equipment. The first method is to fell the tree in parts; this method is shown in the video below.

Thick trees are more difficult to cut down, so you should not try and risk your health if you have never had to cut down trees before.

Another way is to fell the entire tree with the trunk stretched in the desired direction. The cable is fixed to the trunk at a height of at least 5-6 meters, after which a wedge is cut out from the side of the planned fall of the trunk and the cable is tensioned. You can tighten the cable using a winch, a tractor or a car. Next, the feller trims the trunk on the side opposite to the cut wedge. If the length of the tire is not enough, then another cut is made at a height of at least 30 cm from the previous one, after which the wood between the cuts is affected. This is necessary so that the feller has the opportunity to bury the tire to a greater distance.

It is worth noting that the process of felling thick trees is highly individual and depends on many factors. It is for this reason that cutting down a large tree without experience is very difficult and dangerous.

How to use a reciprocating saw?

A reciprocating saw differs from an electric chain saw in its wider range of applications. Many potential buyers are wondering what can be cut with a reciprocating saw? She, in turn, is considered a good assistant in repair and construction work. It can be used to saw metal and gas blocks, perform woodwork in the garden, prepare firewood and saw dry branches. Its great popularity came due to its speed and versatility.

Bosch GSA 1300 PCE reciprocating saw in use

So, in the video you will see what and how to cut correctly with a reciprocating saw:

The main advantage of reciprocating saws is that they practically do not emit sparks. It is for this reason, and due to the absence of exhaust from the electric motor, that reciprocating saws can be used indoors.

Pay attention to how you hold the saw. You must cut strictly along a straight line, without changing the direction of sawing while working. This is especially common when sawing large-diameter pipes. As a result of incorrect direction of the saw during cutting, you can bend the equipment, it will begin to come into contact with the material, causing additional vibration.

Many operators think and ask questions on the forum, how to cut a gas block with a reciprocating saw? In fact, this process is not at all complicated, since aerated concrete blocks are not particularly hard. You don't need to use any lubricant because the saw makes smooth, precise cuts quickly and efficiently.

Starting a chainsaw

Before the starting procedure, you should first fill the appropriate compartments with fuel mixture and metal chain lubricant. Check the chain tension and tighten it if necessary. After this, you need to place the chainsaw on a flat, stable surface, at some distance from the refueling site (for fire safety purposes). Next, take the front handle with your left hand and place your right foot on the back.

Then you need to press the ignition button, pull out the throttle and pull the starter handle several times. When the chainsaw engine emits a flash, the throttle valve is pushed back, and the starter handle, on the contrary, is pulled outward to the maximum. This movement must be repeated until the engine starts.

The next step: you need to turn off the chain brake and press the gas several times so that the chainsaw warms up. The technician should also check the lubrication supply to the chain. To do this, the saw must be brought to a clean sheet of paper. The appearance of an oil stain on the sheet will mean that everything is in order and there is enough lubricant.

If the chainsaw has already worked for a certain time and was simply turned off, then it is started according to a simplified algorithm - that is, only the starter handle is used, and there is no need to touch the throttle valve.

Selection of ingredients for the mixture

The basis for our mixture will be gasoline. You need to take a petroleum product with an octane number of more than 90. You should not save money and take questionable fuel, then you will pay more for repairs. Additives that increase the octane number are also a dubious choice.

Owners are faced with a choice between leaded and unleaded gasoline. For an engine without a catalyst, you need to take the first option, respectively, if a catalyst is installed, take the second type.

Choosing oil is not difficult, just take a branded lubricant from the chainsaw manufacturer.

If there is no branded oil, use JASOFB or ISOEGB class oils.

First start of the chainsaw

A new chainsaw cannot be immediately operated under maximum load. All rotating parts of the tool must first rub against each other. It is recommended to use a full gas tank when starting for the first time, without applying high forces to the saw. If such a test is successful, you can subsequently cut with a chainsaw without additional restrictions.

The chainsaw is started on a flat horizontal platform. The starting procedure using the example of a Stihl saw should be as follows.

- Manually pull the chain along the bar, making sure it moves smoothly and there is no excessive resistance.

- Engage the chain brake by moving its handle away from you.

- Open the cylinder decompression valve.

- Feed the fuel mixture into the carburetor with a few clicks on the primer.

- To properly start the saw, you need to press the rear handle with your right foot to the ground. Hold the front handle with your left hand and lock the fuel supply lever in the working position with your right.

- Place the combination switch in the cold start position.

- With a jerk of the starter handle, start the ignition of the engine, which should stall almost immediately.

- Open the throttle valve to the half throttle position.

- By pulling the starter cable again, start the engine again, immediately turning the fuel lever to the idle position.

- Pull the chain brake handle towards you, moving it to the working position.

- By holding the far end of the guide bar to a clean, bright surface, check that the chain lubrication system is working by sprinkling small drops of oil.

After making sure that all components and mechanisms of the saw are in good working order and do not make any extraneous noise at idle, you can proceed to work under load.

How to safely operate a chainsaw?

Not everyone knows how to operate a chainsaw, so this question interests everyone who has purchased this high-tech device. Some people think that they already understand everything and don’t even look at the instructions. But such actions can lead to further serious injury or damage to the chainsaw. Therefore, before starting work, do not be lazy and carefully study the instructions.

Preparing for work

First, you need to make sure that the device chain is tensioned correctly, for which you need to slightly pull the upper links - in this case, the shank should come out a few millimeters from the groove of the bar. Also, you need to make sure that the lower links do not sag. After this, try to pull the chain by hand - it should pull easily. If the chain tension is very strong, then it should be loosened. Next, you need to check what position the inertia brake is in - its handle and the main handle should not touch, since when you turn on the chainsaw with an offset inertia brake, the clutch may be damaged.

After checking the chain tension, you can start threading the tool. To do this, the chainsaw must be placed on a horizontal surface and filled with oil to lubricate the chain and the fuel mixture. The best option is considered to be a fuel mixture of oil intended for two-stroke engines and A-92 or A-95 gasoline. The ratio of gasoline and oil should be 1 to 40 or 1 to 50 (approximately 20-25 grams of oil per liter of gasoline).

For the motor and chain, you should choose a special lubricant designed for chainsaws, since such lubricant contains components that can extend the life of the cutting element and engine parts. At the end of the check, having carried out all the procedures described above, you can start the saw.

Remember that before starting the engine, it is necessary to remove the saw from the place where it was refueled so that there is no fire when starting. Place it on a stable, solid base.

First start

After making sure that the chain is not in contact with any surfaces, you must engage the chain brake by moving the brake handle away from you so that the chain does not start rotating prematurely. Since the engine is initially cold, it is necessary to fully extend the lever that controls the air damper. Next, you should insert your toe into the rear handle, while holding the front handle with your hand, and pull the handle several times until the engine “sneezes.” Then you need to move the air damper to the working position and start the saw, briefly pressing the throttle and moving the saw to idle speed. After this, you need to move the brake handle to the position towards you and your chainsaw is ready for work.

Remember:

- Before starting work, you must definitely check the brake of the chainsaw, for which you need to place it on some flat surface and press the throttle. Next, you need to activate the brake by pressing the handle. The brake is considered working if the chain stops.

- among other things, before starting work you need to check the lubrication mechanism. To do this, you need to find any light surface, start the tool and, holding it above this surface, increase the speed of the chain by simply pressing the throttle. If a small strip of oil appears on the surface, then everything is in order with the lubrication mechanism.

Safe work

The following things may happen during operation:

High probability of inadvertently touching the hand with a pollen set; Falling branches or bouncing towards the sliding operator. Safety glasses will protect you from jumping branches, crawlers and dust. Contact of leg tissue with the working chain

To reduce the chance of foot tissue coming into contact with the work chain, wear close-fitting, padded trousers. Of course, they will not save them from prolonged contact, but they will become a big obstacle, and if you quickly remove the saw from your leg, this is a great opportunity to avoid injury to it. Leg damage. To protect your feet, you need to buy chunky shoes with a metal insert on the toe. This is for safety reasons because the saw often likes to slide over this part of the body. Head damage. A helmet will help here; it will protect your head from bounced headphones and large branches.

Follow these rules when using:

- The chainsaw should be held firmly in your hands; your hands can be pressed closer to your body so that they are much less tired. The saw must be controlled.

- When cutting, never cut multiple logs at the same time. It is forbidden to see the tip of the tire, because in this position it often slips. The beam must be blocked and controlled so that nothing can touch the chain.

- The position of the operator's body should not be in the same plane as the operating chain. You should not bend too much because you can easily lose your balance, which can lead to disastrous consequences.

- Most cases involving saw rejection occur during woodworking, or more specifically, when cutting branches. The area where the bar falls may touch a branch or tree, which could cause the saw to fall.

- The chainsaw is not designed to cut materials above shoulder height. This method is strictly prohibited as the consequences can be very serious. Your safety is in your hands.

Safety precautions when cutting

When performing tree felling procedures, it is necessary to ensure full safety precautions for both individuals and employees of organizations. You cannot fell trees yourself. Having a partner is a must. You should not light an open fire when working, and if there is one, you should extinguish it before turning on the chainsaw. Also you can't smoke. You should take care in advance to protect your face from sawdust, as they always fly off when cutting wood.

Before sawing a tree, you need to make sure that if it falls, it will not affect people, living beings, or damage cables or wires through which current passes. Do not work in strong winds. It is advisable to calculate in advance the direction of fall of the trunk down to the exact contour on which all the rods and other elements are cleared, so as not to damage the tree, and also not to cause its inertial revolution.

When working with full-length, thick posts, the chainsaw is held with both hands, and tension is constantly felt.

When cutting thick posts or massive branches, it is advisable to raise the chainsaw to shoulder height.

How to cut wood correctly - basic rules and technology

The main aspects necessary to comply with when cutting trees:

- If the trees are dry, then no sources of not only sparks, but also smoke should be allowed, since adding gasoline to dry wood can cause a fire, which not only slows down the work process, but also harms the environment.

- Before turning on the chainsaw, you need to look around. There should be no children or animals nearby. Only workmates or bosses.

- You should always try to hold the chainsaw. Even if malfunctions occur and it automatically turns off, you should behave carefully, since falling of the device with a sharp part can lead to dire consequences.

- Workers prepare in advance for sawing wood. Wear thick clothing and a face mask to cover the entire body from possible ingress of dust and dirt.

First, all the technological features are determined, only then you need to clearly plan the stages of work, which will help to ensure that you protect yourself from the impact of the weight of a falling tree. Even with extensive work experience, it is necessary to constantly take care of your own safety, since the highest number of injuries are suffered by workers who have been in this field for a long time and are accustomed to a constantly tense and dangerous environment.

Rule #4. Chain oil.

Use special chain adhesive oil to lubricate the bar and chain. It is the adhesive oil that has the property of stickiness and remains on the tire during operation. The use of other oils is ineffective, since during operation of the cutting set it simply flies off without the necessary stickiness. Moreover, the use of other oils may cause the oil pump to fail.

If you want your tire and chain to last longer, remember the rules:

a) use only special high-quality adhesive oil;

b) always check the oil level in the oil tank, so as not to forget, it is best to fill it first, and then the fuel mixture;

c) if the chainsaw has an oil supply adjustment, then in the cold season, the supply should be set to maximum.

Electric chain saws

Unlike gasoline analogues, electric chain saws have a number of advantages: they are environmentally friendly, do not depend on the availability of fuel, are less noisy, and have less weight. Using a universal electric chain saw, you can make cuts of materials of various structures: wood, wood boards, brick, laminate, slate, metal, ceramic tiles, drywall.

Electric saw (power saw) Partner P 620 T

On the other hand, the capabilities of chain saws may be limited by the availability of a power source, the length of the power cable, limited power and performance. In addition, electric chain saws are potentially dangerous equipment; before using an electric chain saw, each owner must carefully study the instructions and then strictly adhere to the prescribed requirements and recommendations of the manufacturer.

The cutting element in a chain saw is a closed chain mounted on a bar. Depending on the location, saws can have a longitudinal or transverse electric motor. The design with a transverse arrangement is the most appropriate: due to the absence of a gearbox, the need for its maintenance and repair is eliminated, and the saw is much lighter in weight.

Electric saw Stihl MSE 141 CQ,

Assembly, running in the saw, getting started

Electric chain saws are delivered to consumers in an assembled state; they need to install the saw set and tension the chain. With proper tension, the gap between the guides and the chain is 3-4 mm. Over time, the chain can stretch, the tension weakens, so the adjusting screw sets the correct tension.

It should be taken into account that the tension of a cold and hot chain is different, and a poorly tensioned chain is a serious source of danger. After running in the saw set, you are allowed to begin full operation of the electric saw.

Before starting sawing, check the oil level and, if necessary, add to the specified level. The serviceability of the lubrication system is tested in a simple way: after refueling, turn on the saw, let it work for a while with raised hands over paper spread underneath. If oil stains appear on it, then the lubrication system is working properly. As work progresses, the oil level is constantly monitored and topped up.

Be sure to check the locking condition of the saw guard.

The reasons that an electric saw cuts poorly or does not cut under load, or cuts unevenly to the side or crookedly to the side, may be: a dull chain, a sagging chain, a lack or absence of oil in the lubrication system, and incorrect work methods.

How to use an electric chain saw: tips and tricks

- Constantly test the voltage in the network and do not work at low voltage, this can lead to engine overheating and breakdowns.

- Do not use the chain saw too intensively. If a large amount of work needs to be done, it is more advisable to choose a gentle pace of operation with breaks.

- When sawing large logs or trees, you should be especially careful: the electric saw must be installed at the smallest angle to the workpiece to avoid jerking.

- Particular care must be taken when felling wood; you should master the correct techniques and techniques of work, take into account the direction of the tree's fall, wind speed, and the presence of surrounding objects (power lines, poles, structures).

- Before the onset of the spring work season, if the saw was in a cold room, the tool should be kept in a heated room for at least a day. This will allow condensation in the electric motor winding to evaporate and avoid a short circuit when turned on.

- Before using a chain saw, you should sharpen the chain, this will significantly extend its service life. You should periodically contact a professional chain sharpening service.

- When working with a saw with an extension cord, it is necessary to select the correct power cable for its cross-section and protective sheath, and install a lock to prevent it from accidentally falling out of the socket.

- If you plan not to use the electric saw for a long time, you must remove the saw set - guide and chain, and store them in a container with oil.

Warnings

First of all, you need to be careful and remember what injuries a chainsaw can cause to a person if a chainsaw running at full throttle is thrown towards the operator. You should never touch the bar end of a running chainsaw to any tree, as this will throw the chainsaw back at the operator. In addition, you should try to hold the chainsaw as far to the right as possible so as not to stand in line with the rotating chain, so that in the event of a kickback, the running chainsaw will not hit the operator in the face.

How to operate a chainsaw - you must use all the recommended personal protective equipment - a helmet that will protect you from flying debris and branches, glasses, noise-absorbing headphones, anti-vibration gloves, overalls, durable pants (this is the minimum set).

It is strongly recommended to buy boots made of special material that a running chainsaw will not cut through if it hits your leg (such boots cost about 3,000 rubles or even cheaper).

It is necessary to use a chainsaw with a sufficiently long bar, since sawing a trunk that is thicker than the length of the chainsaw bar doubles the likelihood of a kickback.

If there is no one to monitor safety precautions while operating a chainsaw, it would be wiser to wait until an experienced operator has the opportunity to supervise the work of a novice chainsaw operator. Or it is worth telling someone that a person with no experience will work with a chainsaw and when he should finish - one wrong move with a working chainsaw can end in disaster.

Each type of sawing, as mentioned above, has its own warnings and skills. If described in detail, it would be a very long article. If something is not clear, it’s better to ask!

It is better to remove fuel for refueling away from the place where the chainsaw is used.

You should always keep your chainsaw in good technical condition. The chain brake and other chainsaw safety features are designed to protect the operator from injury.

Criteria for choosing a power saw

When going to the store to buy this useful and indispensable tool for the household, think carefully about several important points:

- Think about what you need a saw for: a 30cm guide bar can cut almost twice that length - that's a half meter diameter log.

- Another thing to think about is what type and maximum size wood you will be cutting. If you don't know, it's best to measure the thickest wood you're likely to cut. Additionally, if you are cutting hardwood such as beech, oak or ash, you will need a slightly larger power saw.

- If this is your first time purchasing an electric saw and you have never used one before, we recommend the smallest one to get you going.

- Check for safety features such as chain overrun brake, side chain tensioner and chain catcher.

- When purchasing an electric chainsaw, it is a good idea to think about the accessories you may need to maintain or operate the machine.

- We always recommend having a spare chain and storage kit on hand as you can dull your chain very quickly and if you are in the middle of a job you want to make sure you can replace/sharpen your chain there and then to save time. and keep cutting.

- Personal protective equipment is very important and should definitely be equipped by all power saw users, regardless of your experience. The basic items required are protective gloves, a helmet with a visor and ear protection.

- Another deciding factor is ease of use. Is it easy to start a chain saw? Are the controls accessible and easy to operate?

Additional Features and Functions

When choosing an electric chain saw, you also need to pay attention to additional functionality:

- light weight,

- manual chain tension,

- easy starting mechanism

- economical engines,

- chain oil supply adjustment,

- safety devices for the operator and saw.

The presence of these features must be looked at in the description of a specific model.

A saw that is easy to use is safer. Find a well-balanced machine with a good power-to-weight ratio: light enough to handle but with enough power to get the job done.

What is carving

The word “carving” came into our language from English and means “cutting”. This is the name for figured wood carving with a chainsaw. This art of skillful use of an instrument is beginning to gain popularity in our country. For carving, ordinary lightweight chainsaws are used, for example, the Husqvarna 135.

Chainsaw Husqvarna 135

The chainsaw has small dimensions, develops the necessary power, weighs 4.4 kg and makes it easier to start the engine. The tire needs to be installed in a medium size, about 14 inches. The chain is selected in 3/8 inch increments. It is recommended to immediately purchase special chains. For example, the STIHL Carving Rapid Micro Spezial (RMS) chain has a ¼-inch pitch, short teeth, and is designed specifically for carving wood. The Husqvarna 135 saw is well suited for beginner carvingists.

The Husqvarna 450e II chainsaw, shown in the following photo, has also proven itself well among craftsmen.

Chainsaw Husqvarna 450e II

As you gain experience, you can use more powerful units.

Sculptures created from wood using a chainsaw are very widely used in recreation parks, on city streets, near cafes, restaurants and other public places, and always attract the genuine attention of passers-by. For example, seeing such a product in the park, few people will pass by it indifferently

For example, seeing such a product in the park, few people will pass by it indifferently.

The imagination and skill of professional carvingists sometimes causes surprise and admiration.

To achieve such results, you need to make a huge effort, it will take years of practice to hone your skills. After all, even if you try to make some simple product with your own hands, you will immediately understand that carving wood with a chainsaw is not an easy process. But if you are filled with the desire to learn this art, then, undoubtedly, you will be able to realize all your plans and decorate your site with unparalleled products.

Pro recommendations

In addition to the basic rules, there are a number of useful recommendations that can improve the productivity of sawing work without violating safety rules.

First of all:

- before starting work, it is necessary to remove from the workplace all foreign objects that impede free movement;

- during work, uncomfortable postures that contribute to the rapid accumulation of fatigue are not recommended;

- Excessive bending or holding a running chainsaw at outstretched arms or above shoulder level is undesirable;

- at the beginning of each new cut you should be especially careful, since there is a high probability of kickback;

- You should also abandon the practice of sawing wood of any diameter with the end of the headset.

The technology does not exclude work on both sides of the tire. The main thing to remember is that sawing wood with the bottom side moves the tool forward, and the top side creates the opposite effect.

How to saw with a chainsaw: bar and chain and everything you need to know about them

The chain and bar are the cutting tools of the chainsaw. It is on them that it fully depends on how well the chainsaw will cut. There are a lot of nuances regarding these parts of the tool, knowledge of which ensures long-term operation of the tool.

- Tire. Figuratively speaking, this is a guide along which the chain moves - over time it works and, if used incorrectly, does so unevenly. In order for the tire to wear evenly (this is necessary in order to extend its service life), it must be turned over during the work process. For example, today it works as is, but tomorrow you remove and turn the tire over to the other side. The second point regarding the chainsaw bar is the tension of the chain - it is the chain that is responsible for this process. Before work, the chain tension must be checked and, if necessary, tightened.

- Chain. Ideally, there should be three of them - this is necessary in order to equalize the degree of wear on the chain and drive gear. The fact is that the chain wears out faster, but during the period of time when it fails, a groove forms on the drive gear (the chain makes it). It is thanks to this groove that the new chain may not fit as expected, as a result of which gear wear will accelerate several times. Having three chains at the same time and using them alternately, as they say, as they become dull, you balance the service life of these two elements of the chainsaw - while the three chains wear out, the time will come to replace the drive gear.

There are a couple more important points regarding the chain. Firstly, you can’t cut with a dull chain - this increases the load on the tool, and the work time is long, and most importantly, it’s not very safe. You can determine how sharp a chain is by one factor - the quality of the sawing. The saw cuts either poorly or crookedly. So, if you are wondering why the chainsaw cuts crookedly, you should know that it is a dull chain. Secondly, when putting the tool aside for a long time, the chain should be loosened.