What is a pipeline? In fact, it is a series connection of pipes, measuring equipment and other elements provided for by the project. How can pipes be joined? There are many different methods; the optimal choice is made depending on the purpose of the pipeline, the conditions in which it will be operated, the size of the pipes and the material of manufacture.

When installing pipelines, a variety of pipe connection methods are used. Some of them are detachable, that is, they allow the possibility of dismantling and subsequent reassembly. Others are monolithic, and it is impossible to disassemble them without destroying the pipes.

The most popular type of permanent connections is welding; it is used when working with different types of pipes - steel, plastic, copper and even cast iron. However, welding is far from the only way to assemble a pipeline; other installation methods are also used. Let's figure out how to connect metal pipes without welding.

Thread

Threaded connections are among the most ancient. They are used only on round pipes. Based on the direction of torsion, a distinction is made between right-handed and left-handed threads. The second is rarely used, only in special cases.

This type of joint is suitable for water, gas, and oil products.

The ends themselves are twisted using additional fitting coupling parts.

Couplings are standard with internal threads on both sides. There are also combined ones, internal on one side and external on the other.

Threaded connection of steel pipes

Threaded connections

But what to do in cases where it is not possible to carry out welding work? There are quite a few ways to join pipeline elements without welding. The most popular option is threaded installation. Pipe threading is done using cutting machines or an ordinary die. If it is necessary to apply threads to a product with thin walls, use the rolling method.

If you follow all the rules for installing a threaded joint, you will get a durable and sealed structure. Let's consider the main advantages of using such a connection:

- ease of installation.

- the ability to repair or replace without damaging the pipeline;

- installation is carried out without the use of special equipment.

In addition, there are several thread parameters that determine its operation:

- cutting step;

- depth;

- direction.

The pitch determines the distance between the top of the coil and its base. Depth is a parameter that is determined as follows: the distance between the base of the coil and its top is measured. The direction of the thread is an important point; if you ignore it, you may encounter problems when installing the pipeline structure. The thread has two directions:

- right;

- left.

Many types of pipes are equipped with threads; they are used where it is necessary to create a reliable but detachable connection

Detailed description of each method

Threaded

They can be done in several ways, the most common being squeezing.

The following tools will help you do this job:

- Pipe wrench.

- Coupling with internal thread.

- Seals for sealing. Maybe: hemp rope, FUM tape or sealant.

- Lock-nut.

Two pipes have external threads . We apply sealant to them. One has a longer thread length than the other. Where there are more turns the nut is screwed on until the end. Then the clutch. Then we screw it onto the second part, twisting it with the first one. When the coupling stops screwing, we support it with a locknut. Tighten with wrenches, carefully, so that the coupling does not burst.

Flanges

For a flange joint you will need:

- two flanges;

- paronite gasket;

- bolts, washers, nuts;

- keys;

- manual arc welding;

- level.

The flanges need to be welded. Avoid displacement; they must be in the same plane.

We catch using a horizontal level. We screw two bolts into the upper holes. We put the part on the edge of the tube so that the bolts are at the top. We put a level on them and catch the position of the bubble between the strips in the middle. When caught, we make a tack by welding at the top point. The horizontal plane is ready.

We rearrange the level to a vertical position, leaning it against the flange mirror. We catch the level by slightly adjusting the lower end of the flange that is not yet stuck. Having established the vertical, we installed the second tack. And then two more, resulting in four even sections.

Then the welder welds the flange on both sides. Manipulations are carried out similarly with the second pipe.

After welding, we get two pipes that can be connected. We insert four bolts into the holes from below and tighten them a little. We make a gap, insert a gasket. We insert four more bolts and tighten everything.

Bonding

This method is used very rarely in metal parts. The process itself does not require any special skill from a person, but it takes a lot of time.

This job requires:

- glue. BF-2 or 88N or EDP;

- brush.

Before gluing the parts, first apply the first layer on their surface and allow to dry. This layer will be the bonding layer. Each glue has a drying time written in its instructions. Then a second layer is applied and the parts are placed under the press for a day or even more. It all depends on the glue.

Then clean the seam from any glue leaks.

Crimp connectors for steel pipes

Welding

The welding process is used in almost all metal pipe joints.

In order to obtain a seam, the following welding methods are used:

- gas;

- electric arc;

- contact

Gas welding is used to obtain permanent connections in small diameter pipes with minimal thickness.

When welded in this way, it can also conduct water. The main thing is to test the seams for leaks after welding.

The gas welding station consists of:

- oxygen cylinder;

- acetylene;

- rubber hoses;

- burners.

Resistance welding is rarely used. This method has proven itself more effective in working with plastic pipes.

The most popular method of producing permanent joints is electric arc welding, divided into:

- manual

- semi-automatic in protective gas environment

When constructing pipelines, connections are made only by welding. An important part is preparing the joint for welding.

The pipe must be connected to another:

- no fractures or displacements;

- the joint must be cleaned;

- make a chamfer;

- set the gap to 1-3 mm.

Required welding equipment:

- electrodes;

- power source (transformer or rectifier);

- cable;

- Personal protective equipment for welders: overalls, mittens, brushes.

Soldering of polyethylene pipes end-to-end and using an electrofusion coupling

Trumpet

This type of connection is widely used in cast iron pipes for the oil and gas industry, housing and communal services. One of the simplest options for permanent joints.

The main process of obtaining a joint is to seal the gap between the socket and the surface of the conical pipe. Cement material is used for this.

First, a response pipe is inserted into the socket and then sealed with caulk, an airtight material. After the cement solution is diluted, the gap is tightly stamped with it.

To seal the socket, grade 300-400 cement is used, which is thoroughly mixed with water in a ratio of nine parts cement to one part water. The socket is filled with cement mortar using a scoop and embossed until the latter begins to bounce off the cement.

Pressing

This method of obtaining a permanent weld has become necessary for small-diameter connections made of non-ferrous metals. Conventional electric arc welding is not capable of welding such metals due to its technical parameters, so in this case they found a different approach.

In order to weld, you need to insert the prepared end into the fitting until it stops. Then treat its surface with a manual or hydraulic press.

To join such thin-walled non-ferrous metal pipes, press fittings with crimp sleeves are used. They perform crimping on the inside of the pipe, and external seals ensure the joint is sealed.

General information

Methods for connecting steel pipes. Steel pipes are connected in a permanent or dismountable way. It depends:

- 1.from the material from which the riser and pipes are made. Pipes can be made of metal, cast iron, glass, polymer materials, or copper.

- 2.on the characteristics of the liquids that flow through the pipeline.

- 3.on the conditions in which the log houses operate.

Threadless methods include welding, cold welding to glue pipes, and connection using a flange.

The threaded method remains a common connection method. The method with bending the pipe is not suitable for this method; the elements are connected using tees, couplings, taps, etc.

The connection method using a union nut is considered special; it uses two methods at once: threaded and threadless.

Features of the threaded connection. Threaded connections are suitable for pipes made of steel or ductile iron. The thread is made using a die or on a lathe. Risers with thin walls use a type of rolled cylindrical thread. The pipes can simply be twisted together, or special adapters can be used.

To transport steam or water through pipes, cast iron structures are used. The ends of the pipes are equipped with thick sides, which provide greater tightness during installation. Steel elements are suitable for pipelines of any circumference with low pressure or free-flow sewerage. The pipes are not equipped with thickened sides.

Various fittings, nuts, plugs, as well as couplings and locknuts are considered auxiliary parts when connecting pipes of straight lines or plugs.

If you need to turn the pipe, use a tee or square.

Connecting structures made using threads are not always detachable. It happens that threaded pipes are welded to surfaces that do not move, thereby achieving increased strength. Thus, the connection loses its detachable properties and is called a permanent threaded connection. This species is very rare.

If the installation work of connecting elements using threads is carried out correctly, the plumbing system will last for many years without failure.

Advantages and disadvantages of each method

Thread

Advantages:

- reliability;

- ease of assembly, possibility of disassembly;

- low cost.

Flaws:

- tension in the thread cavities increases material fatigue, reducing its strength;

- the need to use locking means to prevent the working element from unscrewing.

Flanges

Advantages:

simplicity and convenience of reusable connection and disconnection.

Negative properties:

- high labor intensity in manufacturing, therefore, high price;

- with prolonged use, the location of its connection decreases, loss of tightness.

Bonding

The advantages of this method include its not labor-intensive process, which does not require much skill and effort.

But the wait for gluing sometimes reaches three days, which is not always convenient.

This type of connection cannot be considered a reliable method.

Welding

Advantages:

- reliability;

- durability;

- tightness;

- the ability to connect parts of any shape.

Flaws:

- the occurrence of residual stresses;

- possibility of changing geometry;

- risk of destruction under vibration and shock loads.

Trumpet

In comparison with all types, socket pipes have the advantage of low cost, the possibility of small axial and lateral movements of the pipe, which is very useful during temperature changes and soil shrinkage.

The negative indicator lies in the difficulty of connecting the connector and insufficient reliability at high pressure.

Pressing

A common positive factor is excellent self-centering of the joined parts and stable state under shock loads. A simple and non-labor-intensive process.

Cannot be disassembled or dislodged from each other. Here are a few disadvantages of this method.

Methods for connecting metal pipes

Compression fittings for pipe systems

The technology for using crimp parts, which allows connecting metal pipes without welding or threading, has appeared relatively recently.

A pioneer in the production of fittings for pipe connections without threads and crimp welding was Gebo Armaturen GmbH, which received the first patent for this technology back in 1937.

Today the name of the company has become a household name; the fittings for crimping pipe connections are called “Gebo coupling”.

In the production of connecting fittings, Gebo Armaturen uses ductile cast iron. The company's product range includes fittings for various types of connections and branches.

Gebo fittings are designed to work with pipelines made of different materials. With their help you can connect plastic pipes, tubular products made of steel, copper, aluminum. There is no need to use welding or threading.

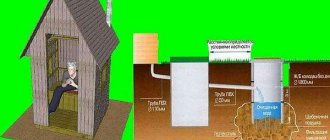

Methods for connecting metal pipes to plastic

Areas of use:

- repair, replacement of old pipeline;

- construction, when installing a gas pipeline, plastic pipes are used, but in a residential area, gas should only be in metal pipes.

In such cases, several connection options are used:

- Welding-threaded. In this case, combined couplings are used. Here one side has a thread, the other a coupling. The thread connects to the metal end. The other side has a plastic end. Such adapters are used for small diameters.

- Flanged. For larger diameters, flanges are used. In some cases, metal hoses are used.

Types of connections

All existing pipe connections are divided into two main groups:

- detachable;

- one-piece.

The use of detachable connections allows, if necessary, to disassemble the joint section. Thanks to this property, it is possible to repair and replace the joint without compromising the integrity of the pipes. Detachable joints include threaded connectors (fittings) and flanges.

In the case of permanent joints, it is possible to disassemble the pipeline, however, this will lead to damage to the pipe material. The most popular option for permanently connecting pipelines is welding. In addition, there are a number of other methods: gluing, pressing, installing a socket using cement mortar.

All of the above methods are quite popular and are used to connect pipelines transporting various media: water pipelines, heating communications, gas networks, sewer systems, as well as industrial and technical lines.

Tips and tricks

- When working with cast iron pipes, you must remember that they are fragile. For embossing and pressing, use rubber hammers.

- If the installation of a socket joint is carried out outdoors in hot weather , then when the cement is in the gap, it is suggested to lay a damp cloth on it. So that the cement does not crack.

- When gas welding, the flammable gas acetylene is used. If desired, it can be replaced with propane, which is cheaper and safer.

- When constructing a water or gas supply pipe system, try to weld the rotary joints first, and then, when the entire structure is assembled, weld the fixed joint last.

- When tightening the bolts on the flanges, do not overtighten. It is possible to strip the thread, this also applies to threaded connections.

About threaded joining of steel risers

The threaded connection method is typical for working with steel pipes. To apply threads, use a lathe or die. Cylindrical rolling threads are applied to thin-walled risers.

If the installation rules are followed when laying steel pipes, then twisting in this way will ensure high-quality functioning of the pipeline for many years.

Screwing using threads can be carried out either by directly connecting pipes to each other, or using tees, couplings, shut-off valves, and additional devices.

Connections that do not require welding

Methods that do not require a welding machine, or tools with taps:

1.Using fittings. High quality connections and low price are advantages for these products. Rigid fittings tightly connect two metal pipes without leaking liquid. The most reliable in operation are German and French brands.

2.Using flanges. The design of the flange is similar to a regular clamp; inside it is equipped with a rubber seal. The advantages include: simple assembly, low price, increased wear resistance.

3.using Gebo coupling. The coupling has a simple structure, based on three rings: clamping, pressing, sealing, and the design also includes nuts with a flange. Based on the instructions, you can quickly assemble the product. The part provides a guarantee for the tightness of the joint, the product itself lasts a long time, only the seal should be changed from time to time.

4.Using a clip for repair and installation. The part has two parts that are held together using bolts. The product is used temporarily during accidents.

These types of connections are used for rigid pipes: metal, cast iron or steel, made of polyvinyl chloride.

For pipes that do not require a tight connection, the following types of fastenings are used:

1.using a crab system. The structure includes bolts, brackets and nuts. Use nuts to tighten the parts. This system is used to tighten several products at once, ensuring high tightness of the joints. Crab systems have different numbers of clamping holes.

2.using clamps. Applicable in any area. Several rolled pipes are held together with clamps; the quality of the connections is comparable to welding.

Connection using a repair and mounting clip

The clip does not require special knowledge or equipment for installation. The design is reliable, which is installed without welding with threads. This type of fitting is used only in emergency situations for temporary use. It consists of two parts made of metal material, four bolts.

Installation features:

1. The fitting is not suitable for connecting pipes; it is convenient to close a crack in a pipe. If a crack occurs, clean the area around it using sandpaper. The area must be clean and smooth so that the seal fits well.

2.A rubber seal is applied to the area, closing it completely, because a small gap will form a new leak.

3. Place both parts of the holder on top of the seal, tightening it with bolts.

Attention! Do not over-tighten to avoid stripping the threads.

4.carry out a test for the operation of the pipe; if necessary, tighten the nuts and bolts.

The method is easy to use and economical, so it is often used.

Steel pipes: types of joints

Steel pipe connections can be permanent or collapsible, depending on:

- materials from which the risers are made. In addition to metal pipes, cast iron, glass, polymer, and copper products are used;

- properties of transported media;

- operating conditions.

Most often used:

- coupling (threaded, welded, bayonet, sleeve);

- flanged;

- threaded

Disconnect joints. Let's focus on the last option.

Fitting method

Fittings have many positive characteristics; many recommend using this method to connect structures.

Affordable, also practical, easy to install, and have a long service life. Using fittings, you can achieve high quality connections, just like welding.

Fittings are widely used for laying pipelines; they are also used to create compression equipment or gas turbine mechanisms, which indicates the possibility of using parts in systems operating under pressure.

What types of fittings are there:

1. Straight fittings are products in which the diameter does not change on both sides, that is, they are suitable for fastening two identical pipes.

2.adapters are designed for joining pipes of different cross-sections. Necessary to carry out repairs of old-type pipelines that use pipes of different diameters.

3. Tees divert pipes from the system without requiring welding with threads.

4.crosspieces are similar in purpose to tees, facilitating numerous branches of the main network.

5.Fittings connect flexible pipes made of metal material. The part guarantees a tight connection in case of unstable pipe structure.

6.plugs have the function of blocking the end of the pipe.

Fittings can be used to connect elements both outside and inside the building; you should choose the right material of manufacture.