» Tools and equipment » Tooling and accessories for milling machines

Industrial milling machines, more than others, require the use of additional devices and all kinds of technological equipment - without it it will be impossible to even install a workpiece on the machine, not to mention the ability to carry out high-quality processing of parts. It's simple, no tools or equipment - no milling.

All additional devices for milling machines can be divided into universal ones, which are used on almost all milling machines, and unique ones, intended for the manufacture of a certain type of product and even performing specialized operations.

Universal accessories for milling machines

Universal milling equipment for machine tools includes all kinds of vices for clamping the workpiece; rotary tables that allow processing of a part without reinstalling it; dividing heads responsible for rotating the product to the required angle; mandrels for installing cutting tools of various sizes and purposes. For horizontal milling machines, it is quite common to use slotting heads, which will allow you to create keyways on all kinds of gear products.

Copy ring

Copy rings are devices used as edges.

During the milling process, the ring moves along the template, giving the required position to the tool. To fasten the rings, screws, threaded holes and antennae are used.

The diameter of the ring approximately corresponds to that of the router. The device is made from steel that can withstand heavy loads. Flexible metals are not used because they deform quickly.

To produce a similar device, an angle lever and copying probes will be useful. The angle lever has a scale, each division equals 0.1 mm. It helps center the stop ring under the cutter to create the desired shape of the holes on the blanks. For convenience, chip protection and a support plate are added to the device, which can improve the quality of edge processing.

During cutting, the router does not touch the edges of the ring. In the opposite situation, the cutting tool will be damaged and will soon fail.

Using copy templates and rings

Templates are designed for the production of specific types of products. They help make the shape of finished items more accurate and even. Ready-made templates, which can be purchased in the store, have the following characteristics:

- Some template models are used to create models along a rectilinear contour, while others involve circular or charcoal cutting. Often, for household purposes, a template is used to help round corners at different radii.

- Certain types of templates are supplemented with rings or bearings for manual processing. If the model has a ring, then during processing it does not touch the edges of the router.

- Templates are also used when milling blanks with grooves of unusual shape. For example, you can quickly make a template with your own hands to create grooves for door hinges.

To make templates at home, wooden blanks are used. This is done due to the fact that wood is easy to process, so any patterns can be made on it for future work. And when milling, the template fits perfectly with the processed objects due to its ability to accurately repeat the geometry of the object.

To make a template with your own hands, place a piece of wood under a router and, after marking, cut out fancy shapes. For use in work, the template is attached to the blanks with double-sided tape and pressed with clamps. It is especially convenient to use homemade templates to cut not the entire edge of the material, but only its corners.

Unique accessories for milling machines

As mentioned above, it is intended to expand the range of capabilities of machines of this type and perform non-standard operations on them. First of all, the specialized equipment of milling machines includes non-standard tools - for example, cone and shaped cutters, made to perform individual operations and produce grooves of complex shapes.

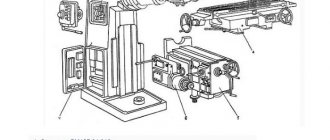

All types of devices for milling machines can be divided into three main types - devices for installing and fastening the workpiece, devices for fastening cutters and devices that expand or completely change the capabilities of the machine. The first include machine vices, corner plates, clamps, prisms, deliveries and tables. The second includes various mandrels and auxiliary devices for installing cutters into the machine spindle. A prominent representative of the third group of devices is the slotting head.

All types of milling equipment are designed both to increase machine productivity and reduce auxiliary time for part processing, and to expand the capabilities of milling equipment.

What can you do with a hand router with different cutters?

A brief overview of cutters will give a complete understanding of what can be done with a hand-held wood router and how it can be used at home and in a carpentry workshop. The main types often used in woodworking include groove, edge and combination cutters.

Types of groove cutters and their purpose

As the name suggests, groove cutters can be used to make grooves using a hand router. And also used for applying decorative milling on the front parts of furniture.

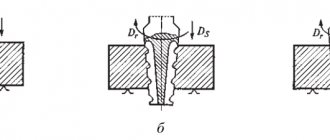

- Straight grooved. A simple cylindrical shape allows you to make a rectangular groove, the width of the groove is determined by the diameter of the cutter. Suitable for thicknessing.

- Disk groove. The width and thickness of the disk determines the depth and width of the groove, which can be made with a hand router. Also used for thicknessing of workpieces.

- Fillet groove . Depending on the shape of the cutter, rounded or V-shaped, you can make a rounded or triangular groove of different widths with a hand-held wood router.

- Structural groove. Provides a stronger and more stable joinery joint, T-joint or dovetail joint depending on the cutter shape.

- Shaped groove. Used for decorative design of facades and other front blanks.

Types of combined cutters and their purpose

In order to make a tongue-and-groove joint with a wood router, you may need two cutters at once, which are called “combined” in the set. There is also an option to make a “tenon and groove” using one cutter, by moving one workpiece relative to the other by the width of the tenon and groove.

Single combination cutters allow you to increase the length of a workpiece from short remains by flipping one part relative to the other (so that the tongue-and-groove joint meets).

Double combination tenon and mortise cutters are used to make wood paneling and other siding panels with specified joinery. The kit comes with a couple of different positions, you should be careful when using it. Some types involve turning the workpiece over, others require working in one plane so that the joint comes together.

Feeder combination cutters are designed for decorative design of the façade of furniture. Using a federation horizontal cutter, you can use a router to make a relief along the plane of the facade, and with a vertical cutter, you can shape the base (plinth) in height. A double-sided horizontal cutter allows you to make decorative carvings for subsequent assembly into a groove with a panel.

Please note that this type is equipped with a bearing so that you can mill not only along a straight line, but also along a radius, a template of any curved shape.

Types of edge cutters and their purpose

Using edge cutters, you can use a router to make any chamfers on the ends of workpieces. As a rule, this type of cutter is almost always equipped with a bearing on the top or bottom of the cutter. This addition helps to work clearly and evenly according to the template and to run the base of the workpiece along any radii and bends, with trimming.

Edge cutters are used to remove edges at right angles. With their help, you can use a router to make wooden blanks for subsequent gluing into a single furniture panel.

Edge rebate cutters are used to make a rectangular or square groove, suitable for thicknessing workpieces.

Edge moulders and taper cutters are designed for chamfering semicircular or beveled edges on workpieces. The moulder allows you to create a chamfer both with a “step” and without it, depending on the position of the router.

Edge shaped and half-rod cutters help to beautifully shape the end of the workpiece throughout its entire thickness, capturing the lower part. You can work with them with a milling cutter power of 1600W or more.

The types of wood cutters are also divided according to other criteria; you can learn more in the video.

To avoid burns on the workpieces, and also to avoid overloading the motor of a low- and medium-power milling cutter, do not try to achieve the desired effect in one pass. It is better to go over the workpiece several times to achieve a neat and clean cut on the end.

With the help of additional devices, fixing the tool on a workbench or a movable carriage in a vertical and horizontal position, you can use a router to manually make truly original and beautiful objects of decoration, decoration and furniture.

Guide rail for milling machines

This device for the router is needed to ensure straight movement of the cutting edge. The tire saves significant time by allowing you to guide the tool at any angle to the edge.

The user can create a unique version of the bus for his own needs. The simplest option is a ruler, fixed in any convenient way. To ensure stability, plywood is used by nailing a board or beam to it, against which the edge of the milling base will rest, while the base will provide the processing area. The board does not need to be nailed down, but rather attached with spring clips. This will make it possible to use cutters of different diameters and adjust the distance from the working area depending on the size of the cutter.

What is a rip fence?

A rip fence is a vital device when working with a milling machine, needed to directly move the cutter along the surface of the base (the edge of a workbench or a smooth cut of a part). The stop holds the part very firmly, which makes it possible to process edges and grooves.

Often, when selling a milling machine, the manufacturer also supplies one of the options for this device. But everyday situations may require it to be refined or even remade. There are a variety of designs adapted to solve various problems.

Each design has its own pros and cons, which requires the master to be creative and responsible in making a decision regarding the proposed unique design.

In the detailed description, you can find only two real facts about this functional device - it plays an important role in the performance of certain processes and can be supplied by the manufacturer as part of a kit for hand tools - for example, for a circular saw. The supplied tooling for any rip fence contains:

- rods that fit into the recesses on the cutter;

- fasteners holding a given position, support part;

- materials for the manufacture of the supporting part can be very different - furniture plywood, wood lined with plastic.

This is standard fittings, the manufacture of which you don’t have to worry about, since spring clamps, flywheels and profiles can be purchased in specialized stores. On the back side of the bed there are flywheels for adjusting the gaps with the cutter and fixing the stop on the table. If you want to make the design more functional and reliable, you can add a casing for attaching a vacuum cleaner, which will make the work process cleaner, but will add complexity to assembly and noise.

Small modifications make it possible to make not only straight cuts, but also curly ones. Wooden blocks with one side flat and the other angular or with a notch, inserted between the supporting part and the edge of the material, will help guide the machine along a given route.

The block adds instability, requires greater care in work and complicates the designed structure.