The fittings in the toilet cistern are a device that automatically fills and drains water.

Brands Alcaplast and Geberit are considered the most popular among manufacturers of toilet flushing devices. Modern toilet models are equipped with a two-button valve adjustment system. With one press of a button, the filling volume of the tank is changed, usually to 3 or 6 liters. Even if you correctly configure the operation of the simplest model, water costs will be significantly reduced.

Types of toilets depending on the water supply to the cistern.

The system designed to fill the tank with liquid comes in two types:

- 1.Water is supplied from the side.

- 2.Water is supplied from below.

In apartments, systems with lateral supply are more common. Adjustment and repair of this type of fittings are simple even for an untrained person.

Floats for toilets: types, features of installation and repair

The toilet is an integral part of the plumbing unit. Today it is an indispensable element in every home and apartment.

However, there are times when inconvenience may arise due to its incorrect functioning. The reason for possible unsatisfactory operation of the device is most often precisely problems with adjusting the float, which is located in the drain tank. There are several options here.

For example, there may simply not be enough water entering the tank to perform a proper flush, or, on the contrary, an excessive amount will accumulate. Therefore, it is worth considering the question of how to properly configure the operation of such an element.

Composition of the fittings if the water supply is from the side

If a side type of supply is installed to the tank, then the mechanism consists of:

- 1. The shut-off valve can be rod or diaphragm. The rod type is simpler and less expensive.

- 2. The rod or lever for control can be brass or plastic.

- 3. The filling tube is designed to reduce the noise effect from flushing and filling water.

- 4.Float. Floats are used that move along a horizontal guide.

How does a mechanism that moves along a horizontal guide work:

- 1. During flushing, the float mechanism lowers down, moving the rod behind it, while opening the shut-off valve.

- 2.Water enters the tank, the control element rises.

- 3. The flow of water in a device with a rod type valve stops gradually as the tank is filled, with a membrane type it stops as soon as the control mark is reached.

What does the fittings consist of if the water supply is from below:

- 1.float

- 2. glass, where the float mechanism is lowered during draining.

- 3. guide.

- 4.membrane valve.

- 5. The rod is attached simultaneously to the float device and the locking element.

Types of fittings for flush cisterns

The principle of operation of a regular tank is not complicated: it has a hole through which water flows and a place where water is discharged into the toilet. The first is closed with a special valve, the second with a flap. When you press a lever or button, the flap rises and the water, in whole or in part, flows into the toilet, and then into the sewer.

After this, the valve returns to its place and closes the drain point. Immediately after this, the drain valve mechanism is activated, which opens a hole for water to enter. The tank is filled to a certain level, after which the inlet is closed. The water supply and shut-off are regulated using a special valve.

There are separate and combined designs of fittings that collect the volume of water required for flushing and drain it after activating the flushing device.

Separate and combined options

The separate option has been used for many decades. It is considered cheaper and easier to repair and configure. With this design, the fill valve and damper are installed separately, they are not connected to each other.

To control the flow and shutdown of water, a float sensor is used, in which sometimes even a piece of ordinary foam is used. In addition to a mechanical damper, an air valve can be used for the drain hole.

A rope or chain can be used as a lever to lift the damper or open the valve. This is a typical option for retro-style models, when the tank is placed quite high.

In compact toilet models, control is most often carried out using a button that needs to be pressed. For those with special needs, a foot pedal may be installed, but this is a rare option.

In recent years, models with double buttons have been very popular, which allow you to empty the tank not only completely, but also halfway, in order to save some water.

The separate version of the fittings is convenient because you can repair and configure individual parts of the system separately.

Combined type fittings are used in high-class plumbing; here the drain and water supply are connected into a common system. This option is considered more reliable, convenient and expensive. If this mechanism breaks down, repairs will require completely dismantling the system. Setup can also be a bit tricky.

Materials for making devices

Most often, toilet fittings are made of polymer materials. Typically, the more expensive such a system is, the more reliable it is, but this method does not provide clear guarantees. There are also counterfeits of well-known brands, as well as quite reliable and inexpensive domestically produced products. The average buyer can only try to find a good seller and hope for luck.

Fittings made of bronze and brass alloys are considered much more reliable, and such devices are much more difficult to counterfeit. But the cost of these mechanisms will be significantly higher than that of plastic products.

Metal filling is usually used in luxury plumbing fixtures. With proper configuration and installation, such a mechanism functions smoothly for many years.

Water supply point

An important point is where water enters the toilet. It can be done from the side or from below. When water is poured from the side hole, it produces a certain amount of noise, which is not always pleasant to others.

How does a device that moves along a vertical guide work?

Water from the bottom supply to the tank is drained according to the following principle:

- 1. During flushing of water, the float mechanism moves along a guide.

- 2. The draft, acting on the valve, opens it.

- 3. The liquid is poured into the container.

- 4. The float device rises to the limit set by the draft, the diaphragm valve shuts off the liquid supply.

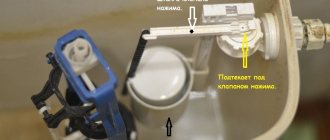

Water leaking from the tank into the toilet bowl indicates a broken fitting.

Attention! If the fittings have been in operation for several years, they become covered with a coating of lime and rust, which complicates the adjustment process. Special products to combat limescale will help solve the problem. You need to add a little product directly into the tank and rinse it off after a couple of hours.

Adjusting the volume of liquid filled

To adjust a tank with a bottom water supply, you need to turn the adjustment screw, which gives the correct position of the float device on the rod.

To increase the volume of water filling, you need to turn the screw against the clock, and vice versa to reduce the volume of water flow.

In order to adjust the liquid level in a container with a side supply, when the control device is positioned horizontally, you must move the float to the right or left along the rod.

You can increase the level of filling the tank with water if you increase the length of the lever; if the volume of water in the tank needs to be reduced, then we reduce the size of the lever. We unscrew the screw that secures the lever, move it in the desired direction and tighten the screw, you can move the float along the teeth of the rod. If the fittings have a metal rod, then the water level in the tank can be adjusted by bending the rod to the left or right.

A drain system with a bottom supply to the tank is considered comfortable for use in everyday life, because it is equipped with better sound insulation, but fittings with connections from the side are easy to adjust and repair with your own hands.

Reducing the flush volume

Why is this necessary?

The toilet and cistern provide up to half of the total water consumption. Another approximately 25 percent each comes from washing dishes and taking a shower.

If water is very expensive in your region, it is logical to save it. The most obvious way is to reduce the water consumption for each flush of the tank.

Tip: many fitting kits allow you to use water more flexibly.

The tank is equipped with two buttons; pressing one of them leads to a flush using the entire volume of water (usually 8 liters), pressing the second - to the consumption of half of this amount.

Solution

Adjusting the toilet flush in this case comes down to adjusting the amount of water in the toilet at the moment when the valve turns off the water.

The operation of a float valve is very simple: water is drawn in, the float floats up and, using a lever, moves a brass or plastic plug, which, with a rubber gasket, blocks the nozzle supplying water.

How to adjust the float in the toilet so that it shuts off the water earlier?

- If the lever is brass , just bend it. By raising and lowering the float, it is easy to see in what position it shuts off the water.

Here the entire mechanics of the valve is depicted extremely clearly. To shut off the water earlier, simply bend the brass lever (No. 6 in the diagram)

- If you have a newer set of fittings and the lever is made of plastic , inspect it carefully. To position the float, either a mounting screw is used, which allows you to change the bend of the lever, or a simple plastic ratchet that fixes the float in one of the positions.

One of the alternative designs. Usually it is enough just to carefully inspect the valve to understand the method of its adjustment.

Adjusting the toilet flush and fill system

Most often, adjustment of the fittings is required if there is leakage from the drain tank. If after flushing a trickle of water leaks out of the tank, then the drain mechanism needs repair. The reason may be a decrease in the elasticity of the bulb, which is responsible for releasing water, then the entire toilet needs to be replaced. If water does not stop flowing into the toilet after the tank is filled, then the filling mechanism needs adjustment. In this case, the culprits of the problem will be the float mechanism or the ball valve.

In older toilet models there is a brass float lever; to adjust it, you need to bend its rod so that it does not interfere with the operation of the drain system and at the same time the lid closes well.

If there are any shortcomings in the draining process, you need to adjust the device. We remove the rod from the drain pipe and clear the approach to the drain system clamp so that the float cup moves freely. We change the position of the device to the desired position, not reaching the edge of the tank by about five centimeters. Then we fix it and set the rod so that the overflow tube is in the water at a level of two centimeters.

You can also adjust the height of the overflow safety mechanism. The mechanism is located in the center of the drain device in the form of a small tube. We turn the tube to the desired level, move it clockwise, and if necessary, loosen the nut. We fix the position of the tube by turning it in the other direction.

Selecting the internal structure of the tank

Using a ruler, we determine the cross-sectional size of the pipe intended to fill the water. A diameter of 1.5 cm corresponds to a 3/8-inch liner; if the cross-section is two centimeters, then the liner is 1⁄2-inch. For convenience, it is better to choose the model of fittings that was used. We take out the fittings and buy the appropriate ones in the store.

A set of tools that will be needed for adjustment and repair:

- Roulette or ruler.

- Adjustable wrench marked 1.

- Several wrenches.

- New fittings.

How to install new fittings

Included with the new fittings are instructions for use. First of all, let's get acquainted with the instructions.

1. We install a valve that regulates filling using gaskets and adapters. There are plumbing models in which the inlet and filler mechanisms are installed simultaneously.- 2. The fittings can be inserted into the tank before installing the toilet; we place the gasket on the upper surface of the drainage system and place the device in the tank, fastening it with nuts.

- 3. Rubber gaskets are used for internal fasteners, and plastic gaskets for external fasteners. The internal gaskets can be lubricated with silicone sealant for sealing. We replace old gaskets after disassembling the device.

- 4.If possible, the gasket connecting the tank and toilet bowl is also lubricated with sealant.

- 5. The fittings must be located at a distance of at least half a centimeter from the walls of the drain container.

- 6. Having completed the installation, the tank is attached to the toilet bowl.

- 7. Close the tank with a lid by screwing on the drain button.

- 8.Connect the water and perform a test drain.

Main types of drainage equipment designs

First of all, they depend on the type of filling and drainage mechanisms. The water drainage functions are performed by lever, push-button and automatic products.

Read more: Which pipes for water heated floors are better? Compare 4 options!

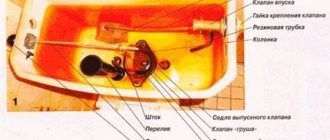

The float (1) controls the inlet valve (3) through the lever (2). The water level depends on the adjustment of the float lever on the valve lever (4). The water pressure during filling is adjusted at the valve using a set screw.

Lever models were the main models installed on toilets of the last century. They are still used in some places today. Lever devices are distinguished by their simplicity. The first products drained only at the moment of pressing, while the shut-off valve was manually held (by the “pull” - a chain or fishing line).

The toilet flush mechanism, made in a push-button version, is installed on most modern plumbing products. The predominant location of the button is at the top, on the covers of compact systems, and can also be on the wall for products installed in building structures. Their advantages, in addition to good aesthetics, lie in the ability to adjust the drain and overflow parameters.

Automatic

Today, there are rare and expensive products for draining water, which justify themselves when installed in luxury products or used in public places. Their work is controlled by infrared sensors.

Shut-off valves for the toilet, represented by filling mechanisms, work, as many years ago, using the principle of a refill valve, opened and closed by a float. In the classic version, the float transmits force to the valve of a faucet with a side connection through a horizontal rocker arm.

Floats that shut off the water supply through a system of levers.

However, now more often floats are installed that move along a vertical guide, cutting off the water supply through a system of levers for both the side supply and the bottom.

Important! Modern filling valves, due to their design features, allow you to collect water much faster than systems with a rocker arm.

First of all, they depend on the type of filling and drainage mechanisms. The water drainage functions are performed by lever, push-button and automatic products.

Lever

The float (1) controls the inlet valve (3) through the lever (2).

The water level depends on the adjustment of the float lever on the valve lever (4). The water pressure during filling is adjusted at the valve using a set screw. Lever models were the main models installed on toilets of the last century. They are still used in some places today. Lever devices are distinguished by their simplicity. The first products drained only at the moment of pressing, while the shut-off valve was manually held (by the “pull” - a chain or fishing line).

Push-button

The toilet flush mechanism, made in a push-button version, is installed on most modern plumbing products. The predominant location of the button is at the top, on the covers of compact systems, and can also be on the wall for products installed in building structures. Their advantages, in addition to good aesthetics, lie in the ability to adjust the drain and overflow parameters.

Automatic

Today, there are rare and expensive products for draining water, which justify themselves when installed in luxury products or used in public places. Their work is controlled by infrared sensors.

Floats that shut off the water supply through a system of levers.