What types of fittings are there for the drainage system?

There are several classifications that are based on operating and installation features. The first is based on the location of the pipe. They can be located both on the outside of the pipeline and inside the sewer system.

Another fundamental feature is the fastening method. Parts can be connected in two ways:

- using an O-ring;

- by gluing.

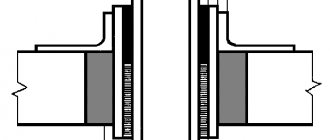

Scheme of connecting plastic pipes with fittings

The external and internal networks are also characterized by different types of fittings for sewer pipes, each of which performs a strictly defined function. The structure of the external side of the mechanism includes the following components:

- couplings;

- audits with a cover;

- crosses;

- expansion pipes;

- reductions, etc.

Non-return valves, plugs, bends, etc. are used as specific devices for internal sewerage.

Fittings for internal sewerage

Types of sewer fittings

There are several types of sewer lines:

- plastic;

- cast iron;

- ceramic;

- asbestos-cement.

All these varieties have their own characteristics, pros and cons. Each type produces its own fittings for sewer pipes. The predominant option is a plastic system, which is quickly installed, lightweight and low cost. The main advantage of these channels is considered to be high assembly speed. PVC (or polypropylene) sewer pipes and fittings have two connection options:

- under the rubber ring;

- under the glue.

Most often, PVC products with a connecting element in the form of a rubber ring are used, since assembling such lines is not difficult even for a completely untrained person.

Fittings for PVC sewer pipes are produced in accordance with the current pipe sizes. Their design allows you to change direction, connect lines end-to-end, or make a channel branch. Available for sale:

- coupling _ Used to directly connect two identical channels;

- reduction _ An element operating on the principle of a coupling, but intended for joining pipes of different diameters;

- revision . This is a type of coupling with a hole in the central part. It is tightly closed with a threaded lid and is used for cleaning or other work;

- tee _ Provides straight passage and outlet at an angle of 45° or 90°;

- crosspiece (another name is a sewer quadrant). This is a large group of fittings capable of connecting lines in the same plane or with intersection, designed to connect channels of the same or different diameters;

- tap . A fitting that allows the line to bend at 30°, 45° or 90°;

- compensation pipe . Needed to replace a cut out defective area, capable of compensating for thermal expansion of the line;

- stub . It is installed on the free end of the pipe and ensures the tightness of the internal cavity of the channel;

- check valve Prevents waste from moving in the opposite direction;

- ventilation valve. Designed to normalize air pressure inside the system, protects plumbing water seals from failure.

There are also flexible connections consisting of an elastic corrugated section of pipe. They are used in cases where the angle of the joint of the lines is non-standard and requires local adjustment.

Fittings for the internal part of the system

Fittings for sewerage located inside the building are gray in color. This makes it easy to distinguish them from other elements and prevent confusion. The material of pipes and fittings for internal sewer lines must be the same, since hot water is constantly being discharged here.

The dimensions of the connecting pipes exactly match the parameters of the pipes, which facilitates assembly and eliminates errors when purchasing accessories. For installation, special clamps made of metal or plastic are sold that allow you to fix the channels on the wall or floor.

If adhesive joints are used, it is necessary to allow some time for the composition to harden. Rubber ring connections can be used immediately after installation. Some sources recommend reinforcing joints with sealant or wrapping them on the outside with special tape. However, such fittings can work quite well without additional measures.

External fittings

To assemble the external parts of the system, orange sewer pipes and fittings are used, the dimensions of which correspond to accepted standards. The most common variety is samples with a diameter of 110 mm. The external parts of the system are located underground and withstand considerable mechanical loads. There is practically no hot water in them, so the main emphasis is on ring strength and frost resistance. Installation of such pipes can be done in winter, so users prefer rubber ring fittings. Elements for adhesive joints are also used, but are not in high demand due to the complexity of assembly.

The composition of the elements of external sewerage differs little from the nomenclature of internal lines. It is complemented by a two-arm siphon, which forms a water seal and does not allow sewer gases to pass through. Installation of such a device is allowed only when the system is immersed below the freezing depth, otherwise the liquid will turn into a plug of ice.

You may also like:

Where does the water go from the sewer - where does the waste go?

Plastic sewer bends 110, sizes and types

How to choose the right fittings

Creating a coherent sewage system requires precise selection of the appropriate sizes of pipes. When choosing fittings for sewerage in the catalog, you need to take into account a number of important features, which include the following items:

Sewer fitting classification table

- nomenclature;

- installation method;

- material;

- type of installation;

- diameter.

If internal elements are selected, their walls should be about 2.2 mm. For the external area, more durable parts with a wall thickness of at least 3.5 mm are needed.

The main distinguishing feature of the connecting parts for external and external sewage systems is the color of the part. Orange fasteners are installed on the outside, and gray fixtures are installed on the inside.

Dimensions of connecting products for internal sewerage

Fittings for external waste drainage systems have a wide range of sizes, and different types of parts also imply certain parameters. When selecting the size of fittings for sewerage, each type of fastening is considered separately.

There are two main parameters:

- fastening diameter;

- angle of rotation.

Considering in detail each type of fastening of the sewer network, we especially highlight elbows, tees, crosses and revisions.

Fittings for sewer pipes - parameters

Standard knee parameters:

Parameters of the internal sewerage elbow

- diameter – from 32 to 110 mm;

- angle – from 20 to 87 degrees.

The tee has three holes, which allows for parallel branching of the pipeline, as well as tilting to the side. For these purposes, the tube is equipped with holes with an inclination angle of 45, 65 and 90 degrees.

The size range of couplings and plugs is 11–50 cm, and the diameter of check valves and plugs ranges from 11 to 31.5 cm. Crosses have some similarities with tees and differ from them by one hole, each of which has a typical diameter of 5 up to 11 cm, while the angle averages 35-40 degrees.

Cost of PVC pipes

Looking through product catalogs, you may notice that the price of products varies quite widely. How to choose high-quality pipes without compromising quality? All factors that may influence the formation of their cost should be studied:

- manufacturer (quality of raw materials used in production, production technology, markup for the brand - this all affects the price of pipes);

- length of the product, its diameter;

- pipe wall thickness.

Some manufacturers are trying to reduce the cost of their products precisely by reducing the thickness of the pipe wall. This makes it lighter and cheaper. And installation in this case will be easier. But, you need to take into account the requirements for the level of rigidity of the product, and if they allow, then use the pipe only in this case.

The price and size of PVC sewer pipes are largely related, the product catalog will confirm this. As for specific prices, the approximate cost of a meter of pipe with a cross-section of 110 mm will be 210 rubles. The same piece of PVC pipe with a cross-sectional diameter of 50 mm will cost about 80 rubles. These prices are estimates only and will fluctuate depending on the factors listed above. Pipes used for plumbing will cost less because they have a smaller diameter.

Today, plastic pipes are increasingly used for indoor sewerage installations. They have many advantages over their metal counterparts:

- affordable price;

- light weight;

- ease of installation;

- long service life;

- a wide range of.

Dimensions of connecting products for external sewerage

The dimensions of the fittings for the external network sewage system practically do not differ from the parameters of the components of the internal system, in mm:

Sewage fitting sizes

- transitions – 160x110, 200x160;

- audits – 110–200;

- three-bell tees – 110–200 (87 degrees);

- transition tees – 110–200 (45 degrees);

- check valves – 50–160.

Correct sizing of fasteners is very important for a tight connection of sewer pipes. A part of too small a caliber simply will not fit on the pipe, and a large element will not give the network proper tightness.

Advantages of PVC pipes

Metal-polymer pipes are particularly durable elements. Plastic parts are easy to install and require less time and effort to install. Good throughput allows you to bend the pipeline at different angles. Installation with plastic elements can be done independently.

Their advantages include:

- low thermal conductivity;

- light weight (unlike cast iron construction);

- reliable protection against the spread of bacteria and viruses;

- resistance to corrosion, external factors and chemicals;

- affordable price (unlike products made of cast iron);

- long service life.

Adhesive installation method

The following elements are used as connecting elements with adhesive installation:

Glue method for installing fittings

- bends;

- plugs;

- saddles;

- tees;

- crosses;

- metal fittings.

When connecting pipes using the adhesive method, standard PVC products are used, which are the same for both external and internal networks.

The adhesive connection is valued for its high sealing qualities, because special glue is used in the process of working with pipes. When solidified, the substance becomes dense and hard, preventing liquid from leaving the pipeline at the junction points. Connectors for the adhesive installation method are practically no different from the analogues used in the standard circuit.

Related video: Types of sewer pipes

Publications on the topic

Simple and affordable methods for connecting pipes without welding

Criteria for choosing between polypropylene and metal-plastic

Selection and application of sealant for sewer pipes

Features of plastic line wiring

There are the following types of wiring: collector, serial, with feed-through sockets (such wiring is extremely rare).

Before you begin installing plastic pipes, you need to draw up a detailed diagram of the pipeline: the fewer turns and elements in the system, the better.

Open wiring involves vertical pipe placement in the corners, or horizontal pipe placement just above the floor. With this layout, the pipeline will not be so noticeable.

Hidden wiring is much more difficult to implement; moreover, it requires very careful calculation. You can only hide the pipe itself in the wall. All connection points must be freely accessible. Bending plastic pipes is not recommended.

If there is a need to make a transition to pipes with a different diameter or to connect two pipes to each other, then couplings should be used. To create branches you will need tees. The system is rotated using corners.

Begin laying the pipeline from the most distant place from the entrance to the room. When cutting pipes, you need to take into account that the installed fittings will add from 3 to 5 cm to their length (the depth of the pipe entry is directly affected by the size of the fittings). The fittings should not be pushed all the way, otherwise the pipe will narrow towards the connection point. In addition, the elements must heat up simultaneously. They need to be inserted with a certain force, without turning along the center line.

The connection of fittings to PVC pipes is carried out using a special soldering iron equipped with nozzles of various diameters (for the pipes being mounted).

Installation of fittings for PVC pipes is carried out as follows:

- first, cut the pipe and clean it of burrs (using a chamfer remover), then, using a calibrator, get rid of the ovality of the end;

- the soldering iron is heated to a temperature from +250° C to +300° C;

- the pipe and fitting are placed on the nozzle and held for 10–15 seconds;

- The elements to be connected are joined together until they stop (1–2 minutes).

The resulting connection is highly reliable; it can withstand operating pressure up to 16 Bar and very high temperatures.

If the pipe diameter is large enough (more than 50 mm), the chamfer should be chamfered before welding at an angle of 45°. The pipes are secured to the wall with clips, the distance between which should be no more than 1 m.

When assembling the pipeline, plastic pipes with slip-on fittings are also used.

The operating principle of this method is based on the so-called memory effect. That is, a polymer that has taken on a new shape tends to return to its original position. The connection is made using brass or plastic fittings with push-in couplings using special tools and equipment.

Place a sleeve on the pipe and move it as far as possible from the edge. Then the expander tip, consisting of two or more connected fragments, is placed inside.

A working device pushes the sections apart, causing the edge of the pipe to look like a funnel. Then you need to quickly pull out the expander and insert the fitting of the fastening element into the hole.

Now you need to turn on the axial press mechanism, which, with its U-shaped “jaws,” covers the two parts of the fitting and with great force pushes the sleeve towards the end of the pipe. Thus, the product is clamped by the sleeve and fitting. After some time, the pipe will again narrow to its previous diameter and tightly fit the fitting.

In this way, pipes can be installed without negatively affecting the internal flow area at the connection (as opposed to radial fasteners with a narrower cross-section of the fitting than the pipe). To perform this type of work, special electric and manual tools are used.

Working with hand tools will require significant effort; in addition, they have maximum standards for the diameter of the pipes being installed, and the diameter limit for electric tools is much higher.

There is a device similar to this tool - an expander. Manual reamers are affordable, but they are not suitable for large diameter pipes. There are quite a lot of models of electric tools, they are universal and, importantly, convenient to work with. The price for them is quite high, so not every professional plumber can afford such a purchase.

Manufacturers of axial tools call for pipeline installation using equipment of a specific brand that is most suitable for HDPE pipes and fittings (for cold water supply). This is explained by the fact that a specialized tool exerts an impact on the joint with the required degree of force. It is almost impossible to damage the fitting or push the sleeve insufficiently when using such equipment.

The tool must be such that you can change the nozzles on it; this will allow you to install a wide variety of fittings for plastic pipes. Some manufacturers produce axial presses with paired “jaws,” which is very convenient: you can work simultaneously with two fittings of different diameters located on one nozzle.

Using such a tool, you can save time on fitting fittings, since there is no need to change the “jaws” to install a fastener of a different size. The paired “sponges” just need to be turned over.

Read material on the topic: Fittings for polypropylene pipes wholesale