Most home craftsmen always have a tool at hand that helps them cut a piece of metal of the required size, sand the surface, or even sharpen a kitchen knife. This is an angle grinder. Its disk rotates at high speed, which ensures efficient performance of work. But not every operation requires maximum speed. Then a grinder with speed control will come in handy, which will ensure quality and safety.

Tool types

Typically, devices used at home are characterized by small sizes and increased requirements for working conditions. Their technical capabilities do not go beyond household operations. As a rule, after 15-20 minutes the technician’s hands will feel an increase in the heating of the device body. This means that you need to take a break from work. Intensive work every day is beyond the capabilities of such an angle grinder.

For industrial use, you need a high-performance, reliable angle grinder with soft start and speed control, with a moisture- and dust-proof housing for manipulation in adverse environments. Typically, such devices are difficult to break , so it is perfect for daily full-time work. When performing operations with such a device, you do not choose the type of material, even if it requires delicate processing. All you have to do is reduce the rotation speed of the disk and any tool will do the job.

Such units can also be used at home, for example, during the construction of suburban housing or major renovations. He will show himself only from the best side.

Types of breakdowns in grinders

Typical minor damage

In the event of a malfunction, it is first necessary to eliminate elementary breakdowns:

- The grinder does not turn on. The angle grinder suddenly became faulty - it stopped turning on. In this case, you need to check the serviceability of the socket, then the plug and the power cord; perhaps the drive simply does not work due to the fact that no current flows into the product.

- The cable and plug are intact, but the drive does not work. You need to check the start button. It is easier to repair an angle grinder switch by purchasing a new button and replacing it. Since it is rarely repairable - mainly, the plastic switch rod inside breaks. If you want to experiment, you can disassemble it, numbering the contacts, and put everything back in its place so that after assembly there is no short circuit.

- The above parts are unharmed, but the angle grinder does not want to work - which means it’s time to check the brushes. Perhaps it's time to change them in the grinder. Brushes constantly heat up from work, so they wear out quickly and need to be replaced more often than other parts, and in pairs.

Major faults

Having ruled out all minor damage, you need to figure out why the tool does not want to turn on and how to repair it. Most likely, the malfunctions are serious and require additional knowledge. This happens if:

- the body is deformed;

- one of the bearings is jammed;

- the armature or stator does not work;

- the gear teeth of the gearbox are broken or worn out;

- the collector has failed;

- The control electronics sensor shows no signs of life.

If it is determined that the malfunction has occurred in the mechanical part of the angle grinder, then you need to pay attention to the condition of the large gear located on the shaft and the bushings. If the teeth are partially worn out or the shafts become wobbly, they must be replaced immediately.

The most common breakdowns

Grinder malfunctions happen quite often. Everyone who works with this tool knows about this. What goes wrong most often?

The spindle lock button is broken.

Just one awkward press on the spindle lock button while the disk is rotating leads to its breakdown. Sometimes it can be broken if it is used to remove a jammed disk. To prevent this from happening, you need to use an open-end wrench inserted into special holes near the place where the disk is attached.

Main characteristics

The grinder itself is simple both in design and in working with it. However, like any tool, it must be used effectively and safely. In order to combine these qualities, it is necessary to understand the technical features of the device.

Engine power

Most angle grinders with a speed controller have an electric motor power ranging from 500 to 1500 watts.

There are, of course, samples with parameters that go beyond this framework, but these are the ones that are popular. The average power model of 700-800 W will cope well with most cutting materials. The grinding operation will require a more powerful tool, because with such work the contact area with the surface being processed is larger. If the engine cannot cope, shutdowns and, as a result, overheating of the tool are inevitable. Therefore, for insurance purposes, you need to choose a more powerful device. Then you won’t have to carefully choose the scope of its application.

Protective automation

Safety has become the main condition for working with power tools. Any rotating machine, be it a drill with speed control or a grinder, has a whole range of protective systems that protect people from injury. The most popular automatic types of health protection are:

- The soft start device ensures smooth operation initially after the start button is turned on. Limits starting currents, which extends the life of the electric heart of the angle grinder.

- If the tool disk jams or bites, an emergency stop using a safety clutch will help to avoid injury.

- During operation, if the tool is skewed, it may break out of your hands. The emergency disc brake will stop rotation in 3 seconds.

- The worst enemy of windings after a short circuit is abrasive dust that gets inside during grinding or cutting. To prevent it from getting inside the electrical circuit, the coils are impregnated with special compounds.

- For comfortable operation in conditions of intensive use of the device, the case has heat dissipation slots.

- If the grinder's circles are ground unevenly, beating and trembling of the tool occurs. To smooth out these consequences, there is an automatic balancing system.

- When heated above 160 degrees, the rotation speed slows down, reaching 200, and stops completely. This is how automatic overload protection works.

Safety precautions when working with angle grinders

When working with an angle grinder, strictly follow safety rules. This is the law of life, written in blood. Be sure to install the protective cover in such a way that it protects you from sparks and debris. Install the additional handle so that it is separated from the disk by the casing.

Particular attention should be paid to protecting the face and neck.

Using a face shield when working with an angle grinder

When working for long periods of time, you should also protect your hearing by using noise-cancelling headphones or earplugs.

Adjusting the disk rotation speed

The quality of the work performed is often determined by the set speed of the tool, if the design allows it. Thick, hard materials are easier to cut at maximum speed. An aluminum billet, on the contrary, will melt when heated. Therefore, there are operating modes that require the use of an angle grinder with speed control:

- Reduced speed is required for stone work. Each variety has its own.

- Sanding and finishing at high speeds can damage the product.

- When changing a wheel from one size to another, speed adjustments are required.

- Diamond-coated discs and bits are used at low speeds to avoid breakage due to overheating.

If the device is used exclusively for cutting operations, a speed controller is not necessary, but as a tool for universal use, it is simply necessary.

How to disassemble an angle grinder for diagnostics

In order to diagnose the electrical part of the angle grinder, as well as eliminate mechanical breakdowns of the device, you will need to disassemble it. Disassembly is carried out according to the following algorithm.

- Using a wrench, remove the disk or other attachment from the spindle of the unit.

- Unscrew the handle.

- Remove the protective cover.

- Open the special windows located on the sides of the angle grinder casing and remove the electric brushes, having first disconnected the terminals.

- Unscrew the gear housing from the angle grinder motor housing.

- Pull the gear housing lightly and remove it from the housing. In this case, the gear unit will be removed along with the rotor.

- After removing the armature, the motor stator will remain in the casing, which can also be easily removed for diagnostics after unscrewing the fasteners.

- To disassemble the gearbox, unscrew the screws holding the cover. After removing the cover, you will see the gears of the gearbox.

- To remove the anchor from the angle grinder, you will need to unscrew the nut located inside the gearbox.

- In order to remove the bearing from the armature, it is recommended to use a special puller. Otherwise, the shaft may be damaged.

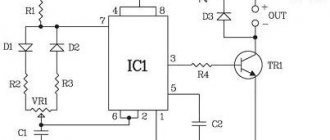

Speed controller circuit

To install this system, variable resistance alone is not enough. If you simply lower the voltage in the circuit, the power and speed of the device will decrease. Having dropped to minimum values, such voltage will not turn the angle grinder shaft. Therefore, it is necessary to develop a complete scheme.

The most modern regulators are manufactured using integrated circuits. The electrical circuit of the simplest tool includes a motor and a start button. These are reliable components that often outlive the device itself. Therefore, you should not be afraid of including electronic components in the form of a tuning module and a soft start system.

The wide distribution of products with such devices in the mass sector is hampered by the high price. However, very often they make homemade devices or purchase a ready-made product.

Mechanical breakdowns and their elimination

Mechanical failures of angle grinders include the following.

- Worn motor armature bearings. Typically, when the bearings wear out, you may experience strong vibration while the machine is operating. In addition, grinding and other noises may be heard. Sooner or later, the bearing will collapse, and the spilled balls will fall on the gears of the gearbox. If this happens, then in addition to the bearing, the gears will also have to be replaced. Of course, it is better not to wait for this problem, but to replace it at the first sign of bearing failure. How to get to this part of the angle grinder was described above.

- Worn ball bearing or plain bearing of the gearbox. As in the previous case, when you turn on the device, vibration will be felt and noise will be heard that is unusual for the normal operation of an angle grinder. To prevent further damage to the gearbox, it is necessary to replace the faulty part.

- Reducer gear wear. Gears wear out quickly due to insufficient lubrication. For the same reason, the gearbox heats up. It is necessary to monitor the condition of the lubricant inside the gearbox and change it if necessary. How to disassemble the gearbox was described above. You need to use lubricant specially designed for angle grinder gearboxes, and you can buy it at points where this tool is sold. If for any reason the teeth of at least one gear are broken, then the entire set of gears (a pair) needs to be replaced.

Mechanical faults can also include a broken shaft lock. In order to replace the retainer, you will need to disassemble the gearbox and remove the large gear.

Popular models

All well-known world manufacturers produce a huge number of angle grinding tools. There are simpler models, for not the most demanding client, and there are also highly effective specialized modifications. There are several Bulgarian women who deserve special attention:

- Metabo WEV 10-125 Quick. The device with the highest possible speed performs its duties efficiently even when the voltage drops. This is achieved by adjusting the electronics, which includes a speed controller and a soft starter. Has a protective coupling. The long cord makes this model a versatile and convenient tool.

- The Japanese company Makita is known for the memorable appearance of grinders, electric drills, screwdrivers, as well as high quality. This is confirmed by the Makita GA5030 model, which has proprietary reliability, noise protection, speed control, soft start and locking the start button. All this is placed in a compact case.

- The Bosch GWS 12-125 CIE angle grinder turned out to be the best option for a professional tool. Its entire design is aimed at uninterrupted and safe operation. Several speeds, a power of 1200 watts, a protective shutdown system when biting - all this is created for comfortable work with the tool.

An angle grinder with a speed controller can perform many different operations in skillful hands. You just need to know when to increase the rotation speed and when to turn on low speed. Which tool is more suitable is up to each owner to decide for himself.

Originally posted 2018-04-06 09:07:39.