Sanding under high pressure allows you to quickly and effectively clean surfaces of dirt. For this purpose, a special device is used - sandblasting, which is used both in auto repair shops and at home. The main problem with this cleaning method is the high cost of equipment and components. If you have free time and a desire to save money, you can try to assemble the device yourself. To create a sandblasting machine with your own hands, you need a powerful compressor; the remaining parts are assembled from scrap materials and elements that can easily be found in the nearest hardware store. The work also requires studying the drawings and strictly following the instructions below.

Main components of sandblasting machine

Homemade sandblasting is assembled on the basis of standard schemes, differing in the method of supplying sand to the contaminated part. Despite the existing design differences, the components for both options are the same:

- compressor - a device for pumping air mass;

- a receiver necessary to create the necessary air supply;

- abrasive tank;

- gun - the main device designed to supply an abrasive mixture to the surface to be cleaned;

- hoses.

In order to increase the duration of continuous operation and maintain the supply pressure, it is recommended to equip the sandblaster with a moisture separator. When using a plunger compressor, an oil filter system should be installed on the air intake duct.

Design of a sandblasting machine

The device, regardless of the assembly scheme, forms a combined outgoing flow of air and abrasive. When assembled according to a pressure circuit, sand under the influence of pressure enters the outlet pipe, in which it is mixed with the air supplied from the compressor. To form a vacuum in the abrasive supply channel in ejector devices, the Bernoulli effect is used. Sand is fed into the mixing zone under the influence of only atmospheric pressure.

The existence of many options for sandblasting manufacturing schemes is explained by the possibility of creating it from materials at hand, which often seem unnecessary. To understand the essence of the process, it is enough to consider the general principles of assembly.

Advantages and disadvantages

Sandblasting equipment allows you to quickly clean the surface of various contaminants and outdated finishes:

- dirt;

- oil;

- scale;

- fat;

- dye;

- primer;

- putty.

It takes several times less time to prepare a part for further processing and painting than using detergents and solvents.

Sand is easy to obtain. If used continuously, it can be used several times. It must be sifted and calcined.

The air flow with sand and other abrasives penetrates narrow cracks and small holes. The cleaning speed does not depend on the complexity of the design.

Sandblasting machines have a simple design. It is enough to connect the compressor and a container with sand with hoses.

Disadvantages include operating equipment under high pressure. If a hose ruptures or enters the work area, a person may be seriously injured.

The attachments wear out quickly. A metal nozzle made of abrasion-resistant steel is enough for 1 – 2 hours of operation.

Assembling a sandblaster from a gas cylinder

The simplest design for self-assembly is a homemade pressure-type sandblaster from a gas cylinder. The following elements will be required:

- ball valves – 2 pcs.;

- gas cylinder;

- a piece of pipe from which a funnel is made for filling the chamber with sand;

- tees – 2 pcs.;

- hoses with a passage of 14 and 10 mm, respectively, used to transfer air from the compressor and remove the mixture;

- clamps for attaching sleeves;

- fum tape intended for sealing threaded connections of apparatus parts.

In order to assemble the sandblaster, you must perform the steps in the following order:

- Preparing the tank. Remove all contents from the container, clean the inside surface using non-abrasive detergents and wait until it dries.

- Making holes in the cylinder. The top one will be used to fill in sand - its size should correspond to the diameter of the selected pipe. The bottom hole is for connecting a tap.

- Crane installation. The regulator can be tightly welded or screwed through an adapter pipe.

- A tee and a mixing block are installed behind the tap. Fum tape is used to seal the threaded connection.

- A tap is mounted on the cylinder valve, behind which a tee is installed.

At the final stage, you should take care of the mobility of the device - weld wheels or handles for moving. To increase resistance to do-it-yourself sandblasting, supports from corners, pieces of reinforcement, and tubes are welded.

Then the elements are connected to create channels for supplying and discharging the mixture:

- fittings are placed on the tee located below and the balloon valve;

- a sleeve with a 14 mm passage for air flow is placed between the mixing block and the tee;

- an injection unit is connected to the unoccupied branch of the tee with a fitting;

- a hose for the finished mixture is connected to the remaining outlet of the lower tee.

To ensure tightness, a screw cap should be installed on the pipe for filling the cylinder with sand.

Cleaning candles at home

There are several ways to clean carbon from candles:

- Mechanical.

- Chemical.

- Ultrasonic.

- Combined.

How to remove carbon deposits from spark plugs mechanically

Spark plugs can be cleaned mechanically without any coatings of noble metals, such as iridium. For rough mechanical cleaning, a needle file and fine-grained sandpaper are suitable.

Burning candles on a gas burner

If the candles are heavily soiled, they can be preheated on a gas burner until the thick oily carbon burns out. Care should be taken not to overheat the spark plug insulator; allow it to cool in air to avoid cracking of the insulator.

Some candles cannot be ignited. This will lead to their failure.

Large deposits on the skirt and electrode must first be cleaned with a needle file. Then sand with sandpaper until shiny. Mechanical cleaning can also be done using a solvent. White spirit will do. A hard brush or toothbrush is moistened with solvent. Then, carbon deposits are removed from the electrodes using circular movements. An iron brush used by welders in their work is also suitable for mechanical cleaning of carbon deposits. After cleaning the spark plugs mechanically, the recommended gap should be restored by bending the side electrode. The gap can also increase due to natural burnout of the electrode material during operation of the internal combustion engine.

Video: mechanical cleaning of candles with sand at home

How to clean spark plugs chemically: instructions

Dry cleaning

The chemical method is suitable for candles whose electrodes are coated with noble metals. For chemical cleaning of simple or iridium candles at home, household products for cleaning limescale and rust from sinks and bathtubs are perfect. Ordinary acetic acid, available in every home, is also a good remedy. It is better to use a 70% solution. Can be diluted with water one to two for safety when working. The cleaning liquid is poured into a glass or plastic container of a suitable size. The candles are immersed in the cleaning solution up to the level of the nut and left for several hours. It is advisable to change the cleaning fluid once or twice. All carbon deposits will precipitate at the bottom of the container. After this, you should remove the candles and dry them with a hairdryer or in the open air, if there is enough time. You can place candles on radiators or radiators of the heating system. After drying, check the gap between the electrodes and screw the spark plugs into place.

Option for a sandblaster made from a fire extinguisher

The circuit diagram of a fire extinguisher apparatus is similar to a device assembled with your own hands from a cylinder.

To seal the top of the fire extinguisher on turning equipment, a plug should be made in advance. A sealing rubber ring is put on it, and the part is screwed into the upper neck of the fire-fighting device. The existing hole is intended for filling sand.

At the next stage of manufacturing the sandblasting machine, holes are drilled with your own hands: on the body near the top and in the bottom. The places are pre-cleaned of factory paint, and welded into the holes according to the welding strip. Legs are welded to the bottom of the fire extinguisher, for the manufacture of which you can use a round rod or fittings.

To make tightening and unscrewing easier, a knob is welded to the plug. After assembling and installing the fitting system, the manufactured sandblaster is ready for use.

Do-it-yourself Laval nozzle - Metalist's Handbook

To produce affordable building materials, various types of equipment are used, including a foam generator for foam concrete.

Despite the ease of manufacture and low cost, the technical requirements for foam concrete blocks are strict.

To achieve high quality in the production of this building material, it is necessary to strictly comply with all technological standards.

Purpose of the foam generator

Currently, foam concrete is in demand in individual construction as an affordable and high-quality material. This is due to its high performance characteristics.

Low-rise residential buildings, garages, country houses and various outbuildings are erected from foam concrete.

Foam blocks do not burn and are not subject to shrinkage; they are sufficiently resistant to any atmospheric influences.

In winter, buildings made of foam concrete retain heat well; in summer, such rooms are not hot. You can produce foam concrete yourself using a homemade foam generator.

:

The practice of recent years shows that more and more people are striving to build a house or garage on their own. This approach has become widespread due to technical capabilities.

Equipment for the production of foam concrete can be purchased at an affordable price or made independently.

One of the main elements of the installation is a foam generator. This device is used to ensure that the concrete block is saturated with foam, thereby giving the block its characteristics.

Today on the construction equipment market you can find and buy a foam generator suitable for power.

However, you can make a foam generator for foam concrete with your own hands without significant financial costs, which will reduce construction costs.

The quality of the foam that is formed in homemade foam generators is exactly the same as in factory ones.

Once you become familiar with the operating principle of such a unit, you can draw your own drawings and begin manufacturing.

The foam generator consists of the following elements:

- shut-off and control equipment;

- chamber for forming the mixture;

- nozzle.

The specific design of the foam generator may undergo changes, but the principle of operation remains the same.

Operating principle

The main function of the foam generator is to ensure the supply of foam to the sand-cement mortar prepared in advance.

To produce foam concrete, an ordinary concrete mixer is used. Concrete is mixed in it for pouring foundations and walls or mortar for brickwork.

When, during the process of mixing the solution, a certain amount of foam gets into it, ordinary concrete turns into foam concrete.

All specialists are aware of the advantages and disadvantages of foam concrete. Today, this building material can be prepared directly on the site where a house, garage or other object is being built.

Foam Generator Structure

When starting to make a foam generator with your own hands, you need to optimize all the drawings and descriptions that catch your eye.

The fact is that many specialists, having become familiar with the operating principle of a foam generator, immediately apply the acquired knowledge, turning it into reality.

Schemes and drawings:

A clear demonstration of the operation of a foam generator can be seen at any car wash.

The foam, when mixed, fills a certain volume of the concrete block and thereby reduces its original density.

The simplest foam generator can be assembled from the following elements:

- foam solution supply pipe;

- compressed air supply pipe;

- mixing chamber;

- foam cartridge.

Factory-made foam concentrate is always available on the shelves in building materials stores.

If this is not possible, then the emulsion can be prepared by mixing gum rosin, caustic soda and bone wood glue. The cooking process is not complicated, but requires care.

After the homemade foaming agent is ready, you need to check its quality. The foam must have sufficient density and durability.

Assembly and connection

The main elements of a foam generator for the production of foam concrete are a mixing chamber and a foam cartridge. In this context, it is important to emphasize that behind these terms lie ordinary elements that are well known to masters.

The mixing chamber is an ordinary pipe. The diameter of the pipe is selected depending on the power of the future generator. Two pipes are welded to the pipe.

:

The first is at the end, intended for air supply, the second is in the middle of the pipe at an angle of 90 degrees. A foaming agent solution is supplied through it. A shut-off valve must be installed on each branch pipe.

Foam generators for factory-made foam concrete are equipped with two valves - a shut-off valve and an adjustment valve.

The practice of recent years shows that for small production volumes, when it is necessary to produce foam blocks for the construction of a garage or country house, one shut-off valve is sufficient.

A pipe is welded to the second end of the mixing chamber, which serves as a foam cartridge. If possible, the inner surface of the pipe is treated in the shape of a funnel.

This is done to reduce the flow rate of the foaming agent and air mixture to ensure foam formation.

Some nuances

When the mixing chamber and foam cartridge are connected, an element called a Laval nozzle or another device, a nozzle, is fixed between them.

These elements are designed to increase the flow rate of the mixture during the transition from the chamber to the foam cartridge. It is in the foam cartridge that the final formation of foam occurs.

To make the process more efficient, the flow of the foaming agent is “broken” against a special filter.

In homemade foam generators, kitchen metal mesh, which is sold in every hardware store, is used as such a filter.

Building a foam generator with your own hands to produce foam concrete is not a difficult task. The main thing here is to understand the principle of operation of the generator.

:

A technically more difficult task is to correctly connect the foam generator to the main equipment.

Currently, the designs of concrete mixers that are used for the production of blocks can be found in a variety of ways.

Before assembling the foam generator, it is necessary to determine all the installation elements that are used when connecting hoses and pipes.

Sandblasting nozzle: rules for choosing and making it yourself

The nozzle, which is used to equip a sandblasting machine, is the most important design element of such a device.

Only a correctly selected nozzle will allow you to most effectively use the sandblaster for its intended purpose: to clean various surfaces from dirt, old coatings, traces of corrosion, degrease them and prepare them for further processing.

For each application, you can select a nozzle of a certain diameter, depending on the fraction of sand used

The tasks that a sandblasting nozzle solves are to compress and accelerate to the required speed a mixture consisting of air and abrasive material, as well as to form a working spot and saturate it with abrasive acting on the surface of the workpiece.

Depending on the size of the surface to be sandblasted, different types of holes can be made in the nozzles.

Thus, for processing narrow surfaces, nozzles with the same diameter along the entire length are used, and for cleaning large surfaces, products are used, the holes in which have larger diameters at the inlet and outlet (Venturi type, developed in the middle of the last century).

How to make a machine from a pressure washer

You can also use a Karcher sink or a similar unit of another brand as a compressor for sandblasting.

The device, whose original purpose is to wash cars, is capable of creating high water pressure with low water consumption. The task comes down to modernizing efficient, dust-free equipment. For Karcher you only need to make a special attachment for the outlet pipe. The following materials will be required:

- ceramic nozzle, purchased in a store or made by yourself;

- reinforced hose;

- mixing unit (tee with a nozzle of suitable diameter);

- cylindrical dispenser, supply control unit;

- a tube for collecting abrasive with an air supply channel into a sealed tank.

The sandblasting installation from a high-pressure washer operates according to an ejector scheme. The injected liquid, passing through the mixing block at high speed, forms a vacuum in the sand supply channel. It enters the cleaning zone along with water under high pressure.

Causes and types of soot

A small amount of carbon deposits also forms during normal engine operation, but sometimes it forms abnormally quickly. There are several reasons for this:

- Incorrectly selected candles.

- Low quality fuel.

- High oil loss due to wear of the CPG.

- Fuel system malfunction.

- Rich air-fuel mixture.

- Incorrect ignition timing.

By the appearance of soot, you can understand the reason for its formation. Black oily deposits indicate that oil has entered the combustion chamber. Dark brown soot indicates the fuel mixture is too rich. Whitish soot indicates a lean mixture. Red soot indicates the presence of tetraethyl lead in the fuel, a substance prohibited as an additive to modern motor gasoline. But, due to its low cost, it is often used by unscrupulous owners of gas stations to increase the octane number of fuel. The normal color of soot is considered to be light brown with a brick tint. Such deposits indicate that the engine is running on the correct fuel-air mixture. This mixture is called stoichiometric (the ratio of gasoline to air is 14:1 by weight). This mixture burns most completely, releasing less CO into the atmosphere, allows the engine to operate more economically and increases the life of the lambda probe and exhaust system.

Upgrading a blow gun to sandblasting

Sandblasting, made from a blow gun, is small in size.

The performance and efficiency of the device depends on the power of the compressor used. To create a mini sandblasting machine you will need the following materials:

- blow gun;

- tee;

- ball valve designed to regulate the supply of abrasive;

- outlet nozzle with clamping nut.

You can use a small fire extinguisher or a regular PET bottle as an abrasive tank.

DIY Laval nozzle

FEDERAL STATE BUDGET EDUCATIONAL INSTITUTION

OF HIGHER PROFESSIONAL EDUCATION

"IZHEVSK STATE AGRICULTURAL ACADEMY"

DEPARTMENT

"ELECTRICAL TECHNOLOGY OF AGRICULTURAL PRODUCTION"

Methodical manual for calculation and graphic work on hydrogas dynamics

Specialty 140106 – Energy supply for enterprises

Compiled by: P.L. Lekomtsev

Izhevsk 2009

Introduction

A Laval nozzle is a technical device that serves to accelerate a gas flow passing through it to speeds exceeding the speed of sound. Widely used on some types of steam turbines and is an important part of modern rocket engines and supersonic jet aircraft engines.

The nozzle is a channel narrowed in the middle. In the simplest case, such a nozzle may consist of a pair of truncated cones connected by narrow ends. Efficient nozzles of modern rocket engines are profiled based on special gas-dynamic calculations.

The nozzle was proposed in 1890 by Swedish inventor Gustaf de Laval for steam turbines. The Laval nozzle was first used in a rocket engine by General M. M. Pomortsev in 1915.

The phenomenon of gas acceleration to supersonic speeds in a Laval nozzle was discovered at the end of the 19th century. experimentally. Later, this phenomenon found a theoretical explanation within the framework of gas dynamics.

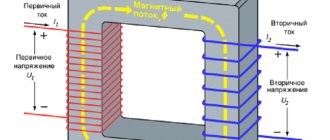

General information

When analyzing gas flow in a Laval nozzle, the following assumptions are made:

— the gas is considered ideal;

— the gas flow is isentropic (that is, it has constant entropy, friction forces and dissipative losses are not taken into account) and adiabatic (that is, heat is not supplied or removed);

— the gas flow is stationary and one-dimensional, that is, at any fixed point of the nozzle, all flow parameters are constant in time and change only along the nozzle axis, and at all points of the selected cross section the flow parameters are the same, and the gas velocity vector is everywhere parallel to the symmetry axis of the nozzle;

— gas mass flow rate is the same in all cross sections of the flow;

— the influence of all external forces and fields (including gravitational) is neglected;

— the axis of symmetry of the nozzle is a spatial coordinate.

At the nozzle inlet, the flow moves at subsonic speed. At the critical section the flow velocity reaches the speed of sound a

, called the critical speed of sound.

The ratio of speed to critical speed a

is called the speed coefficient

. (1)

The ratio of the areas occupied by the inviscid core in the critical and analyzed sections is the gas-dynamic function q ( )

, (2)

where dcr, d are the diameters of the critical and analyzed sections, respectively, mm;

*cr, * – displacement thickness of the boundary layer of the critical and analyzed sections, respectively, mm.

When calculating functions q ( )

in the first approximation, the values of *cr and * are taken equal to 0, and in subsequent approximations their values are determined from the calculation of the boundary layer.

Maximum value equal to 1 function q ( )

takes in critical section. In the same section, the velocity coefficient is equal to 1.

Relationship between function q ( )

and the speed coefficient is expressed by the relation

, (3)

where k is the adiabatic index (for air k = 1.4, for combustion products k = 1.33).

It is impossible to obtain an exact analytical solution to equation (3). The required solution can be found by the method of successive approximations.

The essence of the method is to replace an equation of the form

f ( x ) = 0

with an equivalent equation

x = f ( x ).

The transition from equation (3) to the equivalent equation can be done in two ways

; (4)

. (5)

The root of scheme (4) or (5) is found by the method of successive iterations with repeated use of the iteration formula

. (6)

where n is the first approximation.

The iterative process converges if at.

The iterative process ends when the condition is reached

, (6)

where is the specified calculation error.

In the converging part of the Laval nozzle, where the flow moves at subsonic speed and the velocity coefficient takes values less than 1, the convergence of the solution is ensured by scheme (4). In the expanding part of the Laval nozzle, where the flow moves at supersonic speed and the velocity coefficient takes values greater than 1, the convergence of the solution is ensured by scheme (5).

Using the found value of the velocity coefficient for a given section of the Laval nozzle, gas-dynamic functions are calculated

; (7)

; (8)

. (9)

Critical speed a

kr is equal

, (10)

where R is the gas constant; T*—temperature of the stagnated flow, K.

The gas constant of 1 kg of working fluid is equal to

, (11)

where is the molar mass of the working fluid. For air = 29 kg/kmol.

The mass flow rate of the working fluid in the analyzed section of the nozzle is calculated using the formula

, (12)

where is the cross-sectional area of the potential core, m2;

m included in expression (12)

determined by the expression

. (13)

The absolute values of the velocity in the flow core, its pressure, temperature and density are determined by the expressions

(14)

The found parameter values can be used when calculating the boundary layer as boundary conditions on its outer boundary.

Manufacturing method from a spray gun

Sandblasting can also be done using a spray gun. For assembly you need to prepare:

- a gun that functions as a mixing valve;

- handle with air supply device;

- a plastic bottle that acts as a tank for abrasive;

- tee;

- ball valve for regulating sand supply.

Using an airbrush instead of a spray gun will allow you to apply abrasive at higher pressure due to the smaller thickness of the outlet channel.

Assembly is performed in the following sequence:

- The gun is bored to increase the diameter of the output nozzle.

- The mixing tee is attached to the gun.

- The supply and circulation hoses are installed and attached.

The abrasive is released after the trigger is pressed. The volume of a small plastic bottle is enough to clean surfaces for 30 minutes.

see also

Comments 26

excellent manual. bookmarked)

The best option so far is ceramics, but it also works

Let's just say it's the cheapest so far.

Just yesterday at work we were discussing this topic and then bam, instructions for action =)

When I work with a forge, I simply pour a pound of candles, they warm up and the cores are removed from them with pliers, and the cores are removed from all types of candles.

This is how we use metal nozzles... in principle, not bad either)))

How long does the “nozzle” work?

What pressure and abrasive?

Do you work outdoors or indoors? If indoors, how do you deal with dust?

I work outside, I want to make a camera

Shall we chat in private?

I work outside, I want to make a camera

In order not to carry a car pump with me, about 35 years ago I made a compressor for inflating wheels on a VAZ 21011 and then it was necessary to use a spark plug without a core along its entire length. Spark plugs made in the USSR were suitable for this. Everything is the same thanks to heating.

What else can a nozzle and gun be made from?

Making your own sandblasting gun is not difficult.

For assembly, you can use a nozzle for a regular ball valve located at the end of the hose for discharging the air-sand mixture. The nozzle is a nut that clamps the outlet nozzle for the abrasive. The nozzle, in turn, can be made on a lathe. But it is more rational to use a spark plug. The worn-out part is cut with a grinder, while the durable ceramic rod is separated from the metal parts of the structure, and its length is adjusted.

The process of cutting a candle requires appropriate skills. In addition, when cutting, a large amount of dust is generated, and a not very pleasant smell appears. If you don’t have a separate room and the skills to work with an angle grinder, it’s easier to purchase a suitable nozzle in a store.

DIY designs are often more effective than pistols, a wide range of which are commercially available. Therefore, if you have free time, it is wise to spend it on implementing your technical solution, and spend the saved money on other, no less important goals.

Making sandblasting yourself allows you to reduce the cost of purchasing a serially assembled machine by 3–5 times. Maximum savings can be achieved by using a homemade compressor, but it is very difficult to achieve sufficient power. The best option is do-it-yourself sandblasting in combination with a powerful factory compressor.

What happened to you? What did you use to build your own sandblasting machine? Did everything go smoothly or did you encounter any difficulties during the production process? Please share your experience in the comments.

Design and characteristics

The purpose of the nozzle is to increase the speed of air flow with sand and form a treatment spot. The straight nozzle has the main elements:

- frame;

- thread for fastening to the nozzle holder;

- confuser;

- diffuser.

The housing protects a person from injury in the event of destruction of the internal nozzle. It is quickly erased by abrasive particles passing through it. At the same time, on the back of it there is a thread for a union nut or clamp, with which it is attached to the handle - the nozzle holder.

The confuser is a long conical hole in the insert that regulates the speed of the supplied mixture. Has standard holes with a diameter of 6–16 mm, with a pitch of 2 mm. The choice depends on the performance of the installation.

The diffuser is conical, short, expands at an angle of 7–15⁰. Thanks to it, turbulence is eliminated and the sand is evenly distributed over the working spot. The outlet of the nozzle can be round or oblong, depending on the size of the workpiece and its shape.

Between the confuser and the diffuser there is a section with a uniform cross-section. Having passed along the tapering cone of the nozzle, air and sand form a mixture of uniform composition.

Venturi nozzle

The complex design of the high-performance Venturi nozzle has an internal diameter with a stepped variable cross-section, consisting of a number of cylinders. The diameter of the inlet hole is almost 2 times larger than the outlet hole. This changes the nozzle parameters and increases the flow rate when operating in one mode. For example, an air-sand mixture comes out of a classic nozzle at approximately 320–350 km/h. When installing a Benturi nozzle, the speed of the outflow flow increases to 700 km/h.

The nozzle has a complex design. In addition to the standard elements, the tip is protected by a shockproof rubber shell. There is an aluminum bushing underneath for strength. Insert made of durable and abrasion-resistant tungsten carbide alloy.

Sandblasting with a Venturi nozzle