I decided to make a small hydraulic press with my own hands. The main goal was to produce a device of the highest possible quality at minimal cost. The most expensive part in the drawings was a glass jack with a lifting capacity of 4 tons. I took most of the materials from my supplies - bed frame, pallets. When assembling the structure, no welding was used, only simple screw fastenings, which means that such a structure can be assembled with the most common tools.

Do-it-yourself hydraulic press: a universal tool made from a jack

Hydraulic press is widely used in everyday life. It is necessary for work that requires applying a lot of pressure to the material being processed. A high-quality multifunctional tool has a high cost, which is completely unjustified for household use. You can make a hydraulic press with your own hands using a car jack.

Manual hydraulic press: tabletop or floor press (read more)

The hydraulic press is used for work in which it is necessary to exert great pressure on the material being processed.

Options for using a hydraulic press at home

To squeeze metal elements out of the shell or base, you can buy or make a hydraulic press with your own hands for the garage. The equipment is also suitable for pressing out bearings and silent blocks that cannot be mounted and dismantled manually. Using such a device, you can straighten, join two elements, and bend a metal workpiece.

Helpful advice! When making a press with your own hands, you need to decide on the further purpose of the device, its dimensions, piston performance, weight and the possibility of installing a pressure gauge.

When manufacturing a hydraulic press for a garage, it is necessary to take into account the dimensions of the vehicle being serviced.

When creating a hydraulic press for a garage, you should take into account the size of the car. For passenger vehicles, it is enough to make a simple design, but for large vehicles it is better to make a more complex and larger unit.

The device is often used as a waste paper press. With your own hands you can make good fuel for the stove from old paper. For such purposes, it is enough to make a simple design with an average power rating, which will allow you to recycle a large amount of waste paper.

The equipment is also suitable for pressing sawdust. Such briquettes are good fuel for stove heating; they burn for a long time without producing smoke, creating intense heat. Instead of sawdust, coal chips are also suitable as a filler for the press. Such a unit will consist of a work table, a base, a power frame and a drive.

A good result is ensured by a self-created press for PET bottles, which turns the container into neat layers. The hydraulic tool can be used as a hay picker. In this case, the design is complemented by a frame frame made of timber or metal without an upper part. The element is fixed to the front using special fasteners. You will also need a transport pick-up and running gear.

Hydraulic press is also used for squeezing juice from fruits.

Features of a self-made electro-hydraulic press

You can independently make not only a manual hydraulic press, but also a device equipped with an electric drive. Such a device is capable of developing enormous forces, which expands the functionality of the equipment and increases its efficiency.

A hydraulic press with an electric motor can be created as either a floor-mounted or a table-top type.

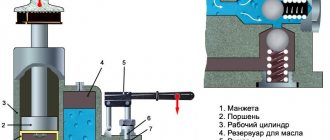

The operating principle of a self-made hydraulic press with an electric drive is as follows. The hydraulic pump is driven by a motor that is connected to an electrical outlet. In turn, the hydraulic pump helps maintain the required pressure of the working fluid in the first chamber of the press. The piston ensures the transfer of pressure to the second reservoir of the press, where it increases several times. Thus, the resulting force is transferred from the second cylinder to the material being processed.

Note! The magnitude of the force transmitted to the workpiece will depend on the ratio of the areas of the pistons in both cylinders.

With an electric motor, you can create both a floor-standing and table-top hydraulic press with your own hands. Both options will differ in size and the amount of force exerted on the workpiece being processed. For tabletop devices it does not exceed 20 tons, and for floor-standing devices – 100 tons.

Construction of a homemade garage press: design characteristics

Before making a hydraulic press, you should decide on the type of installation. Depending on this, the equipment can be desktop or floor-standing. The first type of tool is located on a workbench, and the second is placed on a special pedestal. Such presses differ in size and load capacity. A self-made tabletop hydraulic press provides a force of up to 12 tons, and for a floor-mounted device this value reaches 25 tons.

The desktop design is more stable and mobile. Thanks to its small size, it does not take up much free space. This type of press is used for processing small workpieces.

The floor-mounted hydraulic press is characterized by its large size and heavy weight. To install it, you will need to build a special platform. Such a machine will cope with processing large metal elements, disassembling and assembling complex components.

A self-made hydraulic press for a garage can have a vertical or horizontal design

Important! To expand the functionality of a floor-mounted hydraulic press, it should be equipped with an electric motor.

You can make a complex structure that will be used to perform a wide range of tasks. However, making such an option will take a lot of time and require the use of specialized tools and equipment. As a garage hydraulic press, it is better to make a manual model equipped with a hydraulic pump and drive. This design is two-speed, its piston is characterized by mobility.

A self-made hydraulic press for a garage can have a horizontal or vertical design. The first type of device is used for straightening, cutting and bending individual metal elements. Vertical equipment is designed for unpressing and pressing parts. A self-made hydraulic press for waste paper is becoming increasingly popular.

Purpose and scope of use of a hydraulic press

A hydraulic press is a device that exerts great pressure on the material being processed through little effort. This operating principle is based on Pascal's law, according to which the applied force acting on a certain area is transmitted throughout the entire volume and is equal in all directions.

The hydraulic press is used for stamping, pressing, extrusion, assembly, forging, and bending.

The hydraulic press device consists of two cylinders. When exposed to a smaller chamber, the pressure of the liquid in it increases, which is transmitted through a special channel to the larger chamber. The working fluid exerts pressure on the piston, which contributes to the effect of the element on the workpiece. Cylinders are usually located vertically, but there are also options that have horizontal placement. A special oil is used as the working fluid.

The installation is used for pressing, stamping, extrusion, assembly, forging, bending, and straightening of metal elements. You can buy or make your own cardboard press, which will be indispensable for packaging, briquetting, pressing and recycling materials made of plastic, paper and rubber. The equipment is characterized by versatility and can be used in different areas of life for repair, maintenance and preventive maintenance. Depending on this, the press has a certain design.