Metal is one of the most common materials in construction and industry. Even with the advent of new high-tech composites on the market, it continues to be used as often as before. But even such a durable and reliable material sooner or later ages, losing its original properties. The main disadvantage of metal products is that they are susceptible to corrosion. The effect of “metal fatigue” is being widely studied today and is forcing technologists to develop new methods to neutralize it.

Tempering and aging of steel

3. Tempering under load

4. Tempering after grinding

5. Editing. Kinetic plasticity effect

6. Heat treatment after straightening. Dimensional stabilization methods

ABOUT

vacation

is called

a heat treatment operation

in which,

as a result of heating below the critical point A 1 of martensite-hardened steel,

transitions

from a metastable state to an equilibrium state or one close to it

.

Tempering is often the final operation of heat treatment

.

Therefore, its goal is to obtain certain characteristics of finished parts or semi-finished products

. Depending on the heating temperature, the following types of tempering are distinguished: low-, medium- and high-temperature. The effect of tempering temperature on the hardness of steels is shown in Fig. 8.

Fig.8. Dependence of the hardness of carbon steels on the tempering temperature.

Low Vacation

is performed at temperatures of 80-250 °C to obtain a tempered martensite structure in carbon, low- or medium-alloy steels and leads to partial relief of internal stresses.

Such tempering is carried out for carburized, nitrocarburized hardened parts and after hardening

, as well as for tools that must have a high hardness of 60-63HRC.

Average holiday

is performed at temperatures of 320-450°C and provides

tempered troostite structure with a hardness of 41-49HRC

and

almost complete removal of residual stresses

. Parts with such a structure have a high elasticity and fatigue limit, so this type of tempering is used for springs and leaf springs.

High holiday

carried out at temperatures of 450-700°C and

ensures the decomposition of martensite of carbon, low- and medium-alloy steels into tempered sorbitol

.

The combination of hardening and high tempering is called improvement.

This is due to the fact that after such processing

a combination of high values of strength, ductility and toughness of steels is achieved

.

Hardness is in the range of 250-350 HB, strength decreases by 1.5-2.0 times compared to the hardened state, and ductility and toughness decreases by several times. High-temperature tempering

is used for a wide range of parts that need to have the listed set of properties.

A type of high tempering

is

dispersion hardening for high-alloy steels:

heat-resistant, high-strength, high-speed. This heat treatment is most often performed at temperatures of 460-700°C.

When assigning tempering temperatures, one must not forget about tempering brittleness.

, which leads to a significant reduction in the impact strength of hardened products.

Irreversible temper brittleness of the first type

manifests itself at temperatures of about 300 °C; therefore, steels are not heated to this temperature during tempering.

Reversible temper brittleness of the second type

is observed at a temperature

500 °C only in steels alloyed with chromium, nickel, manganese, especially when they are introduced together. Propensity of steels to type II brittleness

increases when the steel contains impurities of phosphorus, arsenic, antimony and tin. This type of temper brittleness does not manifest itself in carbon and high-purity alloy steels.

Aging –

This is

a heat treatment operation

during which

decomposition of a supersaturated solid solution

occurs in an alloy quenched without polymorphic transformation .

The reason for the aging of steel

is

the supersaturation of ferrite with carbon and nitrogen

, as well as impurity atoms and is typical for low-carbon steels (≤ 0.03% C).

As a result of aging,

there is an increase in hardness, strength and a decrease in ductility and toughness of steel, while their value remains the same over time.

Depending on the heating temperature of the hardened alloy, aging can occur at room temperature

(natural aging) or elevated (artificial).

In addition, two more types of aging are distinguished depending on the driving force of decomposition

:

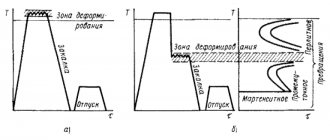

thermal aging

, which occurs in a hardened alloy, and

deformation aging

, which occurs in products after plastic deformation at a temperature below the recrystallization temperature.

Thermal aging

most often observed in low-carbon steels with a carbon content of 0.03-0.05%.

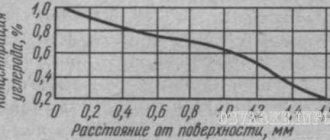

When quenching, a supersaturated α-solid solution is formed

, which, upon aging, decomposes with

the release of excess phases, which leads to an increase in hardness, strength and a decrease in ductility. The greatest effect of changes in properties is observed during natural aging

, but considerable time is required.

With artificial aging, the strength characteristics obtained are lower

than with natural aging, while the aging time is reduced.

Cold plastic deformation leads to a significant acceleration of the decomposition processes of the α - solid solution during aging

.

For thin cold-rolled mild steel sheets, aging is carried out after recrystallization annealing. Aging can be carried out according to two technological schemes

.

The first one includes accelerated cooling to

400 °C, isothermal holding at this temperature and regulated cooling at a rate

About natural and artificial aging of documents

Official and unofficial documents, as well as documents of personal origin created outside the framework of procedural actions, are one of the main types of evidence in administrative (Article 26.2 of the Administrative Code of the Russian Federation), arbitration (Article 75 of the Arbitration Procedure Code of the Russian Federation), civil (Article 71 of the Code of Civil Procedure of the Russian Federation) and criminal proceedings (Article 84 of the Code of Criminal Procedure of the Russian Federation).

One of the mandatory conditions for the admissibility of their use in procedural law is the requirement for their reliability. Unreliable evidence is fake documents and documents that do not have legal force (Article 16.1 of the Code of Administrative Offenses of the Russian Federation), as well as documents not prepared in accordance with the requirements specifically established for them (Article 75 of the Arbitration Procedure Code of the Russian Federation).

Written evidence and other documents in administrative, arbitration, civil and criminal proceedings can be considered admissible only if they are authentic and have legal force.

GOST R 51141-98 defines an “authentic document” as “a document, information about the author, time and place of creation of which, contained in the document itself or identified in another way, confirms the reliability of its origin.” “The legal force of a document” is “the property of an official document imparted to it by the current legislation, the competence of the body that issued it and the established procedure for execution.”

GOST R 6.30-2003 establishes the date as a mandatory requisite for the text of an official document. The date is stamped on the document at least once. The “date” attribute contains the time of its creation and/or signing, approval, acceptance, agreement, publication indicated on the document.

Documents issued by two or more organizations must have the same (single) date. And if the date indicated in the text of the document does not correspond to the actual (astronomical) date of its creation, then the document, at a minimum, must be recognized as having no legal force, and in the case of deliberate production of a document not on the date indicated in the text of the document, it may be found to be fake.

Determining the time of production of a document is one of the ways to establish its authenticity/reliability of origin or, conversely, to establish the fact of its falsification.

In the vast majority of cases, documents created by legal entities and/or individuals are paper media on which text, images, signatures and seals and stamps are applied in handwritten or non-handwritten ways.

Establishing the time of production of a document comes down to:

- establishing the time of production of its carrier (paper);

- establishing the limitation period for applying its details.

Methodology for establishing how long ago a document was produced

To establish how old a document was produced within the framework of an expert study, two groups of methods can be used:

1. Static . Establishing the characteristics (properties) of document materials (the carrier and coloring substances used to apply the details) and comparing them with reference data or any comparative samples, as well as establishing the prescription of the document by the time of appearance of technologies and technical means for the production of document carriers and the application of details .

2. Dynamic . Divided into two subgroups:

- establishing any changes in the physical and chemical properties of document materials during the storage and operation of documents, followed by their comparison with previously established empirical data;

- establishing changes in the physical and chemical properties of document materials in the process of expert research.

Regardless of the use of the first or second subgroup of methods for establishing the age of manufacture of the document carrier and the application of details, it is necessary to have information about changes in the physical and chemical properties of document materials during the aging process of documents.

According to GOST 9.710-84, aging is a set of physical and chemical processes occurring in a material and leading to irreversible changes in its properties.

About the aging processes of documents

Aging processes can be divided into natural and artificial.

During natural aging, the physical and chemical properties of document materials change without artificial human influence on this process. This is influenced by both internal and external factors. Internal factors are determined by the structure and composition of materials, and external factors are determined by the characteristics and properties of the external storage environment.

As a rule, the natural aging of documents occurs under conditions of so-called dark safe aging, i.e. in the absence of external light exposure, at room temperature (18 - 20 °C), humidity 40 - 60%, no air convention, in a stack of other documents.

Processes that may occur during the aging of document materials are listed in GOST 9.710-84.

To establish the age of manufacture of the document carrier or the application of document details with coloring substances, it is necessary to use the so-called characteristic aging indicator (aging marker), based on changes in the qualitative and quantitative values of which over time, the production of the document can be dated.

With natural aging, the document carrier (paper) undergoes irreversible changes. Paper undergoes a change in the chemical composition of the plant fibers from which it is made, and therefore a change in its mechanical strength. It becomes hard, brittle, changes color towards yellowing, and in case of deep changes - to a brown tone of varying intensity.

Based on the law of conservation of matter, natural and synthetic polymers that make up the material basis of paper gradually and spontaneously disintegrate, and the process of depolymerization occurs. But under natural aging conditions, these processes in paper occur rather slowly and with a high degree of variation depending on the types and composition of the paper.

For example, the shelf life of writing paper before its almost complete destruction is about one hundred years .

And the paper from which Bank of Russia banknotes are made can retain its properties virtually unchanged for up to three hundred years.

In this regard, it is almost impossible to determine the absolute age of paper production using any characteristic aging indicators with a high degree of accuracy .

As a result of the natural aging of writing materials (inks, pastes, gels, printing inks, etc.), their qualitative and quantitative composition, morphological or physicochemical properties also change.

In particular, so-called color fading occurs, as a result of which, over time, the contrast of the writing materials printed on the document carrier decreases or their color scheme changes.

Color fading is usually caused by the destruction of molecules of organic dyes. Other components of coloring substances (binders, fillers, thickeners, plasticizers, solvents, etc.) volatilize (evaporate), depolymerize, or their thermal destruction occurs into simpler substances. For example, glycerin, which is included in various dyes as a thickener, decomposes into acrolein, acetone and water.

In parallel with the decomposition of macromolecules into smaller fragments, a process of joining these fragments, called “cross-linking,” usually occurs, which leads to a change in the chemical structure and structure of the original composition of the dyes. Thus, during the natural aging process, substances may appear in writing materials that were not originally used in their formulations.

In writing materials, at the initial stage after the application of details, processes of change in physical and chemical properties occur at a relatively high speed. And these changes in the physical and chemical properties of writing materials can be recorded during the so-called auto-examination of the document and interpreted accordingly, but only for cases where the documents were stored under standard conditions of dark safe storage. In cases where documents have been subjected to artificial aging, conclusions about how old they were made may be largely incorrect.

Artificial aging is the process of aging documents under conditions that differ for the worse from the standard conditions of dark safe storage.

For example, when storing a document in the open air and its convection, the rate of oxidative destruction of paper and dyes increases. As the storage temperature increases, the rate of thermal decomposition increases. And high humidity speeds up both of these processes.

With the simultaneous presence of these three factors, the rate of change in the physical and chemical properties of document materials increases many times over. The so-called synergistic effect appears - an increase in the rate of change in the physico-chemical properties of writing materials while simultaneously exposing them to moisture, temperature and oxygen.

Artificial aging can occur for both natural (unintentional) and intentional reasons.

Natural artificial aging is due to the fact that the document was stored or used under conditions other than standard ones. For example, for a long time it was not in a pile of other documents, but separately and stored in the open air when exposed to direct sunlight. When documents are temporarily kept in a car in the summer, they are exposed to elevated temperatures (up to 60 - 70 °C).

In the vast majority of cases, copies of disputed documents are repeatedly made using electrophotographic machines or they are repeatedly scanned using flatbed scanners. But with repeated copying or scanning, documents are exposed to very intense light and heat, as a result of which the physical and chemical properties of the paper and coloring matter change. In fact, using copiers and scanners to create copies of documents is, in fact, one of the ways to unintentionally artificially age documents.

In the vast majority of cases, deliberate artificial aging for illegal purposes .

Its goal is the purposeful aging of documents in various ways so that experts cannot establish the actual dates of application of document details, or approximately age the document to the age indicated in the text.

Several main methods are used here: thermal exposure, light irradiation, intense air convection, or a combination of these.

Thermal effects can be divided into low temperature (up to 100 °C) and high temperature (above 100 °C).

At low temperatures, documents are deliberately “aged” on heating radiators, in ovens of gas and electric ovens, blown with warm air using hair dryers, etc. There are practically no obvious signs of low-temperature effects.

High-temperature exposure to a document or its fragment is carried out, as a rule, using objects heated to a high temperature, for example, an iron.

Signs of such an impact are easily determined by changes in the morphological properties of the surface of a sheet of paper and the strokes of document details: increased gloss is observed in areas of thermal impact; the so-called “carrying out” (smearing) of the coloring matter from the strokes beyond their boundaries may be observed.

When exposed to high temperatures, the optical properties of paper and especially the nature and intensity of visible luminescence of paper excited by ultraviolet radiation change significantly.

Quite often, as expert practice shows, they try to age documents by repeatedly running the sheet through the thermal toner fixing unit of copiers and laser printers implemented using the electrophotographic printing method. The signs of this method of artificial deliberate aging can be defined as follows.

Firstly, if the cartridge has been in use for a long time and has been refilled several times, then numerous toner particles are observed on the surface of the sheet of paper, the number and density of which are not typical for a single pass of the sheet through the paper feeder of a copier and laser printer.

Secondly, when a sheet is passed through the paper feeding unit of a copier and a laser printer in a device called an “oven”, at a temperature of 180 - 200 ° C, toner particles are sintered and the toner is thermally fixed on a sheet of paper, and the coloring matter that is applied is reheated document details.

In this case, polymer-based coloring substances (toner, ballpoint pen paste) soften (melt) and then harden again. Strokes lose their gloss, and quite often their fragments come off from the originally applied strokes.

mtomd.info

| Chapter: | Materials Science. Metallurgy. |

Tempering is applied to alloys that have been quenched with a polymorphic transformation. Aging is applied to materials that have been hardened without polymorphic transformation .

Hardening without polymorphic transformation is a heat treatment that fixes at a lower temperature the state characteristic of the alloy at higher temperatures (supersaturated solid solution).

Aging is a heat treatment in which the main process is the decomposition of a supersaturated solid solution. As a result of aging, the properties of hardened alloys change. Unlike tempering, after aging, strength and hardness increase and ductility decreases.

Aging of alloys is associated with variable solubility of the excess phase, and hardening during aging occurs as a result of dispersion precipitation during the decomposition of a supersaturated solid solution and the resulting internal stresses.

In aging alloys, precipitation from solid solutions occurs in the following main forms:

- thin-plate (disc-shaped);

- equiaxed (spherical or cubic);

- needle-shaped.

The shape of the precipitates is determined by competing factors: surface energy and elastic deformation energy, which tend to a minimum. Surface energy is minimal for equiaxed precipitates. The energy of elastic distortions is minimal for precipitates in the form of thin plates.

The main purpose of aging is to increase strength and stabilize properties.

Aging is distinguished between natural, artificial and after plastic deformation.

Natural aging is the spontaneous increase in strength and decrease in ductility of a hardened alloy that occurs during its exposure at normal temperatures.

Heating the alloy increases the mobility of atoms, which speeds up the process. Increasing strength through aging at elevated temperatures is called artificial aging .

The tensile strength, yield strength and hardness of the alloy increase with increasing aging duration, reach a maximum and then decrease (the phenomenon of overaging). With natural aging, overaging does not occur. As the temperature increases, the overaging stage is reached earlier.

If a hardened alloy having the structure of a supersaturated solid solution is subjected to plastic deformation, then the processes that occur during aging are also accelerated - this is strain aging .

Aging covers all processes occurring in a supersaturated solid solution: processes that prepare the separation, and the separation processes themselves.

For practice, the incubation period is of great importance - the time during which preparatory processes are carried out in a hardened alloy (see Hardening of steel. Types of hardening. Hardenability), when high ductility is maintained. This allows cold deformation after quenching.

If only precipitation processes occur during aging, then the phenomenon is called precipitation hardening .

Aging is the main method of strengthening aluminum and copper alloys, as well as many high-temperature alloys.

Artificial aging

Since this process does not always lead to a complete loss of the operational value of the material, and also helps to increase certain qualities, artificial aging is often used. For example, this technique is applied to aluminum and titanium alloys in order to increase their strength. This effect is achieved through heat treatment. If the natural aging of metal can occur very slowly even at normal room temperature, then the artificial process requires special hardening

But it is important to take into account the fundamental difference between this method and the metal tempering technology. Aging under artificially created conditions causes an increase in hardness and strength, but also contributes to a decrease in ductility

Types and modes of metal aging

Aging of the metal can occur as a result of long-term use, in the event of force majeure circumstances, in violation of the manufacturing technology of the structure, and can be carried out specifically. In the first and second cases, the original properties are lost - the material physically wears out, and, as a rule, its complete replacement is required. In the third case, when performing bending, installation, welding and other operations, performance properties are reduced, which in some cases is unacceptable. Therefore, especially critical products are tested for susceptibility to strain aging using certain methods. A specially performed metal aging operation, which has a second name – dispersion hardening – is a type of final heat treatment, which is carried out in order to obtain the necessary physical, chemical and mechanical properties. It can be done naturally, artificially (heat treatment) and plastic deformation. Used for alloys and metals in which a supersaturated solid solution releases an excess component and spontaneously decomposes. As a result of carrying out the operation by any method, the materials increase such indicators as strength and hardness, which are maintained throughout their service life, but the indicators of ductility and viscosity decrease.

Anti-aging measures

In principle, this process cannot be stopped. But it is quite possible to slow it down or eliminate factors that stimulate aging, with varying degrees of success. For example, in some industries, metals of individual structures are periodically treated with protective solutions and polishes, which minimize the influence of negative operating factors - chemical, temperature, mechanical, etc. As for slowing down the effect of metal aging under normal operating conditions, depending on the type structures or parts, the same heat treatment can be applied. Welders, for example, expose seams to high temperatures at temperatures of 600-650 °C. This technique is more closely related to the tempering of metals, but it also makes it possible to reduce the intensity of aging.

Types of metal aging

There are 2 types of metal aging: thermal and mechanical. The thermal type is a type of artificial aging of metal, which is performed by heating to a certain temperature, holding and cooling in air. During the operation, the solubility of carbon in alpha iron changes depending on the temperature to which the workpiece was heated. The operation modes depend on the grade of steel, cast iron, non-ferrous metal or alloy and are indicated in the technological process for performing the operation. The following types of artificial aging of metals are distinguished:

- complete (performed at a certain temperature for a duration that provides maximum strength characteristics);

- incomplete (performed at a lower temperature for a short time to increase strength and maintain plastic properties);

- overaging (performed at high temperature or with long exposure in order to obtain high strength, corrosion resistance, electrical conductivity and other properties);

- stabilizing (performed to stabilize the dimensions and physical and chemical properties of the product).

In addition, the operation can be performed in several stages, the so-called stepwise or double aging. First, heating is carried out at a lower temperature, and then at a high one. At the first stage, numerous centers of solid solution precipitation are created, and at the second stage, their decomposition is ensured. This results in homogeneity and density of distribution of precipitates in the material.

During natural aging, the material is kept at room temperature for a certain time, which leads to an increase in hardness, strength and fluidity. This process is long. It usually takes 15 days or more (depending on the material) when manufactured parts and blanks are stored outdoors. To speed up the process of obtaining high-quality material and obtain the same results, artificial aging is performed in special ovens using a certain technology.

How to age metal - Useful tips - 2021

Today, metal parts and surfaces are in great demand in interior design. They decorate furniture and accessories.

Aged metal is in demand: with a rough surface and its different color shades. Such decorative details give the interior or clothing items a certain time-tested solidity.

Method for rapid aging of metal products

Often, for various creative ideas, antique buttons, needles, pins, nails, horseshoes, etc. are needed. You can quickly age such metal products using vinegar (1/4 cup) and salt (2 tablespoons).

- Mix both substances and immerse the metal part in the resulting solution.

- The composition is mixed, covered with a lid with holes and left for 12 hours.

- Then the parts are taken out and dried on newspaper.

- If excess rust has formed, you can sand it off with sandpaper.

To work with the solution, it is better to take glass or plastic containers that are resistant to chemicals. Mix the ingredients with a wooden, plastic or porcelain spoon. A container of larger volume is required, since after immersing a metal part in the solution, the liquid will begin to foam.

If work is not carried out outdoors, a well-ventilated area should be used.

To age metal you will need:

✔ bicarbonate of soda or active acids,

Sequence of work

— There are currently many methods of metalworking and decorative design of metals, which is facilitated by the development of the chemical industry. Many methods of aging metal have come to us from the distant past. Therefore, the method of decorative metal processing must be chosen depending on the desired result and the type of metal used.

— Before starting work, it is necessary to clean the surface of the material from all kinds of contaminants. The results of labor are largely determined by the quality of this stage. It is possible to carefully anneal the product, which will rid it of any remaining resin or other impurities.

Copper and brass alloys should be bleached in advance in a solution of low concentration sulfuric acid; in this case, it is recommended to use sulfuric acid for iron, and bicarbonate of soda for aluminum products.

After treatment, all items must be thoroughly rinsed and cleaned with a metal bristle brush. Only after this can you begin the finishing itself.

— Nitric acid will help to age brass and copper. The main thing is to take precautions (all work should be done outdoors), since this acid emits dangerous fumes.

A cotton swab must be wrapped around a wooden stick. This device treats the metal surface with nitric acid or its solution.

Then (after the reaction is completed), the object should be heated until the evaporation reaction stops.

— Acid concentration, metal processing time and the degree of subsequent heating are the main factors that determine the future color of the surface.

— If the choice is made in favor of iron products, then they must be treated with drying oil immediately after cleaning. Then the object is heated to 300-450C. A more uniform surface will be obtained by using an oven. Lighter surface tones can be obtained using nitric acid.

— To decorate or age an aluminum surface, you should use soot or kerosene. These substances will maximally emphasize all the features in the relief and give the surface uniqueness.

Watch the video: Blackening metal with a BOW. BlackingBroom metal. (January 2020)

Aging modes

To artificially age a material, you need to know the grade of metal or the base on which it is made (chemical composition). The operation execution mode depends on this. This includes the choice of heating temperature and holding time. Approximate data is shown in the table.

| Metal or alloy based on it | Heating temperature, °C | Exposure time, hour |

| Aluminum | 100÷235 | 1÷17 |

| Copper | 160÷330 | 2÷25 |

| Titanium | 550 | 1 |

| Magnesium | 170÷180 | 16 |

| Nickel | 690÷710 | 16 |

| High carbon steel | 130÷150 | 25÷30 |

The operation can be performed without and with pre-hardening of workpieces or parts. And here it is important to choose the right heating temperature: it should be lower than the one at which the hardening took place. In any case, this is stipulated in the technological process for the manufacture of a particular part, which is developed by production specialists, taking into account the equipment used and aging regimes.

The rate of heating to the temperature at which the operation is performed does not play a special role. However, for aluminum and its alloys, it is better to heat slowly. This will increase the strength of the product.

Aging of ferrous and non-ferrous metals and their alloys is a common technological process that allows one to achieve the desired properties. The operation must be carried out taking into account the structural and physical-chemical characteristics of the metal grade using high-quality equipment specifically designed for artificial aging. Such stoves are produced by domestic and foreign manufacturers in a wide range. They meet modern requirements for energy saving and safety, ease of operation and maintenance. They work at different temperature conditions. Many of the models can be built into conveyor lines, which can increase labor productivity. Such furnaces differ in charge volume, productivity, power and the presence of additional functions that simplify the implementation of this type of heat treatment.

We ask those who have worked on aging issues and performed such operations to share their experiences in the comments to the text.

Aging

In 1906, the German engineer Alfred Wilm discovered the phenomenon of natural aging, discovering that aging a hardened alloy of aluminum with copper and magnesium (duralumin) at three room temperatures leads to an increase in hardness.

Wilm received a patent for a method for refining duralumin, which consists of hardening the alloys followed by natural aging, as a result of which the hardness, strength and fluidity limits increase.

In 1919, American researchers Merica, Waltenberg and Scott published a famous article in which the nature of aging of duralumin was analyzed for the first time. Merica put forward a hypothesis according to which the aging of duralumin is associated with the variable solubility of the CuAl2 compound in aluminum.

When the alloy is heated, the CuAl2 compound goes into a solid solution and does not have time to precipitate back during rapid cooling (quenching), and subsequent aging of the alloy at room temperature leads to the gradual release of very dispersed and therefore invisible under a microscope CuAl2 particles from the supersaturated solution, which cause hardening . This hypothesis simply and convincingly explained the experimental data available at that time. The absence of hardening during exposure of the quenched sample at -1180 °C was explained by the low rate of formation of precipitates, and the appearance of hardening when the aging temperature increased to room temperature and to 100 °C was associated with the fact that the mobility of atoms became sufficient for the precipitation of CuAl2 in dispersed form.

The increase in hardness during aging at 200 °C, the achievement of maximum hardening and a further decrease in hardness were explained by the formation of CuAl2 particles with a certain degree of dispersion corresponding to maximum hardness, and the subsequent coagulation of these particles.

The increase in the effect of hardening during aging as a result of increasing the heating temperature for quenching could easily be associated with a more complete dissolution of CuAl2 during heating, the formation of a more supersaturated solution during quenching and, accordingly, the appearance of a larger number of dispersed precipitates from such a solution during aging.

Jeffries and Archer in 1921 developed Merick's hypothesis of dispersion hardening and proposed a general theory of hardening of alloys by dispersed particles of any origin. According to this theory, solid dispersed particles, acting as “spikes,” “jam” the sliding planes and cause hardening of the alloy.

During coagulation of particles, when their total volume does not change, but only the number decreases, many sliding planes are freed from “spikes” and softening occurs. The maximum hardness and strength corresponds to a certain critical degree of dispersion of solid particles. This degree of dispersion is easily achieved through the decomposition of supersaturated solid solutions.

“Theory of heat treatment of metals”, I.I. Novikov

Return after aging

The phenomenon of relapse after aging was discovered with duralumin. If naturally aged duralumin is heated to a temperature of approximately 250 °C, held for 20 - 60 s and quickly cooled, then its properties return...

Choosing an aging mode

Selection of temperature and duration of aging After a preliminary assessment of the temperature level of aging by ratio or by analogy with other alloys based on the same metal, the aging regime is experimentally tested, constructing graphs, ...

Artificial aging

Depending on the mode, structural changes and the resulting set of properties, artificial aging can be divided into complete, incomplete, overaging and stabilizing aging (the corresponding modes and properties are given in the table Aging modes...

Stepped aging

Aging with exposure first at one and then at another temperature is called stepwise aging. As a rule, the temperature of the first stage is chosen lower than the second. The main goal of two-stage (double) aging is to create a large...

Maximum hardening

Let us consider the practically important case of the complex role of natural aging using the example of alloys of the Al - Mg - Si system, located on the quasi-binary Al - Mg2Si section or not far from it (alloys like...

Aging modes and mechanical properties of aged alloys

Closely related to the role of preaging is the question of the role of heating rate during single-stage aging. Usually, the rate of heating to the aging temperature is not paid attention to. However, the initial stages of decomposition with slow heating...

The influence of small additives and impurities

Special additives and random impurities contained in the alloy in thousandths to tenths of a percent sometimes greatly influence the kinetics of solution decomposition, the structure and properties of the aged alloy. The effects of additives are directly related...

Effect of alloy composition on aging

Influence of composition in binary systems In the figure, the line Atpr schematically shows how the content of the alloying element in a binary alloy influences the increase in hardness during aging in a regime that provides maximum hardening. Like…

Effect of composition in ternary systems

The patterns of influence of composition on the aging of alloys of the ternary system are qualitatively the same as in the binary system. Knowing the isothermal sections at the quenching temperature (solid lines in the figure) and at a lower...

The magnitude of hardening three formation of precipitates of different types

The amount of hardening depends on the type of precipitates, their structure, properties, size, shape, nature and density of distribution, the degree of mismatch between the matrix and precipitate lattices, and test temperature. Due to homogeneous nucleation, the zone distribution density...

The influence of aging duration and temperature on the mechanical properties of alloys

Taking into account the role of different types of precipitates in strengthening and the sequence of stages of decomposition of a supersaturated solution (see Structural changes during aging), it is possible to analyze the influence of the duration of aging at different temperatures on the mechanical properties of the alloy...

Overaging

The stable phase is usually released during the overaging stage. If the alloy is to be operated in a maximum strengthened state, then the appearance of a stable phase is usually undesirable. In this regard, it is necessary to point out the conventionality of the concept...

Metal aging

Metal aging is a process that occurs inside the metal and causes changes in physical and mechanical properties and internal structure. These processes can occur naturally (over a long period of time and at a temperature close to 20°C) or artificially (heat treatment and plastic deformation).

Aging process

Aging as a heat treatment is used as a final operation. Applicable to those metals and alloys in which a saturated solid solution can release an excess component and spontaneously decompose.

After the aging procedure, the metal's hardness and strength increase, but its viscosity and ductility decrease, but these values remain the same throughout its service life.

Aging of steel is carried out to change the internal structure after hardening. The resulting ferrite solid solution, saturated with carbon and nitrogen, disintegrates when heated. Depending on the amount of carbon content in the alloy, the internal structure can take the form:

- disc-shaped (in the form of thin plates);

- spherical;

- cubic;

- needle-shaped

Artificial aging of metal (heat treatment) is applied to those alloys in which the solubility of one element in the solid state is significantly reduced. This occurs when the temperature drops.

During artificial aging in steels with low carbon content, not higher than 0.05%, the saturated solid alpha solution decomposes. In this case, excess phases are released. This metamorphosis leads to a decrease in ductility, but leads to an increase in hardness and strength.

The figure shows the Orowan model, which illustrates the movement of dislocations. The maximum effect can be achieved with natural aging, but the time spent on this will be significant. The speed of the process can be increased by artificial aging, but the strength characteristics will be reduced.

Hardness depending on aging time

The graph clearly shows that reducing the aging time does not allow obtaining high hardness.

The course of the aging process largely depends on carbon and nitrogen. This is especially noticeable in low-carbon steels. As the temperature decreases, nitrogen becomes less soluble in alpha iron. For example, at a temperature of 590°C, dissolved nitrogen contains 0.1%, but already at 20°C its content decreases to 0.004%. When aging, the alpha solution releases nitrides. Therefore, the effect of nitrogen is less pronounced compared to the same carbon under temperature influence.

With an increase in carbon in steels, the effect of changing the structure obtained during thermal exposure increases. The maximum volume of carbon that can be dissolved in alpha iron is 0.02-0.04%. With this content, a hardened product subjected to natural aging has a hardness one and a half times higher than after annealing.

Aging is the main way to increase the strength of heat-resistant alloys (with a high nickel content). This group also includes alloys based on aluminum, copper, and magnesium. In addition, the modified structure of the above metals and alloys gives them coercive force.

Aluminum and aluminium-copper alloys are subject to destruction at different temperatures (over 100°C) due to differences in the temperature of decomposition of the structure of different metals. This is how low-temperature and high-temperature changes in structure are distinguished.

The decomposition of the solid solution occurs in two ways. In the first case, the formation and growth of phase particles occurs throughout the entire volume. In the second case, the decay is discontinuous (cellular). During it, cells grow in colonies. Colonies have a cellular structure, and growth proceeds from the grain boundary and moves inward, decreasing in size.

How to age with your own hands at home?

Making a mirror in retro style is easy. There are several simple and non-trivial methods.

- You need to dilute acrylic glue with water (1:1), apply it to the glass and glue the foil on top. This method has a quick effect.

- A more complex approach involves applying a nitric acid spray to the cleaned surface. Glass or plastic objects are pressed against the mirror, and the surface around them is rubbed with a toothbrush. You can use a toothpick or some sharp instrument.

- The retro effect is achieved by applying patinated varnish or craquelure to the surface.

It must be remembered that water is poured onto the acid, and not vice versa. For dilution you need distilled water.

We invite you to watch a master class on making an aged mirror:

Acrylic spray

Acrylic silver spray is suitable for aging surfaces. The mirror is removed from the frame and the edges are treated with a spray can.

The effect of antiquity is achieved due to the fact that the central part of the product is noticeably lighter.

The method is as simple as possible to implement. You can make a beautiful and stylish thing at home.

It is better to work with a spray can outdoors or in another room, but not in an apartment.

The frame can be aged to enhance the effect.

Acid

Chemicals are used to create a more realistic effect. Depending on what result you want to get, one or another composition is selected.

For beginners, “royal vodka” is suitable. It is recommended to apply it to the back surface of the product. Be sure to use protective equipment and periodically ventilate the room. Acid strongly corrodes the surface. If you overdo it, you can get not a vintage mirror, but ordinary glass.

Watch a video on how to properly age a mirror using aqua regia:

Paint remover spray

- The mirror is removed from the frame and the back side is coated with paint remover spray.

- The mirror coating is removed using a spatula. You can try again if the paint doesn't peel off well.

- Wipe the surface with a cloth while it is damp.

- The mirror surface is treated with a spray bottle of hydrochloric acid. The edges are treated especially carefully and the surface is blotted with a cloth.

- The final touch is to coat the mirror with wet paint.

Alternative Methods

You can quickly and effectively age the surface by rubbing it with fine abrasive sandpaper and covering it with silver-effect paint. Scratches are made with a needle. To avoid destruction of the amalgam, foil is placed. You can look at the drawing on the Internet or come up with it yourself. You should get the effect of a cracked surface.

The aged frame is a great complement to the vintage glass. Modern frames are not suitable for framing as they look eclectic and awkward. A retro style mirror is an art object in itself. You can beat it by adding vintage decorative items to the interior.

Mechanical and thermal aging

There are two types of metal aging: thermal and mechanical. Let's look at each of them in more detail.

Thermal aging

The metal strengthening phase during thermal exposure occurs at the maximum point. There is a metastable solution gap in the Guinier-Preston zone here. This type of hardening of metals and alloys is usually called dispersion hardening.

Dependence of strength on time and aging temperature

With longer aging, overaging begins, that is, a decrease in strength characteristics. This is influenced by:

- coagulation;

- partial replacement of particles with incoherent ones.

Types of thermal aging of metal:

- Two-stage - hardening, then holding at substitution temperature, and then holding at an elevated temperature to obtain uniformity of the solid solution.

- Hardening – hardening and one holding phase with natural cooling.

- Natural – for aluminum alloys.

- Artificial - for alloys of non-ferrous metals heated to a temperature higher than that used for natural destruction.

- Stabilization – high aging temperatures and long exposure times help maintain the dimensions and properties of the part.

Mechanical aging of metal

The destruction of steel with the help of deforming forces occurs in the temperature range below the recrystallization process. This is due to the formation and movement of dislocations. During cold plastic deformation, the density of dislocations increases, which further increases with increasing loads.

The changing mechanical properties of the metal causes the movement of carbon and nitrogen atoms towards dislocations, which are located in the alpha solution. Having reached dislocations, atoms form clouds (Cottrell atmospheres). These accumulations prevent the movement of dislocations, resulting in a change in properties. The inherent properties of parts aged by heat treatment appear.

If the effect of aging by deformation is strongly influenced by nitrogen, nickel and copper, then with the addition of vanadium, titanium and niobium this effect completely disappears. Therefore, it is recommended to use steel with an aluminum content of 0.02-0.07%.

Recommended regimens for aging

- for steels with high carbon content: temperature about 130°C-150°C, holding time about 25-30 hours;

- for alloys made of non-ferrous metals: temperature about 250°C, holding time about 1 hour.

- for a natural process: temperature about 20°C;

- for an artificial process: temperature about 250°C, holding time about 1 hour.

The heating temperature and holding time are selected individually for each grade of metal and alloy, depending on their composition.

If you find an error, please select a piece of text and press Ctrl+Enter.