How to sharpen a hacksaw for wood correctly

Despite the variety of power tools for woodworking, hand saws are still popular among home craftsmen. The advantages are obvious - low cost, compact size and immediate readiness for work (especially if there is no source of electricity).

Any cutting tool that does not saw must be sharp; this affects not only the efficiency of the work, but also safety. How to sharpen a hacksaw

Houses. By exerting great force while working with a blunt tool, you need to lose control and avoid causing injury to yourself. In addition, the quality of the cut made with a sharp hacksaw will be higher.

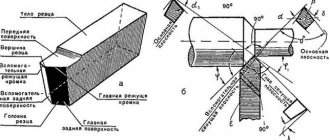

To understand how to properly sharpen a hacksaw for wood, let’s look at the structure of a popular tool:

It is impossible to imagine # in cases where these very teeth are missing, which is simpler - a steel strip with cut teeth. However, each design is developed individually; the shape and location of the cutting elements depend on the type of wood.

If you do not follow this rule, the tool will jam in the cut while digging into the material. This means that it is no less necessary to separate the teeth of the hacksaw. The cutting edge also has features - and this directly depends on the hardness of the wood and the cutting method.

How often should you sharpen?

Knives can be sharpened once a month or once a week. Everything will depend on how often the blade becomes dull. But remember that some tools cannot be sharpened:

- with protective coating;

- in the presence of a toothed surface;

- if the product consists of damask steel or Damascus steel.

Steel knives often require sharpening.

Arguments for"

- Speed of execution. There is no need to take the tool to a repair shop, because you can sharpen it yourself.

- Small costs. The grinder is cheap, and you can use it for a long time for many purposes.

- Perfectly suitable for sharpening kitchen knives.

- One of the usual sharpening methods.

Why do knives become dull?

Many people think about this. It often happens that after buying a new knife, after only a week it begins to cut food poorly. This leads to the fact that the tool is often sharpened, although there is not always time for this.

There are several main reasons why blades quickly lose their sharpness:

- Friction force. If the blade has a softer structure than the product or product, then with assistance the blade begins to rapidly dull.

- Tilt angle. If you cut the product not at a right angle, then the blade will be subject to excessive load, as a result of which the tool will lose its sharpness.

- Strength of steel. If it has characteristics of more than 60 HRC, then it quickly becomes dull. If the iron surface is soft and has a value of less than 45 HRC, this tip cannot be sharpened, because it is fragile in its structure. Products with characteristics from 45 to 60 HRC can be sharpened.

- Surface heterogeneity. The material that is cut does not always have a uniform structure. If the knife is harder than the product, it will slowly lose its sharpness.

Sharpening methods

The blade can be sharpened using the following methods:

- Musata. Used for sharpening tools for everyday use. In its structure it resembles a ratfil.

- Mechanical machines that have special recesses into which a knife is inserted. The blade can be sharpened using physical force.

- Electric machines that choose the angle of inclination themselves and sharpen a blade of any strength.

- Bulgarian . This method is for those who like to work with their hands.

How to sharpen a wood hacksaw with a file

To sharpen, the blade of a hand saw must be clamped between the plates of the equipment so that the teeth rise above them by one and a half to two centimeters. For different types of blades, sharpening a hacksaw for wood is carried out in its own way.

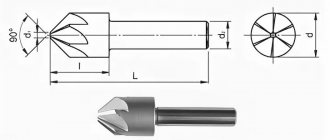

To properly sharpen a cross-section hacksaw, the blade should be set at 45°. The file should be selected with a triangular cross-section profile. To ensure proper sharpening quality, the following sequence of actions must be followed:

- sharpen the left edges of the even (farthest from the master) teeth;

- turn the canvas over;

- sharpen the left edges of the even teeth;

- form sharp cutting edges and pointed tooth tips

To sharpen a longitudinal or universal hacksaw, it should be secured at an angle of 90°. Here you will need a file with a diamond-shaped cross-section. The file moves in the plane of the work table. The sequence of sharpening the teeth is the same as for cross saws. During work, burrs usually appear on unsharpened edges, larger or smaller depending on the thickness of the hacksaw blade. They should be smoothed with a “velvet” file or an abrasive stone of minimal grit. The quality of sharpening can be checked in two ways:

- To the touch. The sharpness should be felt, but no burrs should be felt.

- By color. On properly sharpened edges, no glare appears when illuminated.

The quality is also checked by trial cutting. The hacksaw should not be pulled to the side; the cutting surface should be smooth, without loose wood fibers.

READ How to Make a Stand for a Grinder Video

How to set a saw and what it is

Sharpening a hacksaw. This is not a simple procedure, which begins with a process such as setting the teeth. This procedure is carried out for one common purpose. This is to PROVIDE free movement of the canvas when working with equipment. The lack of routing leads to the fact that the tool will get stuck in the thickness of the workpiece being cut, which will cause inconvenience in work.

Setting the teeth of a hacksaw. This is a procedure that involves the extension of the teeth in different directions. With all this, the main thing is that each tooth is bent by a similar amount to the previous one. The greater the difference between the tooth and the plane of the blade, the greater the width of the cut. The greater the width of the cut, the faster the process of removing chips from the cut, which means the faster the useful work is done.

The width of the tooth set depends on the possibility of the blade jamming. The greater the width of the routing, the less likely it is that the blade will jam inside the workpiece being cut. Not many people know what the size of the tooth set should be. But this parameter must be taken into account, because the quality of the tool’s work depends on it. The size of the tooth set, first, depends on the thickness of the steel blade. This parameter is usually from 0.5 to 2 mm. Everything also depends on the type of wood (dry or wet) with which you plan to work:

- For green wood, the bending value should be between 0.5 and 1 mm. The thicker the canvas, the greater the bend should be

- For dry wood, the deflection value is from 0.3 to 0.5 mm

To determine the size of the wiring, a special device is used. a template that can be made independently from a piece of timber. A photo of such a device is shown below.

Number 1 shows the template, and 2. is the amount of tooth set, and 3. is the hacksaw blade.

When you know the amount by which you need to set the teeth, you can get down to business. To carry out the act, special devices are used. It is not necessary to use these devices, because a regular screwdriver with a wide blade will do. The disadvantage of a special device for setting the teeth of a hacksaw is that the cost of such a device in the form of pliers is quite high.

Instead of Special pliers, you can use adjustable plates. This tool is designed with manual adjustment and stop. The straightening process begins with the fact that the blade must be fixed in the jaws of the vice, and then get down to business. First you need to go along one side, and then repeat the function on the other. In this case, it is necessary to twist the teeth not along the cutter itself (the base or sharp part), but from the middle.

READ How to Put a Disc on a Grinder

Necessary tool

To quickly and efficiently sharpen a hacksaw for wood, you should prepare a set of equipment for setting the teeth and sharpening. Required:

- Workbench;

- bench vice;

- pliers;

- whetstone;

- sandpaper;

- measuring tool: protractor and caliper;

- plumber's hammer;

- equipment that allows you to secure the blade at angles of 90° and 45°.

- cross-section in the form of a triangle;

- cross-section in the form of a rhombus;

- flat ;

- files.

The notch must be intact and not clogged with metal dust. you sharpen on time and correctly , working with it will be easy and convenient. Such a tool will last much longer, delighting its owner with an even and precise cut and high quality surface of the wood cut.

The need to sharpen a hacksaw

During the operation of a hacksaw, the cutting edge of the blade is subject to wear. First, the pointed tip of the tooth is rounded. Secondly, the side cutting edges of the teeth become dull and partially lose their function. Wear can be uniform and appear on all teeth, but local wear is also possible, affecting only some of the teeth. In addition, the tooth setting parameters change over time. Some of them can increase the angle of inclination and thereby slow down sawing. More often there is a decrease in the width of the routing, which leads to wedging of the blade during sawing.

The moment when it is necessary to sharpen a hacksaw for wood is determined practically. First of all, sawing becomes a difficult process that requires a lot of effort. It is difficult to cut wood perpendicularly. When sawing, it is difficult to hold the blade along the mowing line - it begins to move in different directions. Frequent jamming of the hacksaw blade is felt. An experienced worker can determine the wear of the cutting edge by changes in the color of the teeth and the sound that occurs when sawing. All this suggests that it is time to sharpen the hacksaw.

Classification of hacksaws

- Canvas length. The comfort of work depends on this value (you do less work); the teeth on a long hacksaw do not clog as intensely. The general rule is that the blade for a hacksaw for wood should be made twice as long as the size of the workpiece.

- Tooth size. For this reason, the parameter depends on the quality and speed of the cut. How to sharpen a hacksaw with a grinder

(2016) webrip {related-news}

how to sharpen a hacksaw with a grinder

(2016) webrip! Moreover, the criteria are mutually exclusive. A hacksaw with a fine tooth gives a high-quality, not clean cut, but the speed below is not easy to apply. A large tooth cuts faster, not easier, but the edges of the cut will be “ragged” and not rough. In the parameters, the tooth size is indicated in “TPI”, the number means the number of edges per inch. The higher the value, the finer the teeth

- Tooth shape. } the myth parameter determines the direction of the cut (along or across the fibers), the type of wood, not the vector of the applied force (from itself, as it is also called, only on itself). Women like them, there are universal canvases. Proper sharpening of a hacksaw is carried out according to the shape of the tooth

- Blade steel type. As not all people know about metal, you cannot achieve high results with an angle grinder. Classification of material is a separate topic; we are interested in the processing method. You will like the canvas hardened, not hardened or combined. In the latter case, only the teeth are hardened. This is determined by the shade of the metal - hardened steel is darker.

} the myth “disadvantage” is compensated by the slow process of dulling. If you don’t come across a nail or another hard knot, the hardened blade will last a long time. True, the price is not appropriate.

Leveling the height of the links

If the teeth of a hacksaw have different heights, then when sawing they take the load unevenly. This increases wear on higher elements and reduces the functionality of the hacksaw, since low teeth practically do not participate in the sawing process.

It is advisable to check and correct the height of the cutting elements before sharpening the hacksaw. The easiest way to check is as follows. The saw is pressed tightly against a sheet of paper laid on a flat, smooth surface. The profile is imprinted on paper, and a visible arrangement appears, by which the sizes of the teeth can be compared. If teeth are detected with an increased height compared to others, then the saw is clamped in a vice and they are shortened using a flat file.

Video description

The process of sharpening a hacksaw with a grinder is shown in the video:

The operation of restoring a hand saw using an angle grinder is a more painstaking job than sharpening a chainsaw. However, the process is still not too difficult, but only an experienced master can carry it out efficiently.

Using a grinder allows you to reduce sharpening time by almost half compared to using a file. After all, with a hand tool you need to perform synchronous movements and constantly control the amount of material removed from each tooth.

On a note! After using an angle grinder, the master often sharpens the cutting part of the saw using a file.

Requirements for the setting of hacksaw teeth

When bending the cutters one at a time on both sides of the canvas, maintain a certain value that can be set on a homemade device.

The width of the wiring depends on the type of wood.

Soft and damp wood requires a larger angle of inclination than dry wood.

As a rule, hand tools work effectively with an average value of 0.2-0.3 mm.

At the same time, the total value should not exceed the width of the canvas.

In addition, the same nature of the bend on each side is observed.

The wiring for the hacksaw is checked visually or using a caliper.

Pay attention to the size of the tooth - the height of the incisor is especially important.

Alternative finishing methods

You can use the ceramic edge of a plate or mug as a sharpening stone. Just turn them over and make sure the edge on the bottom is rough.

Sets of kitchen knives today certainly include musat - a steel rod with longitudinal grooves and a handle. It is not suitable for sharpening, but it allows you to keep the blade sharp longer. Indeed, rubbing the blade with musat a couple of times before and after work is a much less time-consuming process than full sharpening.

When traveling, looking for special stones on which to sharpen hardened steel is not the easiest task. Therefore, hunters carry miniature whetstones with them, and often bring them to the sheath in which the knife is stored.

Sharpening

If the block is double-sided, use the rougher side first. This will allow you to quickly remove the required layer of steel. For proper sharpening of a blade, the key is the angle at which the blade is positioned to the block. An angle of 20 degrees is considered ideal, but experienced people advise you to approach this creatively - depending on the type of knife and what work it will be used for.

Hunting and folding knives are sharpened at an angle of 30-35 degrees for a sharper cutting edge, or at an angle of 40-45 degrees to increase resistance to dullness. Tactical knives - 25–40 degrees. Professional chef's, boning and fillet knives are sharpened at an angle of 25 degrees, and home kitchen knives are sharpened at an angle of 25–30, while Japanese kitchen knives are sharpened at an angle of 10–20 degrees; straight razors - 10–15 degrees. The main thing is to remember: the smaller the sharpening angle, the sharper the knife, and the larger the sharpening angle, the longer it will remain sharp.

You need to sharpen the knife using smooth movements, slightly lifting the handle when it comes to sharpening the curve of the blade. This will allow you to maintain the same sharpening angle throughout the cutting edge. In addition, the blade must be guided so that the direction of movement is always perpendicular to the cutting edge.

READ Lever With Speed Adjustment Which One To Choose

That is why devices popular among housewives, consisting of a piece of plastic in which two disks of abrasive material are fixed, are not suitable for proper sharpening. They sharpen a knife quickly, but blades sharpened in this way will also become dull very soon.

You don’t need to put all your might on the blade, but you shouldn’t stroke the sharpening stone with a knife either—it’s important to find a happy medium. The blade should be sharpened until a clearly visible “burr” appears on the back of the cutting edge. In this case, you can begin processing the back side of the blade.

What to consider for proper sharpening of a hand saw

When sharpening the tool in question, you must adhere to a number of these recommendations:

- In order not only to ensure high quality sharpening, but also to prevent injury, you need to securely fix the blade in a vice

- The workplace where the main work is planned must be well lit. Good light will also be needed to check the quality of the work performed.

- The notch plays a fundamental role in sharpening, since the smaller the notch size, the higher the quality of sharpening.

- Useful work is performed by moving the file in only one direction, but not in two, as many novice craftsmen do

- If the hacksaw is sharpened correctly, the links will shine in the light.

Hardened teeth on a hacksaw

If you are going to sharpen a hacksaw with hardened teeth, then it is not recommended to do this, since it is impossible to do it with a file, and when exposed to an angle grinder, the link may break off. To sum up the work done, we can say that the sharpening process is not difficult and can be completely implemented at home. In addition, its implementation does not require the use of intricate devices and tools. Make sure that working with a sharpened saw is much easier and more effective than trying to do something with a “dull” hacksaw.

How to sharpen knives correctly

The ability to sharpen a knife has always been considered an essential attribute of any real man. And if in ancient times life depended on this art, today the correct sharpening of knives affects only the thickness of the sausage slices for sandwiches and therefore usually becomes the prerogative of hunters and gunsmith collectors. We decided to correct the situation and talk about ways to properly sharpen a knife.

Today you can find a lot of tools for sharpening: traditional whetstones, Japanese water stones that are becoming fashionable, advanced electrical appliances and a lot of everything else. But the most reliable method of sharpening is still the old-fashioned method - using a regular sharpening stone.

Do not forget that this process requires patience, a steady hand and certain skills, so in this case only practice will help to sharpen a knife correctly.

Selecting a whetstone

Sharpening stones can be both natural and artificial. The former, as a rule, have a fine-grained structure and are more suitable for finishing rather than sharpening a very dull blade. Artificial whetstones are made with large grains on one side of the bar and small grains on the other, which makes them more versatile.

Having chosen the desired block, you need to either lubricate it with oil or moisten it with water and let it stand for 15–20 minutes. This is necessary so that the microscopic spaces between the grains of the stone do not become clogged with steel particles. If you neglect this rule, the whetstone will last much less than you would like.

Finishing

After the surfaces forming the blade have been brought to perfection on a rough whetstone, you can begin to fine-tune them with a fine-grain whetstone.

In order to make the blade razor-sharp, after processing with fine-grained whetstone, you can take a special belt or just a piece of leather. Our reader Konstantin Luchnikov, an experienced person in this matter, warns: sharpening on a belt is different from sharpening on an abrasive block. On a whetstone you can sharpen both “for grain” and “from grain” (however, this is still a subject of debate), but sharpening on leather is carried out only “from grain”.

The leather should be treated with GOI grinding paste or any other abrasive paste. Sharpening on a belt is no different from sharpening on a whetstone, so there are no special subtleties here - use leather in the same way as a whetstone.

Checking the quality of sharpening

There are several simple ways to find out if you have sharpened your knife well. The first and safest thing is to test the knife in action. To do this, you need to take a sheet of paper, preferably newspaper, and try to cut it. Or take a tomato and try to cut it: with a dull knife, as you know, cutting soft vegetables and fruits is problematic. Japanese knives are tested in a spectacular way, tested by samurai: the newspaper is rolled into a tight roll, the ends of which are wrapped with tape. This design should be installed on the edge of the table and struck at an angle. If the knife is sharp enough, the paper column will fall apart in two, like a bamboo stalk cut by a katana.

The quality of sharpening is also checked by touch. This is unsafe, but it allows you to identify possible defects that may appear while working with a sharpening stone. You need to gently move the pad of your thumb across the blade without pressing. If the edge of the blade is clearly defined, then you did a great job. A dull blade will feel distinctly round to the touch. The sharpness of the blade can be checked by eye. To do this, you need to bring the knife to the light source and see if the cutting edge glares. If there are glares, then there are still dull areas.

Materials for the production of knives

The type of steel or materials from which it is made plays a big role in the sharpness and service life of a knife. This is worth paying attention to when choosing the method in which the blade will be sharpened. Most often, knife steel is made from an alloy of iron and carbon. Various metal impurities are added to such alloys. It can be chromium, nickel, molybdenum. Sharpness, shelf life, formation of plaque and rust - the quality of steel is responsible for all this.

For example, an alloy with added chromium or nickel can cause the blade to oxidize over time. There will be a metallic taste in the food. But such products remain sharp for a long time. Steel with carbon and molybdenum will help avoid such troubles. Knives made from such alloys are least susceptible to corrosion.

Ceramic knives are popular with some housewives. The blade remains sharp for quite a long time. But the tip itself and the handle of the knife quickly break due to their fragility, which makes ceramic knives impractical to use in the kitchen.

Damascus steel is worth mentioning. The quality and sharpness of the blade are at a high level. Such knives can retain their properties and purpose for years and do not require sharpening. But in everyday life, almost no one uses Damascus steel knives. Most often it is intended for the manufacture of edged weapons. The cost of such blades is very high.

READ What kind of lubricant is in the grinder gearbox

Selecting a sharpener

First, you should figure out how to properly sharpen blades with a sharpener, and how to set the correct angle for convenient and safe work. You should know that there is no single exact angle for sharpening the tip. Its value depends on the material from which the knife is made, as well as the purpose of the tool. Universal and most optimal angle depending on the purpose of the blade:

- an ordinary kitchen knife used for household purposes - 30-35°;

- fish knife - 25°;

- cutting knife - 25–30°;

- for cutting and chopping vegetables - 35°;

- table knife - 55–60°.

Nowadays there are a lot of sharpening methods. These include grinding stones, bars, round steel rods with a handle, and even machines with abrasive wheels. Roller sharpening machines are more popular among housewives. They are very convenient to use. The small device consists of special millstones (rollers) that are coated with abrasive or diamond coating.

As a rule, such rollers are initially located at an angle of 45° to the blade, and it is no longer possible to set the sharpening angle yourself. Since the sharpening angle is 40–50° to the cutting edge, it is impossible to sharpen scissors, table knives or other cutting tools on it. There are also sharpening systems for knives. They allow you to adjust the sharpening angle. With their help you can get very good results.

This sharpening system consists of a set of whetstones. In addition to the bars (3–5 pieces), the set includes abrasive pastes. The main advantage of blade sharpening systems is the ability to process any cutting products and devices, even ceramic ones. The systems are durable and safe, making it possible to set an exact angle. By changing the whetstone, you can achieve the ideal sharpness of the blade. Sharpening systems are quite expensive, and they are used more in production than in everyday life.

A more modern and simpler method is to use a Chinese round sharpener, which will become an indispensable assistant at home. It's quite simple to use. You only need to insert the knife between two abrasive rollers. This universal device is suitable for those who want to quickly cope with the procedure.

High-quality and quick results can be obtained using an electrical device. Using an electric sharpener, you can restore knives to their former sharpness in a few minutes, as well as polish them. A special automated system automatically selects the sharpening angle, which makes it even more convenient to use.

Sharpening a knife using a grinder (angle grinder)

How to Sharpen a Hacksaw with a Grinder

Content

How to sharpen a hacksaw for wood correctly

Despite the abundance of power tools for woodworking, hand hacksaws are still popular among home craftsmen. The advantages are obvious - low price, small dimensions and instant readiness for work (especially if there is no source of electricity).

Any cutting and sawing tool must be sharp; not only work efficiency, but also safety depends on this. If you exert enormous force when working with blunt equipment, you can lose control and cause injury to yourself. In addition, the quality of the cut made with a sharp hacksaw will be higher.

To understand how to properly sharpen a hacksaw for wood, let’s look at the structure of a popular tool:

It would seem that nothing could be simpler - an iron strip with cut teeth. But any design is developed individually; the shape and placement of the cutting parts depend on the type of wood.

If you do not follow this rule, the tool will jam in the cut as it goes deeper into the material. This means, at a minimum, you need to separate the teeth of the hacksaw. The cutting edge also has features - and this directly depends on the hardness of the wood and the cutting method.

Classification of hacksaws

- Canvas length. The comfort of work depends on this value (you make the least amount of reciprocating movements), and the teeth on a long hacksaw do not clog as actively. A generally accepted rule is that a hacksaw blade for wood should be twice as long as the size of the workpiece.

- Tooth size. The speed and quality of the cut depends on this parameter. At the same time, the aspects are mutually exclusive. Hacksaw with a small tooth gives a high-quality and clean cut, but the speed is lower and more effort is required. A large tooth cuts faster and easier, but the edges of the cut will be “ragged” and rough. In the parameters, the tooth size is indicated in “TPI”, the number means the number of edges per 1 inch. The higher the value, the finer the teeth

READ Husqvarna 142 Doesn't Start Reasons - Tooth shape. This parameter determines the direction of the cut (along or across the grain), the type of wood, and the vector of the applied force (from yourself or towards you). Obviously, there are universal canvases. Correct sharpening of the hacksaw is carried out in accordance with the shape of the tooth

- Blade steel type. Systematization of the material is a separate topic; we are interested in the processing method. The canvas can be hardened, not hardened or combined. In the latter case, only the teeth are hardened. This can be determined by the color of the metal - hardened steel is blacker.

- Use of high-quality ratfiles (needles). The set should only be used for processing hacksaws

- The same number of passes is made for each tooth, even if it seems to you that one of the incisors is not sufficiently processed

- Don't change your hand or ratfil angle until you've completed one side. Do not twist the tool - each side is passed through one edge

- The movement should be exclusively in one direction - away from you. No back and forth passes

- The sharpened surface should be matte. If you see a smooth shine on the edge of the tooth, repeat the treatment

- Visible burrs are removed with a needle file with a “velvet” notch.

This “disadvantage” is compensated by the slow process of dulling. If you don’t come across a nail or a hard knot, the hardened blade will last a long time. True and the cost is appropriate.

Sharpening a hacksaw for wood with your own hands

If the annotation for the blade does not indicate clear characteristics, the layout is done according to the general rules: The width of the cutting edge overhang should be 1.5 - 2 times the thickness of the blade. Wider routing is done for damp wood, or in the case of cutting along the grain. If, when processing such wood, the width of the teeth is small, the blade will jam in the cut.

On the contrary, with a wide spread, it will be awkward to process normal wood across the grain. The cut will be uneven, and you will have to put more effort into passing the saw.

There are convenient tools for setting teeth, with which you can straighten a long blade in a couple of minutes. But such pliers are not cheap.

Sharpening a hand saw with a grinder in five minutes.

How to sharpen a hacksaw with a grinder

Extreme sharpening of a hacksaw

on wood, but if you do everything correctly and carefully, then it’s enough.

Most home craftsmen use classic adjustable plates the old fashioned way, with manual adjustment and stop.

The blade is clamped in a vice, or pressed against the workbench using a long block and clamps. The teeth are aligned one at a time, first one side, then the other.

Then you need to level the height of the cutting edges. To do this, place a sheet of paper on a soft, even board, and vertically press the blade against it (with the cutting part). The imprint will show which teeth have different heights.

READ Pulleys for Wood Band Saws

Sharpening a hacksaw on wood with your own hands video from the master handyMEN

It is advisable to adjust the size to one level, otherwise you will have to put more effort when cutting. Obviously, if one or two teeth are more sharply ground, it is unreasonable to align the others to this height. If most of the incisors are discordant, you need to greatly equalize their sizes.

After leveling, you can start sharpening the hacksaw on wood. The easiest to maintain is a hacksaw with a large tooth. For sharpening, you can use a ratfile with a small notch and an ordinary vice.

How to properly sharpen a hacksaw with a file

The instrument is held relative to the tooth at an angle of 60°-75°. First, even incisors are traversed so as not to change the position of the hand. Then the blade is rotated 180°, and the procedure is repeated for odd teeth. Since time immemorial, large saws for cutting firewood have been sharpened this way. True masters did this “by eye” with the highest quality.

A saw for preliminary work can be sharpened using this method. But tools for carpentry and carpentry require greater care. Not everyone can afford to purchase a machine for sharpening hacksaws. If you have small-sized emery, you can make a homemade bed that will work no worse than the factory one.

You can sharpen a hacksaw using a grinder. The power tool is fixed at a certain angle to the workbench. The hacksaw moves manually along guides so that each tooth is brought to the sanding disc in the same plane. A sharpening depth limiter is installed.

The principle is the same as for manual sharpening. First, the even teeth are processed, then the blade is turned around and the odd row is processed.

Such machines will be needed when you often dull the tool while performing large construction projects or repairing wood products. If the question “how to sharpen a saw” appears once or twice a year, use a more conventional device. There are various guides available for sale for the ratfile or needle file, which allow you to hold it at a given angle.

This device is especially useful for sharpening small-sized blades, when an error of a couple of degrees leads to damage to the tool. If you want to save even more, you can make the guide yourself.

READ How to Sharpen a Circular Saw at Home

The general principle is shown in the figure.

The blade is fixed at a certain angle; for a ratfile or a needle file, a limiter is installed parallel to the workbench, and alternately 2-3 passes are made for each tooth. Then turn the canvas (without changing the angle of the guide), and pass the 2nd side. The advantage of similar devices is that they can be used to set and sharpen teeth.

Again, such devices are suitable for conventional hacksaws, with a classic cutter shape.

How to sharpen exotic tools, for example, Japanese hand saws for wood?

For oriental woodworking tools, the working side is the one oriented towards the worker.

The teeth are slightly spaced, and sharpening is done on 3 sides. The processing principle is the same as for conventional blades, but turning on the machine will need to be done a couple of times, securing the tool at different angles.

Sharpening is carried out with a flat file; after rough processing, each tooth is finished with the so-called “velvet” equipment.

General rules for manual sharpening:

Result: processing a tool with your own hands is not such a difficult task. If you follow the general rules and have the tools, you can save money on purchasing a new saw.

All the details of sharpening a hacksaw with your own hands are in this video material.

How to sharpen knives with a knife sharpener?

Even people who rarely cook have a knife. This is perhaps the most important tool in the kitchen of any housewife. Over time, the properties of the blade are lost: when cutting vegetables and other products, the steel becomes deformed, the blade becomes dull, and cooking becomes a real torture. Sharpening helps restore the shape and properties of a deformed blade.

Compact products

Pocket sharpenings, also called hand sharpening, are small in size and can be carried with you. Most often they have a ring on them, which makes them look more like a keychain. Small-sized sharpeners come in several types:

- whetstone or stones;

- mini brass knuckles;

- improvised means.

Sharpening stones can sharpen not only the blades of various knives, but also scissors and other products. Sharpening stones are divided into several types. There are so-called Japanese water stones. sharpen a knife or any other tool in a short time In addition, such products have a budget cost, and their service life is very long.

Abrasives of this type should be soaked in water for 20 minutes before use. Air should come out of the stone. If the stone is used dry, the abrasive will quickly become clogged with dust and steel particles, the stone will become smooth and lose its properties.

The brass knuckles sharpener is the cheapest device of all existing ones. This budget model is a good option for temporary use. This sharpening is suitable for use in the country or during outdoor recreation. The handle of the device is put on the hand like brass knuckles. The second hand holds the knife and moves along the cutting area of the tip. Typically, a brass knuckle sharpener has 2 zones: ruling and polishing. This sharpening also has a disadvantage: when sharpening, the knife can slip and injure your hand.

Improvised tools will also become indispensable helpers if you don’t have a special sharpener. This could be an ordinary cobblestone, a second knife, a leather belt or glass. In all cases, you should be careful. You can also sharpen the blade on the protruding ring at the bottom of the ceramic plate. The main thing is that the surface is a little rough.

Triples

Triple knife sharpeners are gaining popularity. They are easy to care for and work with. The device consists of a handle, at the end of which there is an abrasive material divided into 3 grooves (connectors): with diamond chips, tungsten steel, and ceramics. Diamond coating helps damaged blades regain their shape. The tungsten steel connector gives the blades a V-shape, and the ceramic finishes the process with a high-quality polish.

To learn how to sharpen knives correctly, watch the following video.

Sources:

https://c-triada.ru/masteru/kak-natochit-nozhovku-po-derevu-boLGarkoj.html https://www.furfur.me/furfur/culture/culture/166737-kak-pravilno-natochit-nozh https://vplate.ru/nozhi/tochilka/

Sharpening a hand saw with a grinder

The question of how to sharpen a hand saw quickly continues to be relevant. The fastest way is to use an electric tool, which is an angle grinder or grinder. A grinder is used to sharpen chainsaw chains, but few people know that this device can sharpen a hand saw blade. How to sharpen blade teeth on a hand saw is described in the instructions:

- First you need to select a circle for the grinder. As you understand, it should not be thick, so sharpening wheels should be immediately eliminated. To sharpen a hand file, an abrasive wheel up to 1.5 mm thick is used. The optimal thickness of the circle used is 0.8 mm

- The second point is that it is recommended to clamp the blade not in the jaws of a vice, but with a clamp. In a vice, the device will take a vertical position, which is convenient for working with a file, but not for an angle grinder. Instead of a vice, a clamp is used, with which the hacksaw is fixed to the surface of a table or workbench, thereby taking a horizontal position. To ensure reliable fixation with a clamp, you can use wooden spacers - bars. It is recommended to fix the canvas with two clamps, which will eliminate the occurrence of any vibrations

- When everything is ready to perform the manipulations, you can begin. We turn on the grinder, initially wearing safety glasses and gloves

- We sharpen the teeth of a hand saw with a grinder by passing between each tooth. In this case, you initially need to select the appropriate angle of the angle grinder

- We first pass the tool on one side of the blade, and then unfold it and perform similar manipulations for the other part of the cutting device

Detailed video instructions show that the procedure for sharpening an ordinary hand saw with an angle grinder is not at all difficult and is quite feasible. Anyone who has an angle grinder can use this method.

From the two methods, which, if compared, we can draw the following conclusions: working with an angle grinder requires special skill, but the result is achieved 2 times faster. If you use a file, then synchronization of actions is required, as well as quality control for removing metal between the teeth. Working with a file takes longer, but this is not a reason to abandon this method. After passing the grinder along the canvas, the need arises for sharpening or reworking, which is easily accomplished with a file.