For those who love to tinker and do men's housework, as well as professionals, the tool industry offers a lot of useful devices. Drilling holes and grooves is perhaps the most common operation. For such needs, drills have been created, improved and continue to be modernized. This consumable tool has become a unique element on which the accuracy of the process, the speed of its implementation and reliability in operation depend.

Drill marking

To drill through stainless steel, you must use special equipment.

Any drills, including those for stainless steel, have certain markings. It indicates the technical characteristics, material and size of the equipment. Basic designations:

- The letter “M” indicates the presence of molybdenum in the product. Its percentage is indicated by the number following this letter.

- Letter “P” - the equipment is made of high-speed steel. The percentage of tungsten is indicated by a number.

- The letter “K” indicates the presence of cobalt in the alloy. Its quantity is indicated by a number.

Foreign manufacturers make HSS markings, which contain information about alloying components and their quantities:

- HSS-TiN - titanium coating is applied to the surface of the tooling during production. Thanks to this, the strength and wear resistance increases. Technical characteristics do not change when heated to 600 degrees Celsius.

- HSS-E - contains cobalt.

- HSS-E VAP are special drills designed for drilling stainless steel of different thicknesses.

- HSS-R - drills with increased strength. Used for drilling bronze, cast iron, brass, cupronickel.

- HSS-4241 is a tool designed for working with aluminum workpieces.

Selection principles

When choosing, you need to consider:

- product color;

- purpose of equipment;

- quality of sharpening;

- symmetry of incisors;

- equipment material, type of protective coating.

Drills of different types (Photo: Instagram / koleso_ast)

Advantages and disadvantages

Advantages:

- the ability to perform various technological operations;

- strength, reliability, durability;

- low price.

Manufacturers and prices

Manufacturers:

- Bosch;

- Haisser;

- Ruko.

Gimlets with the USSR designation are considered the most reliable and durable. The price of a classic drill marked HSS is 500 rubles.

Bosch brand drill (Photo: Instagram / sergei.wood_man)

Main selection criteria

When considering various models, you should pay attention primarily to the following criteria:

- color;

- symmetry and quality of sharpening;

- diameter;

- type and quality of metal;

- capabilities and purpose;

- manufacturer.

In order to simplify the purchasing process, it is better to clearly define your purpose in advance, as well as set price limits. Also, do not forget about the features of the drill: punching large holes will require a powerful tool, and individual drills require the use of coolant.

Let's take a closer look at all the mentioned parameters.

Drill classification

Today, there is more than one classification of this tool that cuts almost any surface.

Depending on the design of its working part, we can distinguish: spiral types of drills for wood, centering ones, as well as flat and even drills with exclusively one-sided cutting, and used only for deep drilling.

If you look at photos of wood drills, paying attention specifically to the design of their tail part, you can distinguish the following types:

- conical;

- cylindrical;

- 3,4,6-sided;

- SDS drills.

Also, all tools can be divided into several groups, based on the type of material they can process. So, these are long wood drills, as well as drills for hard concrete, glass, high quality metal, stone and ceramics, as well as universal tools.

Overview of species

Long drills can differ significantly from each other in shank design. There are devices with cylindrical and conical shanks. The first are thin cylindrical metal rods. There are four grooves on their surface (2 screw and 2 spiral) - they are needed for cutting material and removing chips.

Straight drills are used for drilling steel, wood and non-ferrous metals. They can be left-handed or right-handed, but the first option is more common. According to GOST, these devices are manufactured with a centering recess, but some of them can be manufactured without it.

Cylindrical drills are sometimes made with a small neck, which makes them easier to grind. The total length of such drills can be up to 320 mm.

Models with a tapered shank are considered more preferable among specialists. They are securely mounted in the drill chuck, providing the most accurate centering during operation.

The conical type of shank allows you to avoid the appearance of burrs and irregularities on the material when drilling. The upper part at the end will be completely smooth, the walls of the drilled holes will also be smooth.

Conical-type devices have the most convenient design, which allows, if necessary, to replace them with a new model. Such tools are used for drilling metal. But they may be suitable for wood or plastic.

Using these drills, you can make holes of different diameters in alloy or carbon steel, cast iron, cermet alloys, and non-ferrous metals. The drill itself is fastened with a conical shank thanks to the adapter sleeve. Devices of this shape are produced with a spiral working part.

There are several varieties of long metal drills, which differ in strength, the part that is fixed to the equipment, the cutting part, and the working surface for removing chips.

Next, we will consider the most common models of elongated nozzles in more detail.

- A polished version for metal with a conical shank. This type is suitable for working with products made of building and structural metal or cast iron. The drills are made of high-speed steel HSS and have a sharpening angle of 118º.

- Cutters made of quick cutters contain an admixture of cobalt and are covered with a titanium-nitrite layer on top. Used when working with steel parts having the highest strength (900 N/mm²).

- Extra-long and long elements for metal. They are equipped with cylindrical shanks and have a reinforced rod. To effectively remove chips in this version, a spiral groove in the shape of a parabola is made. This type of drill is characterized by increased rigidity.

- A pointed spiral nozzle with a long or extra-long size. Has a cone-shaped shank. This option is used for drilling holes with both large and small diameters.

- Drill bits for drilling hollow parts. They have a small cutting part.

- A device for drilling holes in hard alloys. They have a sharpening angle of the cutting part of 135º and a cone-shaped shank.

Extended drills can be divided into several separate groups depending on the structure of the working parts.

- Feather drills for metal stand out. Similar models are used for drilling deep holes of large diameter. They are equipped with centering sharpened tips. They also look like a small flat blade.

- Core drills are of particular importance. These models can also be suitable for creating large diameter holes (it can be up to 150 mm). They are used to work on milling and drilling machines. The devices first cut out the outline of the future hole, and then make the depression itself on the surface.

- There are models with a cone-shaped working part. These devices are used for drilling non-ferrous metals or steel. But they process metal sheets of small thickness, which should be less than 10 mm. They can be made in a standard design, or they can have a stepped design. The latter facilitate further processing of the metal.

Models with a conical tip allow you to make recesses of different diameters. In this case, there will be no need to regularly change the drill in the chuck. Such tools are perfectly centered.

Drills for small work 0.5 0.8 1.5 2.0 mm. Minor repair of a remote control machine

I ordered these drills without any particular purpose - in case someday I need to drill something small. I was so undemanding and inattentive to the purchase that I didn’t even notice that the set included not one drill of each diameter, but 10. Well, I divided my expectations from the drills by 10. So they lay there until they arrived hands to repair a radio-controlled car, which I once reviewed, and during the review I dug into the wall so that the pin connecting the wheel and steering rack broke off. At the same time, I decided to take pictures of the drills and conduct a couple of primitive tests. Let's go over the drill bits first. As I already said, the set includes drills of four diameters: 0.5 mm 0.8 mm 1.5 mm 2.0 mm, 10 pieces of each. The seller states that they are suitable for drilling wood, plastic, and aluminum. Each diameter is placed in its own bag.

My compass is very simple and not suitable for precise measurements. But taking into account its error, the declared diameters can be considered correct.

Drill length

Drills close up. I’m not an expert in this, so anyone in the know, write in the comments what’s going on with sharpening, etc. by appearance.

0.5 mm

0.8 mm

1.5 mm

2.0 mm

Now let's check how they drill. For mounting in the engraver, I also used a set of collets purchased in reserve for drills of 0.5 mm, 1.0 mm, 1.5 mm, 2.5 mm, 3.0 mm.

Or rather, three of them. The 1.5 mm collet turned out to be actually 2 mm, and I tested the 1.5 drill by inserting it into a screwdriver. I tested the two smallest drills on a board from a dead flying ball with blades.

The recording of the drilling process has been slightly sped up, the real time is displayed on the timer.

0.5 mm

While watching the video, I noticed that I was drilling at an angle. I read that such thin drills usually break because of this, but it held up.

0.8 mm was normally fixed in the collet at 1 mm.

1.5 mm, as I already said, had to be installed in a screwdriver. I started with textolite, recording speed 1:1

Then I thought that we were promised aluminum drilling. I didn’t find anything aluminum that I wouldn’t mind, so I took a bottle cap.

Rejoiced, I decided to give the task a more difficult one and tried to drill a 1 mm thick steel ruler. Not too fast, but the drill did the job. It seems to me that the result is quite good.

2 mm. I didn’t even try it on PCB. Of course, it drills through tin lids.

But there was a puncture with the ruler. I tried two drills, with an engraver and a screwdriver, the result was the same, within 30 seconds they went a little deeper into the metal and didn’t go any further.

Now about practical application. For quite some time now I have had a 1/14 scale RC car lying around with a broken steering wheel. When she collided with a wall, the pin that connects the steering rack and the wheel itself broke off. Fortunately, I managed to find the pin itself after the accident.

Just gluing it on is not the answer. Therefore, I decided to put it on a metal pin for reinforcement. An ordinary paper clip acted as a pin. Diameter 0.7 mm.

I straightened the paperclip and bent one end with thin pliers.

Next, using a 0.8 mm drill, you need to make holes in the pin and the car wheel mount. He acted a little barbarically. Since it was already a little late, my wife was putting my daughter to bed, I didn’t want to buzz the engraver on the balcony. Therefore, I attached a collet holder to a drill with a diameter of 2.5 mm and installed it in a screwdriver. It doesn't even hit the eye.

I drilled a hole in the wheel mount, inserted a paper clip, heated it with a lighter and melted it into the plastic.

I drilled a pin, threaded it onto a paperclip, and “polished” everything with superglue.

After installing the part in the car and checking it, I had to remove some of the remaining glue with a file. After all procedures, the steering functionality is completely restored.

How to understand the markings

Markings help you choose the right tool for drilling metal products. It's not difficult to figure it out. The marking of drills depending on their working diameter contains the following information about the presented tool.

- Miniature products, the diameter of which does not exceed 2 mm, are not marked at all.

- The markings of drills, the diameter of which is in the range of 2–3 mm, contain information about the grade of steel from which they are made, as well as the size of their cross-section.

- The marking of metal drills with a diameter of 3 mm or more contains the following data: working diameter, steel grade, and an imprint of the manufacturer’s logo.

Thus, the letter “P” in the marking of metal drills means that they are made of high-speed steel. Steel alloys used in the manufacture of drills for metal work may contain additional substances that improve their performance characteristics. Such substances, in particular, can be molybdenum, which is designated by the letter “M,” and cobalt, designated in the labeling by the letter “K.”

Drill markings are applied to the shank of the product

Foreign manufacturers include more detailed information about the presented tool in the labeling. Having decided to purchase such drills, you will receive the following data from their markings:

- name of the country of origin;

- manufacturer's trademark;

- steel alloy grade;

- working diameter of the tool;

- accuracy class;

- short recommendations on materials that such a tool can drill.

Popular brands of instruments from foreign manufacturers

In order to know, when choosing foreign-made drills, which ones are better suited for solving certain technological problems, it is enough to have an idea of the material that will be processed with their help. Thus, foreign manufacturers give the following recommendations for choosing a tool with a certain marking.

HSS-R and HSS-G

Using tools marked as follows, it is recommended to drill:

- steel parts manufactured by simple casting and injection molding; products made of carbon and , the strength of which does not exceed 900 N/mm2;

- products made of metal alloys containing aluminum, graphite, copper, nickel, zinc (bronze, brass, cupronickel, etc.);

- blanks made of gray and malleable cast iron.

Geometry of HSS-R and HSS-G drills

HSS-G Co 5

Drills with this marking can be used for processing metals whose strength reaches 1100 N/mm2. Such metals, in particular, can be the following steels:

- carbon;

- stainless;

- thermally improved;

- acid-, heat- and heat-resistant;

- alloyed.

Ground self-centering drill HSS-G 5% for drilling hard metals

HSS-G TiAN/TiN

If such a designation is present on metal drills, this means that titanium-aluminum-nitride coating is applied to their working part. This coating significantly increases the resistance of drills not only to corrosion, but also to wear, which helps to increase their service life. Tools with this marking can also be used for processing metals and alloys with strength reaching up to 1100 N/mm2. Manufacturers recommend using the following types of drills for processing:

- malleable and gray cast iron, in the structure of which graphite inclusions are spherical;

- copper-based alloys (brass, bronze, cupronickel);

- steel blanks produced by casting (including injection molding).

Classification

You can find different types of drills on sale. They are classified depending on color, material, type of shank, type of coating, and accuracy class.

By color

A faded yellow tint appears after a vacation at work. Thanks to additional processing, the durability and strength of the equipment increases.

The bright yellow equipment is durable and wear-resistant. It has a low friction index. The equipment has a titanium coating, which provides it with increased strength.

Black color indicates additional steam treatment. This is durable equipment with a long service life. The cost is not very high.

Drills of the lowest quality that have not been subjected to additional processing are gray in color. Such equipment has a low price, but you won’t be able to save money, since the drills break quickly.

By material

Drills are made from different types of steel:

- carbon tool;

- alloyed instrumental;

- high-speed

Additionally, plates made of hard alloys are attached to the cutting parts.

Steel drills (Photo: Instagram / linkorspb)

By shape

Kinds:

- Stepped, conical. They are also called gimlets. The working part has a conical shape. Designed for drilling holes of different diameters in metal sheets up to 2 mm thick.

- Centering. Multifunctional gimlets, which are needed for creating special holes in metal workpieces. The parts are fixed in drilling equipment.

- Elongated. Used to create blind, through holes.

- The first ones. Tool with replaceable inserts. With its help you can make large diameter holes with smooth walls.

- Crowned. Hollow crowns that have many sharp teeth along the edges. Suitable for drilling holes in thin metal sheets up to 30 mm in diameter.

- Threaded. Used for cutting threads in pre-prepared holes.

- Highly accurate. With their help, you can perform precise technological operations.

- Left-handed. Equipment for highly specialized purposes, which is needed for drilling damaged equipment out of holes.

The most common type of metal drills is twist drills. Designed for drilling holes of different depths and diameters.

Conical drills (Photo: Instagram / dismart_kh)

By shank type

Types of shanks:

- Conical. The equipment is designed for high-power, professional drills or industrial drilling machines.

- Cylindrical. Suitable for power tools.

- Hexagonal. Used for fastening in jaw chucks and clamps.

By type of coverage

The following can be applied to drills:

- titanium aluminum nitride;

- titanium carbonitride;

- diamond chips;

- titanium nitride ceramic coating;

- oxide film.

The last type of coating is the most affordable and reliable.

Cobalt drills (Photo: Instagram / vmiha80)

By accuracy class

Accuracy class:

- Normal accuracy marked B. Designed for drilling holes with an accuracy of up to 15 grade.

- Normal accuracy marked B Designed for drilling holes up to accuracy class 14.

- High precision equipment marked A1. Suitable for creating holes with accuracy from 10 to 13 classes.

Types of drills

Products are divided into several groups according to design and purpose.

This allows you to quickly select a tool for specific tasks.

BY FORM

Based on the shape of the drill, it is quite easy to determine what material it can be used for:

Spiral

Classic instrument.

The working part has two teeth, which are twisted in a spiral.

The tool, biting into the material, pushes the chips to the surface with its grooves.

The shape of the tip depends entirely on the material for which the tool is intended.

As a rule, the diameter of products does not exceed 80 mm.

Screw

A modernized previous version, which has a more advanced form of grooves that remove chips.

Another difference is that such products are longer.

Feather

The product is flat in shape, the cutting part is made in the shape of a sharp peak, the outlines of which turn into a wider blade.

Other names are flat cutting drill, which is dictated by its shape, feather drill.

Builders call it perka.

Used where you need to get a deep and at the same time wide hole.

Ring

For those cases when you need to drill a hole with a large diameter without preliminary preparation.

More commonly known as a crown.

The shape of the tool resembles a hollow cylinder, and on the axis of rotation there is a centering twist drill.

The part that cuts the material is made either in the form of teeth, carbide tipped, or has a coating of diamond chips.

Conical (tapered)

Its shape resembles a cone with a sharp tip.

Suitable for working with metal whose thickness does not exceed 0.5 cm.

Just one tool can make holes of different sizes.

It all depends on the initial and final diameter of the cone, as well as on the immersion depth.

On the opposite sides of the drill there are special grooves with sharpened edges.

Stepped

A type of cone version.

The cone is divided into steps with increasing diameter, which have their own size.

The tool is convenient in that it allows you to monitor the diameter of the hole being formed during operation.

Spear-shaped

The shape resembles the tip of a spear, hence the name.

Used when working with hard, but at the same time fragile materials, such as glass and tiles.

Ballerina (ballerina)

Circular drill, which is used when working with wood and tiles.

It all depends on the installed cutting part.

Designed in such a way that the output is a perfectly smooth hole of large diameter.

The tool has a cross-shaped shape with cutters, the distance to which from the center can be adjusted.

This sets the diameter of the required hole.

The central part is a spiral drill, around which the cutters rotate.

Single cut drills

The cutting edges are located on one side relative to the axis of the tool itself.

In turn, they are divided into cannon type (the front end of the rod-shaped form is half cut off, which forms an outlet channel for chips)

and rifle-type (a compressed tube with a cavity through which coolant is supplied, and a groove angle of up to 120 degrees).

Tubular

Similar to crowns, but with a longer working part.

Forstner designs

An improved version of the spiral tool, but with additional cutters.

Zhirov's designs

A subtype of screw tool that has three cones on the cutting part, which is why its length is increased.

The design is also supplemented with a jumper with a groove, which is sharpened by a third of the cutting edge.

Designs by Yudovin and Masarnovsky

A tool with a large groove angle and a special shape, which distinguishes it from other types.

Countersinking

A monolithic cylinder having several cutting edges forming a cone.

Used for countersinking holes for screw heads.

BY PURPOSE

The instrument is divided according to its purpose, which is the reason for its special shape in each specific case.

The following drills are used in construction, at home and in production:

Universal

As the name implies, they cope with most materials.

They have a special sharpening, which received the corresponding name - universal.

On wood

These include spiral and feather, ring and screw.

Forstner drills and ballerina drills work well on wood, among others.

For metal

Conical, crown, stepped, as well as classic spiral.

On concrete

Crowned with carbide tipped, impact spiral and screw.

They have different shanks for hammer drill chucks.

For ceramics

Crowns, spear-shaped and ballerina.

The first ones are produced without teeth.

The cutting function is performed by a special diamond coating.

When working on glass, these are the types that are used.

For plastic

Special spiral options and crowns that can pass through material without breaking it.

There is a specialized tool that is used strictly to perform a specific task:

For deep drilling

Spiral tool with through channels.

Their purpose is to supply coolant directly to the cutting part.

This includes rifle and cannon subspecies.

Single-sided cutting

A tool whose main purpose is to create precise holes.

Subtype - ejector drills designed for drilling machines.

As the name implies, the cutting edges are offset to one side of the axis around which the tool rotates.

Centering

A specific tool capable of making only center holes in parts, but nothing more.

Differences in the operation of an extra-long drill from a regular drill

Extra-long metal cutters are subject to more heat than ordinary ones. This is due to the large contact area of the tool with the channel walls and poor heat transfer due to the closed space. Therefore, it is necessary to organize forced cooling during drilling. An elongated drill has increased bending strength, but if you drill continuously, passing a channel at a time, then the probability of the drill breaking due to the metal shavings formed in the channel is very high

It is important to remove these chips from time to time by returning the tool back. Fast and continuous feed of the cutter can also cause destruction of the tool, so you need to go forward with short feeds. It is difficult to use an extra-long metal drill with a conventional electric drill: it is impossible to hold the tool perfectly level. The hole may turn out to be of poor quality, parallelism will not be maintained, and the probability of breaking the equipment is high

All this can be avoided by drilling using a special machine. To drill hard alloys, it is necessary to work at low shaft rotation speeds. This will prevent the cutting edge from overheating and becoming damaged. Sharpening of cutters for metal must be done using special equipment, strictly observing the angle. It is better to use a template for this.

Metal drills: external differences

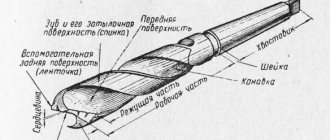

A drill is designed as a tool capable of making a hole in solid metal (concrete, tile, wood). Therefore, it has a special design that can overcome the resistance of the metal layer; There are three parts in any drill.

The cutting part is the first to come into contact with the material in which the hole is made. Behind the cutting blade there is a working part that helps remove chips. The back part is also called the shank or fastening part; it is fixed in the drill chuck. The question of what types of drills there are can be answered based on their appearance; There are several types of cutting tools.

Flat (feather)

The working part is solid or with replaceable cutting plates, narrow, reminiscent of a feather (hence the name). Allows you to drill stepped and shaped holes. The device has a simple design and is inexpensive. But with its help it is difficult to drill a wide hole, and the chips must be removed manually.

Prefabricated feather drills for metal Source prom.st

Spiral

The most common type is in the form of a rod with two (less often four) spirally cut grooves through which chips are removed. If the spiral grooves twist to the left, then this is the left-handed variety, which will help remove the fastener. There are products of a higher accuracy class, but in everyday life, spiral cylindrical drills of normal accuracy with a diameter of up to 82 mm are more often used.

Design of a twist drill Source kerner.ru

Crown (ring, hollow)

They have the appearance of a hollow cylinder, are more efficient (fast) and less expensive than spiral models. Feature: material is removed along the periphery of the hole (in). Core bits are especially useful when it is necessary to drill into curved surfaces (such as pipes).

Metal annular cutter for magnetic drills Source snabzhenie.com.ua

Countersink

It has a conical working part with longitudinal cutting notches (there can be 3 or more cutting edges). Used where high precision is required, especially in mechanical engineering. Countersinking is more often used to clean the surface before cutting threads and to calibrate holes.

Drill with countersink for metal Source stroy-podskazka.ru

Conical (stepped)

The working part is in the shape of a cone with notches that allows you to create and expand holes. Thanks to the complex stepped surface, the tool is easier to center than its spiral counterpart, which is especially convenient when working with thin material. Each stage corresponds to a specific diameter, which allows you to obtain holes of different sizes without changing the drill bit in the drill chuck.

Step metal drill with helical flute Source amazon.com

See also: Catalog of companies that specialize in finishing materials and related work

What can the color of a drill tell you?

In addition to the markings indicating the composition of the steel and impurities, you need to understand what the color of the drill indicates. This will tell you what additional processing the metal has undergone and how this will affect the characteristics of the equipment. Here are the common types of colors.

Steel gray color

These are the simplest drills without additional coating. If they are left in a humid environment for a long time, they will rust. When drilling, do not put excessive pressure on the tool, otherwise the rod may break.

Golden tone

This color indicates that it has been hardened. The treatment makes the outer part very strong, but increases the internal fragility. Drills hold an edge for a long time, but are prone to breakage. To extend their service life, periodic re-hardening is required.

Golden bright color

Such drills are immediately noticeable on the counter with their bright color. The effect is ensured by titanium surface treatment. The coating reduces wear from friction and promotes long-term operation. The drills belong to the high-strength class and are priced accordingly.

Black color

The steel is steam treated. An inexpensive way to increase external strength while avoiding internal brittleness. The drills hold an edge better and last longer than the gray ones.