Installation of lifts in a car service center

The PRO-PODEMNIK company provides services for the installation of car lifts in car services, workshops, service stations, workshops of transport companies, etc. Correct installation of a car lift is the key to its functionality, efficiency and quick payback. We carry out installation work in professional quality with a guarantee at an affordable price from 8,000 rubles.

We install different types of car lifts:

- scissor;

- pneumatic;

- two-post;

- four-post.

cargo;

We carry out installation strictly according to technology in compliance with safety regulations. This approach ensures error-free assembly and stable operation of the lifting structure throughout its entire service life.

Car lift installation service is a process that requires careful planning and preparation. The first step is to select equipment taking into account the workload of the service center and the type of vehicles being serviced. The foundation is prepared in advance. It is usually made of concrete with reinforcement. You can use concrete with topping, technical porcelain stoneware. The main thing is that the coating is smooth and durable. Installation begins after the floor has hardened.

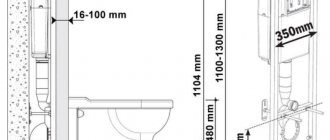

Optimal dimensions and height

Not every garage will be able to install a car lift. For example, if you are the owner of a minibus, which almost touches the ceiling when entering the garage, there is no question of any single/two-post lift. The garage space must have appropriate dimensions.

Next, you can familiarize yourself with the minimum garage dimensions required for a certain type of car. Add to the height of the garage the value of the height to which you plan to raise the car. This way you will determine what minimum height the garage ceiling must have to install a car lift.

For passenger cars

The length of the garage should be three meters greater than the length of the car, and the width should be the same. The optimal height is three meters.

For jeep

The length, width, and height of the garage space for a jeep or other SUV should be eight, five, three meters, respectively.

For minibus

If you own a minibus, the garage should be large. The optimal length is seven and a half meters, width is five meters. The minimum garage height for a minibus is three and a half meters.

If you have a Gazelle cargo truck with an extended platform, the length of the garage space should be ten meters. The minimum height here increases to four meters.

Stage 1. Site selection, design

When choosing a location, we take measurements, take into account the specifics of the object and the wishes of the customer. We plan placement taking into account the dimensions of the structure and the vehicles being serviced, the distance from the walls to the lift, ceiling height, type of equipment and other factors.

Result:

- free access to the car lift;

- convenient and safe conditions for repairs and maintenance;

- eliminating the possibility of damage to vehicles;

- access to power supplies;

- ergonomic use of space.

Communities › Garage Equipment and Tools › Blog › Installing a Car Lift

Hello, friends! As promised, I want to tell you about my installation of a Nussbaum screw car lift (load capacity 3000 kg). When I brought it to the service center it was in this condition:

Comments 25

Plastic bushings are bullshit (the photo shows a clearly homemade bushing). In addition, it is not only the bushings that wear out on such lifts. but also the steel screws themselves. They are usually sold due to wear and tear on the screws.

Explained clearly, thank you, how much does the repair cost? a set of all this stuff to restore; if you have the part numbers, I’d be grateful.

there are 2 nuts - a working one and a safety one. there should be a gap between them. Once the gap is gone, the lift cannot be used and the working nut must be replaced. all the load goes to the working nut. as many do, leaving no gap to lift a heavy car is incorrect and dangerous. If you use everything correctly and do not neglect the safety rules, everything will be OK! I think I explained it clearly!

In September there are also plans to do some maintenance on approximately the same lift/MAHA econ 3) - replacing the nuts and side guides (maybe they can just be swapped with each other if they are not worn out). I do it every 3 years + not myself, since insurance requires a stamp from a competent company. I’m not happy with the lift - it’s complicated, it was idle for several weeks due to its breakdowns. The lift is 6 years old and doesn’t seem to be old. It's easier to make friends with a hydraulic one.

We service it ourselves, everything is simple if you figure it out.

there are 2 nuts - a working one and a safety one. there should be a gap between them. Once the gap is gone, the lift cannot be used and the working nut must be replaced. all the load goes to the working nut. as many do, leaving no gap to lift a heavy car is incorrect and dangerous. If you use everything correctly and do not neglect the safety rules, everything will be OK! I think I explained it clearly!

Explained clearly, thank you, how much does the repair cost? a set of all this stuff to restore; if you have the part numbers, I’d be grateful.

Stage 3. Equipment testing

The next step is to test the mounted and connected car lift. We perform a series of descents and ascents. We check the smoothness and speed of movement. Let's see how the lift works; the installation is considered successful if no failures occur during the diagnostics. In this case, the equipment is considered ready for everyday loads and is put into operation.

The car lift installation service does not include floor preparation, delivery of the lifting device to the installation site and wet cleaning.

The best place to place a lift

Before installing a car lift, you need to correctly select the installation location. The equipment must be installed on a concrete surface, the thickness of which is in the range of 25-40 centimeters.

The surface on which the equipment is mounted must not be uneven. This does not apply to lifts with a frame base, which are installed even on uneven floors.

In addition, when choosing a place, keep in mind that when servicing and repairing a machine on a car lift, it should not touch the ceiling surface when fully raised.

When choosing equipment for a garage space, you must consider the following characteristics:

Safety precautions when installing a lift

Each type of lift has its own specifics of assembly, adjustment and connection. Therefore, specialized teams must carry out the installation. Savings on professional services often result in losses and downtime because:

- Installation errors lead to incorrect distribution of the load on special equipment, accelerate its wear and reduce its service life.

- The slightest misalignment can lead to the vehicle being serviced falling, injuring people and causing the structure to fail.

When ordering the service, installation of car lifts

In our company you receive a guarantee for the work performed. The lifting device will be installed by specialists with at least 5 years of experience. We use professional tools and special equipment. We offer affordable prices. We ensure precision and reliability of assembly, which in the future will allow you to use the car lift with maximum efficiency, complete safety and high productivity.

Do-it-yourself foundation for a car lift, part 2

Hi all. I don’t have time to create new blog entries, because I’m on vacation and work and everything, everything, everything.

The time for reinforcement has come. I didn’t have to agonize over the choice of material for reinforcement for a long time. The choice fell on fiberglass reinforcement, which is no worse than metal, especially for the foundation. There is a lot of information about it on Google, I think it won’t be difficult for you to find it. The reasons why I chose fiberglass. 1. Light weight. 2. Low price. 3. Easy to knit.

Now about suppliers. There were three ways - Leroy, StroyDvor and private owners. I came across a private owner who produces fittings. Evgeniy told me, showed me and suggested how and what is best to do. I highly recommend it. And in terms of prices... A private owner is cheaper, and significantly so.

They decided to do the installation in “two floors”, with a cell size of 200 mm. Knitting was done with plastic ties. To maintain the interfloor distance, vertical pins were used, which were fixed in the ground. And the first floor must be knitted with an indentation from the base to create a protective layer of concrete. We spent approximately 1000 plastic ties and 2 days of work.

April 1st is concrete pouring day. 8 cubes of M300 brand were ordered here. Do you know why? I called about 6 companies that deliver concrete to the site. But it was the Euroconcrete manager who was able to answer all my questions, ask me the right questions so that the cooperation would be as productive as possible. And an excellent final touch was made by the mixer driver, who, firstly, called in advance, on the day of delivery, and clarified what exactly the concrete was needed for, and clarified about the consistency. Secondly, during unloading he did not stand still, but gave valuable advice and actively helped us. I had a great pleasure communicating with the employees of this company, so I recommend it.

And according to popular custom, we did not have enough solution, since I miscalculated. At least everyone thinks so except me))) I had to leave it as is and let this concrete gain strength. During this process, we set the level of the future finishing floor, set up the beacons and poured another layer of concrete. This time I bought concrete from a lesser-known company, but delivery was from 1 cubic meter. The manager asked to put a 3 meter extra. tray (the kind they brought Euroconcrete). As a result, a short tray arrived that did not reach the unloading point. The driver suggested that we build a tray from boards, or he unloads a cube of solution onto the floor, as close as possible to the desired place, and we spread it with shovels. We rejected these proposals. He (the driver) had to go around the neighbors and build a tray, that’s a plus for him.

After unloading and leveling

Honestly, this solution is extremely strange. The first two days it was soft, but on the third day it seized sharply. It seems strong, but the drill is a bit weak on it, I hope it’s a real M300.

At the time of publication of the article, we are already resolving issues regarding the fastening of the lift struts and hope that from May 15 there will be a technical discovery if the supplier does not let us down))))

Click on the bell at the bottom left and subscribe to updates.

Any interest? Donate and the new record will come out faster.

Security issue

When choosing a particular car lift, pay attention to the fact that such equipment has a fairly high level of danger. After all, car lifts are used to work with heavy vehicles. This imposes additional obligations on manufacturers. It is preferable to choose those models that are equipped with auxiliary safety devices and safety systems.

Also, when working with a lift, you must first study all the safety rules prescribed by the manufacturer and strictly follow them when performing lifting operations.

Mobile systems are considered the most dangerous. Although mobility is rightly one of the advantages of car lifts, since they are widely used in car repair shops where the unit needs to be moved frequently.

Features of lift drives

The type of lift drive is essential. The cost here directly depends on the configuration and functionality. A simpler option is the electromechanical model. The design is simple, which ensures ease of operation. It is necessary to monitor the connections so that the equipment does not wear out. We will indicate the most important points.

- Electromechanical lifts do not have stoppers. This slightly reduces the level of security, but increases the speed and efficiency of work.

- You can make equipment more durable if you lubricate it regularly.

- Single motor models have chain and belt drives which make the lift less reliable. A more modern version has a transmission shaft that transmits force to the second column. This increases the level of security.

- If there are two engines, they are synchronized by a special electronic program. It is extremely important that the control system is of high quality and reliable, since the effectiveness of work and safety depend on it.

- The electro-hydraulic drive ensures smooth, quiet, high-speed work. At the same time, significant energy savings are guaranteed.

- Among the different types of lifts, two-post and single-post lifts are in the greatest steady demand. They save space, are simple in design and reliable.

- It is extremely important to consider the height of the ceiling when choosing a specific type of lift. Unfortunately, most garages have fairly low ceilings, making it difficult to accommodate large lifting equipment. Sometimes, if possible, it is worth building an additional garage height.

The speed and height of lifting, the level of load capacity, as well as design characteristics must be taken into account. Remember that this is important equipment, so you should trust only manufacturers with a good reputation and experience.

Reliable installation is a prerequisite for successful and safe operation

Many people are interested in how to install a lift in a garage. It is important to make a solid foundation, reinforce and fill it well, and securely fasten the structure. Otherwise, even high-quality equipment can become dangerous and ineffective.

Minimum paw lowering height

The lower point of descent is of great importance. This is why they choose a garage with a lift. The plane at the bottom point should be flat. The minimum lowering height of the lamps differs among different manufacturers. However, there is a standard: a maximum of 110 mm and a minimum of 95.

Determining the height of the ceiling

It is necessary to correctly calculate the height of the ceiling along with the lift. In this case, the raised trunk is not taken into account. The type of equipment also matters. When the model has retractable legs, you need to subtract the height between the bottom of the car and the floor from the final figure, this is approximately 300 mm. If the lift is overpass, the height of the machine is added to the formula.

Pay attention to the approximate parameters. Overpass lifts are 440 cm for an SUV, and 3990 cm for a passenger car. The model with retractable legs for an SUV has a height of 410 cm, and for a passenger car - 360 cm.