Pulley hoists: from calculations to reeving

A chain hoist is a portable block system designed for lifting and moving loads of varying degrees of severity.

This device is used in the construction industry, logistics, mountaineering and during rescue operations.

To make a chain hoist with your own hands, you need to know the design features of this device, methods of attaching ropes to a forklift, and reeving technology.

General information about pulley hoists

A pulley block consists of 2 or more pulleys (blocks) connected using rope ropes or chains:

- Fixed pulley. This block is attached to strong static elements or special equipment. It includes several videos. Each of them carries ropes, metal ropes or iron chains. A fixed pulley distributes pressure between structural elements. The amount of pressure on each rope is determined by the number of rollers.

- Movable pulley. This block is attached to the load and is used to maintain the operation of the lifting mechanism. It is equipped with a hook, carabiner and magnet. A movable pulley, attached to a load, can benefit from effort.

Simple pulleys can consist of 1 pulley and rope. In them, the roller is located above the load: on the ceiling, beam or support. The first end of the rope is connected to the hook and goes down to the load being lifted. A man pulls on the other end of a rope, lifting a heavy object. Complex lifting devices include several simple pulleys and provide greater gains in strength.

The operating principle of pulley blocks is based on the rule of leverage. A rope is thrown over a stationary pulley. The load is raised to a height by applying forces commensurate with the weight of the object being lifted.

The length of the rope or chain should be comparable to the height to which the load is lifted. To reduce the amount of effort required, it is necessary that the moving block moves parallel to the load.

There are the following types of pulleys:

- Purpose: power and speed. Power mechanisms are designed to transport heavy objects. They provide gains in strength at the expense of distance and speed. High-speed pulleys allow you to speed up the process of transporting light loads by reducing the applied effort.

- According to the complexity of the scheme. In simple schemes for lifting loads using blocks, all rollers are connected in series using 1 chain or rope. Complex systems are characterized by high performance. The gain in strength comes from fewer blocks.

Pull blocks are used for the following operations:

- For tensioning cables, power lines and suspended structures.

- Together with a winch for pulling out a car or other type of transport stuck in mud or ground.

- For carrying out rigging work when transporting heavy structures.

Various types of cranes, hydraulic and electric drives are equipped with pulleys. They were also used in older elevator prototypes.

Calculation of the chain hoist

Before manufacturing a chain hoist, it is necessary to calculate the main technical characteristics of the load-lifting structure. Calculations are required for drawing up drawings and are made according to the parameters of the working premises and the weight of the load.

To determine the loads affecting the block system during operation, it is necessary to calculate the parameters acting on individual blocks:

- The force of the load being lifted (SC).

- Engine tractive force (SM).

- Deflection angle (α). When calculating the parameters of a pulley, this characteristic can be neglected, because modern devices do not have a deflection angle.

- Block diameter (D).

- Bushing diameter (d).

The equation used to find the moments of force is as follows: SM * R = SC*R + l*SC*R + N* g*d/2, where:

- SM * R is the moment of force with which the load affects the block system.

- l – coefficient characterizing the rigidity of the hand rope when bending around the roller. It depends on the structure of the rope turns and is determined experimentally.

- Pulley axle load. It is determined by the formula: 2*SC*R.

- g – coefficient characterizing the friction force of the pulley bushing.

The efficiency of the pulley is determined by the following formula: η = SC/SM. This parameter is influenced by the quality of the blocks and the complexity of the circuit. There are the following efficiency levels of the block system:

- 97% - used as an average value if the elements of the lifting device contain rolling bearings and bushings made of bronze.

- 95% - plain bearings are used.

- 93% and below – when the lifting mechanism operates in harsh natural conditions or in rooms with high temperatures.

When calculating, it is also recommended to determine the efficiency of the remaining bypass rollers, depending on the design features of the lifting mechanism.

Methods for attaching a rope to a lifting mechanism

The cargo rope allows you to automatically fix the lifted load, which affects the passage of knots. It must be filled in such a way that there is no possibility of chafing due to frequent contacts with other parts of the lifting structure. There are 3 main methods of attaching a rope to a pulley system:

- Using gripping units made from cords with a diameter of up to 8 mm. They have high strength and begin to slide off the rope only when the load is 10 – 13 kN. The gripping knots do not subject the rope to deformation. With prolonged use, they melt the braid and stick to the rope, becoming fuses.

- Using a general direction clamp. It is recommended for use on wet and icy ropes. The clamp begins to slide without deformation at a load of 6-7 kN.

- Using a personal clamp. It slips under loads of 4 kN, breaking the braid.

To secure crane ropes, you need to secure 1 end of the rope with a lock or cable clamp. On winches, the cable is fixed to special fastenings using a wedge and a clamping bar.

The simplest do-it-yourself lifting mechanism

In home workshops you can make a simple chain hoist from scrap materials. It is capable of lifting light loads and can only be used for occasional jobs. To make a chain hoist with your own hands, you need to purchase the following components:

- Threaded studs made of metal materials.

- 2 videos.

- Bearings.

- Rope or cable.

- Hook.

A bearing is installed on a steel stud, a nut is screwed on and locked. A hook is attached to the stud to reduce the effort required to rotate the homemade shaft. The first end of the rope is located on a static platform.

To lift the load, you need to pull the second end of the cable up. For ease of operation, it is recommended to make an additional block and pass a rope through it.

This will allow you to connect the rope to the winch and fix the transported object in an intermediate position.

Refilling chain hoists

Reeving is a procedure for changing the location of pulleys and the distance between them. The purpose of this operation is to regulate the speed and height of lifting loads in accordance with a certain pattern of cable passage through the blocks of the lifting mechanism. There are the following types of reserve:

- One-time. 1 rope is attached to the hook, which is passed through all the fixed blocks and wound onto the drum.

- Double. The first end of the rope is attached to the head of the crane's rotating element, the second - to the winch. This reeving method can be used on jib-type cranes.

- Quadruple. 2 working branches of the cable are routed through the working boom pulleys. Adjacent pulleys are fastened together using a static block installed on the platform stand. This reeving method is used for heavy-duty applications.

There is also variable reeving. It can be either double or quadruple. The movable rollers are mounted on several movable cages held by a rope. The reeving ratio is changed by lowering the hook suspension onto the support while reeling in the rope.

Do-it-yourself chain hoist for a car - Metalworker's Guide

≡ April 5, 2021 Category: Interesting to know

A person is not very strong for lifting large loads, but he has come up with a lot of mechanisms that facilitate this process, and in this article we will discuss pulleys: the direction and design of systems of this type, and we will also try to make the simplest version of such a device with our own hands.

1 How do we make lifting easier?

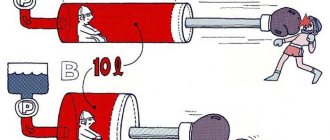

A cargo pulley is a system that consists of ropes and blocks, thanks to which you can gain effective strength while losing in length. The principle is very simple. In length we lose exactly as many times as we win in strength.

Due to this golden rule of mechanics, it is possible to lift large loads without exerting considerable effort. Which is usually not very critical. Let's give an example.

Now you have gained 8 times the strength, and you will need to take out a rope 8 meters long to lift the object to a height of 1 meter.

The use of such devices will be more affordable for you than renting a crane for lifting work; moreover, you can control the gain in strength yourself.

The pulley has two opposite sides: one of them is fixed, which is fixed on the support, and the rest is movable, which clings to the load itself.

The gain in strength is achieved thanks to the movable blocks, which are fixed on the movable side of the pulley. The fixed part serves solely to change the path of movement of the rope itself.

Types of pulleys are distinguished by problem, parity and multiplicity.

According to the problem, there are ordinary and difficult mechanisms, and the multiplicity means multiplying the force, in other words, if the multiplicity is 4, then in theory you gain 4 times in strength.

Also, infrequently, but still, a high-speed pulley is used; this option provides a gain in the speed of moving loads at a very low speed of the drive components.

2 How does conventional block construction work?

Let's first consider a simple assembly pulley. It can be obtained by adding blocks to a support and a load. In order to get an odd mechanism, you should strengthen the end of the rope on a moving point of the load, and in order to get an even one, we fix the rope on a support.

When adding a block, we gain +2 to strength, and the moving point provides +1, based on this. For example, in order to get a pulley for a winch with a multiplicity of 2, you should strengthen the end of the rope on a support and use one block, which is fixed to the load.

And we will have an even view of the device.

The working principle of a chain hoist with a multiplicity of 3 looks different. Here the end of the rope is fixed to the load, and two rollers are used, one of which we fix to the support, and the other to the load. This type of mechanism provides a 3-fold gain in strength; this is an odd option.

To understand what the gain in strength will be, you can use a simple rule: how many ropes come from the load, such is our gain in strength.

In most cases, pulleys with a hook are used, on which, essentially speaking, the load is fixed; it is wrong to think that it is just a block and a rope.

3 Difficult block system - how to calculate the gain in strength?

Now let’s find out how a difficult type chain hoist works. This name refers to a mechanism where several conventional versions of this cargo device are connected into one system; they pull each other.

The gain in strength of such structures is calculated by multiplying their multiplicities. For example, we pull one mechanism with a multiplicity of 4, and another with a multiplicity of 2, then our theoretical gain in strength will be equal to 8.

All the above calculations take place only for wonderful systems that do not have friction force, but as practice has shown, things are different.

In any of the blocks there is a small loss in power due to friction, since it is still spent on overcoming the friction force. In order to reduce friction, we must remember: the larger the bend radius of the rope, the less frictional force will be.

It is advisable to use rollers with a large radius where this is feasible. When using carabiners, it is necessary to make a block of similar options, but rollers are much more effective than carabiners, since the loss on them is 5-30%, but on carabiners it is up to 50%.

It is also useful to know that the most effective block should be placed closer to the load to obtain the greatest effect.

How can we calculate the real gain in power? For this, it is important for us to know the efficiency of the blocks used. Efficiency is expressed by numbers from 0 to 1, and if we use a rope of large diameter or too stiff, then the effectiveness of the blocks will be much less than indicated by the manufacturer.

To calculate the gain in strength of difficult types, you need to multiply the real strengths of the ordinary ones that it consists of.

4 Rope and its role in the operation of the pulley system

It is also necessary to remember about the friction of the rope, since its branches can twist among themselves, and the rollers from high loads can gather and pinch the rope.

To prevent this from happening, the blocks should be spaced apart in relation to each other, for example, you can use a circuit board between them. It is also necessary to buy only static ropes that do not stretch, since dynamic ones give a serious loss in strength.

To assemble the mechanism, either a separate or a cargo rope can be used, attached to the load regardless of the lifting device.

The advantage of using individual rope is that you can quickly assemble or prepare a load-lifting structure in advance. You can also use its entire length, this also makes it easier to pass the knots.

One of the disadvantages is that there is no possibility of automatic fixation of the lifted load. The advantages of a cargo rope are that automatic fixation of the lifted object is possible, and there is no need for an individual rope.

Among the disadvantages, the main thing is that it is difficult to move the knots during operation, and you also have to waste a cargo rope on the mechanism itself.

Let's talk about the reverse motion, which is inevitable, since it can appear when the rope is caught, or at the moment of removing the load, or when stopping to rest. To prevent reverse motion, you need to use blocks that allow the rope to pass only in one direction.

At the same time, we organize the structure so that the blocking roller is fixed first from the object being lifted. Due to this, we not only avoid backtracking, but also allow us to fix the load for a certain period of time during unloading or simply rearranging the blocks.

If you use a separate rope, then the locking roller is fixed at the end of the load being lifted, and the locking roller should be very effective.

5 Options for fastening the rope to the lifting mechanism

Now a little about fastening the lifting mechanism

to the cargo rope. It’s not often that we have a rope of the required length nearby to fix the moving part of the block. Here are a couple of types of mechanism mounting.

How to lift a load to a height with your own hands?

Almost any construction site cannot be done without special equipment, especially a construction crane. It becomes an indispensable assistant when it is necessary to lift heavy loads to different heights.

Most people associate this technology with huge size, but there are many types of faucets that are ergonomic and compact.

You can even do some options yourself, saving personal savings during construction. In this article we will look at how to assemble a homemade Pioneer crane for building a house.

Mini construction crane: scope of application

Mini cranes are in great demand. They are used during construction and repair work. Modern manufacturers offer innovative solutions in the manufacture of their products.

These devices are different:

- maneuverability;

- wide range of applications;

- functionality;

- ease of use.

Thanks to the presence of various attachments, various manipulations can be carried out with this technique.

Mini cranes, both purchased and assembled at home, are capable of working in the most difficult to reach places: in cramped courtyards, dense urban construction, uneven sites, inside buildings and on roofs. Compact dimensions allow special equipment to even pass through single or double doors.

They are often used for fine, almost jewelry work.

Manufacturers of modern technology conducted an experiment with a matchbox that had to be moved from one place to another.

At the same time, the device did not crush or crush a cardboard box of such a tiny size.

The presence of a control panel for the units allows users to control the work process while standing next to the equipment near the load, but only purchased units assembled in production have such advantages.

You are unlikely to be able to make such a device yourself. But you can try to build something similar.

Of course, a mini crane assembled by yourself will not be very functional, but it will be able to lift loads of a certain mass to a specified height.

Simple mini-faucet with your own hands

If you make a mini crane with your own hands, it will be able to lift loads weighing up to 250 kg. This will greatly simplify the construction process on site.

It can handle lifting logs, concrete mortar, and roofing materials.

With it, you can do construction yourself without involving a large number of workers.

The main thing when making a mini crane is to prepare a drawing, the necessary tools and parts. The weight of this structure can reach 300 kg.

It depends on what materials you will use during assembly.

Despite its impressive weight, the mini crane will be distinguished by its compact size and high performance.

Assembling a mini crane with your own hands consists of the following steps:

- Using a gearbox, a cargo winch is attached to a worm base.

- Construction supports are the basis for screw outrigger systems.

- In addition to the basic structure, drums for winches will be required to assemble the unit. Making them on your own is quite problematic. Therefore, it is recommended to purchase ready-made products.

- Rotors from an electric motor can be used as a basis.

Attention: when assembling a mini crane yourself, special attention must be paid to the ratio of the sizes of the elements and the dimensions of the future device.

To make the device convenient to use, its platform can be equipped with wheels. This is where the old transport cart comes to the rescue.

Features of mini cranes assembled by yourself include:

- The optimal boom height is 5 meters. To make it yourself, you will need to use a pipe with a diameter of 8 cm.

- A profile of 2 corners is mounted on the base and a rotating mechanism is created to rotate the boom. An automobile hub from a truck is suitable as a turning mechanism.

- To build a counterweight, you don’t need any special materials. Ordinary bricks can serve as them.

Types of manual taps

All construction cranes are classified into:

- self-propelled;

- stationary;

- tower;

- special purpose.

This equipment is equipped with a boom extension mechanism, a cargo trolley, and a rotating support.

By type of movement they are divided into:

- stationary;

- adjustable;

- self-elevating;

- mobile.

According to the type of control, these devices are electrically driven and manual (mechanical).

Lift

Modern lifts are divided by type into:

- Foot. They are capable of lifting heavy loads weighing up to 2 tons to a height of 8 meters.

- Telescopic. Their advantages include: light weight and compactness. These devices are capable of lifting loads to a working height of up to 150 kg.

They, in turn, are divided into:

When choosing a lift, it is worth considering several factors: their dimensions, load capacity, scope of application.

https://www.youtube.com/watch?v=5TXmEhIBS5ou0026t=32s

To make a lift yourself, prepare materials and a preliminary drawing. To build it we will need:

- a winch, which can be made from a drum and a cable;

- pipes;

- electric drive

The advantages of construction hoists include:

- maneuverability;

- high load capacity;

- safety;

- ease of use.

Scissor crane

The scissor crane is a simple and easy-to-use design.

Due to their versatility and functionality, these devices are used in installation and construction work.

They can also often be found in supermarkets and warehouses.

A scissor crane lifts tons of loads every day. This technique, in addition to the construction industry, is regularly used in the maintenance of advertising billboards, facade signs, and elevators.

Their main advantages include:

- performance;

- high load capacity;

- compact dimensions when folded;

- wide range of applications;

- maneuverability.

Their advantages also include autonomy - they can operate on batteries. In addition, cranes can be equipped with different types of drives:

- electrohydraulic;

- diesel;

- electrical;

- hydraulic.

Most often, models with electric drives are used in construction. They are affordable, environmentally friendly and easy to use.

There are a large number of variations of devices of this type, but almost all of them consist of:

- lifting device,

- mobile platform;

- equal-speed drive wheels.

To build a scissor crane yourself, you will need to make the base and platform of the apparatus from a channel. To make scissors you will need:

- two-section distributor;

- bushings;

- pump;

- hydraulic cylinder;

- I-beams.

A DIY scissor crane is capable of lifting loads weighing up to half a ton.

This device is installed on the UAZ, and after operation it is removed.

The basis of the structure will be a thick square bolted to the frame, and the retractable pores will be held on the car bumper.

Crane Pioneer

The Pioneer type lift has excellent technical characteristics.

It is light in weight and distinguished by maneuverability and mobility.

The advantages of this device include the ability to quickly and easily assemble and disassemble.

To deliver the device to the construction site, it can be disassembled and folded into a simple gazelle.

After work, it can also be easily disassembled and transported back.

The crane can be installed anywhere: on the ground, in a pit, on a roof, on building floors.

This special equipment is produced by different companies in three main modifications of cranes, lifting capacity, and booms.

If necessary, you can make a Pioneer crane on your own, having with you the necessary consumables, tools, a well-drawn drawing and free time.

As for the scope of application of the Pioneer, it can be used to move various objects in any weather conditions.

It is capable of delivering cargo to any floor or building structure.

With its help you can deliver: tools, equipment, building materials and the like.

How to lift a load to a height with your own hands

The weight of objects can be such that one, or even five people, cannot move them manually, but it is necessary.

In such cases, a homemade device for lifting or moving heavy objects will come in handy. A hand winch is the most popular device in this business.

It’s not at all difficult to make a manual winch for a garage with your own hands, even at home. But first you need a calculation and a drawing of the mechanism.

Types of lifting devices

What the pulley for lifting loads and the construction crane have in common is the use of the idea of increasing force - the rule of leverage. In order to balance the load on the short side of the lever, you need to apply less force to its long side to the extent that the short arm is less than the long one. The ratio of forces at the ends of the lever is called the gear ratio.

You can balance and even lift a weight with an effort less than its weight, but the path made by the end of a long lever will be longer than that of a short one, just as less force was applied to lift it. There is no gain in work (F1*L1=F2*L2), but this is not required.

We create a simple lifting mechanism with our own hands

Any construction site cannot do without effective and simple devices to facilitate labor and increase the speed and quality of the object being built. Today in this article I will talk about some of them, the simplest and most effective.

The easiest way to climb along guides, two ropes and fixed guides are enough for it.

This method is simple, but there are some tricks and difficulties; you need to pull at the same time and the guides must be securely fastened.

This is a very simple device, but it also makes the work easier, since the force is applied downwards, and this is always easier than simply pulling on the rope.

A lift in the form of a well crane perfectly reduces the time for lifting loads. The only negative is that. that lifting heavy loads using such a device is very difficult.

But lifting the load is much easier than without a counterweight.

Types of chain hoist fastenings

With the help of chain hoists, you can make your work several times easier. It all depends on the method of securing it.

If you apply fastening number 1, then the force will be equal to the weight of the load being lifted;

2- two times less than in the first case;

3 – three times less;

4 – four times less than in the first case.

With the help of a chain hoist you can lift a load without making much effort.

The figure shows the types and methods of fastening simple lifts with pulley blocks. Lifting mechanisms are made rotating and simple non-rotating.

To facilitate lifting, an electric drive is installed and beam cranes are installed. Such mechanisms completely replace a truck crane.

This is, of course, only a small part of all the devices and you can’t tell about them all in one article. So, wait for the continuation.

The most interesting and useful devices for construction

When building any object, be it a house or something else that requires lifting heavy objects to a height, you need to go in two ways.

The first and easiest way is to hire people to lift heavy materials such as mortar, concrete or something similar.

Second, make a lifting mechanism capable of lifting heavy loads.

This device can replace at least three people and it is made of an aluminum ladder and an electric hoist.

Such a lift is capable of lifting three buckets of concrete and can be used alone. It’s not difficult to make a welded frame on bearings, and anyone with a little knowledge of electric welding can easily attach an electric hoist to the top of a ladder.

If you attach the electric hoist as shown in the photo to a well-reinforced beam, then you will get a very convenient device that can easily replace a crane.

Pulley hoist

A pulley block is a system of 2 or more blocks entwined with a chain and used to lift the load. Now you know another way to lift a load to a height without a crane. It was first used when a mechanism appeared to lift rigging and heavy building blocks during the construction of a building. They are based on the principle of moving or lifting building materials and much more with minimal effort.

Work at height using a chain hoist includes:

- Lifting furniture, equipment, jacuzzi, building materials through window openings into housing.

- Lifting equipment and building materials onto the roof of a home.

- Installation of air conditioner, satellite dish.

- Washing window openings and painting the facade to a high standard.

- Repair and sealing of the seam of a panel high-rise building.

- Installing a banner on the facade of the building.

- Tree pruning, aesthetic crowning of plantings and for other types of work.

A device for lifting weights such as a winch or chain hoist: how to make it yourself

The weight of objects can be such that one, or even five people, cannot move them manually, but it is necessary.

In such cases, a homemade device for lifting or moving heavy objects will come in handy. A hand winch is the most popular device in this business.

It’s not at all difficult to make a manual winch for a garage with your own hands, even at home. But first you need a calculation and a drawing of the mechanism.

Types of holding mechanisms

To ensure that the transported part is held firmly on the lift, there are several types of holding devices:

- Rope slings.

- Special grips.

- Traverses.

- Remote controlled sling devices.

The sling itself is a removable device for lifting weights, in appearance resembling a piece of steel rope with several fasteners at both ends. These can be rings, hooks, carabiners or a rope loop.

How to make useful mechanisms and tools for construction with your own hands

It doesn’t matter whether you’re building your dream home or renovating an old country house, you can’t do without reliable tools and construction equipment.

Almost any device today can be bought in a store, but purchases are not always pleasing with quality and even less often with prices.

Our forum members know how to reduce the burden on the family budget and offer recipes for proven mechanisms and tools for construction, made with their own hands.

Manual drum winches

The principle of operation of winches resembles a simple lever fixed at a fulcrum.

If the short arm of the lever is the surface of the cylinder, and the load is attached to it by a cable, you will get a winch with a gear ratio equal to the ratio of the length of the lever and the radius of the cylinder.

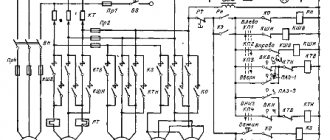

To prevent reverse rotation, a ratcheting mechanism with a spring-loaded pawl is installed on the axis - a ratchet. You can assemble such a hand winch with your own hands according to the drawing:

However, the high gear ratio of the system will require a very long handle, which is inconvenient. The solution is found in two types of drum winches, which increase the gear ratio using gears or a worm gear.

How to make a winch with your own hands using a worm gear can be seen in the drawing:

A ratchet is not needed in this design; the gear ratio, when the worm flange passes over each gear tooth, is equal to the number of gear teeth multiplied by the ratio of the length of the handle to the radius of the worm. But a significant disadvantage will be the friction between the teeth and the comb. The mechanism requires constant lubrication.

A gearbox made of gears operates with much less friction. When using the principle of transmitting force through a pair of gears of different diameters, the easiest way to make a manual drum winch with your own hands is this:

Please note that a stopper is required in such devices. This design is used for small heights or lengths of cargo movement. A cable guide will help increase the movement distance by evenly distributing the cable along the length of the cylinder. The easiest way to get the result is to use a spring-loaded plate or rod that presses the cable to the drum:

Truck...from the old four

Bring sand, crushed stone, boards, transport a concrete mixer and an old refrigerator... The need to deliver materials and tools during construction arises constantly. FORUMHOUSE member g8o8r8

found a way to save on freight transportation: he converted his old four into a truck!

Calculation of the chain hoist

Before manufacturing a chain hoist, it is necessary to calculate the main technical characteristics of the load-lifting structure. Calculations are required for drawing up drawings and are made according to the parameters of the working premises and the weight of the load.

To determine the loads affecting the block system during operation, it is necessary to calculate the parameters acting on individual blocks:

The equation used to find the moments of force is as follows: SM * R = SC*R + l*SC*R + N* g*d/2, where:

The efficiency of the pulley is determined by the following formula: η = SC/SM. This parameter is influenced by the quality of the blocks and the complexity of the circuit. There are the following efficiency levels of the block system:

How to lift a load to a height without a crane?

Almost any construction site cannot be done without special equipment, especially a construction crane. It becomes an indispensable assistant when it is necessary to lift heavy loads to different heights.

Most people associate this technology with huge size, but there are many types of faucets that are ergonomic and compact.

You can even do some options yourself, saving personal savings during construction. In this article we will look at how to assemble a homemade Pioneer crane for building a house.

The simplest do-it-yourself lifting mechanism

In home workshops you can make a simple chain hoist from scrap materials. It is capable of lifting light loads and can only be used for occasional jobs. To make a chain hoist with your own hands, you need to purchase the following components:

A bearing is installed on a steel stud, a nut is screwed on and locked. A hook is attached to the stud to reduce the effort required to rotate the homemade shaft. The first end of the rope is located on a static platform. To lift the load, you need to pull the second end of the cable up. For ease of operation, it is recommended to make an additional block and pass a rope through it. This will allow you to connect the rope to the winch and fix the transported object in an intermediate position.

Methods for attaching a rope to a lifting mechanism

The cargo rope allows you to automatically fix the lifted load, which affects the passage of knots. It must be filled in such a way that there is no possibility of chafing due to frequent contacts with other parts of the lifting structure. There are 3 main methods of attaching a rope to a pulley system:

- Using gripping units made from cords with a diameter of up to 8 mm. They have high strength and begin to slide off the rope only when the load is 10 – 13 kN. The gripping knots do not subject the rope to deformation. With prolonged use, they melt the braid and stick to the rope, becoming fuses.

- Using a general direction clamp. It is recommended for use on wet and icy ropes. The clamp begins to slide without deformation at a load of 6-7 kN.

- Using a personal clamp. It slips under loads of 4 kN, breaking the braid.

To secure crane ropes, you need to secure 1 end of the rope with a lock or cable clamp. On winches, the cable is fixed to special fastenings using a wedge and a clamping bar.

Refilling chain hoists

Reeving is a procedure for changing the location of pulleys and the distance between them. The purpose of this operation is to regulate the speed and height of lifting loads in accordance with a certain pattern of cable passage through the blocks of the lifting mechanism. There are the following types of reserve:

There is also variable reeving. It can be either double or quadruple. The movable rollers are mounted on several movable cages held by a rope. The reeving ratio is changed by lowering the hook suspension onto the support while reeling in the rope.

Source