A chainsaw is a saw with a chain that is designed for sawing wood; it is a symbiosis of a hand saw and a two-stroke gasoline engine. In addition to pruning trees, it is used in the construction of wooden structures and even for wood carving. We will look in more detail about the device, operating principle and main components in this article. This information will be useful both for informational purposes and for the purpose of selecting and purchasing such a tool for your arsenal.

Device

Despite the variety of models and different characteristics, they are all made according to the same principle. They differ mainly in the quality of the parts.

The photo shows the main elements of a chainsaw. To understand the principle of operation, you need to understand the structure and purpose of its main elements:

- Rear handle. Performs a supporting role during the execution of work. In addition, there is a gas button with a safety lock on it, which opens the throttle valve;

- Fuel tank. Fuel mixture storage tank;

- Starter handle. Used to manually start the engine. The starter is rigidly fixed to the crankshaft. Turning it starts the saw motor;

- Oil tank. A container for storing oil, which during operation lubricates the drive sprocket, saw chain and guide bar;

- Front handle. Serves to hold and guide the tool during work;

- Chain. The main working element, when rotated, wood is cut;

- Guide rail. Acts as a supporting and guiding element of the saw chain;

- Chain brake. Emergency mechanical brake with manual drive. Serves to instantly stop the cutting element when the saw jams in wood or to prevent possible contact of the chain with the operator;

- Ignition. An electronic mechanism responsible for the timely and complete supply of an electrical discharge to the spark plug.

Classification of saw chains by pitch

Depending on the pitch value, saw chains are divided into 5 classes:

- 0,25 (1/4)’’

Chains installed on one-handed chainsaws have a small pitch. Such a tool is not very powerful, but allows you to perform precise work, incl. in hard-to-reach places.

- 0.325'' and 3/8''

Chains with such pitch values are most widely used. Over 80% of the instruments produced in the world are equipped with just such chain sets.

- 0.404'' and 3/4''

Large chain sets are installed on large saws with increased productivity - felling systems, harvesting equipment, etc.

Obviously, the larger the chain links, the greater the performance it has. It should be remembered that the cut will be wider, which means that a larger saw will be needed to overcome the cutting resistance of the wood.

Design and principle of operation of individual components

To better understand the principle of operation of a chainsaw, it is necessary to consider the order of operation of its main components and mechanisms.

Engine

The main element of any chainsaw is the engine. The most widespread are single-cylinder two-stroke air-cooled internal combustion engines. They have small dimensions and weight, good power.

Such motors are distinguished by their simplicity of design and, as a result, reliability. The absence of intake and exhaust valves allows this engine to operate at high speeds.

To start the engine, you need to supply fuel to the carburetor using a primer, turn on the ignition and pull the handle. As a result of cranking the crankshaft, reciprocating movements of the piston occur.

When moving downward, the fuel-air mixture is sucked from the carburetor through a special hole in the cylinder, and when the piston reaches top dead center, ignition occurs.

As a result of the expansion of gases, the piston moves downward and exhaust gases are released through an opening located on the opposite side of the cylinder liner. Some of them remain in the combustion chamber. This makes the engine run more efficiently.

Saw set: bar and chain, lubrication system, chain tension system

The chain is the working unit of the saw. Made in the form of a flat single-row chain with sawing and tail teeth. Carbon steel is used as the material for its manufacture.

The tail or guide teeth are located on the inside of the chain. Serve to transmit torque from the drive sprocket directly to the chain. The cutting teeth are made of high-strength steel. They are used to cut different types of wood.

One of the main characteristics of a chain is the pitch and number of links. Chain pitch is measured in inches. The larger the step, the higher the power of the tool, and hence the productivity.

The bar is the guiding element of the chain. In addition, it helps with tension and lubrication. It is a flat structure made of elastic metal with a longitudinal guide channel. The tail teeth of the chain and oil from the lubrication system move along it.

The chain tensioning mechanism consists of an adjusting screw and a stop pin connected to the bar. When the screw rotates, the tire moves in the longitudinal plane. This creates optimal chain tension.

The lubrication system ensures a continuous supply of oil to the saw bar and chain, extending their service life. It consists of oil lines and a plunger oil pump, which is connected to the drive sprocket. Rotating, it transmits force to the chain and drives the plunger, which creates the necessary pressure in the oil lines to constantly lubricate the working element.

What is a primer and how does it work?

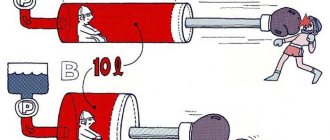

The primer serves to pre-pump fuel into the carburetor chamber, thereby facilitating engine starting. As a rule, it is made of transparent oil and petrol resistant material. The primer body is an elastic diaphragm directly connected to the fuel line.

Fuel is pumped by pressing the housing. The transparent manufacturing material allows you to control the amount of fuel entering the system.

This rubber cap is the primer - the fuel pump

Ignition system

Serves for timely ignition of the fuel-air mixture. Modern saws use a non-contact capacitor ignition system. Its use made it possible to simplify the electrical circuit of the instrument and make it more reliable.

Such a system consists of:

- Flywheel with magnets (aka flywheel).

- Ignition coils.

- Modular board with a capacitor or thyristor.

- High voltage wire.

- Spark plug.

The operation of the ignition system is based on the principle of creating an electromagnetic field resulting from the rotation of a flywheel with magnets. This field charges the capacitor, which at the required moment transmits a discharge to the ignition coil. Passing through the turns of the coil, the electric current is amplified many times and is supplied through a high-voltage wire to the spark plug, which ignites the fuel-air mixture.

Distinctive features of such a system are the lightness of the design and the absence of components that need to be adjusted.

Carburetor

The carburetor belongs to the fuel system of the chainsaw. Serves to prepare the fuel-air mixture and supply it to the combustion chamber of the cylinder. To simplify and facilitate the design, it is combined with a fuel pump.

Fuel is pumped into the carburetor chamber due to the reciprocating movements of a membrane mounted on the body. Fuel is pumped into the pre-filling chamber.

Then it is fed through the jets into the main one, where the oil-fuel mixture is mixed with air in the required proportions. After the mixture is formed, through a special hole connected to the cylinder, it is drawn into the combustion chamber, where ignition occurs.

We also recommend reading an interesting article about the design of a modern chainsaw carburetor.

Clutch

To transmit torque from the engine to the drive sprocket, modern chainsaws use a centrifugal clutch. The leading element is made in the form of several friction counterweights connected by cylindrical or spring extension springs.

The Patriot chainsaw clutch is visually similar to the Husqvarna design

They are designed in such a way that when the engine is off or idling, the springs hold the counterweights in place. As engine speed increases, centrifugal force increases and the clutches engage with the driven clutch element. It is made in the form of a hollow drum and is rigidly connected to the drive sprocket.

We also recommend reading an informative article about the chainsaw clutch; it covers all the main points, from design to repair.

Starter

Most modern chainsaws are equipped with a manually operated mechanical starter. It is necessary to start the engine by turning the flywheel and crankshaft. Consists of such elements as:

- Crank;

- cable;

- tape spring with casing;

- ratchet with thrust elements.

To start the engine, the operator must turn on the ignition and pull the crank several times. At the same time, the cable is pulled out, unwinding the ratchet. Under the influence of centrifugal force, the thrust elements of the ratchet engage with the flywheel, spinning it.

Starter housing, inside view

Each time the cable is pulled, the flywheel and crankshaft rotate up to four times, which is enough to start the engine. The ribbon spring acts as a reversing mechanism, returning the cable to its original position.

Air purification system and air filter

To properly prepare the fuel-air mixture, an air line is connected to the carburetor. When the piston moves downward, a vacuum is created in the combustion chamber, with the help of which air is drawn into the mixing chamber of the carburetor, mixing with fuel, and then into the combustion chamber.

To prevent foreign particles from entering the carburetor, the manufacturer installs a filter at the entrance to the air line. It is made from various materials. The most common of them are polyurethane foam and paper.

During operation, the filter becomes clogged, but the design features allow it to be cleaned with a stream of compressed air or by washing in warm soapy water.

Security systems

The chain brake mechanism is responsible for the safety of the operator when working with the tool. It is a safety device that allows you to instantly stop the movement of the chain, without stopping the engine. The most widespread are contact and inertial mechanisms. Both of them are connected to the clutch, instantly separating the clutches and the drum.

The contact brake is activated when the operator presses the safety handle located on the top of the saw. Shifting the handle sets the brake band in motion, which, when wound around the clutch drum, separates it from the clutches.

An inertia brake works in a similar way to a contact brake. During operation, dynamic shocks may occur that throw the tool. When the saw returns sharply, the operator involuntarily presses the brake handle, instantly stopping the movement of the chain.

The most common tool malfunctions

No matter how competently the unit is operated, problems occasionally arise in the operation of its systems. To fix them, you need to determine the cause. Knowing the design of a chainsaw, we can say that most often problems arise with the operation of the engine . However, do not forget about other components that are also subject to wear.

Problems with the power plant

It can take quite a lot of time to identify the cause of an engine malfunction. Among the main signs of failure, several main ones should be noted:

- The engine does not start.

- The power plant starts to work, but quickly stalls.

- Maximum power is not achieved at idle speed.

- There are interruptions in work.

When diagnosing a malfunction, it is necessary to use the method of exceptions. It is better to start checking with those reasons that will require a minimum of time to eliminate. Most often, a power plant malfunction is associated with the ignition system. It is the condition of the spark plug that can say a lot about the operation of the entire engine. First, using a special key, you need to remove this element and then check its external condition. The performance of the ignition system can be easily determined by sparking. When a strong and stable spark appears, you should proceed to inspect the fuel supply system.

The following problems are possible in its operation:

- A clogged breather cap prevents fuel flow.

- The fuel filter is dirty.

- Insufficient fuel is supplied from the carburetor to the cylinder.

To eliminate the malfunction, you should disassemble the system and clean it thoroughly. Problems with fuel supply can be caused by contamination of the corresponding filter, which interferes with the process of creating a high-quality fuel mixture. If the chainsaw stalls under load, you should inspect the muffler, in which a large amount of combustion products could have accumulated. The most difficult problem is the malfunction of the cylinder-piston group. This applies not only to the repair of Chinese chainsaws, but also to products from well-known brands. In such a situation, it is practically impossible to do without purchasing spare parts.

Lubrication system and chain brake

When using the tool, special attention should be paid to monitoring the operation of the chain lubrication system . Most often, problems arise due to clogging of the channels through which lubricant is supplied. If there is a slight oil leak, you can continue working with the chainsaw. Otherwise, it is necessary to take urgent measures to eliminate the malfunction.

The first step is to check the tightness of the connections between the fittings and the tubes. It is quite possible that these parts will need to be replaced, but everything can be done by simply replacing the sealant. Don't forget about the oil pump, which needs to be checked visually. It must be replaced if there are cracks in the housing. Problems with brake operation most often arise due to contamination of the brake band.

Classification

The main parameter by which chainsaws are classified is the time of their continuous use. According to this, they are divided into the following classes:

- Domestic. Chainsaws belonging to this class are designed for intensive work at home and in the country, up to 40 minutes a day or 20 hours a month;

- Semi-professional. It is envisaged that they are operated from 8 to 10 hours per day or 240 to 300 hours per month;

- Professional. Design features allow you to continuously operate the saw for up to 8 hours. Such a tool can withstand a load of 10–16 hours per day, and 1300–2000 per month. For example, Husqvarna 359, Husqvarna 555, Husqvarna 61

In addition to gasoline chainsaws, there are also electric ones, what is their difference and which is better, read here.

How to use a chainsaw

Using a chainsaw correctly is important to avoid injury hazards. The best information about the rules of operation of a chainsaw is stated in the instructions for it. The main thing is to hold the instrument firmly with both hands and all fingers.

How to start a chainsaw correctly

Before starting the chain saw, you need to engage the chain brake and remove the bar guard.

After this do the following:

- press the decompression valve control button, if equipped;

- activate the mode switch lever

- put the saw on the ground, pressing the rear handle with your right foot and grasping the front handle with your left hand;

- pull the starter handle until the engine starts;

- press the mode switch lever and press it until the saw starts working;

- Increase idle speed and release chain brake.

How to cut with a chainsaw correctly

To operate a chainsaw correctly, you need to follow the basic recommendations:

- Keeping the saw close to your body will help maintain balance.

- Spread your legs wide apart and bend your knees.

- Keep your back straight.

- Before moving to a new location, you need to turn off the engine by activating the brake.

Protective clothing will help protect you from accidental cuts. You should wear a protective helmet with a mask on your head, thick gloves for your hands, a padded suit for your body, and sturdy shoes for your feet.