The essence of soldering acid

Soldering acid can be used to join surfaces of different materials by introducing molten material between the parts. It's called solder. It has a lower melting point than metal.

The solder should be evenly distributed over the surface of the elements and provide good adhesion to the base. After cooling, it hardens and provides an inextricable connection between the workpieces.

The effectiveness of the presented process depends on the cleanliness of the substrates on which soldering will be applied. Soldering acid is used to prepare the surface of parts. Without it, the process will not proceed satisfactorily, and the required result will not be achieved.

What is soldering acid used for?

To perform its direct functions, the presented substance performs a number of actions. It initially cleans the surface of the workpiece from dirt and oxides. In addition to its main function, the acid prevents the appearance of traces of oxidation in the future on various types of parts.

By reducing the surface tension of the solder, soldering acid helps it spread more evenly over the surface. This leads to a reliable connection of parts.

For different metals, suitable types of soldering acid are used. It should also be taken into account that such a substance is a good conductor. Therefore, if it is undesirable for electric current to pass through this path, the electrical flow pattern should be calculated.

Types of soldering acid

To understand how to solder with soldering acid, you should consider its varieties. There are liquid, powder or paste fluxes (as soldering acid is sometimes called).

At home, soldering acid is most often used for soldering copper, silver, brass, nickel and their alloys - rosin. This substance is obtained from the resin of coniferous trees. This happens by evaporating the turpentine from it.

To solder cast iron, steel and iron, you will need an aqueous solution of zinc chloride. This soldering acid contains ZnCl. Zinc chloride is prepared by melting zinc metal in hydrochloric acid.

Orthophosphoric soldering acid is quite common. Its composition contains 1/3. This substance is fireproof. However, it should be stored strictly in accordance with the manufacturer's instructions.

Application

Rosin is a mixture of resin acids and their isomers, which is a flux, i.e. a substance that removes oxide films, grease, and other contaminants from the metal surface and protects against oxidation and corrosion. Why do you need rosin for soldering?

The tip of the soldering iron heats the metal contacts, and an oxide film instantly forms on them, preventing the solder from joining the parts. To remove this obstacle you need rosin (or flux). It is used to treat surfaces and prepare them for applying solder.

Soldering process

If you need to solder, for example, a wire to a board, then:

- First you need to warm up the wire by applying a soldering iron to it, pressing it as tightly as possible.

- After a few seconds, the wire along with the soldering iron tip should be dipped into the rosin, it will boil and be evenly distributed. This way the wire is prepared for applying solder to it.

- Use the soldering iron tip to take a small part of the solder and apply it evenly, in a thin layer, to the wire. In this case, pellets and drops should not form. There should be no untreated areas; the result is the same wire, but in tin.

- Next, you need to clean the soldering iron tip with a metal sponge or cloth and, touching the rosin, run it over the board, creating a thin layer on its surface. The surfaces are ready for soldering.

- Then attach the wire to the board, ensuring maximum contact. Press the tip of a soldering iron with a thin layer of solder onto the wire and “iron” the joint several times for better heating.

- Then let it cool and check the connection for strength.

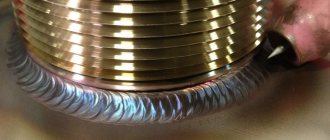

When soldering is carried out correctly, the surface of the joint is shiny, which means that it has maximum strength. If the surface is matte and looks loose, then the connection is weak.

Due to the ability of rosin to dissolve oxides of metals such as copper, lead, tin when heated, it effectively copes with this task at temperatures above 150 degrees. Rosin is used in electrical work as a natural flux. With its help, in addition to removing the oxide film, grease and contaminants, spreading is improved and the surface tension of the substance used as solder is leveled. At the same time, the seams are filled faster and the quality of the connection improves.

At home, the most common solder is low-melting tin. It is impossible to use rosin with refractory solders. Its boiling point is +250 °C, at which rosin evaporates; accordingly, the protective and cleaning properties of the flux also disappear when exposed to metal.

Orthophosphoric acid

Another type of soldering agent is It has the formula H3PO4. It is used for alloying chromium and nickel.

However, it is not used in its pure form. Acid occupies only 32% of the solution. Another 6% is allocated to rosin.

Sometimes orthophosphoric soldering acid, the composition of which is diluted with zinc chloride, can have a mass content of the latter from 50% to 0.005%. The mass fraction of insoluble residue is 0.001%, and ammonia - no more than 0.5%. The maximum pH level for such a solution is 2.9%.

Under normal conditions, the substance looks like colorless crystals with hygroscopic characteristics.

It dissolves well in water. Therefore, if it accidentally gets into your eyes, you should rinse the mucous membranes for 10 minutes with running water.

Types of flux

For different applications, rosin is available in pure and diluted form. There are three types of fluxes based on colophon resin: solid, liquid and gel. Liquid and gel-type fluxes are more expensive and difficult to produce.

It is acceptable to use rosin-based fluxes for small-sized components of a certain metal composition. Other types of fluxes are used for processing large compounds, complex alloys, rare metals and on an industrial scale.

- Solid flux is rosin in its pure form. It is the most popular and has both undoubted pros and cons. The main disadvantage is the inconvenience and inaccuracy of application to hard-to-reach solder areas.

- Flux based on an alcohol solution, diluted in equal proportions of alcohol and solid rosin. It is very convenient when applying it with a brush to the surfaces of parts that will be connected by soldering.

- Gel-based rosin flux. The viscous consistency allows you to accurately dose the applied composition and easily process the most difficult areas of the parts to be joined. The gel takes longer to dry compared to an alcohol-based composition. This gives some time for soldering; it is more plastic and pliable compared to solid rosin flux.

Liquid or gel flux is first applied with a brush to the soldering areas and begins to work without simultaneous exposure to temperature.

Making at home

The substance presented is freely available for sale. However, craftsmen still wonder how to make soldering acid at home. This is quite easy to do if you have the appropriate chemicals.

To do this you will need zinc, in the proportion of 412 g Zn and 1 liter of HCl. Zinc is placed in a glass, porcelain or ceramic container. Then hydrochloric acid is added to the laboratory glassware. This should be done very carefully. Hydrochloric acid in the container should not exceed ¾ of its volume.

To understand how to make soldering acid, you should familiarize yourself with the chemical reaction. As a result, hydrogen will be formed (bubbles will come out). When this stops, the liquid will lighten and become clear. After this, it is poured into another container and tightly closed with a lid.

How to replace soldering acid

If you cannot find soldering acid at home or even the ingredients for its preparation, you can replace it with aspirin or You must work with such a flux in a well-ventilated area. When heated, aspirin releases caustic fumes, so the technology for using such a substance differs from the usual one.

To tinning the part, it is sprinkled with acetylsalicylic acid powder. Sometimes the wires are placed on a tablet and heated with a soldering iron.

When deciding what to replace soldering acid with, you should pay attention to VTS flux. It is made on the basis of VTS and reliably protects parts from corrosion, so it is often used in repair work.

Aspirin and battery electrolyte

Many experts consider the most affordable option to be the use of pharmacy aspirin.

Please note that it will not be possible to replace rosin with effervescent tablets. They contain fillers (sodium compounds) that are not needed for soldering. Therefore, the most common simple aspirin is used.

The tablets should be crushed to a powder and dissolved in water or regular wine-vodka alcohol. You can use cologne as a solvent.

Acetylsalicylic acid dissolves well. Its properties are often sufficient to clean the surface and remove dirt. It can replace rosin without difficulty.

The inconvenience is the need to work under a ventilation hood or in a ventilated place. Solders without rosin with aspirin release sharp-smelling, harmful gases when heated. It is not necessary and impossible to breathe them.

If aspirin is not available, it is recommended to replace rosin with electrolyte from a used salt battery. It is important that it is not alkaline.

What can replace rosin for soldering?

Depending on the manufacturer, substances differ in the method of application. This could be a dropper-shaped neck or a jar with a brush. If the product is not equipped with special means for applying it to the part, you can even use just a piece of paper rolled into a tube.

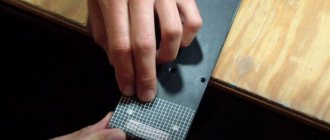

The part must be cleaned before applying acid. This is best done with a file or sandpaper. The application of a substance such as soldering acid requires serious attention. How to use it is necessarily indicated by the manufacturer in the instructions.

The substance should be evenly distributed throughout the part. At the end of the work, any flux is removed from the surface of the part. This is necessary to prevent accelerated oxidation of the surface of the workpiece and the solder itself.

You can remove acid using water or soda solution. Residues of VTS are washed off with acetone or ethyl alcohol. The soldering iron tip melts a little solder and transfers it to the surface.

Acids with stearin

It happens that there is nothing suitable for replacement nearby.

Then any acid except concentrated sulfuric and nitric acid is suitable for removing oxides. To prevent oxidation of the metal, you can thoroughly clean it and the solder, then coat them with stearin. Stearin (paraffin) can be taken from candles.

Before applying a protective layer to the metal, stearin must be melted without overheating. The protective layer will prevent contact with oxygen. Soldering should be carried out under the stearin layer.

Some craftsmen, in order to replace rosin, spread the well-known BF-6 glue onto the cleaned metal surface. In this case, you need to solder while pressing the soldering iron firmly.

The above methods are a “first aid” for a solderer. In unexpected situations, a way out can always be found using simple and accessible means. But still, for the quality of soldering, it is better to use special tools.

Precautionary measures

To avoid unpleasant incidents, you should carefully adhere to the rules for storing the substance presented. It should be stored in a tightly closed container, out of reach of sunlight, heat and children. The substance is stored at temperatures from -25°C to +35°C.

Soldering with soldering acid is carried out in a well-ventilated area. Before starting work, you must open all its windows wide. Even after completion of work, the room must be ventilated for at least 30 minutes.

During the soldering process, it is necessary to use protective equipment for the respiratory tract, eyes and skin of the hands. In case of accidental contact of the substance with the skin of your hands or eyes, you should thoroughly rinse the area with running water for a sufficiently long time.

If soldering acid gets on various surfaces, they should be cleaned with a soda solution, which is washed off with water after treatment.

Having become familiar with the essence of such a substance as soldering acid, you can safely use it in the process of repairing various equipment. Knowing its composition, as well as ways to replace acid at home, processing parts before soldering will not be difficult at all. This technology will help extend the longevity of the functioning of equipment and mechanisms of varying complexity. By performing work in accordance with safety regulations, you can not be afraid of unwanted incidents that could harm your health.

What are they made from?

Pine rosin is obtained by heat treatment of resin - the sap of coniferous trees, mainly pine. Water and turpentine are evaporated from it; after heat treatment, solid translucent pieces are formed, which are then cleaned chemically. This rosin contains no fatty acids, which can be very important when performing certain types of work. This type softens at 66-69 °C.

Extraction rosin is obtained by treating crushed wood with solvents, most often gasoline. This type is darker than all the others, it contains approximately 10% fatty acids, and it softens at a temperature of 58-60 °C.

Tall rosin is produced by distilling tall oil. This oil is a waste product from the pulp and paper industry. It softens at temperatures from 56 to 60 °C.

By the color of rosin you can determine its quality. If the shade is bright and saturated, the cleaning was not carried out according to technology and foreign impurities remain in the composition. They have a detrimental effect on properties and characteristics. The high-quality composition has a lemon tint. Gum rosin is considered the best among all types of rosin.