The air-fuel mixture to operate the engine is mixed in the carburetor. Using a special damper, you can manually lean or enrich the fuel mixture for a specific purpose - for example, for cutting hard wood.

Both the health of the engine and the performance of the chainsaw directly depend on the good technical condition of the carburetor. Let's take a closer look at how a chainsaw carburetor works.

Chainsaw carburetor design

Almost all chainsaw models use an identical carburetor design. As an exception, we can name the carburetor of some very cheap Chinese chainsaw - some parts may be missing, and most of the components are made of very cheap materials.

The main components of the carburetor are:

- Frame. It is made of aluminum to make the structure lighter and has a one-piece shape. The housing contains a diffuser, an inlet fitting, a pulse channel, a main screw and an idle screw, a damper that regulates the air supply, as well as other elements.

- Diffuser. Located at the carburetor inlet.

- Jets. Special valves through which the amount of fuel is regulated.

- Spray.

- Float chamber.

Approximate diagram of a chainsaw carburetor

The principle of operation of a chainsaw carburetor

Before you adjust the carburetor on a chainsaw, you need to understand the principle by which it works.

- When the engine starts, the air damper located at the bottom of the housing opens.

- A vacuum is created in the air channel and float chamber caused by the stroke of the piston, as a result of which an air flow is sucked through the diffuser.

- The intensity of the air flow suction is regulated by the position of the air damper.

- Gasoline enters the float chamber through the inlet fitting from the gas tank.

- The speed of passage of gasoline from the chamber to the diffuser is controlled by means of jets.

- In the diffuser, gasoline is mixed with air.

- The prepared air-fuel mixture enters the intake channels, from where it is directed into the working combustion chamber of the cylinder.

Design and operation of individual units

The design of the chainsaw is designed in such a way that fuel and oil are mixed for its operation. This solution is then poured into the gas tank, from where it is delivered to the engine and ignited with a spark. Next, the motor and chain path operate independently, and to set the cutting side in motion, the throttle button must be pressed.

Ural chainsaw diagram

Before each process, it is important to inspect the accessible structural elements of the chainsaw for serviceability: the chain should be well tensioned, the moving mechanisms should be lubricated, and the air filter should be in good condition. At the end of cutting, it is recommended to clean the tool from dirt and chips.

Ignition system

The design of modern gasoline saws has a non-contact electric starting device. Thanks to this structure, the consumer no longer has to worry about adjusting the gap and cleaning the contacts. This includes the following details:

- flywheel with magnets;

- scheme;

- candle;

- high voltage wire;

- ignition.

Rotations of the shaft create electrical signals that are sent to the spark plug through a circuit. As a result, the liquid ignites.

Carburetor unit

The purpose of this device is to mix the fuel mixture with oxygen. A wind tunnel with a damper is responsible for supplying air to the carburetor. There is also a float inside the unit that regulates the position of the sash. When the chainsaw engine turns on, the valve opens, oxygen enters the diffuser, mixes with fuel and moves into the cylinder cavity.

Carburetor diagram

The gas handle adjusts the width of the open flap, which leads to increased air flow and increased piston speed.

Clutch mechanism

Modern saws are equipped with a centrifugal clutch, which is activated automatically after pressing the throttle button. Springs are responsible for attracting the shaft, relaxing in accordance with the increase in rotation frequency. Next, the drum rotates and the saw chain begins to come into action. There is a locking tape on the outside that blocks accidental activation of the saw. It is important to monitor the locking condition very carefully, because incorrect use can lead to both damage to the tool and personal injury.

Fuel equipment

The device is composed of three components:

- filter;

- carburetor;

- pump.

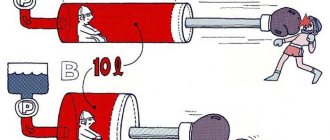

Fuel from the tank flows through a hose to the fuel mixing unit, bypassing the gas filter (it is located at the end of the pipe, which is immersed in gasoline). To facilitate the starting procedure, the fuel system of each chainsaw is equipped with a manual pump. They deliver gasoline directly to the carburetor, which will help make the start much faster.

Chainsaw fuel tank

More expensive types of saws have a mechanical pump that operates in conjunction with the cranking of the starter. To return the excess, a tube is attached and directed back into the tank.

Gas cleaning

In order for a high-quality mixture to enter the gasoline engine part, it is necessary to remove excess fumes. The pre- and fine filter parts are responsible for this function. Also, during the cold season, an additional element is installed to block the ingress of snow. However, this structure consists of dense material, which negatively affects the power. The rest of the time, standard filters made of nylon, foam rubber and similar materials are installed. Exhaust is removed by turning the flywheel, which releases fumes through a special pipe. Regular checking of this structure is a prerequisite. Otherwise, it will cause poor performance.

Starter device

It is made of a cable drum, a return spring and a housing. Such a set is attached to the crankshaft so that when the handle is pulled sharply, it rotates. Then the spring returns everything to its original position. It is unlikely that you will be able to start the engine the first time, and this requires a certain amount of physical effort.

However, it is possible to speed up this procedure if you enrich the system with a mixture from the gas tank. Also, this unwinding allows you to get a spark, due to which ignition occurs. To stop work, just press the shutdown button.

Stopping the cutting chain

The chainsaw is a high-risk device. Therefore, a chainsaw cutting chain brake is needed here. It is needed to stop in the event of a strong impact, which is likely to throw the device towards a person. Also, rotation stops if the chain breaks during impact. All this is called the inert type of brakes. But there is another (manual) type of brake. It helps to stop the spinning by pressing the corresponding handle. It should be noted that before sawing it is important to ensure the quality of the brake band. Using a saw with a faulty stopper is hazardous to your health.

Basic carburetor malfunctions on a chainsaw

It should be understood that the dimensions of all holes are very small. Even the smallest contamination can block the flow of air or fuel, which is why filter elements are installed at the inlet ports. Unfortunately, they do not always cope with the task. The following signs indicate a malfunction of the chainsaw carburetor:

- High gasoline consumption and thick smoke from the exhaust;

- The engine “does not pull”;

- Floating speed;

- The engine starts, but stalls immediately or after a few seconds;

- The engine does not start at all.

- Chainsaw shoots at carburetor

All these malfunctions are a sign that the carburetor on the chainsaw is not adjusted correctly or that it is dirty. This implies the need for adjustment, cleaning or repair. Let's look at how to do this below.

How to properly adjust the carburetor on a chainsaw with your own hands

The factory settings of the chainsaw carburetor provide optimal fuel and air suction parameters. But during operation, they can become confused due to vibration - even a ¼ turn shift in any of the screws can lead to a serious change in the parameters for preparing the air-fuel mixture and it is necessary to adjust the chainsaw carburetor.

The chainsaw carburetor is adjusted using three screws marked H (High), L (Low) and S. The last screw, depending on the brand and manufacturer, may have other names, for example T or LA.

- H: is responsible for the operation of the main jet and regulates the maximum speed.

- L: adjusts the position of the idle jet and allows you to set low speed.

- S/T/LA: designed to regulate engine idle speed.

To know how to properly adjust the carburetor on a chainsaw, you need a technical passport - it indicates information about the angles of rotation of the adjusting screws. After this, we proceed directly to the adjustment. By the way, here you will need a screwdriver to adjust the chainsaw carburetor or a regular flat-head screwdriver:

- Place the chainsaw on a flat surface, preferably a table or something similar. IMPORTANT: The chainsaw must be positioned so that the bar points in the opposite direction. The engine must be turned off.

- Using a wrench or screwdriver, unscrew the fastenings of the housing casing cover and remove it to get to the carburetor.

- Remove the air filter that covers the carburetor for the chainsaw. The manufacturer may install a shock-absorbing foam insert on top of the carburetor - this must also be removed.

- Now begins setting up the chainsaw carburetor. Screws L and H must be tightened until they stop. Tighten them slowly and carefully so as not to break them.

- Unscrew both screws approximately 1.5 turns.

- Start the engine and let it run for about 7-10 minutes so that it warms up well - you won’t be able to adjust the chainsaw’s carburetor on a cold engine.

- After the engine has warmed up, set it to run at medium speed.

- Slowly begin to tighten the idle screw counterclockwise. You need to turn it until the motor runs smoothly. If the engine starts to stall, you need to continue adjusting the chainsaw carburetor and gradually return the screw clockwise.

After the carburetor of a Chinese-made or any other chainsaw has been adjusted, it is necessary to “drive” the engine at different speeds.

Expert advice

The operating principle of a Chinese chainsaw carburetor was described above. While operating the equipment, you will be able to understand when it requires debugging. Before starting this work, you need to warm up the engine at minimum or idle speed for 15 minutes. Using the L governor you should get the idle speed to be around 2000 rpm. It is important to pay attention to how the engine dials them. Acceleration should occur fairly quickly when the accelerator lever is pressed.

If you notice a drop in speed, the screw must be unscrewed a little to eliminate this phenomenon, since it is caused by insufficient fuel enrichment. The operating principle of the Partner 350 chainsaw carburetor will allow you to understand how to configure this unit. For example, when the mixture supply at low speeds is adjusted, you need to tighten screw T. This must be done until you notice the chain rotating. The screw is then unscrewed by half or a third.

It is important to monitor the alignment of the clutch mechanism. The saw should not rotate at idle speed. This is the norm. Using screw H, you can compensate for high or low speeds, which can be caused by a change in fuel, ambient humidity or a change in oil concentration.

The top setting can be thrown off when the low speed is not adjusted correctly. The operating principles of a chainsaw carburetor will allow you to understand that it is better not to touch screw H at all if you do not have sufficient experience. When the adjustment is carried out by an incompetent person, there is a risk that a lean mixture will enter the combustion chamber at high speeds. Such engine operation under load can cause rapid wear of the piston system. All this will lead to a failure in the ignition system.

How to remove a carburetor from a chainsaw?

Either the engine does not start or stalls immediately, most likely the carburetor is clogged and needs to be cleaned. How to check a chainsaw carburetor? You'll have to take it apart - otherwise it won't work.

Before cleaning the carburetor on a chainsaw, it is still recommended to check other components: air and fuel filters, spark plug and muffler. It is possible that they are clogged - it is easier to clean the filter or replace the spark plug than to clean the carburetor on a chainsaw. By the way, it is the problem with the spark plugs that is the reason why the chainsaw shoots into the carburetor - ignition too late leads to the formation of an excess of the air-fuel mixture, since it does not have time to burn completely.

If the problem persists, you will have to remove the carburetor. It's very easy to do this:

- We remove the plastic back cover - it is held on by a latch or thread.

- Remove the air filter.

- Use a flat-head screwdriver to pry up the air rods and remove them. There can be two or three thrusts, depending on the model.

- The carburetor is secured with two fasteners - they are located diagonally. You need to unscrew them.

- Disconnect the gasoline hose that supplies fuel to the carburetor from the gas tank.

How to clean the carburetor on a chainsaw?

It is necessary to flush or clean the chainsaw carburetor only when it is removed and disassembled. Before cleaning, you need to prepare everything you need in advance: two screwdrivers (plus and minus), open-end wrenches, but preferably a head with attachments, clean rags, a special cleaning agent, a pump and an ultrasonic cleaner (recommended). Before you start cleaning, you need to drain all the gasoline - this is mandatory. After the remaining fuel has been drained and the entire instrument has been prepared, we proceed to cleaning:

- Detach the top cover and remove it.

- Carefully remove the fuel pump diaphragm.

- There are spring clips on the left side of the housing. After they are disconnected, you can see screws under the brackets - these also need to be unscrewed.

- Unscrew the bottom cover.

- By unscrewing the screw, you gain access to the needle valve. It and the spring located under it must be carefully removed, and so as not to dull the needle.

- The air damper is dismantled with a slight longitudinal force, after which the damper axis is removed.

- Lastly, remove the throttle valve, lever and axle.

After the carburetor is disassembled, all parts must be laid out on a flat surface on a clean rag. Carefully inspect each part for blockage or wear. Pay special attention to the jets and inlet fitting. Their clogging is the main reason why gasoline does not flow into the carburetor of the chainsaw.

If any part shows that it is very worn out, it is better to immediately replace it with a new one, so that in the future you do not have to think again about how to repair a chainsaw carburetor. Do-it-yourself cleaning of a chainsaw carburetor is done using a special detergent. You need to rinse each part well, and then dry them with a lint-free cloth, or better yet, with compressed air. All channels are also purged with air.

If you have an ultrasonic cleaner on hand, that's even better. Pour diesel fuel into the bath, carefully place the contaminated parts there for 5-10 minutes and after cleaning, dry them with compressed air.

Assembly is carried out in reverse order. A very important point is the installation of the needle valve - it must rotate freely in the seat. If the petal sticks, lightly press it or push it down so that it sits deeper.

After cleaning, it is strongly recommended to wait 20-24 hours to allow the cleaning agent to completely evaporate. Otherwise, it will mix with the air-fuel mixture and enter the cylinder, leaving carbon deposits on the walls after combustion.

Adjusting the chain brake

The chain brake often does not work due to grease or sawdust clogging the brake band and the space under the cover. All parts should be cleared of blockages. Perhaps the tape is simply worn out, then it needs to be replaced.

The operation of the chain brake is restored by mechanical cleaning

Some parts of a chainsaw wear out faster than others. These include the drive sprocket, tire, chain, and anti-vibration elements. For quick replacement, it is better to always have spare parts on hand. Don't neglect sharpening the chain.