Chemical composition

In addition to iron, grade 60C2A steel contains about 0.6% carbon, 1.6 to 2% silicon, 0.6 to 0.9% manganese, up to 0.3% chromium, up to 0.25% nickel and up to 0. 2% copper. In addition, impurities of sulfur and phosphorus are allowed in amounts up to 0.025%.

Purpose of alloying components

Steel is an alloy of iron and carbon in an amount of up to 2.06%. Increasing the amount of carbon increases sensitivity to heat treatment, hardenability, and the ability to obtain greater strength and hardness. But at the same time, ductility decreases, the metal becomes brittle, unable to withstand shock loads.

In order to balance the properties of the material, simultaneously obtain opposite characteristics (hardness and toughness, strength and corrosion resistance), and reduce the influence of impurities that cannot be completely eliminated, 60C2A steel includes alloying components. They make it possible to neutralize the disadvantages introduced by a high amount of carbon. And in some ways replace it, getting even better results.

Silicon is introduced into the composition for the purpose of deoxidation. Possessing a greater affinity for oxygen than iron, it displaces it from oxides in the melt.

In addition to deoxidation in amounts up to 1%, silicon has a beneficial effect on strength and elasticity.

Manganese, like silicon, displaces iron from oxides. In addition, it prevents the formation of iron sulfides, which increase the tendency to form hardening cracks that occur during thermal hardening of parts with complex shapes.

The inclusion of manganese in the alloy up to 1%, like silicon, increases strength and toughness. In large quantities, it causes grain growth, which reduces strength indicators, in particular the ability to withstand shock loads.

Thus, silicon and manganese mutually complement each other in composition. They work together to increase strength, endurance and toughness. But the reasons leading to increased fragility of the alloy are not allowed to develop.

Chromium, like silicon and manganese, has a greater affinity for oxygen than iron. It helps protect the melt from oxidation and increases hardenability.

Nickel helps protect the alloy from corrosion and, in small quantities, reduces the susceptibility to hardening cracks.

Copper in small (up to 1%) quantities increases strength and resistance to corrosion. At higher concentrations, it leads to the precipitation of intermetallic compounds along grain boundaries, which significantly changes the mechanical properties during tempering.

Comparing the chemical composition and the influence of individual components on the properties of the alloy, it can be assumed that the 60C2A grade should have high strength, elasticity, and impact strength, achieved by observing special heat treatment techniques.

Steel 60S2A spring-spring

Decoding

According to GOST 14959-2016, the number 60 before the letter designation indicates the average mass fraction of carbon in steel in hundredths of a percent, i.e. the average mass fraction of carbon in steel is 0.60%. The letter C means that the steel is alloyed with silicon (Si), and the number 2 indicates the approximate mass fraction of silicon in whole units, i.e. silicon in steel is approximately 2%. The letter A at the end of the steel name means that the steel is high quality, i.e. steel with increased requirements for the chemical composition and macrostructure of metal products made from it compared to high-quality steel.

Substitutes and analogues

60S2N2A, 60S2G, 50HFA.

Foreign analogues

| Germany DIN (EN) | 60Si7 (1.5027) [1] |

| USA (AISI, ASTM) | 9260 |

| UK (BS) | 251A60 |

| Japan JIS | SUP 6 |

| Poland PN/H | 60S2A |

Type of delivery

- long products, including shaped steel, GOST 14959-79, GOST 2590-88, GOST 2591-88, GOST 2879-88, GOST 7419.0-90 - GOST 7419.8-90;

- Calibrated rod GOST 7417-75, GOST 8559-75, GOST 8560-78;

- Tape GOST 2283-79, GOST 21997-76. Strip GOST 103-76, GOST 4405-75;

- Wire GOST 14963-78. Forgings and forged blanks GOST 1133-71, GOST 14959-79;

- Polished rod and silver GOST 7419.0-90 - GOST 7419.8-90, GOST 14955-77;

Characteristics and Application

Steel 60C2A is an alloyed special steel used for the manufacture of the following products:

- heavily loaded springs,

- torsion shafts,

- spring rings,

- collet,

- friction discs,

- Grover washers,

- springs made of strip steel 3-16 mm thick,

- springs made of strip steel with a thickness of 3-18 mm and spring strips with a thickness of 0.08-3 mm,

- twisted springs made of wire with a diameter of 3-12 mm.

Steel is prone to decarburization, is resistant to grain growth, and has deep hardenability. The maximum operating temperature is +250 °C [2], in aircraft construction it is recommended to use steel no higher than a temperature of +200 °C [3].

Conditions for using steel 60S2A for disc springs (GOST 33260-2015)

| ND for supply | Spring standard | Application temperature, °C | Additional instructions for use |

| Assortment GOST 2283, GOST 7419. Technical requirements GOST 14959 | GOST 3057 | -60 to 120 | Used for work in conditions of atmospheric corrosion with anti-corrosion coatings* |

*After electrochemical coatings, heat treatment (tempering) is required to remove hydrogen embrittlement, as indicated in the design documentation.

Conditions for using steel 60S2A for helical coil springs (GOST 33260-2015)

| ND for supply | Application temperature, °C | Additional instructions for use |

| Wire GOST 14963. Rolled products GOST 2590 | -60 to 250 | Safety and pressure relief valves, bypass and shut-off valves, etc. |

NOTE. For class II springs, it is allowed to replace rolled grade 60C2A with grade 60C2.

Maximum permissible dimensions of metal products made from steel 60S2A for the manufacture of springs and springs (GOST 14959-2016)

| strip thickness | diameter or side of a square |

| 14 | 20 |

Chemical composition, % (GOST 14959-79)

| C | Mn | Si | Cr | Cu | Ni | S | P |

| no more | |||||||

| 0,58-0,63 | 0,60-0,90 | 1,6-2,0 | 0,30 | 0,20 | 0,25 | 0,025 | 0,025 |

Chemical composition, % (GOST 14959-2016)

| steel grade | Mass fraction of elements, % | ||||||||

| WITH | Si | Mn | Sk | V | W | Ni | B | Cu, no more | |

| 60С2А | 0,58-0,63 | 1,60-2,00 | 0,60-0,90 | No more than 0.30 | — | — | No more than 0.25 | — | 0,20 |

Temperature of critical points, °C [4]

| Ac1 | Ac3 | Arc3 | Arc1 | Mn[5] |

| 770 | 820 | 770 | 700 | 305 |

Recommended processing modes for springs made of steel 60S2A [2]

| Temperature, °C | Hardness HB of finished springs | |

| oil hardening | vacations | |

| 850-870* | 460-480 | 418-387 |

*When bending sheets and hardening with one heating, the temperature rises to 900-950 °C.

Recommended heat treatment [3]

Low annealing at 650-700 °C; hardening from 870±10 °C in oil, tempering at 430-490 °C (HRC 44-48, σв = 155-180 kgf/mm2)

Hardness of metal products made from steel 60S2A as delivered (GOST 14595-2016)

| Hardness of metal products, HB, no more | |

| without heat treatment (categories 1 B, 2B, ZB, 4B, ZG, ZD and ZE) | heat-treated (categories 1A, 2A, ZA, ZB and 4A) |

| 302 | 269 |

Mechanical properties of metal products during tensile testing (GOST 14595-2016)

| Recommended mode of thermal treatment of samples | Mechanical properties, no less | ||||||

| Hardening | Vacation | ||||||

| Heating temperature, °C | Cooling medium | Heating temperature, °C | Cooling medium | Yield strength σt, N/mm2 | Tensile strength σв, N/mm2 | Relative elongation δ5,% | Relative narrowing ψ, % |

| 870 | Oil | 420 | Air | 1375 | 1570 | 6 | 20 |

NOTE:

- The mechanical properties of metal products during tensile testing are determined on longitudinal heat-treated samples.

- During the recommended heat treatment, temperature deviations are allowed:

- hardening — ±15 °С;

- hardening — ±50 °С;

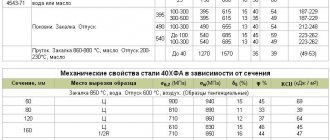

Mechanical properties of steel of various heats [3]

| Workpiece diameter, mm | σпц | σ0.2 | σв | δ5 | ψ | NV kgf/mm2 |

| kgf/mm2 | % | |||||

| 14 | — | 144 | 160 | 10 | 40 | 460 |

| — | 150 | 163 | 10 | 44 | 460 | |

| 15 | 136 | 143 | 162 | 10 | 40 | 445 |

| 135 | 142 | 162 | 11 | 45 | 445 | |

| — | 155 | 160 | 10 | 44 | 445 | |

| — | 152 | 155 | 10 | 42 | 445 | |

| 21 | 133 | 147 | 163 | 10 | 43 | 445 |

| 135 | 146 | 161 | 10 | 47 | 445 | |

| — | 155 | 163 | 11 | 53 | 460 | |

| — | 154 | 159 | 11 | 56 | 460 | |

Mechanical properties of annealed and cold-worked strip made of steel 60S2A (GOST 2283-79)

| Nominal thickness, mm | Tensile strength σв, N/mm2 (kgf/mm2), no more | Relative elongation δ4, %, not less | Tensile strength σв, N/mm2 (kgf/mm2) |

| Annealed tape | Cold-worked tape | ||

| From 0.10 to 4.00 incl. | 880 (90) | 8 | 780-1180 (80-120) |

Mechanical properties

| Source | Delivery status | Section, mm | σ0.2, MPa | σв, MPa | δ5, % | ψ, % | KCU, J/cm2 | Hardness HB, no more |

| no less | ||||||||

| GOST 14959-79 | Steel categories

Hardening at 870 °C in oil; tempering at 420 °C | — | 1375 | 1570 | 6 | 20 | — | — |

| [6] | Isothermal hardening from 860-880 “C, cooling. in molten salt at 310-330 °C; holiday at 310-330 °C, cool. on air | 10 | 1570 | 1770 | 12 | 50 | 62 | HRCе 47-50 |

| [7] | Springs. Winding at 850-950 °C; hardening from 850-870 °C in oil; holiday at 430-460 °C, cool. on air | Not defined | 388-477 | |||||

| Springs. Quenching from 850-870 °C in oil; holiday at 400-450 °C, cool. on air | Same | 387-418 | ||||||

Mechanical properties depending on tempering temperature [5]

| tref., °C | σ0.2, MPa | σ0.2, MPa | δ5, % | ψ, % | KCU, J/cm2 | Hardness HRCе |

| 300 | 1960 | 2160 | 2 | 36 | 10 | 462 |

| 400 | 1470 | 1670 | 7 | 39 | 18 | 425 |

| 500 | 1080 | 1290 | 10 | 42 | 29 | 340 |

| 600 | 730 | 1030 | 17 | 48 | — | 298 |

NOTE. Hardening at 850 °C in oil; vacation.

Mechanical properties at elevated temperatures

| tsp., °C | σ0.2, MPa | σ0.2, MPa | δ5, % | ψ, % | KCU, J/cm2 |

| Rod with a diameter of 17 mm. Hardening at 860 °C in oil; tempering at 550 °C, 3 hours, hardness HB 340-364 [8] | |||||

| 20 | 1090 | 1270 | 11-13 | 33 | 24 |

| 300 | 930 | 1220 | 15 | 44 | 43 |

| 400 | 820 | 950 | 19 | 71 | 44 |

| 500 | 510 | 590 | 23 | 87 | 43 |

| Sunset with 860 °C in oil; tempering at 425 °C [9] | |||||

| 20 | 1570 | 1710 | 10 | 46 | 32 |

| 200 | 1370 | 1670 | 13 | 40 | 34 |

| 300 | 1270 | 1570 | 20 | 58 | — |

| 400 | 1080 | 1220 | 22 | 71 | — |

Endurance Limit [6]

| Heat treatment | σ-1, MPa | n |

| Isothermal hardening, holding at 330 °C, 1 hour + tempering at 300 °C, 1 hour; σв = 1680 MPa | 686 | 106 |

| Quenching + tempering at 420 °C; σв = 1810 MPa | 637 | 106 |

| Oil hardening; tempering at 400 °C; σ0.2 = 1760 MPa, σв = 1900 MPa | 500 | — |

Impact strength KCU [10]

| Heat treatment | KCU, J/cm2, at temperature, °C | |

| +20 | -70 | |

| Hardening at 850 °C in oil; holiday at 460 °C, 1 hour, cool. on air | 39 | 34 |

Technological properties

- Forging temperature, °C: beginning 1200, end 800. Sections up to 250 mm are cooled in air, sections 251-350 mm are cooled in a pit.

- Weldability - not applicable to welded structures.

- Cutting machinability - Kv tv.spl = 0.70 and Kv b.st = 0.27 in the hot-rolled state at HB 270-320 σw = 1080 MPa.

- Flock sensitivity - not sensitive.

- Tendency to temper brittleness - not prone.

Hardenability (GOST 14959-2016)

| Hardness HRCe at a distance from the end, mm (hardening from 850 °C) | |||||||||

| 1,5 | 3 | 4,5 | 6 | 9 | 12 | 15 | 18 | 27 | 39 |

| 60-67 | 59-67 | 57-66 | 54-65 | 44,5-63 | 38,5-60 | 35,5-56 | 34-52,5 | 30-43,5 | 27-39,5 |

Critical diameter d

| Critical hardness, HRCе | Amount of martensite, % | d, mm, after hardening at 850 °C | |

| in water | In oil | ||

| 51-53 | 50 | 47-82 | 24-53 |

| 58-60 | 90 | 60 | 36 |

Density ρп kg/cm3 at test temperature, °С

| Steel | 20° | 100° | 200° | 300° | 400° | 500° |

| 60С2А | 7680 | 7660 | 7630 | 7590 | 7570 | 7520 |

Linear expansion coefficient α*106, K-1

| steel grade | α*106, K-1 at test temperature, °C | |||||||

| 20-100 | 20-200 | 20-300 | 20-400 | 20-500 | 20-600 | 20-700 | 20-800 | |

| 60С2А | 11,8 | 12,7 | 13,3 | 13,7 | 14,1 | 14,5 | 14,4 | 12,2 |

Thermal conductivity coefficient λ W/(m*K)

| Steel grade | λ W/(m*K), at test temperature, °C | ||||||||

| 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | |

| 60С2А | 28 | 29 | 29 | 30 | 30 | 30 | 29 | 29 | 28 |

Young's modulus (normal elasticity) E, GPa

| Steel grade | At test temperature, °C | ||||||||

| 20 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | |

| 60С2А | 212 | 206 | 198 | 192 | 181 | 178 | 158 | 144 | 134 |

Modulus of elasticity in torsional shear G, GPa

| steel grade | At test temperature, °C | |||||||

| 20 | 100 | 200 | 300 | 400 | 600 | 700 | 800 | |

| 60С2 | 82 | 80 | 77 | 74 | 69 | 54 | 54 | 50 |

Specific heat capacity c, J/(kg*K)

| steel grade | s, J/(kg*K), at test temperature, °C | |||||||

| 20-100 | 20-200 | 20-300 | 20-400 | 20-500 | 20-600 | 20-700 | 20-800 | |

| 60С2А | 510 | 510 | 520 | 535 | 565 | 585 | 620 | 700 |

Bibliography

- GOST 33260-2015. Pipeline fittings. Metals used in valve making. Basic requirements for the selection of materials

- Tylkin M.A. Thermist Repair Service Handbook. 1981

- Sklyarov N.M. Aviation materials. 1975 Volume 1

- Brand of steels and alloys. Ed. Sorokina V.G. 1989

- Brand of steels. CBTI. 1961

- Rakhstadt A.G. Spring steels and alloys. 1971

- Brand of steel and alloys. TsNIITmash. 1977

- Properties of steels and alloys used in boiler and turbine manufacturing. Part 1. TsKTI. 1966

- Metals and alloys: Reference data on physical and mechanical properties at various temperatures and loading conditions. 1975

- Solntsev Yu.P., Stepanov G.A. Materials in cryogenic technology. 1982

Find out more

P18 high-speed tool steel…

Steel 55 structural carbon quality…

Steel 25 structural carbon steel…

Steel 60 structural carbon steel…

Mechanical properties of steel 60С2А

The strength properties of 60C2A are determined by the heat treatment modes performed. Since the interest is in the performance characteristics of the parts, the article does not discuss the performance of steel in castings. They are of practical interest only for technologists of large metalworking enterprises engaged in the production of rolled metal.

Here we will consider the strength indicators of commercial steel in the form of a circle and a strip.

As already mentioned in the general description of the 60C2A brand, optimal performance is achieved by quenching in oil and subsequent tempering in order to relieve internal stresses.

Round steel after quenching and tempering has a tensile strength of 12.7 kg/sq. mm, proof strength 11.7 kg/sq. mm. The proximity of the yield point to the tensile strength indicates the high elastic properties of steel.

The endurance limit of 60C2A with a symmetrical tensile cycle is 49 kg/sq. mm, torsion 29.5 49 kg/sq. mm.

To understand the meaning of these numbers, it is worth remembering that the tensile strength of steel 3 is about 37 kg/sq. mm.

Application of grade 60С2А

The scope of use of steel is determined by its properties. Steel 60S2A is widely used for the manufacture of heavily loaded structural elements experiencing alternating loads.

These are various springs, friction discs, Grover washers, spring rings, collets, torsion bars - elastic rods that work in torsion. The latter are found in suspensions of heavy tracked and wheeled vehicles, elastic shafts of multi-threaded gearboxes that transmit high power.

Characteristics of steel 60S2A

For those who know what properties this or that element imparts to steel, it immediately became clear what characteristics the resulting alloy would have. But it should be explained to beginners that the presence of silicon, nickel, chromium and manganese in steel has a beneficial effect on the structure of the alloy, giving it strength, elasticity and ductility. Thus, 60C2A steel has the best strength characteristics, which allows it to be subjected to high loads, and the increased endurance of the metal, together with increased elasticity, allows it to retain its shape and properties for a long time.