A hydraulic jack allows car owners to quickly and safely change a damaged wheel on their car.

To do this, every car must have a jack, since the need to replace a wheel can arise at any time and anywhere on the road. Hydraulic jacks vary in load capacity, weight, dimensions, design, pick-up height and lifting height. In this article we will consider in detail the structure, operating principle, and technical characteristics of hydraulic jacks. Here are the most popular models by load capacity.

Purpose of a hydraulic jack

The main purpose of a jack is to lift and secure a heavy load to a small height. A hydraulic jack uses an incompressible fluid that is forced into a hydraulic cylinder using a hydraulic pump. Oil is most often used as a working fluid. This design of the hydraulic jack allows it to work with very heavy loads.

Hydraulic jacks are not intended for moving loads or holding loads suspended for long periods of time. To do this, after lifting the load to the required height, it is necessary to install additional supports on which the load will be supported. Without such supports, you cannot work under a load to avoid injury.

Classification of jacks

- Mechanical - work from the application of human force (rotating a handle or pressing a lever).

- Hydraulic - work due to a hydraulic mechanism.

- Pneumatic - allow you to lift a load by filling a special cushion with air. Industrial models are equipped with a compressor, domestic ones are connected to the exhaust pipe and filled with vehicle exhaust gases.

- Electrohydraulic - connected to the electrical network, which drives the hydraulic pump.

- Electro-pneumatic - they are connected to electricity, for example to a car cigarette lighter, due to which air is pumped into the pillow.

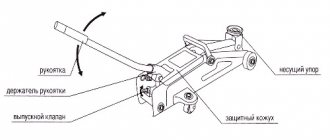

Hydraulic jack device

The hydraulic jack consists of the following elements:

- Frame . The body is made of hardened steel and can be short or long. The housing contains a cylinder with a piston.

- The base of the body is the base on which the jack rests during operation.

- The catch is the uppermost part of the piston, which rests on the load being lifted. It is made of high-strength steel and has a corrugated surface to prevent the load from sliding. It is often equipped with a height-adjustable nozzle, which allows you to place a mechanical initial emphasis on the load without affecting the hydraulics.

- Pressure gauge . Allows you to monitor developing pressure.

- Reserve container in which the working fluid is located. Using a lever system, liquid is forced from the reserve tank into the discharge cylinder, and then into the main one.

- Working fluid . Most often, special hydraulic oils are used as the working fluid in hydraulic cylinders. It is not recommended to fill the hydraulic cylinders with water or brake fluid, as they will cause corrosion of the internal metal elements, which will lead to rapid failure of the jack.

- Oil filter . Needed to clean oil from contamination.

- Main cylinder with plunger. The rise of the plunger is due to the flow of working fluid into the cylinder, the lowering of the plunger occurs when the fluid flows into the reserve tank.

- Discharge cylinder with plunger . Pumps oil into the main working cylinder.

- Inflation valve. Allows fluid to flow from the discharge cylinder into the main cylinder and blocks its reverse movement. That is, it is responsible for the movement of the working fluid in only one direction, preventing its return.

- Pressure relief valve (bypass valve) . After reaching the desired height, the jack must be returned to its original state. To do this, there is a valve that allows the oil to return to the reserve tank and relieve pressure. This valve is needed to drain excess fluid and prevent the jack from being overloaded.

Low hydraulic jacks (DN X P Y)

- The low height of the jacks allows them to be used in confined spaces where it is not possible to use other jacks, for example, when installing and aligning heavy equipment and buildings, incl. spans of bridges, viaducts.

- Single-acting - spring return rod.

- The corrugated support part of the rod prevents the load from sliding.

- Can be used in any spatial position.

- Small dimensions and weight.

Technical characteristics of hydraulic low jacks (DN X P Y)

| Model | g/p, t | Rod stroke, mm | Rod/support diameter, mm (d1) | Working oil volume, cm3 | Dimensions, mm (BxLxH) | Weight, kg | Recommended pump |

| DN5P15 | 5 | 15 | 25 | 12 | 38x125x51 | 1,5 | NRG-7007 |

| DN10P15 | 10 | 10 | 30 | 24 | 55x135x53 | 1,9 | NRG-7007 |

| DN20P12 | 20 | 12 | 45 | 50 | 76x156x52 | 2,9 | NRG-7007 |

| DN30P13 | 30 | 13 | 64 | 75 | 94x174x59 | 4,3 | NRG-7007 |

| DN50P13 | 50 | 13 | 72 | 118 | 120x200x65 | 7,2 | NRG-7007 |

| DN100P15 | 100 | 15 | 72 | 231 | 152x232x85 | 21 | NRG-7007 |

| DN140P15 | 140 | 15 | 72 | 302 | 200x263x88 | 19,3 | NRG-7010 |

Characteristics of hydraulic jack

Material

Hydraulic jacks designed for light weight are usually made of aluminum. More serious models, capable of lifting extra-heavy loads, are made of hardened steel or cast iron. The greater the load capacity the jack is designed for, the thicker the metal used in its manufacture.

Dimensions, weight and lifting capacity of hydraulic jack

All three of these indicators are directly related to each other. Jacks with high lifting capacity are large in size. And accordingly, a large unit has a lot of weight.

Small hydraulic jacks used for passenger cars are small in size, light in weight and have low lifting capacity. Bottle jacks with a lifting capacity of 2 tons have a height of 15-18 cm and a weight of 2-3 kg.

Serious jacks used for trucks, in construction and industry, have a large load capacity - up to 100-200 tons and are large in size and weight. Thus, bottle jacks with a lifting capacity of 200 tons have a height of 40-50 cm and a weight of 130-135 kg.

Limit load capacity

Indicates the maximum weight that the jack can lift. When choosing a jack for a car, you need to add 150-200 kg to the “curb weight” value indicated in the PTS.

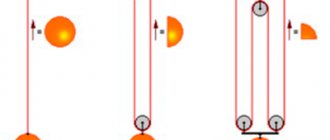

Jack lifting height

The lifting height of a jack is the maximum possible height to which a load can be raised. This value consists of two indicators:

- pick-up height

- the smallest distance from the support surface from which the jack can operate; - The stroke of the rod (the stroke of the jack)

is the maximum distance between the highest and lowest positions of the piston.

For most hydraulic jacks, this figure is 30-50 cm. While a mechanical rack and pinion jack can lift a load to a height of 1 meter.

Pickup height

A very important indicator of a specific jack model. Shows the minimum distance from the support to the lifted load (from the ground to the bottom of the car). May vary between models from 6 to 30 cm. A jack with a high lifting height will not be able to be placed under the machine.

Pad diameter

The diameter of the platform is the size of the support platform for resting on the load. Determines the stability of the stop and distributes pressure on the jack to the load. The larger the platform, the greater the stability and optimal pressure applied.

Universal hydraulic jacks (DU X P Y).

Advantages:

- Basic series. The presence of threads on the body and on the rod, as well as threaded holes in the base, allows you to expand the scope of application of jacks, incl. in special equipment (presses, pipe benders, pullers, etc.).

- The presence of a high-strength hardened steel support mounted on the rod protects it from damage.

- The corrugated surface of the support prevents the load from sliding.

- Models with a lifting capacity of 10, 20, 35, 50 tf can be equipped with jacking supports in order to increase the supporting surface area and stability.

Technical characteristics of hydraulic universal jacks (DU X P Y)

| Model | g/p, t | Rod stroke, mm | Working oil volume, cm3 | d, mm | D, mm | D1, mm | T, mm | Holes in the base, number/d1, mm | Dimensions, mm (BxLxH) | Weight, kg | Recommended pump |

| DU5P100 | 5 | 100 | 70 | 22. | — | M42x1.5 | 35 | — | 45x112x170 | 2,1 | NRG-7007 |

| DU10P100 | 10 | 100 | 150 | 35 | 42 | M60x2 | 35 | 2/M8×1.25 | 60x127x191 | 3,9 | NRG-7007 |

| DU10P150 | 10 | 150 | 225 | 35 | 42 | M60x2 | 35 | 2/M8×1.25 | 60x127x241 | 4,3 | NRG-7007 |

| DU15P250 | 15 | 250 | 530 | 43 | 35 | M68x2 | 50 | 2/M8 | 70x137x330 | 9,3 | NRG-7010 |

| DU20P100 | 20 | 100 | 331 | 56 | 65 | M85x2 | 50 | 2/M10 | 88x155x192 | 9,3 | NRG-7007 |

| DU20P150 | 20 | 150 | 497 | 56 | 65 | M85x2 | 50 | 2/M10 | 88x155x242 | 9,8 | NRG-7010 |

| DU35P150 | 35 | 150 | 754 | 68 | 75 | M110x2 | 60 | 2/M12 | 110x177x255 | 16,3 | NRG-7010 |

| DU50P150 | 50 | 150 | 1062 | 85 | 95 | M127x2 | 75 | 3/M12 | 127x194x265 | 22,3 | NRG-7020 |

| DU100P150 | 100 | 150 | 2145 | 110 | 110 | M180x3 | 75 | 3/M12 | 180x247x317 | 63 | NRG-7035 |

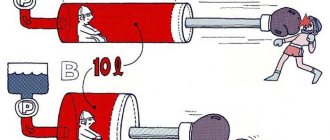

Operating principle of a hydraulic jack

The operation of a hydraulic jack is based on the constancy of fluid pressure in communicating vessels. Inside the jack there are two “vessels” connected to each other. One vessel is the main cylinder with a working plunger, the other is a cylinder with a discharge plunger. This hydraulic system is filled with technical oil.

The injection cylinder is connected to an oil reserve tank and a lever. When the lever is pressed, the injection plunger moves: it lowers and pushes the oil out of the injection cylinder. The oil passes into the main cylinder and pushes the working plunger upward, due to this the load located on the jack’s support platform is lifted.

As a result of each press of the lever, a certain volume of oil is pumped into the main cylinder, equal to the volume of the injection cylinder. The discharge cylinder is filled with oil from the reservoir. Since pressing the lever alone is not enough to lift the load, they usually continue to move the lever until the desired height is reached.

Between the discharge and main cylinders there is a valve that allows fluid to flow in only one direction and prevents it from returning back to the discharge cylinder. The walls of the main cylinder must be designed for the weight of the load being lifted.

After reaching the desired lifting height, the jack must be returned to its initial position; to do this, it is necessary to open the bypass valve. The oil from the main working cylinder will return to the oil reserve tank and the jack will lower.

Hydraulic cargo jacks (DG X P Y)

- Designed for lifting loads during installation, dismantling and repair work.

- Single-acting - spring return rod, implemented by a 3-section spring block, greatly simplifying the hydraulic circuit.

- A high-strength hardened steel support mounted on the stem protects it from damage.

- Models with a lifting capacity of 50 tf and more are equipped with floating supports, which reduce radial loads on the rod.

- Models with low height (with a rod stroke of 50 mm) are indispensable in conditions of limited space.

- By additional order, they can be equipped with a safety system that allows you to keep the load raised for an unlimited time, while the jack rod is hydraulically unloaded.

Technical characteristics of hydraulic cargo jacks (DG X P Y)

| Model | g/p, t | Rod stroke, mm | Working oil volume, cm3 | d, mm | Dimensions, mm (BxLxH) | Weight, kg | Recommended pump |

| DG5P200 | 5 | 200 | 140 | 22 | 45x112x270 | 3,3 | NRG-7007 |

| DG10P200 | 10 | 200 | 305 | 49 | 62x120x297 | 6,3 | NRG-7010 |

| DG20P200 | 20 | 200 | 662 | 68 | 88x155x310 | 13,3 | NRG-7020 |

| DG30P200 | 30 | 200 | 880 | 78 | 105x172x322 | 18,3 | NRG-7020 |

| DG50P150 | 50 | 150 | 1063 | 98 | 128x195x317 | 27,3 | NRG-7020 |

| DG50P200 | 50 | 200 | 1420 | 98 | 128x195x367 | 32,3 | NRG-7020 |

| DG100P100 | 100 | 100 | 1430 | 118 | 185x252x307 | 58 | NRG-7020 |

| DG100P150 | 100 | 150 | 2145 | 118 | 185×252x307 | 65 | NRG-7035 |

| DG200P150 | 200 | 150 | 4250 | 130 | 242x322x385 | 110 | NRG-7080 |

| DG400P250 | 400 | 250 | 12300 | 160 | 330x410x572 | 300 | NRG-7160 |

Advantages and disadvantages of hydraulic jacks

Hydraulic jacks have their pros and cons, which you need to pay attention to when choosing a jack for your car. When buying a car jack, you usually choose between mechanical and hydraulic jacks.

pros

- They have a high load capacity: 2-200 tons.

- A slight effort is required to lift the machine: pressing the lever to pump oil into the main cylinder. At the same time, human energy consumption is minimal, and the rise is fast.

- They have a very high efficiency - at the level of 80%.

- They can operate at sub-zero temperatures, since the oil in the cylinder does not freeze.

- They ensure smooth lifting of the machine, as oil gradually enters the cylinder, the rod rises without jerking.

- Smooth lowering prevents loads from falling and reduces the risk of injury when operating bottle jacks.

- They are highly stable thanks to the wide sole, which provides reliable support.

- Can be placed under any point on the body, since there is no rotating handle.

- There is a very small chance that the car will fall off the support.

Minuses

- They require periodic maintenance, monitoring the oil level, tightness of gaskets and valves, and oil changes.

- They require storage and transportation only in a vertical position, since oil may leak out when turned over.

- They are large in size and weight.

- An even support area is needed.

- The lifting height is greater than that of mechanical jacks, so hydraulic jacks are not suitable for vehicles with low ground clearance.

- The machine cannot be lowered to the specified height.

- They cost more than mechanical ones.

Why doesn't the bottle jack work?

There is little oil in the tank . The rod does not rise to the height specified in the technical documentation. To repair it yourself, we just need to add oil. Open the oil filler cap, fill it, then pump the jack, as described at the end of the article.

Oil is leaking . It happens that oil leaks in places, rubber bands and seals, this is the first sign that a major repair needs to be made, all gaskets and seals need to be replaced, and a flush must be carried out. To repair a hydraulic bottle jack yourself, you will need a repair kit.

It sags under load . Occurs due to the air inside; one of the rubber bands or gaskets allows oil to pass through and instead air enters the working chamber, which tends to compress strongly under load. To eliminate the problem, it is recommended to repair the jack, change all gaskets and fill in new oil.

Application of hydraulic jacks

- Hydraulic jacks are widely used in professional car repair shops and tire shops, as well as by owners of jeeps and heavy SUVs. Passenger car owners most often prefer compact mechanical jacks.

- Due to their high load capacity, hydraulic bottle jacks are used in the repair of heavy cargo and agricultural equipment, and in industrial production for lifting super-heavy metal structures.

- In construction for lifting heavy blocks, parts of buildings, tensioning reinforcement using reinforced concrete.

- When laying oil and gas pipelines.

- When carrying out rescue operations and liquidation of consequences of accidents.

Hydraulic jacks with a hollow rod (DP X P/G Y)

- The hollow rod allows the use of jacks for tensioning reinforcement, ropes, for pressing in and out of parts installed with tension on long shafts, as well as lifting and moving loads, etc.

- Two versions: models of the DP...P... series, single-acting, with a spring return rod, models DP...G...

- double acting with hydraulic rod return.

Technical characteristics of hydraulic jacks with a hollow rod (DP X P/G Y)

| Model | g/p, t | rod stroke, mm | Working oil volume, cm3 | Hollow rod hole diameter, mm (d) | Dimensions, mm (BxLxH) | Weight, kg | Recommended pump |

| Unilateral | |||||||

| DP15P50 | 15 | 50 | 112 | 27 | 80x144x173 | 5 | NRG-7007 |

| DP20P50 | 20 | 50 | 158,4 | 27 | 98x172x162 | 7,4 | NRG-7007 |

| DP30P63 | 30 | 63 | 300,6 | 33 | 115x189x178 | 12 | NRG-7007 |

| DP50P75 | 50 | 75 | 650 | 54 | 159x247x235 | 28,1 | NRG-7010 |

| DP100P75 | 100 | 75 | 1048 | 80 | 216x304x254 | 52,5 | NRG-7010 |

| Double sided | |||||||

| DP10G254 | 10 | 254 | 365 | 20 | 70x144x406 | 11 | NRG-7080R, NE…10…1 |

| DP30G210 | 30 | 210 | 928 | 33 | 115x189x425 | 24 | NRG-7080R, NE…10…1 |

| DP50G156 | 50 | 156 | 1106 | 54 | 159x233x380 | 38 | NRG-7080R, NE…10…1 |

| DP100G168 | 100 | 168 | 2230 | 80 | 216x290x382 | 51 | NRG-7080R, NE…10…1 |

Types of hydraulic jack

There are several types of hydraulic jacks, they differ in design.

Classification of hydraulic jacks

- Bottle.

The simplest version of a hydraulic jack, the name comes from its appearance, which resembles a bottle. It has compact dimensions and a large support area. Allows you to work with heavy and very heavy loads: from 2 to 200 tons. Can be used when working with cars and trucks, special equipment, and for lifting houses in construction. It has a fairly high minimum lift, so it is not suitable for cars with a ground clearance of less than 200 mm. You need to work with a bottle jack on a perfectly level support. - Rolling

. There are several modifications for professional and household use. To work with them, you need a hard, even floor covering such as concrete, asphalt, or tiles. They are widely used in professional car repair shops for passenger cars.

- Telescopic.

It has a telescopic piston, which allows you to increase the maximum lifting height. - Double rod or double piston.

Due to the two pistons in the design, it has an increased load capacity. - Low toe hooks

. Used in cases where a minimum pick-up height is required. Capable of lifting a load from a distance of 15 mm from the support, allowing step-by-step adjustment of the lift and securely fixing the load. They are used for raising railway tracks and in industry. - Specialized:

two-level, diamond-shaped.

Hydraulic aluminum jacks (DG X P Y)

- Aluminum jacks are two times lighter than jacks of the same load capacity made of steel.

- Single acting, spring return rod.

- The grooved support surface of the rod prevents the load from slipping.

- Indispensable when working in confined spaces, where it is not possible to use lifting mechanisms, when working at heights or in cases where it is necessary to carry jacks over long distances, as well as for working under water.

- They have increased corrosion resistance.

Technical characteristics of hydraulic aluminum jacks (DG X P Y)

| Model | g/p, t | Rod stroke, mm | Working oil volume, cm3 | d, mm | Dimensions, mm (BxLxH) | Weight, kg | Recommended pump |

| DGA20P50 | 20 | 50 | 145 | 52 | 96x163x127 | 2,3 | NRG-7007 |

| DGA20P100 | 20 | 100 | 340 | 52 | 96x163x177 | 4,4 | NRG-7010 |

| DGA20P150 | 20 | 150 | 435 | 52 | 96x163x227 | 5,2 | NRG-7010 |

| DGA30P50 | 30 | 50 | 220 | 62 | 108x192x137 | 5 | NRG-7007 |

| DGA30P100 | 30 | 100 | 440 | 62 | 108x192x187 | 5,6 | NRG-7010 |

| DGA30P150 | 30 | 150 | 660 | 62 | 108x192x237 | 7,5 | NRG-7010 |

| DGA50P50 | 50 | 50 | 355 | 78 | 136x212x150 | 8,5 | NRG-7010 |

| DGA50P100 | 50 | 100 | 710 | 78 | 136x212x200 | 10 | NRG-7010 |

| DGA50P150 | 50 | 150 | 1070 | 78 | 136x212x250 | 11,1 | NRG-7020 |

| DGA100P50 | 100 | 50 | 660 | 105 | 198x262x185 | 16 | NRG-7010 |

| DGA100P100 | 100 | 100 | 1320 | 105 | 198x262x235 | 21 | NRG-7020 |

| DGA100P150 | 100 | 150 | 1980 | 105 | 198x262x285 | 25 | NRG-7035 |

Rating of the 10 best hydraulic bottle jacks

Hydraulic jack SPARTA 2t 50341 telescopic

Designed for lifting loads weighing up to 2 tons. The base of the jack is made of cast iron and has a protective anti-corrosion coating. Equipped with a safety valve that prevents lifting of loads weighing more than 2 tons. The weight of the lifted load should not exceed 2 tons.

Not intended for moving loads and maintaining the load suspended for a long time. After lifting the load, it is necessary to secure it with stands for support. If there are no supporting stands under the load, you cannot stand and carry out work. To work, it must be placed on a flat horizontal surface. The presence of a telescopic mechanism allows you to lift the load to a height of 410 mm without much physical effort.

The homeland of the SPARTA brand is Germany, assembly is carried out in factories in China and Taiwan, which allows you to combine German quality and low cost of production. SPARTA jacks are durable and inexpensive.

Technical characteristics of the jack SPARTA 50341:

- Load capacity - 2 t

- Pickup height - 170 mm

- Lifting height - 410 mm

- Case material: metal

- Type - double plunger

- Telescopic mechanism - yes

- Horizontal operation - no

- Weight - 3.2 kg

- Case - no

Hydraulic jack 2t Gigant HBJ-2

The hydraulic jack of the Russian brand Gigant is produced at factories in China and Russia. Manufactured according to GOST R 53822-2010. Designed to work with loads weighing up to 2 tons. The jack is not designed to hold a load for a long time. When working under load, it is necessary to use additional supports. The Gigant HBJ-2 jack is distinguished by reliable operation and good stability due to its large support area.

Technical characteristics of the Gigant HBJ-2 jack:

- Load capacity - 2 t

- Pickup height - 181 mm

- Lifting height - 345 mm

- Case material: metal

- Type - single plunger

- Telescopic mechanism - no

- Horizontal operation - no

- Weight - 2.6 kg

- Case - no

Hydraulic jack SPARTA Compact 3t 50332

The hydraulic jack SPARTA Compact 3t of the German brand SPARTA is assembled in factories in China. It has established itself as a reliable and inexpensive tool, thereby gaining great popularity among car enthusiasts. Designed for lifting loads in construction and during automotive repair work. It has a stable cast iron base, a body made of durable steel, and a polished rod that increases the service life of the jack.

It has a small pick-up height of 180 mm, which allows you to work with cars with low ground clearance. The maximum lifting height is 320 mm. After lifting the load to the required height, it is necessary to securely secure the load with supports to ensure the safety of the working person. It is impossible to work without additional supports. The jack is not designed to move a load and hold it suspended for a long time. The weight of the lifted load should not exceed 3 tons.

Technical characteristics of the jack SPARTA Compact 3t 50332:

- Load capacity - 3 t

- Pickup height - 180 mm

- Lifting height - 320 mm

- Case material - steel

- Type - single plunger

- Telescopic mechanism - yes

- Horizontal operation - no

- Retractable screw stroke - 50 mm

- Weight - 2.4 kg

- Case - no

Hydraulic jack BelAK 3t BAK.10040

The BelAK BAK.10040 hydraulic jack has a lifting capacity of 3 tons and is perfect for car repairs. It is produced under the BelAK brand, owned by the Russian production holding BelAvtoKomplekt. Assembly is carried out at two factories in China, where production meets international ISO standards, all products are manufactured in accordance with GOST and undergo final quality control.

The jack is supplied in a case, which makes its storage especially convenient. It has a wide support platform and two handles. Has a low lift of 145 mm. The BelAK BAK.10040 jack has a long service life, low price, and high quality.

Technical characteristics of the jack

BelAK 3t BAK.10040:

- Load capacity - 3 t

- Pickup height - 145 mm

- Lifting height - 285 mm

- Case material: metal

- Type - single plunger

- Telescopic mechanism - yes

- Horizontal operation - no

- Retractable screw stroke - 50 mm

- Base size - 85x70 mm

- Weight - 2.3 kg

- Case - yes

Hydraulic jack KRAFT 4t KT 800014

The KRAFT KT 800014 jack is designed for lifting loads weighing up to 4 tons, and is widely used in the repair and maintenance of vehicles. Belongs to the German brand KRAFT, which has been producing car parts and auto tools for more than 20 years. Assembly is carried out in China, where all products undergo mandatory quality control of international standards DIN, ANSI.

The jack has a safety valve that prevents lifting loads over 4 tons. Frost-resistant oil is used as a working fluid, which does not lose its properties at a temperature of -45°C. The convenient folding handle makes the jack compact. Supplied in a plastic case with a handle, which is convenient to store and transport.

Technical characteristics of the jack KRAFT 4t KT 800014

- Load capacity - 4 t

- Pickup height - 195 mm

- Lifting height - 380 mm

- Case material: metal

- Type - single plunger

- Telescopic mechanism - no

- Horizontal operation - no

- Retractable screw stroke - 60 mm

- Base size - 108x108 mm

- Weight - 3.6 kg

- Case - yes

Hydraulic jack MATRIX MASTER 4t 50754

Hydraulic jack of the German brand Matrix, assembly is carried out at factories in China and Taiwan. All manufactured products undergo strict quality control, which allows us to combine low price, high quality and long service life. Matrix Master 50754 has a load capacity of 4 tons, is made of durable anti-corrosion metal, resistant to rust and mechanical stress.

The jack has a wide base, which allows it to be used on fairly soft ground. Supplied complete with a plastic case with a handle. The case allows you to properly store and transport the jack - in a vertical position.

Technical characteristics of the jack MATRIX MASTER 4t 50754

- Load capacity - 4 t

- Pickup height - 194 mm

- Lifting height - 372 mm

- Case material - steel

- Type - single plunger

- Telescopic mechanism - no

- Horizontal operation - no

- Retractable screw stroke - 48 mm

- Weight - 3.9 kg

- Case - yes

Hydraulic jack SPARTA Compact 5 t 50333

The hydraulic jack SPARTA Compact 50333 is designed for lifting loads weighing no more than 5 tons. Produced in factories in China using German technology in compliance with all necessary requirements. The jack is distinguished by high build quality, durability and reliability. These characteristics, combined with a low price, make the SPARTA Compact 50333 jack an excellent purchase.

The jack is not designed to hold a load suspended for a long time; for this you need to use special supports, without which it is strictly prohibited to work under a raised load. The body is made of durable steel and has a stable cast iron base. The jack is equipped with a polished rod.

Technical characteristics of the jack SPARTA Compact 5 t 50333

- Load capacity - 5 t

- Pickup height - 180 mm

- Lifting height - 340 mm

- Case material - steel

- Type - single plunger

- Telescopic mechanism - yes

- Horizontal operation - no

- Retractable screw stroke - 50 mm

- Weight - 2.9 kg

- Case - no

Hydraulic jack BelAK 5t BAK.00042

Belongs to a Russian brand, assembly is carried out at a factory in China. Designed to lift cargo weighing no more than 5 tons. Despite its large load capacity, it has compact dimensions and, due to its low lift, allows it to work with machines with low ground clearance. The wide base ensures the stability of the jack and reduces pressing into the ground. If it is necessary to hold the load suspended for a long time, it is necessary to install additional supports, without which it is prohibited to work under the load.

Technical characteristics of the jack BelAK 5t BAK.00042

- Load capacity - 5 t

- Pickup height - 175 mm

- Lifting height - 345 mm

- Case material: metal

- Type - single plunger

- Telescopic mechanism - yes

- Horizontal operation - no

- Retractable screw stroke - 60 mm

- Working stroke - 110 mm

- Base size - 75x85 mm

- Weight - 2.9 kg

- Case - no

Hydraulic jack SOROKIN BottLine Jacks 12t 3.12

Designed to lift cargo weighing no more than 12 tons. The jack is of the famous Russian brand Sorokin, whose production facilities are located in China, Taiwan, Russia, and Europe. The jack is assembled in China, which reduces production costs and, accordingly, the final price while maintaining high quality products. It is used for construction, industrial and auto repair purposes.

Not designed to hold a load for long periods of time. After lifting the load to the required height, it is necessary to use additional fixing supports for safe work under the load.

The SOROKIN BottLine Jacks 12t hydraulic jack is easy to use and has a screw rod that makes it easier to place the jack under the supporting surface of the load. There is a metal handle on the side of the case, which is convenient for carrying the jack. At the bottom of the body there is a wide support base that prevents the jack from sinking into soft ground.

BottLine Jack® series bottle jacks are equipped with a telescopic mechanism that allows you to reduce the pick-up height while maintaining or increasing the lifting height compared to classic models.

Technical characteristics of the jack SOROKIN BottLine Jacks 12t 3.12

- Load capacity - 12 t

- Pickup height - 245 mm

- Lifting height - 570 mm

- Case material: metal

- Type - double plunger

- Telescopic mechanism - yes

- Horizontal operation - no

- Retractable screw stroke - 55 mm

- Working stroke - 270 mm

- Weight - 9.5 kg

- Case - no

Hydraulic jack WIEDERKRAFT 20t. WDK-81200

The WIEDERKRAFT WDK-81200 hydraulic jack is designed for lifting loads weighing up to 20 tons. It is used at service stations for freight transport, special vehicles and agricultural machinery. WIEDERKRAFT is a German brand; jacks are assembled in China. High quality is combined with long service life and reliability.

The jack has a handle, which makes it easy to transport. The wide base ensures the stability of the jack during operation. The screw platform is height adjustable.

Technical characteristics of the WIEDERKRAFT 20t jack. WDK-81200

- Load capacity - 20 t

- Pickup height - 226 mm

- Lifting height - 452 mm

- Case material: metal

- Type - single plunger

- Telescopic mechanism - yes

- Horizontal operation - no

- Retractable screw stroke - 150 mm

- Working stroke - 226 mm

- Base size - 144x150 mm

- Weight - 10.6 kg

- Case - no

What kind of work can you do with a bottle jack?

Table of characteristics of jacks.

The scope of application of bottle jacks is car service related to the maintenance and repair of cars. The bottle type of jack is widely used in the railway industry, as it allows for the repair of trains.

We use a hydraulic jack as a power unit for presses, pipe benders or pipe cutters. If, after inspecting the mechanism, it can be concluded that the device is working properly, then work should begin. Combined with a large load capacity, the compact size of the tool allows it to be used in garages and workshops. The device can be transported in the trunk of a car, which allows you to replace broken tires if necessary.

The mechanism of bottle-type jacks is reliable. Hydraulic jacks are used in the process of car repairs, which need to be lifted and fixed at the desired height. For example, the mechanism allows you to remove a car wheel for its subsequent balancing using special equipment.

It is convenient to transport, which is done exclusively in a vertical position, since oil can flow out in a horizontal position of the tool. In general, its service life is determined by the number of gaskets and seals in its design.

The design of a bottle-type hydraulic jack and its features

Bottle type jack device.

The design of a bottle-type jack is shown in the figure. Each element included in the structure corresponds to a specific number, implying the presence in the mechanism:

- Handles.

- Pump.

- valves.

- Reservoir.

- Cylinder.

- Stock.

- Vinta.

The suction valve is located on the tank outlet. This should prevent the fluid from returning back to the reservoir if the pump plunger is lowered. The location of the discharge valve refers to the cylinder pipe, which prevents hydraulic fluid from leaving the cylinder when the pump plunger is lifted.

The valve is opened with a special screw, which allows the pressure in the device to be released. The load is then lowered to the ground. In general, this design is time-tested.

The connection of the bottle jack to the pump or pumping station is carried out due to the presence of a coupling half, which is a quick-release coupling. It eliminates fluid loss as a result of disconnection of the instrument from the pressure source. The main design elements are:

The quick-release coupling half of the bottle jack eliminates fluid loss as a result of disconnecting the tool from the pressure source.

- Frame.

- Retractable plunger (piston).

- Working fluid (hydraulic oil).

The housing is a guide cylinder for the plunger and at the same time a special reservoir for the working fluid. If the jack has a lifting capacity of up to 20 tons, then the location of its lifting heel is marked in the part of the screw that is screwed into the plunger. Therefore, the initial height of the mechanism can be increased by removing the screw.

The plunger must pump oil from one common reservoir to another, located under the piston. When oil appears under the piston, it must move. The oil no longer returns to the common reservoir due to the operation of the valve. While the plunger is working, more and more oil flows into the reservoir located under the piston from the common reservoir.

An integral element of a bottle jack is a liquid that has the characteristics of an incompressible working material. This allows you to smoothly lower and raise the load, as well as fix it at a certain height, ensuring precision when braking.

Spindle oil allows you to smoothly lower and raise the load, as well as fix it at a certain height.

The speed of the process of lowering the load can be controlled by the hole required for the flow of a special liquid coming from the cylinder, which can have a different composition. It is possible to use non-freezing mixtures, which include the following components:

- Alcohol.

- Water.

- Technical glycerin.

- Spindle oil.

Spindle oil hardens at temperatures below 35°C. When choosing a bottle jack, lifting and lifting heights are taken into account, not just lifting capacity. The lifting capacity may be sufficient to lift the vehicle, but the stroke will be low. This requires control over the level of hydraulic fluid, oil seals and their tightness.

Hydraulic spreaders (wedges)

- The minimum height of the grip allows the use of spreaders for precise installation and alignment of equipment on foundations and for widening narrow openings.

- Model KRA... with built-in drive, models KR..., D K... and DG

- with external drive.

Technical characteristics of hydraulic spreaders (wedges)

| Model | Effort, tc | Min pick-up height, mm | Lifting height, mm | Dimensions, mm (BxLxH) | Weight, kg | Recommended pump |

| KR01030 | 1 | 30 | 150 | 80x350x92 | 7 | NRG-7007 |

| KRA01030 | 1 | 35 | 150 | 96x730x145 | 10,9 | built-in |

| DK2.5P120 | 2,5 | 25 | 120 | 80x322x110 | 8,5 | NRG-7007 |

| DG40G24K | 40 | 5 | 24 | 85x500x120 | 8,5 | NRG-7080R |

Reasons why a hydraulic jack may fail

Repair work on bottle devices is carried out at home with your own hands, but to do this you need to familiarize yourself with all possible malfunctions and the rules for eliminating them. You must first prepare new parts to replace those that have become unusable.

Using wrenches you need to unscrew all the bolts and cuffs that are located in the upper part of the main cylinder. After all protective rings have been removed and the reservoir has been pulled out, the lift should be inspected for damage. Replacement bolts are selected in strict accordance with the dimensions of standard parts, and the bushings must be round.

Hydraulic jack device

To make a calculation of a hydraulic jack for its purchase or self-assembly, it is recommended to find out what the circuit, structure and design features of this device are.

The lifting device consists of three main components:

- Movable piston;

- Cases. It is made of high-strength metal and has the shape of a cylinder. In addition to the functions of the housing, it plays the role of a container where the oil is located;

- Liquid medium. Its role is played by machine oil;

- Levers;

- Valves;

- Plungers.

- Force is applied to the lever, and the use of valves makes it possible to increase it tens of times.

- The plunger allows you to move the piston device by transferring the working fluid, which is oil, into a container under the plunger.

- Due to the valve, oil does not flow back into the housing.

- Gradually, the plunger transfers more oil under the piston, which helps it rise.

- To lower the load, the oil must return to the housing structure. Here you need to open the valve slightly.

A similar operating principle is relevant for all hydraulic jacks. Therefore, the diagram, drawings, video manuals for assembly and operation of these devices are approximately the same.

Advantages and disadvantages

If you decide to assemble a device for lifting bottle-type loads, thereby creating a hydraulic jack, or want to buy factory equipment, you should first find out about the strengths and weaknesses that characterize the device.

Let's start with the advantages, which include:

- High power levels;

- Ease of operation;

- High efficiency, reaching 80 percent;

- The device operates when moving loads weighing up to 200 tons. So the hydraulic jack lifts a decent amount of weight.

But this type of jack has its drawbacks. You should know them before you start working on it.

- The device cannot lift loads from low heights.

- Inability to set the lowering level of parts.

- A device of this type requires close attention and periodic maintenance. The service plan provides for the need to fill in oil, change seals and gaskets.

- The hydraulic jack can only be transported and stored if it is positioned vertically. Otherwise, oil leaks out and must be refilled for normal operation. Refueling the unit is not difficult, but no one wants to do it all the time.

- The principle of the device does not allow it to quickly perform the functions of raising and lowering.

- The rise is carried out cyclically.

- This type of device is quite expensive.

- Breakdowns are not uncommon for hydraulic jacks, and they are quite expensive to maintain.

Read also: Homemade snow plow for walk-behind tractor