Waterstones are specialized, highly effective natural pointing stones that come in a variety of grits so that changing them during the sharpening process from small to coarse grits allows you to get a perfectly sharp blade. They got their name “water” because they cannot be worked with dry; they must be soaked before use.

Japanese water stones for sharpening knives.

Advantages and disadvantages

Opinions on the feasibility and productivity of these stones are very ambiguous, but the following main pros and cons can be identified.

pros

- all grains included in the bar are as homogeneous as possible;

- Due to the softness of its surface, that is, the optimal ratio of pore volume, binder and abrasive, the bar grinds down somewhat faster, constantly opening up new grains. At the same time, a certain special suspension forms on the block in a pile of water. Due to this, Japanese water stones, with faster wear, guarantee the same high efficiency and high-quality clean surface treatment;

- with the use of small-grained stones, it is quite simple and quick to achieve an almost ideal cutting edge without the use of any polishing compounds or similar accessories;

- Water stones for sharpening knives have high productivity and are inferior in this factor only to diamond-coated materials. But it is worth considering that diamond bars have a limited grain size (up to 1200 units).

Minuses

- during the sharpening process it is impossible to do without lubrication and constant washing away of dust from metal particles and abrasive abrasive;

- natural stones wear down quickly, unevenly, which requires leveling the surface;

- the price is an order of magnitude higher than the cost of simple abrasive bars.

Japanese sharpening stones of various types.

Treating a severely dull or damaged blade

Requires coarse abrasive - #80-400. First of all, you should start by removing the nicks. To do this, the remnants of the blade are removed. The material must be removed along its entire length. This way the geometry of the blade will not be distorted. You need to do this until the damage is completely eliminated. A straight edge appears. Next, an assessment of the uniformity of its thickness is required. She can "float". In this case, it is necessary to restore the blade profile. Work is being carried out with descents. Excess material should be removed. Once this work is completed, the width of the edge should be constant along the entire length of the blade. The thickness is selected in accordance with the purpose of the knife. Next comes the turn of preliminary sharpening. In this way, places of descent that still need correction will be identified.

Waterstone grain size

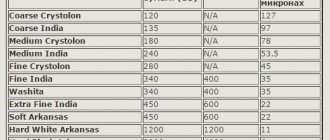

In stones and bars, grain size can be indicated in different units:

- Grit - if the abrasive is designated 250 grit, it will be intended for roughing, respectively, the value of 5000 grit is for polishing the blade.

- Mkm - in this case, everything will be completely different, which means that the greater the number of units, the more coarse processing is performed, and the less, the finer. For example, 50 mkm is rough sharpening, 5 mkm is polishing.

Practical recommendations

The amount of suspension increases during polishing and grinding. You don't need to let it thicken too much. It is also not required to be washed off. The Japanese periodically moisten the suspension. To do this, the fingertips are dipped into water, and the latter is shaken off onto a block. You can also use a disposable syringe or household spray bottle. It is important to prevent it from being completely washed off by accident.

It is recommended to use the entire area of the bar. When working with coarse abrasives during intensive metal removal, wear must be carefully monitored. Basically, the middle part of the bar is most at risk. Thus, the working plane is distorted, and the cutting edge collapses. This phenomenon can be dealt with in different ways. The Japanese make special stones for this. They are based on hard, wear-resistant abrasives. Such stones have a number of parallel cuts. They are involved in the process of leveling worn stone. Reconstitution must be carried out with water. Then the abrasive must be thoroughly rinsed. To do this, use a brush, which is designed to remove stuck particles.

How to choose the right water stone for sharpening a knife

Sharpening stones are selected in three main directions, based on financial resources and goals:

- A set designed for straightening and sharpening an undamaged cutting edge.

- A set designed for restoring, shaping, finishing sharpening and straightening blades.

- A set for keeping already sharpened knives sharp.

To keep knives sharp

In this case, your choice should be one or more fine-grained stones in the range of 5000-8000 units. Such abrasives take a long time to grind down, do not wear out the blade and allow you to achieve a shiny cutting edge.

It is better not to skimp on such a stone, since at the last stage of sharpening any shortcomings will be greatly manifested.

For straightening blades

The best option to sharpen and edit a knife yourself is a set consisting of stones with the following grain size:

- 6000 units;

- 3000 units;

- 1000 units.

Grit 1000

Intended for initial finishing sharpening only if the edge is not severely damaged. It is also used to remove marks left by coarser abrasives.

Japanese knife sharpening stone, 1000 grit.

This stone is considered the basic one; with its help, the minimum working sharpness of the blade is achieved, and it is used often. Wear rate is average.

Grit 3000

It is used at the very beginning of polishing work. If your financial capabilities do not allow you to purchase a couple of stones or you want to purchase only for testing, then this value will be ideal. This abrasive will make the knife very sharp, but over time you will notice that it is not enough.

Japanese knife sharpening stone, 3000 grit.

Grit 6000

Relating to the final stones, it will be the most practical completion of the set.

Japanese knife sharpening stone, 6000 grit.

For comprehensive care

For those who want to seriously engage in the art of sharpening or even organize their own workshop, the first thing you need is a basic set consisting of stones with a grain size of 1000, 3000, 6000 units, supplemented by finishing abrasives with a value of 6000 - 8000.

It’s a good idea to add to this set coarse stones for “grinding” – 120 – 600 units; with their help you can restore and shape the cutting edge even after deep dents and chips.

If you want to immediately turn your set into a professional one, you should add a Japanese stone with a grain size of 10,000 units; you can even sharpen a razor with it.

What size to choose water stone

The issue of area and thickness of water stone is one of the most important. It is believed that larger abrasives belong to the professional line.

To some extent, this is true, because with constant use, the water stone wears off quite quickly, and therefore it must have a certain thickness reserve. The area should be selected based on the size of the product you are going to work with.

Sharpening stones of various sizes.

Maximum spiciness

It can also be called a razor. This requires the highest individual skills in finishing and sharpening. However, such sharpness is not required on every blade and not always. Trying to align it on soft stainless steel is a useless undertaking. The fact is that in this case the effect is extremely short-lived. Soft knives that are made from low carbon steels can be repaired with a grinder. It is worth noting that this will not be enough for a high-quality solid product. Thus, when buying a good knife, it is not advisable to save on sharpening materials.

Water stone 10000 Grit 6 by 18 cm - when I suspected it, but not as much!

I’m not a pro at sharpening, I just, like you most likely, have a kitchen, there are knives in it, which means I have to sharpen them from time to time. In addition to musats and sandpaper, for this I have a small double-sided diamond stone 600/1200 and a Japanese water stone 3000 Grit. Just in case, I’ll explain: grit (grit) means how small the abrasive particles are in the sharpening stone, and the higher the grit number, the smoother and sharper the knife blade turns out when carefully sharpened. After the 600/1200 Grit stone, the knife is, in principle, completely suitable for work in the kitchen: it cuts tomatoes without pressure, it is already trying to shave somehow, but the work is still not as pleasant as the 3000 Grit, after which the knife can still shave fairly. But this, of course, is not the limit, and let’s say, for cutting fillets, sometimes you want a thinner stone.

By that time, I had already heard a lot about Chinese stones - everyone is good, and the price is wonderful, and people even sharpen straight razors with them. On the other hand, by this time I have little faith left that the cunning Chinese will not try to heat where it is easy to heat. So I took a product with hundreds of reviews and sales. And although I would have been completely satisfied with a 5000 Grit stone, I decided, adjusted for the Chinese trick, to take 10,000. I have never even touched such thin stones, but in my understanding, a knife after them should cut a hair lengthwise.

Proof of purchase

The stone arrived in a bubble wrap and in a bag, delivered by courier to the door. Initially, I didn’t plan to shoot a review, so all the photos here are of the stone already used for sharpening several knives. So, this is apparently how the stone is supposed to be stored - in a rubber uh... shell. A good solution, since the stones used for sharpening are quite hard, but fragile. So if you drop a stone without a shell on a tile, you may miss the corner of the stone, or split the tile. Otherwise, the rubber will spring back and the impact will not be so hard.

Without rubber pads, the stone looks... Well, like a block. The proud inscription “10000” is visible.

Let's take a closer look at this inscription, and at the same time we will see a chamfer along the perimeter of the edges.

The main purpose of rubber pads is, of course, not for transportation or storage. First of all, they are so that the block does not slide on the table during the sharpening process. Nnnnuuu... In principle, this helps, but in my opinion it is not enough. I still get slippage from time to time. Pad flexibility:

Here's a newbie surrounded by my other two stones. The largest is the Japanese 3000 Grit, many thanks to the friend who gave it to me. The stone is many years old, but it still makes me happy. Yes, somewhere, when adjusting the angle, the knives were scratched on the surface and this can be seen from the stains on the stone, but in fact this does not affect the work, subsequent new sharpening cycles also polish these tiny defects, so the block can be considered quite fresh.

The smoothness of the stones is on par - the obviously rough surface of the rough side of a diamond stone, the velvety smooth surface of the other side, and both watermen are pleasantly smooth, with a barely noticeable velvety quality. From the feeling on your fingertips, you can quite believe the thinness of the new stone. But of course, actual use will show everything.

The ends of the stones are in the water, and I’m slowly sharpening my knife, this is my boss now, tramontina profissional. In principle, it is not particularly stupid, so you can immediately start at 3000 and continue at 10000.

A few movements on the 3000 stone, lightly rubbed it over my hand - well, okay.

hairs

I move on to fine-tuning at 10,000. As I already said, anti-slip rubber is good, but on a wet table it still slips. And if we use a water stone, then a wet table (and with stains from the stone) is quite common. So I use a stone, resting it on some surface. And from time to time I additionally moisten it with water.

By the way, the new stone drinks water just like it’s crazy. However, why “how”? Water actually flows through the stone, the surface dries before our eyes, and after probably a minute the water flows through the stone. The Japanese three-thousander does not behave like this, of course, and water gradually drips through it, too, but it can easily keep a puddle on the surface for probably a full minute. That is, you don’t have to wet it again and again so often.

The sensations when sharpening are somehow more obvious. If, when sharpening on a 3000-stone, you have to catch the angle with bated breath... that is, yes, literally - not to breathe so as not to miss the right angle, then at ten thousand the blade is well felt, and at the moment of guiding the blade, surface friction is clearly felt. On the one hand, this is good and convenient, but on the other, suspicions awaken.

hairs

And so... something almost doesn’t shave, just a couple of hairs. When cutting food, everything is generally not bad, but nothing special: it cuts tomatoes, meat too, there’s nothing special to say about the rest, but... Well, that’s not it.

Well, okay, you have to get used to the new stone, right? At one time, it took me months to feel the correct angle on the 3000th stone to allow me to get an acceptable result, and then generally years to feel this result on each new knife, and not on ten favorite ones that were shaved. Yes, I’m still a woodpecker, nothing can be done.

But after trying the stone on a decent number of knives, I gradually began to come to the conclusion that the problem here, in general, was not me. The result is repeatable every time, the blade cuts quite normally and is tolerable for the kitchen, the same tomatoes are cut quite acceptable, but the knife does the same even after using a diamond block (600/1200), if not better.

I'll take a closer look. This is the 3000th.

This is the 10,000th. Sorry for the difference in angles, difficulties with shooting macro handheld (I don’t have special equipment for macro - I need it too rarely), so the most revealing photographs turned out to be slightly different.

However, I think it’s clear to everyone from these photos. The 10,000th, or rather clearly “10,000th” stone is clearly rougher than the 3000th.

And if I didn’t have a proven and high-quality three-thousandth stone, who knows what I would have to think. There is so much varied information on the Internet, for example, someone says that the grit content of water stones cannot be compared with a diamond, even if the same units are indicated in both. and it’s normal that a water driver with the same units is much rougher.

Someone in the reviews doubts that the Chinese writes the grain correctly, but what can I say - doubts and sensations are such an ephemeral thing... I already wrote that I would be happy if instead of 10,000 they sent me 5,000.

But here they absolutely turned it up to zero. This is not a 10,000 stone. This is... Well, maybe the 1000th. In a store with a 93% rating, more than three years on Ali, not with any particularly low price, with many orders.

The stone itself is not bad. Well, let him drink water like crazy, but he is big, and because of this it is perhaps more convenient to work with him than with a diamond block, so I will use it as a preliminary before the 3000th. But the grain isn't just inconsistent. It doesn't match by an order of magnitude. I don’t know about you, but I somehow didn’t expect this.

If anyone has any ideas on how to buy a stone with a real high grain size on the same Ali, please share. I'm out of them. But surely there are such people there?

Storage

The bars should be kept in individual containers. It can be either cardboard or plastic. It is acceptable to store medium- and coarse-grained stones in water if they are used regularly - about once a week. Bars that are used less frequently must be dried thoroughly after use. Do not leave a wet block in the cold. Frozen water can contribute to its destruction. Regular editing will benefit the block. This process makes it easier to maintain and also reduces uneven wear. Chipping of stone edges can be prevented. To do this, periodically during operation (in accordance with wear), a narrow chamfer should be placed on its edge. The required angle is 45 degrees. It is recommended to stick a thin whetstone on a flat piece of wood or organic glass. This is done using waterproof glue. Thus, the service life of the bar will be extended.