The universal knife sharpening angle is 30-45 degrees; it can be used to restore the sharpness of the blade of kitchen knives. It is important to remember that the smaller this parameter, the sharper the cutting edge will be, but it will also quickly become unusable and lose its properties.

Sharpening angles must be strictly maintained for a fillet meat knife (10-15 degrees), for a fish cutting knife (25 degrees), a chef's knife (20-25 degrees) and other types of special cutting tools. These indicators must be observed on pocket sharpeners, and on whetstones, and on a grinding machine - on all sharpening devices.

Immediately after purchasing a knife, you will need to take its geometric parameters, write them down, and strictly adhere to the obtained values when sharpening. This is the only way to increase the wear resistance of the cutting tool and reduce the frequency of edits and sharpening.

Basic rules for choosing a knife sharpening angle

The sharpening angle of the knife is selected depending on the purpose of the tool; in everyday conditions, it is customary to take the parameter as a basis at 30-45 degrees. But if you constantly use only average values, the service life of the knives will decrease. The most important rule for choosing a knife sharpening angle is that the smaller this parameter, the sharper the blade. But in this case, you will have to edit and re-sharpen the blade much more often.

How to measure

You can measure the desired parameter at home:

- Using scissors . The blade requiring sharpening is placed between 2 blades of scissors, and the angle is measured with a protractor.

Before starting the procedure, it is important to make sure that the bolt connecting the scissors blades is tightly tightened.

- Ruler-square . It occurs in two stages. The first is to insert the blade between the blades of the scissors, attach the latter to a sheet of paper and trace them with a pencil. The second is to use a square ruler to measure the distance between the drawn contours on paper. The results obtained will be the required parameters.

- Using board and paraffin . Place a cutting board (new) on a flat and hard surface and grease its surface with oil. The edge of the board is lubricated with a thick layer of warm/liquid paraffin. As soon as the coating begins to harden, a knife blade is stuck into it, which should be sharpened.

- After the paraffin has completely hardened, the knife is pulled out and a photograph of its “print” is taken. The resulting image will clearly show the desired sharpening angle, which can be measured with a protractor when enlarging the photo.

We recommend reading the article about knife sharpening options. From it you will learn about how to sharpen knives correctly, types of sharpening, how to dull a knife and how much it costs to sharpen a knife. And here is more information about the characteristics of sharpening stones and recommendations for their selection.

Knife descent angle

Most often it is not necessary to select the angle of descent of the knife, because this parameter is set by the manufacturer. It is only necessary to control it during the process of restoring the sharpness of the blade. The only nuance that should be taken into account: the higher the descent, the sharper the blade will be, and it will be easier to cut even hard materials with the knife.

Knife device

Any knife consists of a metal or ceramic strip and a handle, which is made of wood, plastic, ceramics or other materials. Depending on the way the handle and blade are articulated, knives can be fixed, folding or detachable. The handle can also be positioned perpendicular to the cutting blade.

The blade has a RC formed by two or one microfeed. Depending on the shape of the perpendicular section, the cutting edge can be formed by a bevel without microfeed.

The part of the blade opposite to the RK is called the butt. It can also have a sharpening, as in the case of a double-edged knife. The section of the blade that is adjacent to the handle and has no sharpening is called the heel.

Knife sharpening angles: table of degrees for different types

To avoid errors when determining the sharpening angle of knives, it is worth using a ready-made table of degrees for different types of tools.

| Knife type | Sharpening angle in degrees |

| Kitchen household | 30-35 |

| Kitchen professional | 25-30 |

| Chef's professional (chef's knife) | 20-25 |

| Dining room | 55-60 |

| For cutting fish, including fillet knives | 25 |

| For cutting meat | 30 |

| For working with vegetables | 35 |

| For preparing fillets (separating meat from bones) | 25-30 |

| For cutting loin | 10-15 |

| For working with animal products | 30-45 |

| For slicing hard/plate root vegetables | 22-25 |

| Penman | 20-25 |

| Tourist, when blade sharpness is a priority | 30-35 |

| Tourist when high wear resistance is needed | 40-45 |

| For carpentry work | 30-45 |

| Chopping | 45-60 |

| For shoe repair | 30-40 |

| For cutting leather | 20-25 |

| Hunting for sanding | 15-45 |

| For slicing baked goods | 15-22 |

Separately, you will need to determine the sharpening angle of Japanese knives, and this parameter ranges from 15-40 degrees. This is due to the fact that Japanese craftsmen offer knives on the market for various purposes, with one-sided or double-sided sharpening, and slopes of different heights. Truly professional Japanese knives have special markings on the packaging, where you can find recommendations on the sharpening angle of the blade.

Sharpening angle of kitchen and hunting knives: the importance of care

The sharpening angle of kitchen knives ranges from 30-35 degrees, but for hunting knives you will need to select them taking into account the following nuances:

- if you have to sand the prey and make thin cuts, then the sharpening angle should not exceed 15 degrees;

- Sharpening of a hunter's universal weapon is carried out at 25 degrees (maximum);

- Rough cutting of the prey carcass is performed with a knife with a sharpening angle of 45 degrees.

Reasons for rapid wear

Kitchen knives become dull quite quickly, this happens for the following reasons:

- cutting boards made of stone, glass, hard plastic are used in the work - such materials round the cutting edge of the blade;

- bones and tendons of meat often get under the blade - the high density of these parts negatively affects the cutting capabilities of the tool;

- the knife is used to clean the scales and cut the bones of fish;

- sand, tiny stones, lumps of earth come into contact with the blade - this often happens when working with vegetables and fruits, so they need to be washed thoroughly before work;

- violation of the rules for storing knives - they should not come into contact with any hard objects.

Blades that cannot be sharpened

There are knives on the market with blades that cannot be sharpened - ceramic ones. They have high quality characteristics and do not lose their sharpness even with prolonged use.

Ceramic blades have the following advantages:

- do not oxidize when interacting with any aggressive environment;

- do not change color;

- do not absorb food odors (even very specific ones).

Such knives are sharpened once every 5-7 years, but it is impossible to do this work at home - you need a special professional tool and certain skills.

You cannot sharpen self-sharpening blades, the peculiarity of which is the presence of tiny teeth on the cutting edge.

Why does the knife get dull?

Sharp objects are dangerous because you can get hurt when using them. But even more trouble will come from a dull chef's knife, which can slip and easily injure your hands.

The blades sold in the store are sharp and easy to work with. But their shelf life depends on operating conditions.

Following a number of recommendations will help keep your kitchen knife sharp longer:

- during storage, the cutting edge should not touch surfaces that have a high density;

- cutting should take place on special boards made of wood or plastic;

- blades of all types must be used for their intended purpose, avoiding shock loads on blades whose sharpening has a small degree;

- Immediately after use, knives should be washed and dried.

The sharpness of the cutting edge decreases for several reasons:

- Impact of organic acids contained in products on the blade material.

- Impacts from a fall.

- Cutting on hard surfaces such as stone countertops or ceramic cookware.

- Uneven load on the cutting blade when the composition of the products is uneven (the blade hits bones, tendons when cutting meat).

- Exposure to aggressive chemicals and high temperatures during cleaning.

- Improper use.

If the knife is intended for cutting the fillet of fish, then when opening cans with it, the blade will be damaged. The nature of the RK violations depends on the material from which the blade is made.

Knives made of stainless steel are resistant to aggressive environments, but without proper care, rust appears on the surface of the blade. Such blades are easy to sharpen, but this process must be carried out more often.

Carbon steel has increased strength, such blades are more difficult to sharpen, but they retain their sharpness longer. With insufficient care, the metal quickly becomes covered with rust.

By combining hard and soft steel in industrial production, alloys are created that imitate the blacksmith forging inherent in Damascus blades. Knives are made primarily for hunters using this method.

Products made from zirconium alloy are characterized by increased fragility. These ceramic knives are designed for smooth, soft products and keep their blade sharp for a long time. A special tool is required for sharpening.

Calculate the angle of descent on the knife.

Types of knife sharpening: single-sided, double-sided, wedge-shaped, asymmetrical

Self-sharpening knives can be done in several ways, and the choice depends on the type of blade:

- One-sided . It is characterized by sharpening only one side of the blade, the other remains flat, which makes it possible to obtain a perfectly sharp edge. Most often, one-sided sharpening is used for kitchen, household/professional knives, and hunting (skinning) knives. Since it is almost impossible to perform this type of sharpening on a concave blade, it is used only for working with straight blades and bevels.

- Bilateral asymmetrical . It is performed in such a way that the width of one and the other side of the cutting edges are different. This method makes it possible to cut even very hard products and materials into even pieces of different sizes without any effort.

Double-sided sharpening is most often found in Japanese knives, which is why professionals work with them: human safety is ensured by existing skills, otherwise sharpening both edges leads to injuries when working with products.

- Wedge-shaped . The most popular type of sharpening, which is characterized by smooth, gentle slopes. Suitable for kitchen, travel, folding and hunting knives. This treatment of the blades allows some types of tools to be used as a lever in field conditions - for example, for lifting fallen thin trees.

Wedge-shaped knife sharpening

Sharpening features

During the manufacturing process, based on the professional goals and purpose of the tool, a certain blade shape, thickness parameters and inclination of the cutting edges are selected. It is thanks to the correct inclination of the angles and position of the blade that the most stubborn textures can be processed, since the correctness of the cut is ensured only if certain working positions of the tools are observed.

Optimal knife sharpening angles require maximum pressure on the cutting materials during operation. If the tilt changes, the blades can easily be damaged. It is important to note here that each blade model needs to be sharpened with strict adherence to certain angles. Based on what design features the knife has and what use it is intended for, the optimal sharpening angles are determined.

At the same time, it is undesirable to process some types of professional or chef’s tools (Tramontina and Lansky) yourself; this should be done by a qualified person using special equipment so as not to damage the blade.

How to sharpen a hunting knife, on what tool

You can sharpen a hunting knife using mechanical pocket sharpeners. This tool is lightweight and has no storage requirements. Such sharpeners are manufactured in the form of a rod 150 mm long and 20-30 mm in diameter.

Mechanical sharpeners for hunting knives are sold in special plastic packaging with fastening elements. This allows the hunter to carry the tool on his belt and edit the knives at any time.

Mechanical sharpeners for hunting knives

How to set the knife sharpening angle on a kitchen knife sharpener

For a kitchen knife, there is no need to set the sharpening angle on a mechanical type sharpener, because manufacturers have foreseen this point and enclosed the rotating wheels between the plates according to the required parameters. Such a device will not be able to sharpen the cutting edge to perfection and at the same time maintain its wear resistance - mechanical sharpeners are not used for professional chef knives.

The sharpening angle is constant, which is optimal for frequent sharpening of standard household knives made of medium-hard steel.

Making the optimal angle on the mat

If you are sharpening a knife using musat, the optimal angle would be 25 degrees.

Sharpening work is carried out as follows:

- Take the musat in one hand and rest its end against a hard and flat surface. Make sure that the device does not slip during the process.

- In your other hand, take a knife whose sharpness has decreased.

- Place the cutting edge of the kitchen tool against the rod at an angle of 25 degrees.

- Perform 4-6 movements with the knife along the musat away from you and towards you, while simultaneously turning the blade.

If the musat has a diamond coating, then to restore the sharpness of the knife blade it is enough to run it along the rod once.

Experts warn that this device is not capable of fully sharpening a blade; it is only used for editing.

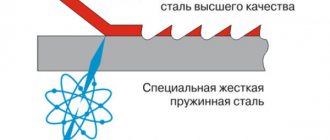

Features of Japanese models

In Japan, there is a very reverent attitude towards kitchen knives. They have a whole cult regarding the method of cutting food before cooking. In appearance, the Japanese knife is not very different from its European relative. However, if you pay attention, there are several differences:

- its butt is more massive;

- the blade is thin and sharpened on one side;

- Heavy-duty steel is used for manufacturing.

This makes the use more difficult, or rather, a little special. Adapt it for left or right hand. But the materials used and the special way of creating the kitchen tool make it more practical and convenient.

Japanese knife.

How to use a whetstone for the perfect sharpening angle

The ideal sharpening angle for a knife on a block is also 25 degrees; this parameter does not change even when using several sharpening stones with different degrees of surface grain.

The algorithm of actions will be as follows:

- Take a block/stone with a coarse abrasive surface. If it is small, then it is clamped (fixed) in a vice.

- Place the knife blade against the surface of the sharpening device at an angle of 25 degrees and move it lengthwise towards you and away from you.

- Perform the same movement on the other side of the cutting edge. Continue the process until pronounced burrs appear on the metal.

- Change the block to a fine-grained one and carry out the same manipulations until even small burrs disappear.

Place the knife blade against the surface of the sharpening device at an angle of 25 degrees. Move it lengthwise towards you or away from you.

It is believed that working independently on a whetstone makes it possible to bring the knife blade to an almost ideal state of sharpness.

How to make a kitchen knife sharpening angle on a grinding machine

On a grinding machine, sharpening a kitchen knife should only be carried out by an experienced person; you will need to maintain a sharpening angle of 30-35 degrees during all work. And you can do it like this:

- Determine in what position the knife will come into contact with the grinding wheel according to the desired parameter.

- Prepare a “support”, a retainer - it can be either a long metal plate or a plastic strip.

- Turn on the machine, bring the blade to the circle at the correct angle and apply the lock on top. Do not press the blade tightly, as this will damage the metal.

First, one side of the cutting edge is sharpened on a grinding machine, then the other. It is impossible to hold the metal on a rotating circle for a long time - due to friction at high speed it will heat up and lose its quality characteristics.

Watch the video on how to quickly sharpen a kitchen knife on a machine:

Cutting edge angles

Typically, several standard sharpening angles are used in everyday life. This is due to the low prevalence of professional sharpening devices that allow you to set an arbitrary angle. Household sharpeners usually come in several varieties. As a rule, this is quite enough for home use.

If you plan to use the knife professionally, it is recommended to purchase a special sharpening device. Using it you can set the required angle. The exact angle values are determined by the area where the knife is used:

- universal kitchen - 30−35°;

- cook's - 20−25°;

- boning - 25−30°;

- for cutting fish - 20−25°;

- for cutting meat - 25−30°;

- for slicing vegetables - 30−35°;

- for frozen meat - 35−40°.

Using the given values, you can easily determine the optimal sharpening angle for kitchen knives for any purpose.

The size of the angle has a significant impact on the effectiveness of the knife and its durability. This can be clearly seen in the example of hunting and tourist models. Many people confuse these concepts. A hunting blade is designed for cutting the carcass of a hunted animal, so it must have high hardness and a small blade edge angle. A camping knife is made with less hardness in order to avoid the possibility of brittle destruction during the process of setting up a camp and repairing equipment.

The process of boning the carcass depends on the sharpening angle of hunting knives. If you make a camping knife as sharp, it will break quite quickly under the influence of significant loads that you have to overcome.

To sharpen a knife, you must first determine the starting angle. It may differ from standard and recommended ones. For example, the sharpening angle of Japanese kitchen knives is much smaller than that of European models.

Read also: Gas water heaters best models reviews

The most accurate way to measure this indicator is to use a protractor. However, not everyone has this useful measuring tool. Scissors and a protractor will help simplify the task. The blades of the scissors are spread so that they come into contact with the corners of the edge of the knife blade. An angle is measured using a protractor. Of course, this method is associated with large measurement errors, but it is quite applicable in everyday life.

How to maintain an angle when sharpening a knife with a pocket sharpener

Maintaining the angle when sharpening a knife on a pocket sharpener will not be difficult - it is already provided by the manufacturer and does not need correction. Such sharpening devices are a small plastic device, between the plates of which small stones of oval, round or square shape are fixed.

Pocket sharpeners are compact, so they are often used outside the home - on fishing, on a hike, on a picnic. They will not be able to fully sharpen the blade, but it is quite possible to restore its level of sharpness.

A set of accessories for working with kitchen and hunting tools

To accurately set the sharpening angle, you can use a set of devices that allows you to process knives for the kitchen and hunting.

The kit includes:

- several touchstones of different colors, which indicate different grain sizes of their surface;

- oil to facilitate the sharpening process;

- guiding elements.

A set of devices for sharpening a knife

The latter allow you to accurately set the desired sharpening angle and monitor compliance with the parameter during the processing of knives. The presence of whetstones/stones with surfaces of different grain sizes makes it possible not only to sharpen the blade, but also to grind and polish it. Experts believe that such a set of tools can bring the cutting capabilities of knives to almost perfection.

Sharpening tools

The optimal method of sharpening a knife and the equipment for this operation should be selected in accordance with experience and the amount of work. Some methods can be used without special skills, while others require precision and adherence to technology.

Abrasive stones

Sharpening stones are the simplest and most common tool. Each bar is characterized by its hardness and grain size. Conventionally, they can be divided into 3 groups:

- Rough. Used to form an angle.

- Average. Gives the blade sharpness.

- Small ones. Used for finishing work.

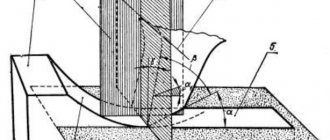

The simplest tool for manual sharpening requires strict adherence to the work technology. Typically the sharpening process looks like this:

- A high-grain stone is taken and placed on the work surface.

- The blade is set at the required angle.

- Sharpening is done by moving the blade along the stone. In one pass, the entire edge should pass over the stone.

- To maintain the correct angle, when reaching the rounded section of the blade, the knife handle must be rotated relative to the block.

- The manipulations are repeated alternately on both sides of the blade until a burr appears.

- Next, you should switch to a stone with a smaller grain size and repeat the operations.

- The last burr is removed on the smallest stone.

Some types of stones require moisture during operation. They are called aquatic. The knives are sharpened on stones soaked in advance; in addition, water is added during the work process.

If desired, you can carry out the final finishing on a piece of leather. For this purpose special belts are used. This operation allows you to polish out the smallest grooves left by the abrasive.

Mechanical device

A manual mechanical sharpener greatly simplifies and speeds up the sharpening process. Despite their versatility, such devices are mainly used for sharpening kitchen knives.

Most sharpeners use rotating abrasive discs to shape the cutting edge. To give the blade sharpness, it is placed between the discs and the blade is pulled from the heel to the tip. To obtain uniform sharpening, you should move the knife smoothly, without jerking, maintaining the same pressure along the entire length.

A distinctive feature of the device is that it is impossible to set the angle on the sharpener. But the knife can be sharpened in different pairs of abrasive discs corresponding to certain angles, if this is provided for by the design of the device.

The electric type of sharpener has a similar principle of operation. It is somewhat easier to work with such a unit, since the rotation of the abrasive discs is carried out using an electric drive. There are no significant differences in the quality of surface treatment.

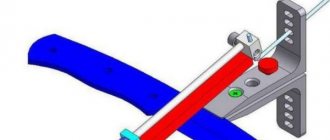

Dedicated desktop device

The most convenient and multifunctional device for sharpening knives can be a simple tabletop device. It consists of a clamp, with the help of which the blade is fixed, as well as a movable element to which the abrasive bar is attached.

The device allows you to arbitrarily set the required angle. To do this, use a vertical guide to adjust the angle of inclination of the bar relative to the plane in which the blade is fixed.

Such machines are currently quite widespread on sale, but the device is easy to make yourself. The advantage of this sharpening method is that it maintains a constant angle of inclination of the tool.

Only a well-sharpened kitchen knife will allow you to cook with pleasure. There is no one ideal sharpening angle; each specific purpose requires a different angle value. There are many different ways to sharpen a blade. It is impossible to say unequivocally which one is better. Only your own experience will help you choose the best option.

Read also: Partner 350 carburetor adjustment instructions

A knife is one of the oldest tools created by mankind and is indispensable in the household. Knives come in different types, are designed for different things, and are made from different types of steel. But most products have one thing in common: they require sharpening. If you do not sharpen the blade for a long time, it becomes dull and ceases to perform its functions well. In order to sharpen a knife in a timely manner and not spoil it in the process, you need to know the rules of how this is done.

Electric sharpeners

You can sharpen a knife as quickly as possible using an electric sharpener. The device is a closed body with slots for inserting blades. Inside there is an electric motor, the axis of which rotates small diamond-coated abrasive wheels.

The sharpening angle in such a tool is set automatically, but there are models with manual setting of the desired parameter - a mechanical switch changes the angle of contact of the knife blade to the abrasive wheels. If the electric sharpener is of high quality and from a reputable manufacturer, then it will contain two types of abrasive wheels - for rough sharpening and for polishing.

Electric sharpener from WORK SHARP

If the cutting edge of the knife is very dull, then you first need to insert the blade into a groove with coarse-grained abrasive wheels and, turning on the device, begin to pull the blade towards you. Only after the geometry of the bevels and the level of sharpness of the blade have been restored, can the knife be moved to another compartment for polishing. Usually 5-10 “pulls” in both grooves are enough to get the desired result.

Blade shapes

There are several blade shapes:

- Wedge-shaped. This knife has straight slopes coming from the butt. It copes well with cutting thick objects made of dense material.

- “Japanese” shape, chisel profile . The blade cuts well and penetrates not too thick materials. Tools with a chisel profile are easy to sharpen and are very common in Asian countries.

- Bullet-shaped. The knife is designed for chopping. Doesn't cut well. The blade has characteristic smooth slopes towards the tip, which is why it gets stuck in the material.

- Razor. The slopes to the tip are concave. The knife is tough and cuts thin fabrics well. It is easy to sharpen.