Metal band sawing machine – equipment for sawing cast, forged, and rolled workpieces. Metalworking professionals and garage hobbyists appreciate these machines for their speed, precise cuts and minimal operating costs.

My review will introduce you to the features of the device, the declared potential, the nuances of operation and maintenance of popular models of metal band saws. The video shows the process of sawing a pack of rolled pipe products into pieces of a given length using an industrial bandsaw device.

This operation is performed similarly on all models with a horizontal position of the saw frame; The design of all metal-cutting cantilever machines is based on a similar principle.

Main nodes

Despite the differences between lightweight desktop models and massive industrial equipment, the design principle of the machines across the entire range is very similar:

- Bed – the more massive the support, the better the engine vibration is dampened. Which has a positive effect on processing accuracy.

- Drive – usually a three-phase motor; less often a single-phase electric motor; always a reduction gearbox that transmits the rotation of the motor shaft to the drive pulley.

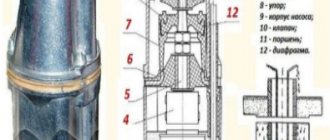

- The saw unit is a closed U-shaped frame with 2-3 pulleys inside, on which the closed saw blade is tensioned. For industrial models, the console moves along 1-2 vertical guides. The design of light and medium-sized machines features a pendulum motion of the saw frame. If we consider the vertical version of the machine, where the saw unit is stationary, it is all the same, in each case there will be fundamentally identical systems that control the position of the blade (mechanisms for adjusting the tension of the band saw and guide units).

Types of band saws

To choose the right blade, you need to have an idea of the types of band saws.

Each type of band saw has its own blade options. Saws are classified based on their intended use.

In stores, band saw tools are presented in three categories:

- For cutting wood . The blades of such saws require special tooth pitches, band width and strength characteristics. Among the manufacturers that specialize in the production of such saws are Super Cut and Extra Hard.

- For cutting metal . When processing metal objects, the strength of the cutting part and the length of the teeth are important. The parameters of the canvas are selected based on the strength of the source material. Saws for metal processing have a narrow specialization. Some models only work with aluminum and its alloys. Such instruments are produced by Wikus, Morse and Eberle.

- Universal . Universal tools work with all materials – regardless of their structure and strength. The main advantage of such saws is their versatility. But in terms of their characteristics, “generalists” are inferior to highly specialized specimens. Such tools are suitable for craftsmen who perform simple work of various types.

General terms

For proper operation of any band saw you need:

- organize the supply of lubricating and cooling fluid (coolant) to the cutting area;

- prevent chips from getting inside the saw unit;

- evenly distribute the load on the working section of the web.

Violation of any point will lead to breakage of the canvas. If the required conditions are met, the operator is freed from manipulations associated with excessive physical exertion - in most cases, before starting work it is sufficient:

- pour coolant into the container provided for this purpose and open the supply (if there is no tank and line, supply it manually);

- control the position and condition of the cord brush, which removes technical dirt from the blade after cutting, before entering the cavity of the saw unit;

- do not overtighten the canvas and adjust the hydraulic unloading correctly (or do not put too much pressure on the spring-loaded console).

Main characteristics of metal bandsaw machines

| Criterion | Meaning | Peculiarity |

| Machine configuration | Vertical | Compact; options with a movable table are controlled manually, the saw unit of the model with hydraulic unloading moves onto the workpiece under its own weight; It’s inconvenient to change the canvas. |

| With pendulum console | Easy to maintain, cuts individually and in batches, most machines are equipped with a coolant supply system. | |

| With guide posts | Industrial equipment. Massive construction; Maintenance requires the use of lifting equipment. The movement of the saw frame of a 1- or 2-post machine is possible only in one plane, which determines the exceptional cutting accuracy. | |

| Permissible dimensions of the workpiece, mm | Up to 120 | Machine for home workshop. |

| Up to 400 | A machine for a small and medium-sized business processing shop. | |

| Over 400 | Industrial equipment. | |

| Saw blade rotation speed*, m/min | Up to 50 | At low speeds, standard saws process stainless steel, heat-resistant steel, and titanium alloys. |

| Over 50 | To process structural steel, aluminum, and copper alloys, a high blade feed speed is required. | |

| Saw feed speed adjustment unit | Mechanical block (shafts – belt). | Strictly specified positions (calculated ratio of pulley diameters). If I have to cut alloy or tool steel, I choose a position of up to 50 m/min; if the table is bronze or steel for cold stamping - over 50 m/min. |

| Electronic unit (frequency converter). | The larger the range of values, the more impressive the list of processed metal. The machine, with an adjustment from 16 to 120, will correctly cut both copper alloy and nickel steels. | |

| Method for adjusting cutting speed | Screw feed vice. | The workpiece, clamped in a vice, is fed to the saw blade. If you need an exact depth of cut, then this is the fastest and most convenient feeding option. |

| Spring (manually controlled machine). | The adjustable spring is convenient because it eliminates the need for the operator to constantly maintain the frame in the desired position. It is enough to lightly press the saw against the workpiece. | |

| Hydraulic unloading | The most convenient system for long-term work - a hydraulic piston lowers the saw frame at a given speed. | |

| Coolant supply line | Present | Forced (the cooling system has its own pump) supply of coolant to the cutting zone. |

| Absent | You will have to pick up an oil can with a supercharger and supply coolant to the saw yourself. | |

| Weight, kg | Up to 40 | Tabletop machines with flat base. |

| 40-100 | Models with a pair of transport wheels for comfortable movement of the machine around the garage or construction site | |

| From 100 | Stationary equipment with high processing accuracy. The greater the weight of the machine, the stronger the floor should be (down to the local foundation). |

*The dependence of the cutting speed on the characteristics of the metal being processed is very conditional.

To accurately determine the possibility of working with any material, it is necessary to take into account the lowering speed of the saw unit, the technical characteristics of the band saw, and the properties of the material being processed. However, ignoring speed = ruining the workpiece and blade. Model summary table

| Model | Peculiarity | For what purpose |

| Industrial machines | ||

| 1. LPS 8535 | A simple and maintainable machine made from domestic components and parts. At the request of the customer, it can be assembled using imported components. There are manual and automatic modes. | For sawing ferrous and non-ferrous rolled steel, alloy and stainless steel, cast iron. The unit is capable of working in 2 shifts, in temperate and cold climates. |

| 2.Fmb OLIMPUS 3+VHZ | Semi-automatic, two-column machine; requires specialized maintenance; installation requires its own pedestal on a monolithic foundation. | Suitable for batch sawing of rolled products and long-term processing of large-sized workpieces made of steel of all grades; work with aluminum-bronze and titanium alloys is possible. |

| Entry-class equipment | ||

| 3. Encore Corvette 422 | Movable console with adjustable spring; rotary vice; collapsible frame-stand; transport wheels; coolant supply is not provided. | For one-time work in a small amateur workshop. |

| 4. Blacksmith S13.11 | The thin-walled stand ensures low weight; common saw blade size; power button on the handle, without fixation; convenient speed adjustment; rotary support of the working console; no coolant supply. | For cutting workpieces from different materials in extremely limited space (balcony, stall, etc.) |

| 5. TRIOD BSM-115/230 | It is possible to work with the saw unit in a vertical position; Belting; worm gearbox of the drive shaft. Manual sawing speed control, Without coolant. | For cost-effective cutting of materials in rooms with an area of 5 m2. |

| Machines for small and medium-sized businesses | ||

| 6. Proma PPS-270THP | Stationary; The rotating saw unit allows cutting at any angle up to 60°. The adjustable hydraulic cylinder and return spring are responsible for the speed of lowering the console. | Suitable for the production of metal structures to order, when frequent changes in the processing angle are expected. |

| 7. LP-160 | Stationary; manual or hydraulic control of the speed of the console is possible; a coolant collection zone is structurally provided. | The best option for long-term sawing of workpieces to size. |

| 8. Metal Master BSG | Mobile; there are no backlashes in critical components; it is possible to work both with diagonal lowering and in a vertical position of the saw unit; the working console lowers under its own weight, with insignificant spring resistance; The saw angle is adjusted by turning the table with a vice. | Meets the needs of a repair shop for machining structural and tool steel parts. |

| 9. PILOUS ARG 220 Plus | Stationary; controls on one panel; independent adjustment of coolant supply, console lowering speed is controlled by hydraulics. | Suitable for long-term work with high-alloy and automatic steels, bronze and copper alloys. |

| 10. STALEX BS-315G | Stationary; a solid table allows you to process small parts; the console rotates in a range of 105°. | For precision machining of structural steels for the needs of small-scale production. |

| 11. JET EHB-270DGSVIP | The body, table, pulleys of the saw unit are made of cast iron; all controls are on the remote control; belt rotation speed – with visualization on the display; console rotation accurate to 1°; control of web tension with a tensiometer. | Meets the needs of continuous production, when not only speed is important, but also processing accuracy up to 0.1 mm. |

Industrial machines

This equipment cuts without restrictions on steel strength, with an accuracy of 0.1 millimeters and operates 24 hours a day. The diameter of the workpiece for “younger” models is at least 400 mm. Scheduled maintenance is assigned to specialized specialists and is carried out taking into account 2000-5000 hours worked. Machines are in demand, and their operation and maintenance are cost-effective only at large industrial enterprises.

LPS 8535 00-01 RE (without rotary table) – from RUB 1,350,000.

Two-column machine from PJSC Kuvandyk plant of forging and pressing equipment “Dolina”. Designed for sawing cast, forged and rolled workpieces from ferrous and non-ferrous metals.

Hydraulic drive of the console, automatic removal of chips into a removable container. The simplicity of the design, standard components and asynchronous motors of the machine determine its reliability and maintainability. Ease of control is due to the remote control on a separate table. The machine operates in manual and automatic modes. It's bad that this version doesn't have a rotary table - sometimes you really need an angled cut.

LPS 8535 has been produced since Soviet times.

But PJSC Dolina produces this version of the machine for no more than 2 years. Apparently that's why I haven't had to repair them yet. I only know that when considering offers from intermediaries, you will most often see a machine with a rotary table. Such a model exists, and it actually costs more. But how much - this will only be told to you in the sales department of the Kuvandyk plant. For more information about the packages, see the table: Delivery package for LPS 8535 from Dolina JSC

| Standard equipment | optional equipment |

| Stepless blade speed adjustment | Automatic feed mechanism |

| Saw frame control hydraulic cylinder | Hexagonal vice |

| Hydraulic vice | Batch cutting mechanism |

| Hydraulic saw tensioner | Rotary table |

| Control and management post | Chip conveyor |

| Coolant supply system | Laser cut line indicator |

| Brush for cleaning the blade from chips | Laser cut line indicator |

| Blade guides, blade alignment bearings | Driven roller conveyors |

| Bimetal saw blade | Non-automatic roller conveyor |

The machine is equipped with an emergency stop mechanism in case of breakage or weakening of the blade, loosening of the vice and limit switches on the pulley covers.

The coolant supply system provides for the reuse of fluid and is equipped with a temperature sensor. Technical characteristics of LPS 8535 (without rotary table)

| Characteristic | Meaning |

| Network / power consumption, V/kW | 400/3 |

| Diameter; height of the workpiece (90°/45°/-45°), mm | 350 |

| Saw blade feed speed, m/min | 20-100 |

| Weight, kg | 1500 |

Video with a presentation of the capabilities of machines from PJSC Dolina:

Find out more about the model on the manufacturer’s website→

Fmb OLIMPUS 3+VHZ – from RUB 2,203,654.

Two-column machine for processing solid workpieces up to 510 mm in diameter and parts with complex profiles up to 450 mm in height. Frame hydraulics and saw tension; frequency converter for motor control; electronic cutting angle indicator; saw break sensor.

The only downside is that replacing a saw blade with a working element that differs in size, pitch or tooth shape requires accurate calculations taking into account the performance characteristics of the saw and the characteristics of the workpieces being processed.

I draw your attention to the fact that the stated limits of workpiece dimensions are valid only in the case of processing parts made of structural steel.

For special steels with these dimensions, a saw with a width of at least 54 mm is used (for OLIMPUS, the permissible maximum is 41 mm). Technical characteristics of Fmb OLIMPUS 3+VHZ

| Characteristic | Meaning |

| Network / power consumption, V/kW | 400/4 |

| Diameter; height of the workpiece (90°/45°/-45°), mm | 510/430/300 |

| Saw blade feed speed, m/min | 16-120 |

| Weight, kg | 2800 |

Video review of Fmb OLIMPUS 3+VHZ:

How to choose

When wondering how to choose a band saw, you must first decide on the range of tasks that it will perform. For a private workshop or small workshop, a Jet, Bomar or Enkor metal band saw of a console type with a rotary table or a vertical one with an inclined frame is sufficient. For a home workshop, you won’t find a better vertical saw. It will also be useful for roofers - such saws cut corrugated sheets and galvanized sheets perfectly.

Industrial production requires more powerful bandsaw equipment - single or double-column machines with hydraulic feed. For large-scale production, it is best to pay attention to CNC machines.

Entry-class equipment

Millimeter play in the saw frame, stamped support elements, saws from the kit torn in the first minutes of operation, and an honest engine power of no more than 0.5 kW form a negative image of budget equipment. But rigidly fixing the device, installing the pulleys in one line and the guides perpendicular to the base, choosing the right saw and 15 minutes of rest after 30-40 minutes of work can improve the situation somewhat.

And if you constantly monitor the position of the blade, then the quality of the cut will be consistently acceptable. In principle, such equipment can be made on your own, especially since today all the parts can be bought. But whether such a homemade machine will be more profitable than a purchased one is an open question.

In addition, the potential inherent in the design of some entry-level machines allows them to be modified to an “adult” level.

Encore Corvette 422 – from RUB 22,355.

Mobile machine with three saw feed speeds. The diagonal stroke of the saw unit is controlled manually. Angle cutting is possible by changing the position of the vice. The reduction gearbox is belt driven, with a worm transmission of rotation to the drive pulley.

The limit switch stops the engine when the working console is completely lowered, the magnetic switch prevents arbitrary starting during a short-term loss of voltage - from the standpoint of safe operation, this minimum can be considered an advantage of “garage” equipment.

The installation angle of the guide and tape receiving units must be constantly monitored; the lack of a coolant supply system affects the wear rate of the saw blade. If measures are not taken in a timely manner to eliminate these shortcomings, they will significantly spoil the impression of using a good (for infrequent one-time work) machine.

I noticed that such devices are popular among those compatriots who, having enough free time and basic knowledge, “cheaply” upgrade them to the acceptable accuracy of more expensive equipment.

Technical characteristics of Encore Corvette 422

| Characteristic | Meaning |

| Network / power consumption, V/kW | 220/0.55 |

| Diameter of the workpiece (90°/45°), mm | 115/70 |

| Saw blade feed speed, m/min | 20-30-50 |

| Weight, kg | 62 |

Video review of Encore Corvette 422:

Blacksmith S13.11 – from RUB 29,367.

Tabletop machine with brush motor and manual control of the position of the saw unit. Setting for sawing at an angle (up to 45°) is performed by turning the working console on the support platform.

Start button on the handle of the saw unit. There is also a convenient speed adjustment. Nearby is the saw tension lever. Each guide unit has 5 bearings. An adjustable return spring balances the console.

Among the obvious shortcomings are the abundance of silumin alloy in the design, the key without fixation, 13 mm between the cutting line and the edge of the vice, and the lack of coolant.

Already in the process of work, it turns out that shortcomings can be effectively dealt with: firmly fix the base - reduce vibration; extension of the jaws of the vice to the cutting line - allows you to process small workpieces; When working with aluminum, you can use a paraffin candle as a lubricant. Blacksmith S13.11 Specifications

| Characteristic | Meaning |

| Network / power consumption, V/kW | 220/1.5 |

| Diameter of the workpiece (90°/45°), mm | 100/55 |

| Saw blade feed speed, m/min | 20-70 |

| Weight, kg | 18 |

Video review of Blacksmith S13.11:

TRIOD BSM-115/230 – from RUB 37,472.

Mobile (due to a pair of transport wheels) machine with a belt drive, worm gear and rotary vice. It differs from its closest analogues in the ability to work on a vertically fixed saw unit.

In the lowest position, the manually lowered console automatically stops the engine by pressing the limit switch; You'll have to lift it yourself. In the middle position, the cutting unit is held by a spring, in the upper position - by a lock. The sawing angle is adjusted by turning the vice.

The main disadvantage is the lack of an integrated coolant supply system.

I recommend that anyone who purchases an entry-level machine initially make sure that there is lubrication in critical components and be sure to take a 15-minute break every 40 minutes of work. Technical characteristics of TRIOD BSM-115/230

| Characteristic | Meaning |

| Network / power consumption, V/kW | 220/370 |

| Diameter of the workpiece (90°/45°), mm | 114/70 |

| Saw blade feed speed, m/min | 20-29-50 |

| Weight, kg | 61 |

Video review of TRIOD BSM-115/230:

Choosing the right type of coolant for your band saw

Oil coolant may contain any combination of fatty oils, sulfide materials, chlorinated materials and EP additives. These additives are added to allow normally incompatible petroleum components to mix with water. This compound does not remain permanent and can separate into different layers to varying degrees, especially when not in use for a long period of time. Oil coolant with the lowest initial cost of additives (components) must be correctly selected taking into account the required viscosity and lubrication characteristics. Any drops of oil coolant that periodically separate from the main flow should be regularly removed to minimize the growth of odor-causing microorganisms, as well as clean painted and welded parts of equipment. Semi-synthetic cutting fluids are fluids based on a synthetic product that typically contain some oil to add lubricity (lubricating function) and corrosion protection. They share some of the advantages and disadvantages of both oil coolant and full synthetic coolant. As with oil-based coolants, semi-synthetic coolants are susceptible to stratification (stratification), causing bad odor (microorganism growth) and reducing the life of the coolant pump. Due to the petroleum content (depending on the additive used), the cutting parts of the band saw must be thoroughly cleaned before they are welded or painted for repairs. Synthetic coolants do not segregate in the coolant tank during long periods of inactivity. Once they are mixed, they form reliable compounds and their concentrate is no longer noticeable in the mixture. Synthetic cutting fluids are heavy-duty, oil-free concentrates. They usually contain EP additives and corrosion inhibitors. Synthetic cutting fluids are tolerant of mixing in water with a high mineral content. Unmixed synthetic cutting fluids are non-toxic and environmentally friendly. As with any type of coolant, once it becomes mixed with metal shavings and flows into the coolant tank, it must be stored (or disposed of) as hazardous waste according to local regulations. However, due to the long useful life of synthetic cutting fluids, disposal costs are likely to be very economical. A quality synthetic cutting fluid concentrate has a higher initial cost than oil cutting fluid. This is to ensure today's best performance in a wide range of cut materials and to reduce time-consuming problem lines. Manufacturing businesses find this more cost effective in the long run.

Machines for small and medium-sized businesses

The requirements for professional equipment are not limited only to the reliability of the mechanisms. Here, kilowatt motors and smooth adjustment of the saw feed speed (and without loss of power) are in demand.

Particular attention is paid to the weight of the equipment and the working dimensions of the saw frame. And such elements of the device as the hydraulic cylinder that controls the console stroke and the coolant supply system are implied by default.

The main feature of professional machines is that the equipment can be selected for specific tasks, be it cutting to size a profile pipe made of structural steel or sawing titanium ingots with a diameter of up to 400 mm.

Proma PPS-270THP – from RUB 390,000.

Stationary machine with control on a separate panel. The rotary stroke of the working console covers negative (from -45°) and positive (up to 60°) values of the radial scale. The saw blade feed speed is switched using a rotary switch.

Positive aspects include the presence of hydraulic unloading and the ability to turn off the hydraulic cylinder; indication of the tension force of the web on a mechanical strain gauge; double-sided coolant supply system.

Among the disadvantages: inconvenient adjustment of the coolant supply, and the bed is a rolled frame covered with sheet metal.

I recommend not neglecting the position settings of the guides - they allow you to correctly distribute the load over the surface of the saw blade.

Technical characteristics of Proma PPS-270THP

| Characteristic | Meaning |

| Network / power consumption, V/kW | 380/1.5 |

| Diameter of the workpiece (90°/60°/-45°), mm | 270/160/240 |

| Saw blade feed speed, m/min | 34,68 |

| Weight, kg | 360 |

Video review of Proma PPS-270THP:

LP-160 – from 75,000 rub.

Band saw machine on a stand made of rolled steel, with a coolant reservoir. The equipment is suitable for daily use, with mandatory cleaning at the end of work. Repairable, does not require special maintenance.

One of the advantages is smooth adjustment of the saw blade feed speed; hydraulic and manual method of lowering the working console; reinforced saw unit shaft bearings; limit switch.

One of the disadvantages is that coolant supply is implemented only on the outlet guide. There are no protective measures in the cutting area and at the entry of the saw blade into the console. Therefore, chips will fall under the casing.

I believe that independently modifying the line for two coolant nozzles and installing a holder for a small cord brush on the receiving guide will not take much time, but will increase the service life of the saw blade

Technical characteristics of the LP-160

| Characteristic | Meaning |

| Network / power consumption, V/kW | 220/750 |

| Diameter of the workpiece (90°), mm | 160 |

| Saw blade feed speed, m/min | 65-90 |

| Weight, kg | 250 |

Video review of LP-160:

Metal Master BSG 220 – from RUB 135,995.

Stationary model on a frame made of cast iron elements. The gear housing, saw frame and vice are also made of cast iron. This allows you to work with massive workpieces without noticeable vibrations.

The machine is convenient in that the controls are located on a separate panel; a strain gauge is provided to control the belt tension; The cutting angle is set by turning the working console; its lock is located at the end of the bed; The coolant supply system has 2 nozzles with independent flow control.

Of the minuses, coolant is supplied directly to the cutting zone by a separate jet from the first nozzle, and the top of the bed is not wide enough (at maximum pressure, splashing is possible).

Please note that the machine “out of the box” requires precise adjustment.

And if during the check the motor does not turn off when the frame is completely lowered, most likely the position of the element that presses the limit switch is off. Technical characteristics of Metal Master BSG 220

| Characteristic | Meaning |

| Network / power consumption, V/kW | 380/1.1 |

| Diameter of the workpiece (90°/60°/-45°), mm | 225/90/155 |

| Saw blade feed speed, m/min | 40, 80 |

| Weight, kg | 185 |

Video review of Metal Master BSG 220:

PILOUS ARG 220 Plus – from RUB 241,199.

Stationary manual equipment with a pendulum stroke of the saw unit and hydraulic unloading. Drive – power electric motor-gearbox with worm gear, rotary table. It is possible to complete the machine with additional equipment. equipment (there are 19 items in the catalogue), for specific working conditions.

Available: cutting angle -45...+60, integrated coolant supply circuit, system that turns off the drive when the saw frame is completely lowered or the blade breaks, measuring stop.

The disadvantages of a machine with production potential should be the absence of a cord brush and adjustment of the saw blade tension without a control device.

Please note - due to the internal carbide plates of the guide units, only 27mm wide belts work stably.

Wider or re-sharpened blades with altered tooth alignment do not bring the expected effect. Technical characteristics of PILOUS ARG 220 Plus

| Characteristic | Meaning |

| Network / power consumption, V/kW | 380/1.0 |

| Diameter of the workpiece (90°/60°/-45°), mm | 200/105/150 |

| Saw blade feed speed, m/min | 40, 80 |

| Weight, kg | 250 |

Review of PILOUS ARG 220 Plus:

STALEX BS-315G – from RUB 317,537.

Band saw machine with gear motor and metal stand, for piece or batch processing of solid and profile metal workpieces in all its forms.

Available: adjustment of the cutting angle on a scale with gradations of 1°, switching the saw feed speed with one turn of the switch; control of the pendulum stroke of the saw console using a hydraulic cylinder with a bypass valve.

The frame design of the bed does not allow one to rely on the stability of the equipment during the processing of large-sized workpieces, even if additional supports and roller tables are used.

Due to the fact that the potential of the machine is many times greater than the capabilities limited by the weak support stand, the best solution would be to replace the base.

But due to the internal placement of the elements of the coolant supply system and the communications of the control system, it would be more expedient to simply strengthen the existing structure and ensure its reliable fixation to the floor. Technical characteristics of STALEX BS-315G

| Characteristic | Meaning |

| Network / power consumption, V/kW | 380/1.1 |

| Diameter of the workpiece (90°/60°/-45°), mm | 230/130/210 |

| Saw blade feed speed, m/min | 40,80 |

| Weight, kg | 350 |

Video review of STALEX BS-315G:

JET EHB 270DGSVIP – from RUB 530,000.

Semi-automatic machine for the needs of mass production, requiring processing accuracy of 0.1 mm. Changing the position of the saw unit is done manually; other manipulations can be carried out using the hydraulic system.

Loaded structural elements – cast iron; control of operating functions and coolant supply is located on the front panel; the result of adjusting the speed of the saw is reflected on the digital display; The limit switch can be adjusted to any position of the console.

There are no obvious shortcomings, the high price is a very controversial disadvantage (the more often the machine is used, the faster it will pay for itself).

In my opinion, Jet has no competitors within the existing range of professional bandsaw machines.

Technical characteristics of JET EHB 270 DGSVIP

| Characteristic | Meaning |

| Network / power consumption, V/kW | 380/1.5 |

| Diameter of the workpiece (90°/60°/-45°), mm | 270/140/240 |

| Saw blade feed speed, m/min | 20-85 |

| Weight, kg | 530 |

Video review of STALEX JET EHB 270 DGSVIP:

My choice

The first thing to do after assembling the Voronezh “ribbon” is to eliminate possible misalignment of the driven pulley. After which, the Encore Corvette 422 works even with a standard saw. Already at this stage, the novice master really feels the difference between an angle grinder and a bandsaw machine. But there is also a replacement of the engine, installation of a hydraulic cylinder, and many small upgrades ahead. In my opinion, this is an ideal option for a novice master.

I saw how, thanks to the capabilities of the semi-automatic JET EHB 270 DGSVIP , a small company coped with the main flow of work and managed to fulfill orders from those customers who were placed at the back of a long queue by competitors. The machine is not cheap, but it is definitely worth the money.

Among industrial equipment, I highlight LPS 8535 . A simple design determines the reliability of the unit, and a wide range of configurations allows the customer to receive a machine tailored to the needs of their production.

FAQ

By tradition, in this section I answer the most frequently asked questions from my clients. Did not find an answer to your question? Ask in the comments!

1. Can a band saw replace a cutting machine?

Yes. Especially if you cut a circle and a square. Plus, it cuts without sparks. And the larger the volume of work, the better the advantages of a band saw are visible.

2. Whose production tapes are best to immediately buy for a budget machine so that they last for a long time?

The service life of the equipment depends least of all on the manufacturer. The tension force, the brand of the saw, and the amount of work matter. However, if you look from the point of view of small-scale production, where only rolled profiles, circles and squares are used, then any bimetal will be better than the native equipment of entry-class models.

3. Which machine should I choose for cutting stainless steel (160 wheel)?

Big. Despite the fact that stainless steel comes in different varieties, it is best to work with it using saws of the M51 brand, and their minimum width is 27 mm. That is, for small machines with a stated maximum workpiece height of less than 200 mm, such equipment will not be suitable.

How often do you service your power tools?

Coolant supply system on a band saw machine

Clean new coolant, a clean coolant tank and clean coolant guide tubes will maximize the effectiveness of any coolant. It is best to check the band saw's coolant tank daily to ensure that the coolant level is not lower than the pump level and that the coupling ratio is correct. Metal shavings or oil leakage from the working parts of the band saw machine deteriorate the coolant. Stop all hydraulic leaks, wash the entire system with a quality detergent, and then refill the coolant tank with properly mixed new coolant. It is necessary to replace the coolant on a regular basis depending on the volume of cutting, at least twice a year. It is also very important to regularly remove chips from the coolant tank, especially cleaning it of small (almost microscopic) metal chips, because during the operation of cutting metal on a band saw machine, it passes through the coolant system, reducing the durability of the band blade (dulling its cutting edge) , as well as generally negatively affecting and prematurely wearing out guides, wheels and other metal parts of the band saw machine.