What is it like?

Diamond knife sharpener consists of tiny particles of artificial diamond grown in laboratory conditions. The grain size of the stone varies. Aluminum or plastic plates are used for binding. They help maintain the required shape of the stone.

Oversized diamond stone with 100/80 grit.

There are CBN whetstones for sharpening knives that have similar characteristics to diamond sharpeners. Experts consider electrocorundum to be an analogue. But in terms of hardness, none of the sharpening elements can compare with diamond. They are considered the fastest at work.

How to sharpen with diamond stones

After you have figured out the choice, characteristics and markings of the bars, you can move on to sharpening technology. For proper use, you need to learn several main rules from which you cannot deviate.

- Before starting work, the stones for sharpening knives need to be slightly moistened with water, you can even apply a little detergent to it, or you can use a special oil.

- During sharpening, it is necessary to wash off the constantly forming emulsion; it is advisable to do this every 15-20 movements.

- If you want to take a break or smoke break, it is better to leave the diamond knife sharpener in a container with water.

- When sharpening a knife, you do not need to hold the whetstone in your hands; it will be much more convenient to place it on a board with a stop, the main thing is that it does not slip.

- You can use the block while holding it in your hands if you don’t have a table or suitable materials at hand, that is, in camping conditions. But you should be extremely careful, as even a dull knife can cause serious damage.

- When sharpening, you should try to use the entire surface of the block so that the diamond coating is ground off evenly.

- One of the most important rules! You cannot press the blade too hard during the sharpening process, as in this case you risk breaking the abrasive crystals from the surface of the stone, which will quickly render it unusable; do not forget that this stone is not a cheap pleasure.

- It is necessary to understand that a newly purchased diamond whetstone initially grinds down the metal very aggressively, but over time it loses this property. After 5-10 full uses, it will reach its normal condition and will delight its owner.

Previous

Combat knivesUSSR diver's knife - NVU

Next

KnivesKnife handle material G10

Advantages and disadvantages

A housewife in the kitchen will hardly need such a sharpening element. Diamond stones are used in special “Edge Pro” type sharpeners. Or they sharpen it manually, having a trained hand in such a craft. Diamond stones have many positive characteristics:

- for sharpening, no additional lubrication with oils is required; just moisten the block a little with water ;

- cleaning the sharpening product after work is done by simply rinsing in running water, wiping with a cloth - the stone is ready for storage ;

- they are not afraid of falls or small impacts , unlike the listed analogues;

- the block does not change its shape after several dozen sharpened knives. The diamond grain has sharp edges and does not change its shape;

- fast grinding of metal , allows you to do the work in a few movements;

- Compared to other abrasives, the surface remains in working condition longer .

The rigidity and durability of a diamond knife sharpener is a key advantage of the product. But it has some small disadvantages:

- The price of the product is not budget . Growing artificial diamonds in laboratories is a painstaking and time-consuming task, requiring special equipment. It is clear that a block of natural diamond will cost the same as an average car. The price of diamond abrasive of standard sizes 150x25x5x2 fluctuates around 2000-3000 rubles. Depends on the percentage of mineral, grain size and manufacturer. The composition of the ligament plays a significant role.

- There is a possibility of damaging the knife . In this case, the proverb applies: make a fool pray to God - he will hurt his forehead. She'll be right on point. Having no experience working with diamond stones, you should try experimenting with cheap blades. Too much pressure and an incorrectly chosen sharpening angle can lead to irreparable damage to the product.

- Quantity of diamond chips from different manufacturers.

Unscrupulous manufacturer. No one is immune from such a turn of events. Insufficient purity of the bond, violation of the technological process, incorrect granulation of diamond powder and other errors.Lead to rapid abrasion of the coating. But such a manufacturer does not stay on the market for long. And those who have proven themselves have earned gratitude for many years.

Cons: Really not very convincing. It is necessary to treat any business responsibly. And counterfeits or defects are accompanying negative elements in any production. A manufacturer that values its reputation will definitely make a return and apologize for the inconvenience.

Set of diamond sharpening stones GANZO G501

Everyone knows that working with a sharp knife is more pleasant and easier than working with a dull one. You can use a hand whetstone to sharpen it, but this requires certain skills. It’s easier, and sometimes faster, to use a sharpening machine.

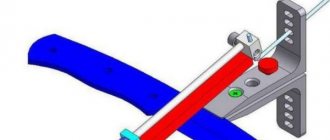

Such a machine is a clamp in which a knife is clamped, and the sharpening bars move along guides, allowing you to maintain a constant sharpening angle.

Previously, the GANZO company had in its assortment sharpening machines with abrasive whetstones. Now a model has appeared with four diamond blocks of different grain sizes.

The set is a bright plastic box, inside of which there are all the elements: a screwdriver, a handle, 4 bars, a clamp, a base for the handle, oil.

The instructions are pasted on the bottom of the package.

Inside the package, although everything is laid out in its own compartments, during transportation the instruments still move and rattle.

The diamond bars are mounted on a plastic base with grooves for better retention. A metal pin protrudes from one end, which does not have a lock and can be removed. Unfortunately, there is no bend at the end of the pin and it can be removed from the guide during operation. The pin in the bar is held in place by rubber seals in the hole.

The bars come in four types of grit: 360, 480, 600 and 800. As you can see, there is no very fine bar to give a mirror shine. The 480 grit whetstone has a groove for sharpening fish hooks.

The clamp in which the knife is clamped consists of two aluminum halves fastened with 2 screws. The screws allow you to clamp even a knife with slopes from the butt. 2 plastic guides with different angles are attached to the clamp to select the correct position. Available in 10, 14, 17, 23, 28, 33 degrees.

When sharpening a knife, the manufacturer recommends using oil - a bottle is included. It is necessary to increase the service life of the bars, so that they clog less and slide better along the knife blade.

The machine can be mounted on a plastic handle, which, in turn, can be attached to a stable working surface. But you can sharpen a knife without it, simply holding the clamped knife by its handle.

The process of sharpening and assembling the set is shown in the video below. But I think everything can be seen quite clearly in the photo.

I would probably classify the disadvantages of the set as:

— lack of fixation of the guide spoke in the block;

— the guide spoke does not have a limiter at the end (because of this, it sometimes flies out of the guide if you get carried away);

— plastic guides for setting angles (although there is no power load on them, metal is still more reliable);

— the red pen included in the kit looks very flimsy.

Pros:

— large selection of sharpening angles;

— good delivery set;

— quite a budget set;

— the ability to clamp almost any blade (even with a release from the butt).

Review for the Fonarik.com blog.

Author serj_32. Any use of materials is permitted only with the written permission of the author.

3 comments

Christinareply May 5, 2021 2:19 pm

Pebbles. I'm so glad to see you. I gave the set to my husband. Although, maybe not only him, because my knives are now sharper than anything else. And, it should be noted, I myself was able to figure out how everything works, although my husband says that I have hooked hands. Overall, great stuff.

Vladreply 13 May 2021 16:39

Good sharpener. I tried sharpening ceramic knives and was pleasantly surprised by the results.

Victorreply 24 May 2021 16:09

Good sharpener. Not only does it sharpen perfectly. It also doesn’t take up much space during storage.

How to choose

The diamond block is selected in accordance with the assigned tasks. It is necessary to understand the tasks ahead.

For convenience, stones are made double-sided, with different grain sizes close in value. For example: 160/125 - 50/40. The meaning of the numbers will be revealed later.

If you are working on a cutting edge restoration or reworking a factory angle, you will need 400/351 or 500/400 for the initial stage. It is clear that the initial treatment will depend on the wear of the knife. Then the editing is done according to the grain reduction scale: 160/125, 80/63 and finally - 7/5 will bring it to the razor.

Markings and symbols

The production of sharpening stones is subject to GOST 9206-81 for diamonds. All markings of diamond bars are divided into four categories:

| Category: | 1 | 2 | 3 | 4 |

| Grain: | 2500/2000; 2000/1600; 600/1250; 1250/1000; 1000/80; 800/630; 630/500; 500/400; 400/351; 315/250; 250/200; 200/160; 160/125. | 125/100; 100/80; 80/63; 63/50; 50/40. | 40/28; 28/20; 20/14; 14/10. | 10/7; 7/5; 5/3; 3/2; 1/0. |

The breakdown of grain size values is as follows. Example: 500/400 means the diamond granule size is in the range of 500-400 microns. The smaller the abrasive grain, the smaller the permissible range of values.

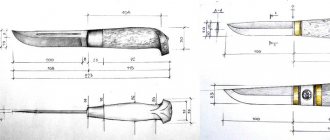

An example of stones with different markings.

A double-sided diamond stone is marked like this: “160/125 - 50/40.” Decoding the category table looks easy:

- Restoring and changing the shape of the knife and cutting edge. Such work is classified as repair work . Deep nicks, chips, burrs and other troubles.

- They will help you acquire the necessary parameters for the blade. Remove traces of roughing work with previous diamond stones.

- Finishing and finishing sharpening .

- Surface polishing and cutting edge correction.

The list items correspond to the category number in the table. If you cannot find a coarse-grained diamond stone for grinding work, it is not forbidden to use a stone with a smaller grain. But it is necessary to take into account that passes will have to be made more times. As a result, the abrasion of the diamond coating will occur more intensely.

Recommendations for sharpening

High-quality sharpening of a knife with a whetstone is an entire art. For this reason, working with a block will require some preliminary preparation. First of all, it is necessary that the surface for sharpening is flat. You can check how flat it is by soaking the block in water and then placing it on a sheet of paper on a flat surface. If roughness is visible on the print, then you need to level the working surface by rubbing one block against another.

The knife to be sharpened should be positioned with the cutting edge facing away from you and moved forward along the working surface. It is important that the knife remains in the same position relative to the block; this feature is the key to successful sharpening. The angle at which the knife should be positioned should be from 15 to 45 degrees. This variability will allow you to achieve the best results. In any case, you need to practice and see how the chosen angle affects sharpening.

For primary sharpening, a stone with a large grain is used. If the blade is as dull as possible, this will give the blade a shape that will later be refined by using a fine-grained whetstone. The key to sharpening knives is practice.

“>

Main criteria when choosing a stone

Before purchasing a sharpening stone, pay attention to the grain size of the abrasive. There are three categories:

- small;

- average;

- large.

Coarse grain is used primarily to eliminate chips on the cutting surface due to the intensive removal of the damaged metal layer.

Then you should decide on the origin of the material. In terms of their technical characteristics, synthetic instruments are superior to natural ones. This statement is true for the average price category. To purchase a high-quality sharpening device, it is better to pay attention to Japanese-made products.

Select your area of use. For sharpening home knives, dimensions do not matter, but on a long hike, the extra weight will definitely be of no use.

Classification of whetstones

Sharpening stones have been used by humans for a long time. To restore the cutting properties of the scythe, peasants used special bars called whetstones. The simplest sharpening stones, which were known to our grandparents, were not very convenient to use: to obtain the required sharpness, the block was soaked in water for a day before use. For this they were called “water stones.”

The first production samples were regularly shaped bars coated with abrasive material of various fractions based on silicon composition.

Sharpening tool markings began to be used in the USSR. This was a forced step related to the standardization of products produced in the territory of the union. The following information was located on the sharpening stones of that time:

- manufacturer's marks;

- product type;

- dimensions;

- the material used and its grain size;

- technical characteristics (hardness, structure, mass fraction of the main fraction);

- accuracy class;

- interstate standard.

According to the type of origin, all sharpening stones are divided into two groups:

- natural;

- artificial.

Let's take a closer look at them.

Natural stones

The oldest type of instrument. Many minerals have properties necessary for sharpening work. There are many sites around the world where natural abrasives are mined and processed. The most popular types are:

- Arkansas. The name was given in honor of the deposit located on the territory of the state of the same name. It is a compound of quartz and rocks. The sizes of the main fractions and their characteristics may vary. There are three strength classes: soft, medium and hard. They are mined from different layers. It should be noted that due to the intensive development of the sites, the reserves of the material are greatly depleted.

In the highest quality Arkansas, the mass fraction of quartz is 100%.

- Japanese water stone. One of the highest quality types. It is mined in several regions of the country. Due to government restrictions on production volumes, such a tool will cost much more than similar devices.

Synthetic stones

A worthy alternative to natural materials. The development of industry and increasing requirements for the processing of cutting products has given impetus to the development of synthetic compounds in which hardness and grain size are absolute values that comply with the requirements of state and international standards. They consist of super-hard materials and synthetic binders, bonded together by heat treatment under pressure. The following types of artificial sharpening stones exist:

- Diamond. Diamond chips, the structure of which has sharp cutting edges, are used as one of the components. Due to its high strength, the thickness of the working layer does not exceed a hundredth of a millimeter, which is quite enough for a long service life.

- Ceramic. Sharpening stones made using advanced technology. The product allows you to perform work with the quality of the best samples of natural stones, and the useful life is comparable to diamond bars.

- Aquatic. Industrial analogue of natural stones. Before use, it is necessary to soak in water in order to improve performance and protect the surface from clogging.