Hand taps

Hand taps are the main thread-cutting tool for plumbing work. It differs from the machine one in that it has a square tail for fixing in a manual crank. Designed for manual cutting of any type of thread in blind and through holes, in accordance with the purpose. Available in two and three sets. The most commonly used are 2-set taps. Three-set taps are typically used for cutting coarse threads with diameters greater than 24 mm. Below are the main metric steps and tap sizes, table:

| Thread size | Main pitch, mm |

| 1 | 0.25 |

| 1.1 | 0.25 |

| 1.2 | 0.25 |

| 1.4 | 0.3 |

| 1.6 | 0.35 |

| 1.8 | 0.35 |

| 2 | 0.4 |

| 2.2 | 0.45 |

| 2.5 | 0.45 |

| 3 | 0.5 |

| 3.5 | 0.6 |

| 4 | 0.7 |

| 4.5 | 0.75 |

| 5 | 0.8 |

| 5.5 | 0.5 |

| 6 | 1 |

| 7 | 1 |

| 8 | 1.25 |

| 9 | 1.25 |

| 10 | 1.5 |

| 11 | 1.5 |

| 12 | 1.75 |

| 14 | 2 |

| 16 | 2 |

| 18 | 2.5 |

| 20 | 2.5 |

| 22 | 2.5 |

| 24 | 3 |

| 27 | 3 |

| 30 | 3.5 |

| 33 | 3.5 |

| 36 | 4 |

| 39 | 4 |

| 42 | 4.5 |

| 45 | 4.5 |

| 48 | 5 |

| 52 | 5 |

| 56 | 5.5 |

| 60 | 5.5 |

| 64 | 6 |

Hand tap - purchasing feature

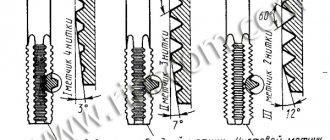

What does such a tool look like in the hands of a mechanic? Since hand taps are classified as metalworking tools and can be used to cut threads by hand, it was decided that they should be made in a set that consists of two or three tools. Typically, a set includes several taps: rough, medium and finishing. They can be distinguished by markings or, more often, by numbers that indicate the sequence of use in the work, as a rule, these are numbers 1, 2 and 3.

Machine-hand taps

This is a universal type of tap for threading, designed for both manual use and installation in a chuck of metal-cutting equipment. When manually cutting, it is possible to cut threads in increments of up to 3 mm. inclusive. Single taps are available in two versions - for cutting threads in through holes, for which there are 6 threads on the working part of the tool. To cut threads in blind holes, taps with 3 threads on a taper are used. Separately, machine taps with screw and shortened grooves are produced, designed exclusively for mounting into a machine chuck.

Do you need an internal thread? Then you need a tap.

To cut internal threads you will need a tap. They come in 2 types - metric and pipe. The first ones are for ordinary metric threads (the kind that goes on bolts and nuts), the pipe ones - respectively, for threads on pipes. Metric ones have the letter M in their designation, pipe ones - G, K or RC.

Metric machine-manual

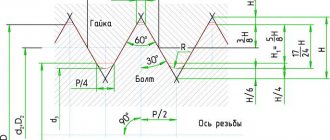

The marking is the letter M, followed by the thread diameter and pitch. For each thread diameter there are several steps (fine, medium, standard), of course the steps begin to increase with increasing diameter. For example, a standard M5 thread has a pitch of 0.8; there are no more steps per diameter of 5. However, already at 6 mm there are standard threads of 1 mm, as well as small threads of 0.75 mm (rare and unclaimed). A 10 mm thread has a standard pitch of 1.5; it also comes in 10*1 and 10*1.25.

Most often, taps are sold in sets of 2 pieces - rough (for initial cutting) and finishing (for cleaning threads). The first number has a sharper approach, the second - more blunt. Often, dashes are used to indicate the first and second, 1 stripe on the rough, 2 stripes on the finishing.

For taps with standard threads, the thread pitch is not written; it is simply designated M10 (standard pitch 1.5) or M8 (standard pitch 1.25). Related article - table of standard pitches for thread diameters. There you can also find out which drill is suitable for which thread - the information is more than useful. You can find out the thread pitch using a thread gauge - a set of pitch templates. For metric threads - one thread gauge, for pipe threads - another (at 55 degrees).

Pipe

There are 3 types:

1. Pipe cylindrical - designation G 2. Pipe conical - marking K 3. Conical inch - designation RC

You don’t have to worry too much, the standard thread for pipes is a cylindrical pipe thread (designated G, G1/2″ is half an inch, G1″ is an inch thread, and so on by analogy).

The most commonly used on the farm are G 1/2″, G 3/4″, G1″, G 1 1/4″ (an inch and a quarter) and 1 1/2″ (one and a half inches).

Price and quality of the tool.

We will talk about the quality of the metal. By and large, there are only two types of steel: carbon steel (U7) and high-speed steel (r6m5, r18, HSS).

Another note: What types of key cutters for metal are there?

If you need threads in soft metal, you can easily get by with carbon threads. They are much cheaper than a quick cutter, 2-3 times cheaper. For example, M6 carbon costs 60 rubles, and high-speed cut costs 170 rubles. The difference is obvious.

High-quality high-speed cutters are needed primarily for hard metal (they often buy from us for cutting threads in alloy steel). Carbon steel can break under heavy load, so if you are doing important work, don’t skimp, buy from a quick cutter.

An excellent manufacturer is the Lviv plant, also look for any taps made in the USSR either with a quality mark or made of P18 steel - it will be very difficult to find them, but their quality is simply excellent. They still knew how to make instruments in the USSR, not like now - it’s all China, you don’t even know what and how to choose. But on this site you will find only truthful information, so follow the advice - you won’t go wrong. You can read about normal metal drills here.

Not bad carbon U7 - you can easily cut threads with them in a regular corner, copper, galvanized iron. The ones in the photo above are quite possible to get by with for your home, fortunately their quality is more or less and their price is low.

Nut

Sold individually, as opposed to machine-manual. It is much longer than the machine-manual one, its entry is very sharp (so it is not suitable for cutting threads in a blind hole). They also come with standard threads, and with fine and medium threads. There's nothing special about him anymore, he laughs just like anyone else. Therefore, if you need to cut a couple of holes on hard metal, but cannot fork out for a set, then buy a single one and save 40 percent.

To cut threads, you will also need a tap holder and oil (household, machine). It is better to take a domestic holder, otherwise all imported ones are made of silumin (powdered metal), are weak and often break.

The cutting technology is simple - drill a hole (each diameter and pitch has its own), then secure the tap (first rough) in the holder, drop a couple of drops of oil on the tap and insert it vertically into the hole. It is advisable to clamp the workpiece in a vice so that the thread does not go askew. Slowly turn clockwise (if right-hand thread). So twist it, a little forward, then back and forward again. The lesson is difficult only for the first time.

Another note: A useful thing in the household is a thread gauge.

Left

For left-handed threads there are special taps marked LH. The price for them is a little higher, and sometimes it can be quite difficult to find them on sale. When cutting, do not forget to twist counterclockwise.

Sets of taps and dies

Nowadays you can find anything on store shelves. Many people want to buy a set of taps and dies for their home at once. And they are available for sale and the price is low. The question arises - is it worth buying sets, how is the quality? My answer is that in my opinion, such sets are worth buying only for home use. The sets are Chinese (no one produces these anymore) and the quality of the metal of the instrument is not very good. Of course, if you need such a set for your home, you can buy it, since thread cutting is not a common task. Of the more or less decent ones. Although, in my opinion, if you really want to have a high-quality instrument, then take it separately. How much do you need for your home - sizes M4, M5, M6, M8, M10, M12 and the same dies. Of course, this will cost you 1000 rubles, and for the dies another 400 rubles. But you will have a really high-quality tool and you can work with it on any metal. It's up to you to decide, of course. Yes, by the way, buy dies only from old stocks, I checked it personally - they are many times stronger than modern ones.

Nut taps

Nut taps are a special type of taps for cutting threads with a longer tail. This type of tool is designed for installation in a lathe or machining center and, due to the increased length of the shank, allows you to cut threads on several nuts without turning the tap out of the hole. As the cutting process progresses, the nuts are threaded onto the shank, thereby increasing the productivity of the operation. Nut taps are produced single and have 12 turns on the working part. The tools used in automatic nut tapping machines have a curved shank from which the nuts are automatically released as they are cut.

Application

Threading tools are divided into types according to design features and application:

- • manual, where the teeth are arranged in a circle. Used in metalwork and manual cutting;

- • nut, for through holes on nuts. With an extended or curved shank;

- • machine, for creating blind holes by machine. Processing takes place on lathes;

- • combined, it is possible to use both manual and machine methods of applying threads to the part.

The tool allows you to apply all types of threads - metric, inch, trapezoidal.

Left taps

This is a thread-cutting tool for cutting left-handed threads - threads in which the protrusion, when rotated counterclockwise, moves away along the axis from the observation point. Accordingly, the part is screwed in or screwed in counterclockwise. They have the same pitch and diameters as metric threads and are marked with the letters LH. They are used much less frequently than taps with right-hand threads, but are indispensable when creating many structural elements, primarily where it is necessary to prevent loosening of the threaded fastening during right-hand rotation. Left hand taps are divided into subtypes depending on the type of thread (conical, cylindrical); they can be straight or screw with grooves to remove chips from the cutting zone; they are produced in the range from M4 to M42.

How to remove a broken tap from a hole

The tap may break if the thread is cut into a hole with a small diameter, and chips may become trapped when the tool is removed.

Extraction methods

- 1. The double ends of the rigid wire must be inserted into the grooves of the tap and unscrewed;

- 2. You can weld the handle to the broken instrument and use it to remove it;

- 3. There are special mandrels and countersinks that will help cope with this problem;

- 4. If part of the tap remains outside, you can weld a shank with a square tip to it;

- 5. Drilling with screw drills;

- 6. Burning with electrical erosive machines;

- 7. Etching with dilute nitric acid.

Inch taps

This is a tool for cutting threads in the inch measurement system adopted in the USA, Great Britain and some other countries. Used for cutting blind and through threaded channels in steel and cast iron products. They are manufactured in two or three sets and have 3 accuracy classes. Inch taps are divided, depending on the standard, into taps with BSW threads (basic British coarse thread with an apex angle of 55°), with UNC and UNF threads - widely used unified types with an apex angle of 60°, as well as UNS (Unified Special), 8UN, UNEF, etc. Below are the inch sizes of taps, tables of some basic standards.

| Nominal diameter, inch | BSW(W) | UNC | UNF | UNEF | BSF | Thread diameter, mm |

| Thread/Inch | Thread/Inch | Thread/Inch | Thread/Inch | Thread/Inch | ||

| No. 0 | — | — | 80 | — | — | 1,520 |

| No. 1 | — | 64 | 72 | — | — | 1,850 |

| No. 2 | — | 56 | 64 | — | — | 2,180 |

| No. 3 | — | 48 | 56 | — | — | 2,520 |

| No. 4 | — | 40 | 48 | — | — | 2,850 |

| No. 5 | — | 40 | 44 | — | — | 3,170 |

| No. 6 | — | 32 | 40 | — | — | 3,500 |

| No. 8 | — | 32 | 36 | — | — | 4,160 |

| No. 10 | — | 24 | 32 | — | — | 4,830 |

| No. 12 | — | 24 | 28 | 32 | — | 5,490 |

| 1/16″ | 60 | — | — | — | — | 1,587 |

| 3/32″ | 48 | — | — | — | — | 2,381 |

| 1/8″ | 40 | — | — | — | — | 3,175 |

| 5/32″ | 32 | — | — | — | — | 3,969 |

| 3/16″ | 24 | — | — | — | 32 | 4,762 |

| 7/32″ | 24 | — | — | — | 28 | 5,556 |

| 1/4″ | 20 | 20 | 28 | 32 | 26 | 6,350 |

| 5/16″ | 18 | 18 | 24 | 32 | 22 | 7,938 |

| 3/8″ | 16 | 16 | 24 | 32 | 20 | 9,525 |

| 7/16″ | 14 | 14 | 20 | 28 | 18 | 11,113 |

| 1/2″ | 12 | 13 | 20 | 28 | 16 | 12,700 |

| 9/16″ | 12 | 12 | 18 | 24 | 16 | 14,288 |

| 5/8″ | 11 | 11 | 18 | 24 | 14 | 15,876 |

| 11/16″ | — | — | — | 24 | 14 | 17,463 |

| 3/4″ | 10 | 10 | 16 | 20 | 12 | 19,051 |

| 13/16″ | — | — | — | 20 | 12 | 20,638 |

| 7/8″ | 9 | 9 | 14 | 20 | 11 | 22,226 |

| 15/16″ | — | — | — | 20 | 11 | 23,813 |

| 1″ | 8 | 8 | 12 | 20 | 10 | 25,401 |

| 1 1/16″ | — | — | — | 18 | — | 26,988 |

| 1 1/8″ | 7 | 7 | 12 | 18 | 9 | 28,576 |

| 1 3/16″ | — | — | — | 18 | — | 30,163 |

| 1 1/4″ | 7 | 7 | 12 | 18 | 9 | 31,751 |

| 1 5/16″ | — | — | — | 18 | — | 33,338 |

| 1 3/8″ | 6 | 6 | 12 | 18 | 8 | 34,926 |

| 1 7/16″ | — | — | — | 18 | — | 36,512 |

| 1 1/2″ | 6 | 6 | 12 | 18 | 8 | 38,101 |

| 1 5/8″ | 5 | 5 | 18 | 8 | 41,277 | |

| 1 3/4″ | 5 | 5 | 18 | 7 | 44,452 | |

| 1 7/8″ | 4,5 | 4,5 | 18 | — | 47,627 | |

| 2” | 4,5 | 4,5 | 18 | 7 | 50,802 |

Pipe taps

Designed for cutting pipe threads with an inch measurement system, marked with the letter G. Available in a range of sizes from 1/8 to 2 inches, the most widely used are ½, 3/4 and 1 inch, more rare 5/8, 7/8, 5 /6 and 3/8 are used, as a rule, in hydraulics. Pipe taps are produced in manual and machine-manual versions and are used for cutting threads in locknuts and other elements of water supply systems. As a rule, they have a two-set design, with a sharp and blunt entry.

Useful tips for using taps

- Select devices that are suitable in size and characteristics for the job.

- For more accurate positioning, craftsmen recommend mounting the tap shanks in chucks with floating, self-centering and reversible properties.

- Pre-chamfer all workpieces to be processed.

- A part made using casting or stamping technology must be prepared for threading. Holes are countersinked or drilled to increase diameters.

- Do not neglect the need to use cutting fluids.

- To cut threads in deep holes, use taps that are longer than the cutting depth.

Conical taps

Used for cutting conical metric and pipe threads. They are marked, respectively, K (conical metric) and Rc (conical pipe). The main design difference is the presence of an elongated initial, intake portion of the working space with an incomplete thread, which gradually turns into a full thread in the calibrating part of the tool. Due to this, the specificity of the operation of a conical tap is cutting threads along the entire length corresponding to the length of the thread in the product. Due to the absence of a calibrating part, great effort is required and cutting is carried out, as a rule, on machines with a protection system that stops the operation of the equipment at the end of cutting.

A set of taps - the pros and cons of such a tool

In theory, everything seems simple when working with taps, but this is not entirely true. If we look at the process in more detail, this is a rather expensive undertaking in terms of physical strength, especially if you set to work manually. After all, cutting metal with metal is not easy, the friction forces are enormous, the chips are not as pliable as in wooden products when drilling, they are also very resistant when exiting through the grooves. Due to the presence of grooves in the body of the tap, the strength of the body is somewhat reduced, so these devices are prone to breakage, especially when using a thin size.

But not everything is so depressing, because it’s not for nothing that the tap was used before and has not disappeared from the toolkit to this day. The structure itself is simple, easy to make and use, you don’t have to think long about how to use it and where to attach it. The accuracy of the thread is quite high, and for very demanding parts it can be increased by improving the quality of the tap itself, which is easier than building complex devices to control the cutting process itself. Having made a more perfect tap, you can already count on the same perfect thread.