Sharpening stones are multifunctional tools; they are needed for repairing, straightening and sharpening devices that have a cutting edge. They cope excellently with such tasks as sharpening, since the force and intensity of manual processing are selected independently, unlike electric machines, which operate at high speeds and, due to a small mistake, can ruin the entire product. Another advantage of the bars will be their modest dimensions, thanks to which any tourist, fisherman or hunter can have them with them.

Stones for sharpening knives.

Rules for sharpening a blade

At first glance, it may seem that even a non-professional can cope with this work. However, practice is much more important than knowledge. A cook with extensive experience can create a sharp razor from a dull knife using an ordinary brick, and a sloppy craftsman will be able to ruin a dagger even with the help of the most expensive and high-quality timber.

- To begin with, the sharpener must be properly prepared. The surface that will be used for work must be smooth and flat. This is easy to check - wet the timber and place it on a sheet of paper on a flat surface. The imprint will allow you to evaluate the level of evenness of the stone. You can smooth out defects using a similar stone by simply rubbing them against each other.

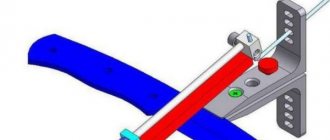

- The surface where the sharpener will be located during operation should not be slippery. Some types of timber are equipped with a special pedestal.

- The knife should be held with the working surface facing you. Using straight-line lunges, we intensively carry out across the edge of the sandpaper. You should not make any longitudinal and/or circular movements.

- The sharpening angle can vary from fifteen to forty-five degrees. The smaller the angle, the sharper the blade.

- Sharpening a knife should be done from the largest grain to the smallest. First you need to come up with a certain shape for the edge, then change the timber and bring the material to ideal condition.

Sharpening household tools

Having chosen a stone for sharpening knives, you need to learn how to set the sharpening angle of the blade, familiarize yourself with the procedure step by step, and the features of the technological process.

Angle Definition

Choosing a whetstone for sharpening knives is not as difficult as setting the required angle. It is chosen depending on the purpose for which the cutting edge will be used. Classic sharpening angles:

- Razors, surgical instruments, blades - up to 10 degrees.

- Fillet knives for cutting vegetables -10–20 degrees.

- Professional chef's knives - 20–25 degrees.

- Universal tools - 25-35 degrees.

- Blades for hunting, heavy work - 30–40 degrees.

Do not forget to lubricate the sharpening stone with oil or moisten it with water. Tables of exact turning angles can be found on the Internet.

Types of thin sections

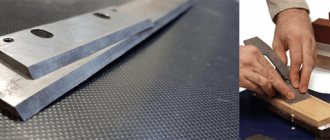

Sharpening stones can be double-sided or single-sided. The second option is more convenient. It is advisable to use several devices according to the grain size, so that it is possible to correct both gross and minor damage to the blades.

Stones of different grain sizes

Step by step procedure

To get a good effect, you need to do the work correctly. Step-by-step instruction:

- Diamond stones for sharpening knives must be prepared before sharpening. Check the abrasive surface for unevenness. It should be smooth.

- Place the stone so that the sanding side faces up.

- Take the knife blade with the cutting edge facing away from you. Perform straight movements. Moisten the stone with water when carrying out work.

It is forbidden to make movements in a circle or move the blade longitudinally. This can damage the cutting edge.

Knives are used in any kitchen; they are used by hunters, fishermen and travelers. To keep this versatile tool in working condition, you need to sharpen the cutting edge. To do this, you need to choose a block of abrasive material.

Sharpening kitchen knives on water stones and sharpening systems

Watch this video on YouTube

Arkansas novoculite stone

The birthplace of this natural material is the American state of Arkansas. It was in honor of him that it received its name. The Arkansas Whetstone whetstone is made from sharpened quartz crystals that have been naturally pressed. The sharp edges of these particles remove a thin metal layer, allowing you to sharpen the blade efficiently and quickly.

The material is extracted from deposits of which very few exist today. Therefore, such a process is considered expensive, which explains the high cost of the whetstone. These devices are used by experienced specialists, since sharpening knives with their help requires a certain skill. In addition, sharpening with an Arkansas stone involves generously treating the surface with an oil mixture.

Natural whetstones

People have been using stones found in nature to sharpen blades for several millennia, since the invention of metal tools and weapons. Initially, the touchstones were simply the first stones of a suitable shape that came across. Subsequently, people discovered that some stones were better for sharpening. Each area had its own source of abrasive rocks. These days, the most popular stones are the following, named after the place where they were mined:

- Arkansas (Arkansas, USA);

- Opinel (France);

- Rozsutec (Slovakia).

Grinding stones are also mined in Russia (Ural) and Ukraine (Kamenets-Podolsky).

Grit of sharpening stones

Before purchasing a tool for maintaining knives in working condition, the first question that will arise is the required grain size of the sharpening stone. In technological documentation this parameter is called grit. The aggressiveness of the impact on the treated plane depends on its value.

Large grains leave deep marks on the edge, which is not always acceptable for some materials. A smooth and sharp surface without the slightest hint of burrs or other defects is considered ideal. For this reason, large grains are used primarily for repair and restoration work.

A sharpening stone made from small fractions can provide a high-quality result, however, the procedure will take a lot of time.

Experienced craftsmen recommend keeping a set of tools of different fractions on hand. The sharpening process should begin with a coarse grain and gradually move to a finer one.

Sharpening history. Emery stone.

The natural stone emery has been used as an abrasive for centuries. Its first deposits have been known since the times of Ancient Greece. Most often, sharpening wheels were made from it, with which sharpeners from different countries and eras walked the streets of ancient cities and offered sharpening services. The stone was mined from deposits and the main mineral included in the emery was corundum.

Corundum is a mineral that is 90% crystalline α-aluminum oxide (Al2O3), trigonal system. The crystal structure of corundum consists of six oxygen ions, between which there are aluminum cations. Corundum crystals have a prismatic shape. The density of corundum is 4000 kg/m³. Corundum is formed when there is a deficiency of silica and a high content of alumina. Known as a product of the metamorphism of bauxite and other high-alumina rocks. It is often found in rocks such as gneisses, crystalline schists, garnet amphibolites, and various types of marble.

Pure corundum is white, it is painted in different colors (red, red-brown, purple, blue or light blue, from yellow to orange, green) due to impurities of chromium, iron, titanium or vanadium. Transparent colored varieties of corundum are expensive jewelry (precious) stones. Red corundums, colored with an admixture of chromium, are called rubies; blue ones, colored with an admixture of iron and titanium, are sapphires, and colorless corundum is leucosapphire. The density of corundum is 3.9-4.1 g/cm3, the Mohs hardness is 9, that is, it is only slightly inferior to diamond.

The largest corundum deposit, Semiz-Bugu, is located in Kazakhstan. Currently, on an industrial scale, natural corundum is replaced by artificial corundum, which is produced by ore-thermal smelting from bauxite and alumina raw materials. This material is called “electrocorundum” or simply aluminum oxide and is widely used in the production of abrasives. However, there is one variety of natural corundum, which, albeit to a limited extent, is still used today. This is an emery stone.

Emery is a fine-grained rock of black and black-green color. It is a mixed rock and is a mixture of corundum (alpha aluminum oxide) and magnetite (black magnetic iron oxide Fe3O4). The composition of emery includes compounds of iron and some other minerals, but the main component is corundum (97%). Corundum is usually mixed with an additional impurity. Various emery materials are fine-grained mixtures of corundum with magnetite, hematite, sometimes with spinel, diaspore, brittle micas, garnet and other minerals. The peculiarity of emery as an abrasive material is the presence of fusible impurities. For this reason, emery can only be used when making tools using silicate, magnesium and organic bonds.

Emery has three varieties: 1) chloritoid-corundum with a corundum content of up to 40-70%; 2) magnetite and spinel-magnetite with a corundum content of up to 30-40%; 3) diaspore-corundum with a corundum content from 40 to 65% or more. On the Mohs scale, emery has a hardness of 7 to 8 units, depending on the amount of corundum and other impurities it contains.

Emery gained popularity as a sharpening material in ancient times and survived into the era of synthetic abrasives. Emery was most effective as an abrasive material in grinding tools when processing low-hardness metals (unhardened steel, iron, non-ferrous metals), where it gave a higher quality of processing than corundum. Particularly high quality surfaces were obtained when using chloritoid emery. In addition, it was widely used for free grain sanding. Back in the middle of the 20th century, emery was used in flexible disks on various substrates, including for knurling on a felt base, mainly for grinding non-critical metal products. In addition, artificial millstones, special grinding stones for sawmills, and defibering stones for grinding wood were made from emery using a magnesium binder. And of course, using sanding powders, sandpaper was produced, which was called “sandpaper.” All these technologies were gradually phased out due to the widespread use of electrocorundum and the depletion of emery deposits.

Currently, emery is still produced in the form of predominantly coarse powders - grinding grains with a particle diameter of the main fraction of 90 microns or more. It is used for sanding paper. Emery mining continues in the ancient Greek deposit on the island of Naxos in the Aegean Sea, as well as in the United States in Massachusetts. In Russia, there is a deposit of emery in the Krasnoyarsk Territory.

Despite the fact that the use of this stone is becoming a thing of the past, it will not be forgotten, since it has long become a household name. Electric sharpeners with round stones and sanding paper are still called “emery”. And emery was replaced by abrasives made from electrocorundum, such as Naniwa Professional stones, and silicon carbide, such as Profile stones.

Classification of whetstones

Sharpening stones have been used by humans for a long time. To restore the cutting properties of the scythe, peasants used special bars called whetstones. The simplest sharpening stones, which were known to our grandparents, were not very convenient to use: to obtain the required sharpness, the block was soaked in water for a day before use. For this they were called “water stones.”

Sharpening tool markings began to be used in the USSR. This was a forced step related to the standardization of products produced in the territory of the union. The following information was located on the sharpening stones of that time:

- manufacturer's marks;

- product type;

- dimensions;

- the material used and its grain size;

- technical characteristics (hardness, structure, mass fraction of the main fraction);

- accuracy class;

- interstate standard.

According to the type of origin, all sharpening stones are divided into two groups:

Let's take a closer look at them.

Natural stones

The oldest type of instrument. Many minerals have properties necessary for sharpening work. There are many sites around the world where natural abrasives are mined and processed. The most popular types are:

- Arkansas. The name was given in honor of the deposit located on the territory of the state of the same name. It is a compound of quartz and rocks. The sizes of the main fractions and their characteristics may vary. There are three strength classes: soft, medium and hard. They are mined from different layers. It should be noted that due to the intensive development of the sites, the reserves of the material are greatly depleted.

- Japanese water stone. One of the highest quality types. It is mined in several regions of the country. Due to government restrictions on production volumes, such a tool will cost much more than similar devices.

Synthetic stones

A worthy alternative to natural materials. The development of industry and increasing requirements for the processing of cutting products has given impetus to the development of synthetic compounds in which hardness and grain size are absolute values that comply with the requirements of state and international standards. They consist of super-hard materials and synthetic binders, bonded together by heat treatment under pressure. The following types of artificial sharpening stones exist:

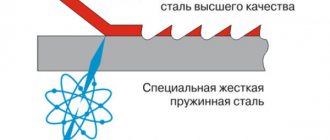

- Diamond. Diamond chips, the structure of which has sharp cutting edges, are used as one of the components. Due to its high strength, the thickness of the working layer does not exceed a hundredth of a millimeter, which is quite enough for a long service life.

- Ceramic. Sharpening stones made using advanced technology. The product allows you to perform work with the quality of the best samples of natural stones, and the useful life is comparable to diamond bars.

- Aquatic. Industrial analogue of natural stones. Before use, it is necessary to soak in water in order to improve performance and protect the surface from clogging.

South African sharpening stones Zulu Gray

These stones get their name from the area where they are mined in the Kwa Zulu-Natal province. Despite the excellent quality characteristics, these stones are not so common among domestic sharpeners, because they do not have a centuries-old history, in addition, the material has a very high cost, these factors do not contribute to their rapid spread.

For a razor, it is recommended to finish the working surface of the stone and the sides without fail. When used, such stones do not release a suspension, but if you use another one, then perhaps it will appear. In work, such material shows itself quite well. Some craftsmen pre-soak in order to achieve more comfortable work. This is usually done for about half an hour or a little more, but when such procedures are carried out with the described stone, no particular difference is noted.

The material works perfectly both with soapy water and with water that does not have additives. With a wide approach towards the end of the work and the use of water, the razor begins to stick somewhat.

Oil is often used in tandem with Arkansas. If you use the described material with it, the result will be excellent. First you have to drop the oil, rubbing it, you can get rid of the excess amount with a napkin. Craftsmen note good and pleasant tactile sensations; the material feels like velvet to the touch. Regardless of which razors are used, the sharpening surface performs well with all of them.

Experts who use Zulu Gray stones for sharpening note that the tool cuts freely and meets all sharpness requirements.

Table of grain size markings according to various standards.

If you intend to sharpen a razor using such a stone, then to complete the finishing you need to slightly raise the angle, and you need to make about 30-50 passes for each side of the tool, applying such pressure that does not exceed the weight of the razor.

Experts note that they do not use razors that have undergone restoration, however, when testing the described stone and testing razors from various manufacturers, the results turned out to be good and indicative.

Methods of sharpening on water stones.

Some argue that South African stones can be considered the leaders in finishing among all others, including when compared with Coticule and Guangxi and Thuringian slate. It is recommended to use oil, but water works just as well as a lubricant. The only disadvantage in this case is the price, but if you operate it very carefully and for your own needs, then it will prove to be very economical. It also does a good job of producing extremely hard blades that some other stones cannot handle. The grain size of the stone is sufficient for this type of work.

Before purchasing a sharpening surface of natural or artificial origin, you should decide for what purpose and with what intensity you will use it.

If you have not previously had experience working with stones intended for turning, and subsequently plan to use them less often, then it is preferable not to purchase expensive material, but to use the help of a specialist.

Factors to consider when choosing a stone:

area of use; intensity of application; grain.

Main criteria when choosing a stone

Before purchasing a sharpening stone, pay attention to the grain size of the abrasive. There are three categories:. Coarse grain is used primarily to eliminate chips on the cutting surface due to intensive removal of the damaged metal layer

Coarse grain is used primarily to eliminate chips on the cutting surface due to the intensive removal of the damaged metal layer.

Then you should decide on the origin of the material. In terms of their technical characteristics, synthetic instruments are superior to natural ones. This statement is true for the average price category

To purchase a high-quality sharpening device, it is better to pay attention to Japanese-made products

Select your area of use. For sharpening home knives, dimensions do not matter, but on a long hike, the extra weight will definitely be of no use.

Japanese stones with water wetting

Wet Japanese stones, both natural and synthetic, sharpen very quickly and have a fine grain that is much finer than oiled stones. It ranges from 800 units for the coarse category, 1000 units for the medium and/or fine category, and up to the finishing categories of 4000, 6000 and 8000 units.

Natural water-wet stones are prohibitively expensive, and only the most sophisticated craftsmen have such high-grade stones. Most craftsmen involved in woodworking are satisfied with artificial stones, having one or two natural stones of this class. Combined stones are presented in regular pairs. To improve the quality of your work, create a “sharpening mixture” on its moistened surface by rubbing it with a chalk-like nagura stone. The technique is especially effective when using any hard stone of extra-fine grain size.

What is the grit of a whetstone?

This characteristic shows how many abrasive grains are contained in 1 square meter. see work surface. Grit is measured in grit and varies from 80 to 10,000. The lower the grit, the larger the abrasive particles. Coarse-grained whetstones are used for initial, rough sharpening of the blade. They remove metal deeply, changing the shape of the blade very quickly. Such bars are used to restore severely dull or damaged cutting edges.

Abrasives with high grit are used for finishing the blade. They remove a very thin layer of metal with each pass, reducing the risk of scoring or other edge damage.

Professionals use sets of whetstones of different grain sizes, gradually moving from coarse to fine, and bring the blade to a high sharpness and the correct sharpening angle. This multi-stage sharpening lasts for a very long time, since the metal layer is perfectly aligned.

Several grain gradation systems are used around the world:

- FEPA-F - the system was developed in the European Union and is also used in America;

- JIS Japanese system;

- GOST 9206-80 – for diamond abrasive materials;

- GOST 3647-80 – for other abrasive materials.

The system values do not match, but transition tables exist.

Why a whetstone?

In order to restore lost sharpness to knives (or give it to them for the first time), there are many devices. There are hand-held sharpeners made up of several abrasive discs, and electric devices, even large sharpening machines that are used in enterprises.

For obvious reasons, you won’t keep bulky equipment at home. As for manual sharpeners, their big disadvantage is the inability to set the sharpening angle, as well as the fact that the blade runs along the working part, which leads to accelerated wear of the knife. In addition, such sharpening does not last long.

Unlike previous options, a sharpening stone (or whetstone) gives the owner of the knife a certain freedom of action, for example, choosing the angle at which the cutting edge will be processed.

If you reach a certain level of skill, then with the help of a set of sharpening stones you can bring the knife to the state that craftsmen demonstrate in the video: shaving, cutting hair on the fly, or cutting off the transparent layers from a tomato without holding it with your hands.

Diamond whetstones for sharpening

Diamond is the strongest mineral on the planet. It is actively used in the production of sharpening devices. The size of the fraction may vary depending on the area of use. The high cost does not allow spraying a thick working layer.

A characteristic feature of diamond bars is a long period of operation with no loss in sharpening quality. Even after 10 years of active use, the plane will remain perfectly flat.

It should be remembered that the structure of diamond has an extremely aggressive effect on the workpiece. This allows you to quickly sharpen any thing, but if you lack the skills, it can simply break. To gain experience, it is better to practice on regular medium-grained bars.

The diamond surface is not clogged by grinding by-products. To clean, simply rinse the tool in clean water.

Diamond and ceramic fixtures

These materials should not be confused with rectangular diamonds. Artificial microcrystals act as an abrasive in diamond whetstones, although the price for such a whetstone or whetstone for sharpening knives is quite high. Diamond sputtering comes in poly- or monocrystalline form. The material differs in the number of working surfaces. Diamond sharpeners differ in the technology of fastening crystals in their structure into the following types:

- Galvanic bond. Diamond crystals are fixed to the surface using a special nickel-based binder. Essentially, the diamonds are evenly distributed throughout the stone. The advantage of such products is their high level of efficiency. You can sharpen a blade using a diamond abrasive in just a couple of movements. In addition, this material is durable.

- Soft organic base. The sharpening stones look like ordinary stones, but the corundum crystals are replaced by diamond ones. The processing efficiency is quite good, but there will be much less scratches on the metal. In addition, with wear and tear, the coating will gradually be renewed, that is, the timber will not lose its user characteristics over time.

Ceramic products are a separate group of products with a fine structure according to the grain size table. It would be more appropriate to call them not sharpeners, but rules, because sharpening a blade on a ceramic bar is very tedious. Therefore, ceramic sharpeners are often used for finishing and straightening knives after rough sharpening.

Regardless of the type of whetstone, you need to use a high-quality lubricant when sharpening blades. For this purpose, you can use machine or spindle oil or ordinary water.

Types of donkeys

The principle of operation of all touchstones is the same. The abrasive particles have very high hardness. If a bar made of an abrasive material is passed over the surface of a steel blade, the hardness of which is lower, then small particles of metal will be torn off by the abrasive grains. By removing layer by layer, the surface of the blade is leveled and acquires the required sharpening angle and sharpness.

All whetstones must have not only high hardness, but also a certain grain size (grain size), and the arrangement of abrasive particles in a strict order, in layers.

Arkansas stone block

Consists of fine-grained quartz crystals. Nature compacted the mineral very tightly. Four types of stone are mined:

- soft;

- solid white;

- solid black;

- solid transparent.

With the help of such bars, a very thin and very even layer of metal is removed in one pass.

Therefore, sharpening blades using Arkansas stone is very precise. It also lasts for a very long time.

To achieve all the capabilities of such a whetstone, you should use a special mineral oil, supplied with the sharpener or separately.

It allows you to avoid clogging the working surface with the smallest metal dust. A bar that has been used “dry” and clogged with such dust is quite difficult to clean.

European bars

Products made from Slovak and French deposits are also of high quality. But their grain size is slightly higher than that of Arkansas. Usually they are used for not the most critical blades.

To sharpen a carpenter's axe, you can get by with an ordinary whetstone made of Ural or Ukrainian stone.

Japanese water stone block

Japanese water stone has long been used to sharpen samurai swords and daggers. It is softer than Arkansas or European stone. Before sharpening, the whetstone is placed in a container with water for 10-15 minutes. The pores of the stone are filled with moisture, and the working surface is naturally cleaned of dirt.

If several Japanese bars of different grain sizes are used, they should be soaked separately. Otherwise, small particles of a fine-grained bar may contaminate the pores in a coarse-grained bar.

The stone has excellent working qualities. With the help of such a sharpening stone, you can return an ideal sharpness to even a dull or damaged blade.

The disadvantage is the rapid wear of the sharpening surface.

Diamond bars

High-quality and expensive sharpening stones consist of a metal base on which a layer of microscopic artificial diamonds is applied. Diamond is the strongest substance known to people, so the working qualities of such whetstones are unrivaled.

The working layer is attached to the base in two ways:

- Galvanic. A thin layer of crystals is sprayed onto a metal base, evenly distributed over it. The advantage is high productivity, the blade is sharpened in a few vigorous strokes. The diamond layer on a hard metal substrate wears out slowly. The downside is that when the working layer is worn out, the block has to be thrown away. It is used for quick rough sharpening, after which the blade should be sharpened on a natural or ceramic whetstone.

- Organic. Organic resin as a binding component holds together a large number of artificial diamonds. The structure of the bar is similar to ceramic. As the crystals wear away, new layers come out from under them. The service life of such a diamond sharpening stone is much longer; it is used until it is completely worn out.

Diamond whetstones allow you to quickly sharpen a blade, but require caution and extra attention.

Ceramic bars

Artificial sharpening stones are made from calibrated particles of corundum or silicon carbide - exclusively solid substances. Ceramics are used as a binding base. The raw product is heat treated at high temperatures and sintered into a neat bar. The main advantage of such whetstones is their high wear resistance. Medium-grained ones take quite a long time to wear out, while fine-grained ones wear out almost unnoticeably.

The disadvantage of ceramic bars is that they quickly become contaminated with metal dust. This leads to a decrease in sharpening properties. Fine-grained debris clogs more than others. For sharpening, sets of ceramic whetstones are used, gradually moving from coarse-grained to medium-grained and bringing the blade to fine-grained ones.

When sharpening on ceramics, you should use lubricating oil - this will slow down the clogging of the pores. The ceramics should be washed and cleaned after each use.

Features and benefits of water stones

Sharpening water stones of artificial origin are made from carbides and oxides of the following elements:

The main requirement for manufacturing technology is careful sifting of the base elements. The content of particles of different sizes in the structure is categorically unacceptable, since this affects the quality of the sharpening stones.

Ceramic or bakelite elements are used as a binder, which differ in the degree of hardness of the finished product.

The use of expensive materials increases the cost of water whetstones. It is higher than that of synthetic analogues, but lower than that of natural water carriers.

The main feature of water tools is the need for pre-soaking, the time of which depends on the size of the grain. For large fractions, 5 minutes will be enough. Bars with small particles should be kept in water for 15 minutes.

Thus, a mixture of abrasive chips, water and metal particles is formed on the grinding plane. It promotes uniform sharpening across the entire width of the knife. After finishing work, the surface is thoroughly washed.

To select the right tool, we recommend that you familiarize yourself with the abrasive materials conformity table.

Review of popular sharpening stones

The market offers a huge selection of Russian-made sharpening stones, which have a favorable price-quality ratio. The most popular are:

- Stones "Petrograd". A popular brand that produces tools of varying degrees of hardness made of silicon carbide. The grain size of all products complies with the Japanese JIS-2017 standard.

- Grinderman stones. The production was launched in St. Petersburg under the leadership of Andrei Petrov. The company is engaged in the production and sale of sharpening stones and means for their maintenance.

- "Gritalon". The brand is responsible for the production of synthetic abrasive stones for both manual and electric sharpeners. The base material is silicon carbide.

Among foreign manufacturers, the Metabo brand is especially popular, which produces hand-held electric and pneumatic tools, as well as high-quality CBN wheels for various needs.

Japanese water stones

In specialized centers there is a sufficient selection of Japanese sharpening stones from the following manufacturers:

- Suehiro;

- YOSHIKIN;

- Yaxell;

- Samura.

The products of the above companies have a high price, which starts at $60.

Arkansas stones

American-made bars have long been loved by Russian consumers. The most popular brands are:

- Dan's;

- Smith's;

- Lansky.

Sharpening stones are a necessary thing that should be in every home where they care about the safety of knives and other cutting tools. What type of sharpening stones do you prefer to use? Do you think modern ceramic materials are better than Japanese water bars? Write your opinion in the comment.

Sharpening stone for knives: description, varieties, sharpening rules

These types of devices greatly simplify the work, but they have one obvious drawback. Even at average speeds, significant heating occurs due to the friction of the abrasive structure on the metal surface. If you gape even slightly and press the knife blade harder, the metal alloy will “release.” That is, the blade will become soft and dull faster.

That’s why experienced specialists try not to use mechanical-type sandpaper, but prefer sharpening stones. And modern industry has brought back into use the familiar stones for sharpening blades, only they are made using a special technology.

Now on the market there are many varieties of this type of product, which differ in quality, price, and ease of use.

Sharpening rules

Even if you have the best and most expensive whetstone, you will not be able to sharpen a knife efficiently without the proper skills. First, you should study the basic rules of sharpening and purchase all the necessary tools.

All you need to have for sharpening knives is a sharpener of different calibers, a lubricant of special oil or plain water, and polishing agents if necessary.

To sharpen at home, it is enough to have only two types of stones, with caliber No. 1000 and No. 3000. They will be enough for rough sharpening and finishing of the blade. But if the cutting edge is significantly damaged, there are dents or chips, you will need to select a coarser bar.

It is very important to choose the right moment for sharpening; there are no specific deadlines that must be strictly adhered to. You need to focus, first of all, on the intensity of use of the knife

There is no need to delay sharpening; as soon as you feel a deterioration in the quality of the cut, you need to immediately fine-tune it. This allows you to avoid removing a large layer of metal and extends the durability of the knife.

If the blade is made of Damascus steel, or has laser engraving, you need to protect its surface. For this purpose, masking tape is suitable, which needs to be used to seal the side surfaces of the blade, leaving only the cutting edge exposed.

Usually the sharpening angle is 40-45 degrees, but you can determine the desired value by eye. You need to place the knife with the blade on a flat surface and lower it until the edge completely lies on the surface. Then slowly begin to pull the knife out until your hand gets used to the desired angle.

After rough sharpening, it is important to carry out fine-tuning, which allows you to achieve an ideal sharpness and maintain it for as long as possible.

Sharpening the knife

Place the whetstone on a stable table. It should be higher so that you can easily move your hand over the stone.

Place the knife on the surface of the stone. Adjust the required angle of contact between the knife and the stone, as described above. Make sure the stone is parallel to your body. The sharpening motion should be parallel to your body, not perpendicular to it.

Start at one edge of the stone. Make sure the entire edge of the blade is touching the stone.

Move the knife in an arc. This will allow you to sharpen all parts of the blade above the stone.

Repeat the strokes until burrs begin to appear on the opposite side. You may need 6 to 12 strokes for them to start appearing.

You can notice burrs by gently touching the opposite side of the knife's cutting edge. Be extremely careful when running the skin across the blade - this applies to all knives.

Sharpen the knife on the other side of the blade until burrs also appear.

Move to a fine-grained stone and repeat the entire process on both sides. Use a slightly larger angle. This will remove burrs and make the knife sharper.

If you started with a medium-grain stone, you may not notice any noticeable burrs. They are more noticeable when working with coarse-grained stone. Make the same number of strokes on each side of the knife.

Test the knife by cutting a piece of paper. Repeat the process if the knife is not sharp enough.

Clean the sharpening stones according to the manufacturer's instructions. This will remove any metal shavings for next use.

Japanese water stone

The origin of this natural stone is clear from the name itself. These sharpening stones are softer than Arkansas sharpening stones. They also have a higher sharpening quality, however, they wear out faster. Therefore, this variety has to be constantly brought back to its original state by grinding the surface with sandpaper of greater hardness.

They are used in a slightly moistened state, because only under this condition does a grinding layer form on the surface of the material. Experienced professionals prefer to use this tool, and its price can reach several thousand dollars.