How often have you visited large metallurgical plants? My colleagues and I recently went on a tour to such a plant. Huge blast furnaces and smelters. We watched how metal was rolled on specialized rolling machines. It was very brutal and hot there. We were shown how keyed steel is made and how keys are made from calibrated steel. We became interested in this topic and decided to look into this issue more. Time for popular science content, which means that today I will tell you what key rolling is. How often have you visited large metallurgical plants? My colleagues and I recently went on a tour to such a plant. Huge blast furnaces and smelters. We watched how metal was rolled on specialized rolling machines. It was very brutal and hot there. We were shown how keyed steel is made and how keys are made from calibrated steel. We became interested in this topic and decided to look into this issue more. Time for popular science content, which means that today I will tell you what key rolling is.

A keyed or calibrated alloy is used to create “keys”, or more specifically, a piece of keyed steel is cut into keys. A key is a connector for various types of mechanisms. The expression “key connector” is used very often.

A key or key connector is a small, oblong piece of keyed steel with different shapes:

- prismatic

- segmental

- cylindrical(pin)

- wedge

Keys are used in machinery, machine tool and mechanical engineering, as well as in automobiles, production machines and robotic technology. A key is a very reliable mechanical element used to secure bushings and shafts of vertical connections against rotation. It is very important to use keys of sufficient rigidity when using bushings that operate at high angular speeds with no runout during rotation. The keyed connection acts as a wedge, but if excessive load is applied, the veneer will simply tear off. Replacing the key is not difficult, and its price is quite low. See for yourself! Prices. This store has a large selection of key products, you can select them by diameter.

DIN keys

DIN key - connecting fastener

A key is a special fastener used to connect shafts and hubs to flywheels or cylindrical wheels.

The dowel is used to fasten wooden structural elements, and it takes on shear forces.

We are ready to offer our customers different types of keys and keyed steel, you just need to indicate the dimensions of the products, and we will quickly fulfill your order.

Its operational properties depend on the standard size of each key. The use of a particular key depends on the parts being connected, as well as on the diameter of the mounting hole. On our company’s website you can find a list of fasteners we sell and their standard sizes.

A friction key is a type of wedge key. More often it is used as a safety link under significant overloads. A distinctive feature of this type of key is the ability to adjust the position of the hub not only in the angular, but also in the axial direction. This quality is often used in practice.

Wedge keys of all types belong to the group of stressed joints. The dimensions of these keys are standardized like their tolerances. Using a taper key can present some challenges.

Due to the design and shape of this key, a misalignment of the part may occur, which will lead to a malposition of the plane relative to the shaft axis (not perpendicular). To avoid this, sometimes it is necessary to individually fit the key, which is unacceptable in large-scale production conditions.

It is for this reason that large enterprises engaged in volume production are currently abandoning taper keys.

The connection with parallel keys and segment keys is called a stress-free connection. The use of segmental and parallel keys leads to the fulfillment of a number of requirements.

For example, it is necessary to precisely manufacture the shaft and, accordingly, the holes in the hub. Often the hub is seated on the shaft with a large interference fit.

Through the narrow side edges of the key, the moment is transmitted from the shaft to the hub.

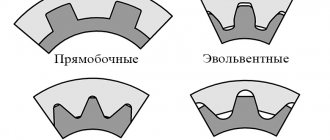

A segment key is a type of prismatic key.

A deep groove makes the shaft weaker; for this reason, segment keys are used more often to fasten parts in areas that are less loaded.

Size - key

GOST 10753-86 cross-shaped slots for screws and screws.

dimensions and control methods How to determine the dimensions of keys and keyways.

How to set dowel sizes.

The shape and dimensions of the keys are standardized and depend on the diameter of the shaft and the operating conditions of the parts being connected. Most standard keys are prismatic, segmental or wedge-shaped with a rectangular cross-section. Dowels in a longitudinal section are shown uncut, regardless of their shape and size.

The shape and dimensions of the keys are standardized and depend on the diameter of the shaft and the operating conditions of the parts being connected.

Known: key dimensions, number of keys and permissible stresses. The load-bearing capacity of the key joint is determined in the form of torque.

How dowel sizes are determined.

Maximum deviations of the key dimensions: the main landing dimension b, along which the key is mated with the grooves of the shaft and bushing (see Fig. 18), - according to.

Maximum deviations for the dimensions of keys, grooves on shafts and bushings (hubs) along width b are given in table. 38 and 39 and in fig.

Maximum deviations for the dimensions of keys, grooves on shafts and bushings (hubs) along width b are given in table. 35 and 36 and in FIG.

A keyed connection is a type of connection consisting of a key on the shaft and a hub. A key is a part that connects nodes by installing them in grooves. Its main function is to transmit torque between nodes. There is a certain standardization of their varieties. The key has special grooves cut by milling.

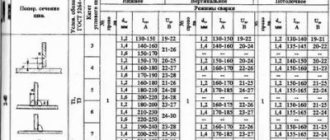

Keyed connections with parallel keys. Dimensions, mm

Parallel keys are divided into:

- ordinary,

- tall,

- guides.

Ordinary and high keys are used in fixed joints.

Table 1a

Guide keys with mounting on the shaft according to GOST 8790-79 (ST SEV 5612-86)

If axial movement of parts is necessary, guide keys of the same cross-section as ordinary ones are used, but they are secured to the shaft with screws.

In table 1, a and b show the cross-sectional dimensions of ordinary prismatic and guide keys and grooves.

Table 1, b

Three versions of keys are provided:

- with rounded ends;

- with flat tors;

- with one rounded end and the other flat end.

Symbols of ordinary and guide parallel keys

An example of a designation for a key of version 1 according to GOST 23360-78 and GOST 8790-79, respectively, with dimensions b=18mm, h=11mm, l=70mm:

Key 18x11x70 GOST 23360-78 Key 18x11x70 GOST 8790-79

The same, execution 2:

Key 2 - 18x11x70 GOST 23360-78 Key 2 - 18x11x70 GOST 8790-79

In table 2 shows a number of key lengths provided for by GOST 23360-78 and GOST 8790-79.

Designations on the drawings

In the drawings, the designation of parallel keys is based on the GOST regulatory document. They are divided into keyways: high, normal height and guides. Their working faces are the lateral ones.

In the assembly drawing, the designation is made taking into account the shaft diameter, torque, cross-section and length.

For example:

Key 3–20Х12Х120 GOST 23360-78; Where 3 is the design, 20Х12 is the section, 120 is the length.

The designation of other types of keys in the images is carried out in the same way, based on the corresponding GOST standards developed for each individual model. The specified designation must clearly characterize the part, which is very important for obtaining a reliable connection. After all, even the slightest gap can cause rapid wear of working units and loss of efficiency during operation

Characteristics of key steel

The above information indicates that the steel for keys must have certain performance characteristics. From the name of the material you can immediately determine its scope of application. Among the features we note the following:

- Metal keys are often produced using metal that meets GOST 8787-68.

- Foreign manufacturers take into account the DIN standard

- In most cases, rolled keys, represented by structural carbon steel, are used.

- A special feature is that the surface layer has better performance characteristics.

- The basic characteristics can be improved by carrying out various types of heat treatment. Hardness is often increased by quenching or tempering.

The grade of steel used lends itself well to cold and hot drawing. Due to this, a volumetric or combined calibration is released.

The 8×7 key material has become quite widespread. The use of standards at the time of production of blanks allows us to significantly simplify the task of producing an intermediate element

When choosing a material, pay attention to the following points:

- Hardness of the surface layer.

- Resistance of the material from environmental influences.

- Processability degree.

Common alloys can be used for the manufacture of prismatic and other versions of intermediate elements that are installed to transmit force. It is worth considering that most often keyed steel is used to create rectangular bars of various sizes that are installed on the shaft.

The classic version is represented by the St45 brand. The key features include:

This is structural carbon steel of ordinary quality, the cost of which is relatively low. Traditionally used in the manufacture of critical parts. Do not pay attention to the fact that this grade is not suitable for welding.

In addition, the St50 grade can be used, the properties of which do not differ significantly from the previous version.

In cases where it is necessary to significantly increase the strength of a joint, attention should be paid to the possibility of using alloyed alloys. Adding certain chemical elements to the composition can significantly improve performance characteristics

An example is the 40X brand, which is characterized by the following features:

- Hardness varies between 35-45 HRC. To increase this indicator, heat treatment is carried out, as well as tempering to reduce the likelihood of internal stresses.

- The addition of chromium allows you to slightly increase the degree of protection of the material from exposure to high humidity. This point determines that corrosion does not appear on the surface over a long period of use of the product.

- A carbon concentration of around 0.4% ensures the required strength and hardness of the product. At the same time, other substances may be included in the composition in small concentrations, thereby ensuring the required performance characteristics.

Other alloys with special performance characteristics, for example, with good resistance to elevated temperatures, can also be used. The choice is made depending on performance characteristics and many other points.

Key blanks for production order

| Name | Become | Dimensions | GOST |

| Key blank | Art. 20 | 6x8mm | 8787-68, 10748-68 |

| Key blank | Art. 20 | 8x7mm | 8787-68, 10748-68 |

| Key blank | Art. 20 | 10x8mm | 8787-68, 10748-68 |

| Key blank | Art. 20 | 10x9mm | 8787-68, 10748-68 |

| Key blank | Art. 20 | 12x8mm | 8787-68, 10748-68 |

| Key blank | Art. 20 | 12x11mm | 8787-68, 10748-68 |

| Key blank | Art. 20 | 14x9mm | 8787-68, 10748-68 |

| Key blank | Art. 20 | 14x12mm | 8787-68, 10748-68 |

| Key blank | Art. 45 | 6x8mm | 8787-68, 10748-68 |

| Key blank | Art. 45 | 10x9mm | 8787-68, 10748-68 |

| Key blank | Art. 45 | 12x11mm | 8787-68, 10748-68 |

| Key blank | Art. 45 | 14x12mm | 8787-68, 10748-68 |

| Key blank | Art. 45 | 2×2mm | 8787-68, 10748-68 |

| Key blank | Art. 45 | 3×3 mm | 8787-68, 10748-68 |

| Key blank | Art. 45 | 4x4 mm | 8787-68, 10748-68 |

| Key blank | Art. 45 | 5×5 mm | 8787-68, 10748-68 |

| Key blank | Art. 45 | 6×6 mm | 8787-68, 10748-68 |

| Key blank | Art. 45 | 6×4 mm | 8787-68, 10748-68 |

| Key blank | Art.20, 45 | 7×7 mm | 8787-68, 10748-68 |

| Key blank | Art. 20, 45 | 8x8 mm | 8787-68, 10748-68 |

| Key blank | Art. 20 | 10×10 mm | 8787-68, 10748-68 |

| Key blank | Art. 20 | 12×12 mm | 8787-68, 10748-68 |

| Key blank | Art. 35 | 14×14 mm | 8787-68, 10748-68 |

| Key blank | Art. 20 | 16×16 mm | 8787-68, 10748-68 |

| Key blank | Art. 45 | 18×18 mm | 8787-68, 10748-68 |

| Key blank | Art. 35 | 20×20 mm | 8787-68, 10748-68 |

| Key blank | Art.20 | 22×22 mm | 8787-68, 10748-68 |

| Key blank | Art. 45 | 25×25 mm | 8787-68, 10748-68 |

| Key blank | Art. 45 | 30×30 mm | 8787-68, 10748-68 |

Types of keys

The main types of keys are divided into two types: stressed and unstressed. Among which are the following types of keys:

- Wedges. A special type that differs in the angle of inclination of the upper edge. In general, the division into types is based on the classification of key joints. It is installed in the groove using physical force, using the impact method. The use of this type of connection allows you to achieve the required voltage. The cut wedge, being in the groove, expands it from the inside. Due to the pressing force, the shaft and hub rotate together. It is used quite rarely, since its use requires individual adjustment. This can be considered a disadvantage for mass production of mechanisms. The main purpose is to use it in low-speed transmissions and fixed connection units.

Among the wedge keys there are:- mortise;

- on a flat;

- friction;

- without head and with head.

- Segmental.

They are produced in the form of a segment plate driven into a groove. Produced by milling. They are widely used in production, as they are easy to manufacture, do not require special precision when cutting and are easy to install. It differs in installation in a deeper groove, in comparison with analogues. A deep groove is not suitable for heavy loads, as it significantly reduces the strength of the shaft, so it is used for small torques. Long hubs can have multiple keys installed because they have a fixed length. Perform a safety function against shearing and crushing. - Prismatic. They are distinguished by parallel edges that are installed in a groove and fix the hub. In such cases, the working faces are the lateral ones. They are a non-stressed type of keyed joints, so there is a possibility of corrosion at the joint. To avoid corrosion, the coupling and shaft are connected with interference. The ends are usually produced with rounded or flat ends. For a rounded type, the working surface is considered to be the length of the straight edges. The groove is cut using a cutter. The force is transmitted by pressing the surface of the groove onto the key, which transmits torque to the hub groove. This type of parallel key connection is often used for moving connections, so additional fastening with screws is used. Like many other types, it functions as a fuse during crushing and shearing.

- Cylindrical. The pins in such keys are made in the form of cylinders. I work in tension with a hole at the end of the shaft, which is drilled to fit the corresponding key sizes. Used in cases where the hub is installed at the end of a shaft. Requires a special approach to the installation of keyed connections. Allows work on shear and crushing. Therefore, the choice of key is made based on the crushing strength.

Based on the type of landing, the following are distinguished:

- Free – used in cases where it is quite difficult to carry out welding work and there is a need for movable coupling of parts during work.

- Dense - needed to create clutches, the movement of which during operation is carried out in one spatial position.

Assembling keyed joints

Parallel keys must be replaced when:

- crushing of the side faces;

- weakening of the landing;

- collapse of the keyway.

Disassembly of a keyed connection can be done in various ways, depending on the design of the connection. To disassemble, make a threaded hole in the middle part of the key and screw a screw into it. When adjusting and assembling parallel keys, it is recommended to make a bevel on the surface of the key from the shaft side, to a length not exceeding the height of the key, and make a mark on the reverse side. An indispensable condition for the process of disassembling the key joint is maintaining the cleanliness and accuracy of the seats.

If the groove wall is slightly worn out, it is necessary to level the walls of the keyway until the correct shape is obtained and make a new key with an increased cross-section. Expansion of the keyway is allowed by an amount not exceeding 10-15% of the original size. When making a new key and repairing a keyway, processing should be carried out with the appropriate tool. Drilling of keyways must be done with a milling cutter.

Before assembly, the parts are cleaned and the fit dimensions are checked, the presence of nicks, burrs and other defects on the mating surfaces. Measuring the depth of the grooves, the height and correct installation of the keys is carried out using probes, templates, dial-type movement indicators and special stands.

The key is seated in the shaft groove with light blows of a copper hammer (or a soft metal hammer), under a press or using clamps. Skewing the key and cutting into the body of the groove is not allowed. The absence of lateral clearance between the key and the groove is checked with a feeler gauge, then the covering part (wheel, pulley) is installed and the presence of radial clearance is checked.

When assembling wedge keys, it is necessary to ensure that the key fits tightly to the bottom of the groove of the shaft and bushing and has gaps along its side walls. The upper edge of the wedge keys must be made with a slope along the length of 1:100. The slopes on the working surface of the key and in the groove of the bushing must coincide, otherwise the part will sit on the shaft with a skew. The accuracy of the key fit is checked with a feeler gauge on both sides of the bushing. During assembly, the grooves of the shaft or the surface of the key are sawed or scraped to prevent distortion and displacement. In the assembled connection, the head of the taper key should not reach the end of the hub by an amount equal to the height of the key. To prevent the wedge and tangential keys from falling out (when they are loosened), stops are installed on the screws at the heads. It should be noted the uncertainty of the forces that arise when pressing the wedge keys. This may damage the hubs of the male parts.

Dowels with a cross-sectional size of more than 28×16 mm must be checked for paint on the seats until five or more prints are obtained per square centimeter of surface. Before installing the key, the key and keyway must be cleaned and oiled. It is not allowed to install any pads in all types of keyed joints to achieve a tight fit of the keys.

Segmental keys are less susceptible to misalignment and do not require manual fitting (since the keyway is produced with a cutter corresponding to the size of the key); the groove for the segment key is deeper, which weakens the cross-section of the shaft.

In the assembled connection between the upper edge of the parallel key and the base of the hub groove (), the radial clearance must correspond to those given in the data. In connections with a wedge key (), the lateral clearance between the groove and the key should not exceed the values specified in.

Figure 4.1 – Gap when installing parallel keys

| Shaft diameter, mm | Radial clearance, mm |

| from 25 to 90 | 0,3 |

| from 90 to 170 | 0,4 |

| over 170 | 0,5 |

Figure 4.2 – Gaps when installing wedge keys

Table 4.2 – Lateral clearance values for wedge keys depending on the key size

| Normal dimensions of keys, mm | Side clearance, mm |

| b = 12…18; h = 5…11 | 0,35 |

| b = 20...28; h = 8…16 | 0,4 |

| b = 32…50; h = 11…28 | 0,5 |

| b = 60...100; h = 32…50 | 0,6 |

The guide keys are installed with additional fastening in the groove with screws; a looser fit is made in the groove of the moving parts.

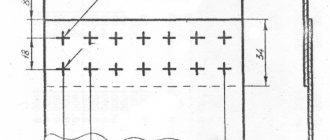

Drawing dimensions on keyed joint drawings

Details Category: Keyed connections Drawing dimensions on drawings of keyed connections.

Three methods are used to apply the size of the groove depth on the shaft: 1) from the extreme point of the shaft diameter opposite to the location of the groove (Fig. 579, a); 2) from the edge of the cylindrical surface of the shaft closest to the groove (view b); 3) from the extreme point of the diameter lying on the axis of symmetry of the groove (view c). The last two sizes differ by the value m, determined by formula (135) or by Fig. 568, b.

The most correct is the third scheme, which directly follows from the methods for measuring the depth of the groove on completed parts. The depth of the groove on critical shafts is measured with a micrometric depth gauge with a prism based on the cylindrical surface of the shaft (Fig. 580, a). The groove depth is determined as the difference between the depth gauge readings in the position shown in the figure and on any smooth section of the shaft surface.

The correct size is controlled by applying a gauge to the cylindrical surface of the shaft (Fig. 580, b).

Thus, in both cases, the depth of the groove is determined in relation to the diameter of the shaft.

The depth of the groove in the hub is most correctly determined by the size of the diameter point opposite the groove (see Fig. 579, d), which can be easily checked with a caliper or a gauge.

In Fig. 579 shows examples of detailed application of dimensions on the key shaft (view e), in the hub (view f) and in the assembly (view g).

Tolerances and fits of key joints

General information about keyed connections

A keyed connection is one of the types of connections between a shaft and a bushing using an additional structural element (key) designed to prevent their mutual rotation.

Most often, a key is used to transmit torque in connections between a rotating shaft and a gear or pulley, but other solutions are also possible, for example, protecting the shaft from turning relative to a stationary housing. Find out more about the types of keyed connections here.

Unlike tension connections, which ensure mutual immobility of parts without additional structural elements, keyed connections are detachable. They allow the structure to be disassembled and reassembled with the same effect as the initial assembly.

According to their shape, keys are divided into prismatic, segmental, wedge and tangential. Parallel keys make it possible to obtain both movable and fixed connections. Segment keys and wedge keys, as a rule, are used to form fixed joints. The shape and dimensions of the sections of keys and grooves are standardized and selected depending on the diameter of the shaft, and the type of key connection is determined by the operating conditions of the connection.

Typically, keys are installed in grooves on the shaft along a fixed one, and bushings - along one of the movable fits. The tension of the key is necessary so that the key does not fall out during installation and does not move during operation, and the clearance at the bushing is necessary to compensate for the inevitable inaccuracies in size, shape and relative position of the grooves. In mechanical engineering, connections with feather keys are most widely used. Their dimensions and the dimensions of the keyways are standardized by GOST 23360-78 “Prism keys. Dimensions, tolerances and fits." The maximum deviations of the dimensions of parallel keys in width and height are established for three designs of keys (Fig. 1):

- with curves at both ends (A);

- rectangular (B);

- with a curve at one end (C).

Rice. 1. Types of parallel key designs (top view)

The key connection includes at least three fits: shaft-bushing (centering mate), shaft key-groove, and bushing key-groove. The accuracy of centering of parts in a keyed connection is ensured by the fit of the sleeve on the shaft. This is a conventional smooth cylindrical mating that can be installed with very small clearances or interferences, therefore transitional fits are preferred.

Another connection is possible - along the length of the key, if a parallel key with rounded ends is placed in a blind groove on the shaft.

The depth of the groove at the shaft for the key is set by size l, (preferably) or d-t1, the depth of the groove at the hole for the key is set by size t2 or D+t2 (Fig. 2).

Rice. 2. Key connection parameters

The dimensions of the keys are made: width b keys (Fig. 2) with a tolerance range h9, height h keys with a tolerance range h11 (with a key height of 2 ... 6 mm - according to B9), length l keys with a tolerance range h14. This designation of tolerance fields for the dimensions of parallel keys makes it possible for them to be centrally manufactured, regardless of the fit.

All types of keyed joints are formed in the shaft system. The type of connection is selected depending on its functional purpose, taking into account the assembly technology. For preferred use, the standard provides three types of connection (Fig. 3):

- Free - a connection with a guaranteed clearance to allow the sleeve to move along the shaft with a key. The connection is movable. For the width of the groove on the shaft, the tolerance field is set to H9, for the width of the sleeve groove - Z10.

- Normal - a connection with a transitional fit, more likely to obtain a gap, and does not require frequent disassembly. The connection is fixed. For the width of the groove on the shaft, the tolerance field is set to N9, for the width of the sleeve groove - J9.

- Tight - a connection with a transitional fit, with approximately equal probability of obtaining gaps and interference, used for rare disassemblies and reverse loads. The connection is fixed. For the groove width of the shaft and sleeve, one tolerance field H9 is specified.

The standard establishes tolerance fields for the width of keys and keyways b for loose, normal and tight connections. The length of the shaft grooves and the hole for the key are made with a tolerance zone of Z15, the depth of the shaft grooves and holes - with a tolerance zone of Z12. Additional requirements for the location of surfaces are imposed on the places where the keys are installed.

***

Key material

For the manufacture of keyed joints, calibrated rolled metal is used. The most commonly used steel is grade 45. It is a regular type of carbon steel, which is often used to produce high-strength parts. The steel is used in the form of a 1 m long bar.

In some cases, carbon steel grade 50 can be used. It is necessary when increased strength properties of the resulting keys are required. Less commonly used are alloy steels, for example, grade 40x, which is characterized by a high hardness index achieved by heat treatment.

Steel blanks are processed using cutters, drilling machines, chopping machines, grinders and other tools. The machines used have a control unit that allows, using numerical programs, to produce a part with the required parameters.

The price of the resulting key is quite low, so purchasing the necessary part is quite easy. But in some cases, when there is an urgent need to obtain a key, you can make it yourself. Most often, such a need arises in agriculture, where during seasonal work breakdowns often occur that need to be repaired. At the same time, the nearest points of sale of the necessary parts are located at a distance of several tens of kilometers.

With a small amount of tools on hand and a blank made of the appropriate material, you can quickly make a temporary replacement. If the technical specifications are observed, the resulting part can fully replace the factory one, but it is best to purchase a key of the required strength and geometric parameters at the first opportunity. This is necessary to avoid premature wear of the mechanisms.

It is better to use different types of wood as a material; for a dowel, a softer material than the main one is suitable. This will protect the main structure from damage in case of increased load. It is easier to replace a key than a large structural unit.

To prevent moisture from penetrating into reinforced concrete structures, special dowels called waterstop are used. They are made from high quality rubber and PVC. This allows you to achieve the required degree of waterproofness and resistance to solutions of aggressive chemicals.

Application

The main application of keyed connections is mounting on a shaft using a grooved connection. In most cases, the keyway resembles a wedge. This type of connection of parts allows the shaft and hub not to rotate relative to each other’s axis. The fixed position of the hub to the shaft with a key allows for high efficiency when transmitting force.

Most often, keyed connections can be found in mechanical engineering, during the construction of machine tools. It is often used in the production of cars and other mechanisms, where increased reliability of fixing machine parts is required. High reliability is achieved thanks to the function of the shaft safety unit with keyway.

The key acts as a fuse in cases where the maximum torque level is exceeded. In such cases, the key is sheared, absorbing the excessive load and removing it from the shaft and hub.

Due to its properties, it has become widespread in mechanical engineering; it is characterized by high efficiency, ease of manufacture and installation, and low cost. Such characteristics are especially important in industrial production, especially in agriculture. At the height of the season, there are often cases of breakdowns of individual components that need to be replaced as quickly as possible. Most often found in baler units.

Considering all of the above, the main positions for which a key is needed are highlighted:

- Ensuring the safety of connected nodes under increased loads.

- Achieving a high degree of fixation of individual elements of a mechanical assembly.

- Performs the function of preventing rotation of the unit and hub.

- The reliability of such a connection exceeds the reliability of analogues when fixing the shaft with parts.

In general, you can find a keyed connection in almost any complex mechanism, which is due to its technical characteristics.

Advantages and disadvantages

Like any type of connection, keyed connections have a number of advantages and disadvantages. The advantages of keyed connections include the simplicity of most types of keys. At the same time, installation and replacement of such a part is easy and quick. Thanks to this, they are widely used in mechanical engineering. Also provides protection function.

Disadvantages include weakening of the hub and shaft. It arises from increased stress and reduced cross-section. Also, the weakening of parts is caused by the cut groove, which reduces the axial strength of the shaft.

To minimize the shortcomings, you need to ensure that the key is not skewed in the groove. To do this, you need to ensure that there is no gap, which is done by individually manufacturing and adjusting the key. Because of this, any type of keyed joints are rarely used in large-scale production. If it is not possible to ensure the absence of misalignment, the working contact area decreases, as a result of which the degree of maximum load decreases.

Also, the presence of a gap causes a runout effect, especially at high speeds. This will lead to rapid wear of working parts. Because of this, such a connection is rarely used for rapidly rotating shafts. To select a suitable key, it is better to use the table of key connections.

Designations on the drawings

In the drawings, the designation of parallel keys is based on the GOST regulatory document. They are divided into keyways: high, normal height and guides. Their working faces are the lateral ones.

In the assembly drawing, the designation is made taking into account the shaft diameter, torque, cross-section and length.

Key 3–20Х12Х120 GOST 23360-78; Where 3 is the design, 20Х12 is the section, 120 is the length.

The designation of other types of keys in the images is carried out in the same way, based on the corresponding GOST standards developed for each individual model. The specified designation must clearly characterize the part, which is very important for obtaining a reliable connection. After all, even the slightest gap can cause rapid wear of working units and loss of efficiency during operation

DIN 6885 B/P Prismatic steel key

- Modifications

- Description

- Specifications

- Your discounts

Parallel keys DIN 6885 are produced in different variations. They can be square, oval, with rounded corners on only one side, with or without holes, as well as with cuts in one of the corners.

The key is manufactured according to the German standard DIN 6885, as well as according to the Russian standard GOST 23360-78 and the international standard ISO 773. The DIN 6885 key is made of steel, by default it does not have an additional coating, and also does not have increased strength classes.

Installing a key in any mechanism requires care and experience in installing such products. To correctly install the key in the mechanism, you need to align the part and the shaft so that their grooves coincide. A key according to DIN 6885 secures the flywheel/gear/pulley mounted on it to the shaft. This shaft is often designed for thousands of revolutions per minute.

The unit in which the shaft rotates at such a huge speed most often works continuously for years. And all this time, the parallel key experiences shear forces.

Purpose

The key DIN 6885 is prismatic, or otherwise it is also called “keyway”. DIN 6885 keys are very often used in manufacturing and industrial applications.

Technical characteristics of the key DIN 6885 (part 1):

| Key parameters | Key width, B (h9) | ||||||||||||||||

| 2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 25 | 28 | 32 | ||

| Height, H (h11) | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 8 | 9 | 10 | 11 | 12 | 14 | 14 | 16 | 18 | |

| Radius | min. | 0,16 | 0,25 | 0,4 | 0,6 | ||||||||||||

| Max. | 0,25 | 0,4 | 0,6 | 0,8 | |||||||||||||

| Nominal length L | min. | 6 | 6 | 8 | 10 | 14 | 18 | 22 | 28 | 36 | 45 | 50 | 56 | 63 | 70 | 80 | 90 |

| Max. | 20 | 36 | 45 | 56 | 70 | 90 | 110 | 140 | 160 | 180 | 200 | 220 | 250 | 280 | 320 | 360 |

Technical characteristics of the key DIN 6885 (part 2):

| Key parameters | Key width, B (h9) | ||||||||||

| 36 | 40 | 45 | 50 | 56 | 63 | 70 | 80 | 90 | 100 | ||

| Height, H (h11) | 20 | 22 | 25 | 28 | 32 | 32 | 36 | 40 | 45 | 50 | |

| Radius | min. | 1 | 1,6 | 2,5 | |||||||

| Max. | 1,2 | 2 | 3 | ||||||||

| Nominal length L | min. | 100 | 110 | 125 | 140 | 160 | 180 | 200 | 220 | 250 | 280 |

| Max. | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 | 400 |

| Order price | Discount amount for each order |

| 5,000 - 20,000 rubles | Basic wholesale price |

| 20,000 - 70,000 rubles | 5% discount |

| 70,000 - 200,000 rubles | 10% discount |

| over 200,000 rubles | Discount up to 25% |

If YOU are a large wholesale supply organization, there are special conditions for YOU, notify our managers and receive personal discounts!

Flat inner retaining ring for holes

Back

Key material dimensions

During production, the dimensions of the key material are taken into account. In most cases, the rod is delivered to the production site. Its length can be about 1000 millimeters, in some cases it is produced to order. The most common key sizes are:

- 4×4.

- 5×5.

- 22×22.

- 25×25.

- 32×18.

- 40×40.

Do not forget that weight also depends on size. In addition, various alloys are used in the production of products of certain sizes. The size of the connecting element is selected depending on the load that will be applied. In addition, the size is influenced by the dimensions of the connected products.

At the time of product release, quality control is carried out using several different methods, including visual inspection.

The shape largely depends on the area of application of the product in question. The following types are distinguished:

- Wedges.

- Prismatic.

- Segmental.

- Tangential.

- Cylindrical.

Steel is characterized by fairly high ductility to machining. In most cases, the product is obtained from a workpiece, which is a rod.

State standards

When creating dowels, certain standards apply. In most cases, production is carried out in accordance with GOST 23360-78. Among the features of the applied standards, we note the following:

- The material used for the keys is standardized. This is due to the fact that the wrong alloy can cause the intermediate element to fail. An example is too high ductility or reduced hardness of the surface layer. The use of keyed steel allows you to avoid a fairly large number of problems, as well as significantly increase the service life.

- As previously noted, the dimensions of the product are also standardized. That is why GOST 8787-68 is often taken into account during production.

- There are quite a large number of different types of keys, all of them are characterized by their specific operational features. An example is a segment or rectangular version of the product.

Special equipment can be used to produce dowels. When creating critical mechanisms, the material is improved by applying thermal effects or introducing special substances into the surface layer.

Key. Keyway. Types, sizes and maximum deviations.

Parallel keys according to GOST 23360-78.

Fig. 1. Basic designations of parallel keys and keyways.

Table 1. Dimensions and maximum deviations of parallel keys and keyways according to GOST 23360-78.

| Shaft diameter d | Key section bхh | Keyway | Length l mm | ||||||||||

| Width b | Depth | Rounding radius r or chamfer s1 x 45° | |||||||||||

| Free connection | Nominal connection | Tight connection | Shaft t1 | Bushing t2 | |||||||||

| Shaft (H9) | Bushing (D10) | Shaft (N9) | Bushing (JS9) | Shaft and bushing (P9) | Nom.. | Nom. | Prev. off | no more | no less | ||||

| From 12 to 17 » 17 » 22 | 5×5 6×6 | +0,030 | +0,078 +0,030 | 0 -0,030 | ±0,015 | -0,012 -0,042 | 3,0 3,5 | +0,1 | 2,3 2,8 | +0,1 | 0,25 0,25 | 0,16 0,16 | 10-56 14-70 |

| St. 22 to 30 » 30 » 38 | 8×7 | +0,036 | +0,098 +0,040 | 0 -0,036 | ±0,018 | -0,015 -0,051 | 4,0 5,0 | +0,2 | 3,3 3,3 | +0,2 | 0,25 0,4 | 0,16 0,25 | 18-90 |

| 10×8 | 22-110 | ||||||||||||

| St. 38 to 44 » 44 » 50 » 50 » 58 » 58 » 65 | 12×8 | +0,043 | +0,120 +0,050 | 0 -0,043 | ±0,021 | -0,018 -0,061 | 5,0 | 3,3 | 0,4 | 0,25 | 28-140 | ||

| 14×9 | 5,5 | 3,8 | 36-160 | ||||||||||

| 16×10 | 6,0 | 4,3 | 45-180 | ||||||||||

| 18×11 | 7,0 | 4,4 | 50-200 | ||||||||||

| St. 65 to 75 » 75 » 85 » 85 » 95 | 20×12 | +0,052 | +0,149 +0,065 | 0 -0,052 | ±0,026 | -0,022 -0,074 | 7,5 | 4,9 | 0,6 | 0,4 | 56-220 | ||

| 22×14 | 9,0 | 5,4 | 63-250 | ||||||||||

| 24×14 | 9,0 | 5,4 | 70-280 |

Table 2. Limit deviations of dimensions (d + t1) and (d + t2).

| Height of keys | Maximum dimensional deviation | |

| d+t1 | d+t2 | |

| From 2 to 6 | 0 -0,1 | +0,1 0 |

| St. 6 to 18 | 0 -0,2 | +0,2 0 |

| St. 18 to 50 | 0 -0,3 | +0,3 0 |

Parallel keys with mounting on the shaft in accordance with GOST 8790-79.

Fig. 2. Basic designations of parallel keys with mounting on the shaft and keyways.

Table 3. Dimensions of parallel keys with mounting on the shaft according to GOST 8790-79.

| Width b (h9) | Height h (h11) | Rounding radius r or chamfer s1 x 45° | Diameter d0 | Length l2 | Length l (h14) | Screws according to GOST 1491-80 | ||

| no less | no more | from | before | |||||

| 8 | 7 | 0 25 | 0,40 | M3 | 7 | 25 | 90 | M3×8 |

| 10 | 8 | 0,40 | 0,60 | 8 | 25 | 110 | M3×10 | |

| 12 | M4 | 10 | 28 | 140 | M4×10 | |||

| 14 | 9 | M5 | 36 | 160 | M5×12 | |||

| 16 | 10 | M6 | 11 | 45 | 180 | M6×14 | ||

| 18 | 11 | 50 | 200 | |||||

| 20 | 12 | 0,60 | 0,80 | 56 | 220 | |||

| 22 | 14 | M8 | 16 | 63 | 250 | M8×20 | ||

| 25 | 70 | 280 | ||||||

| 28 | 16 | 80 | 320 | |||||

| 32 | 18 | M10 | 18 | 90 | 360 | M10×25 | ||

| 36 | 20 | 1,00 | 1,20 | 100 | 400 | |||

| 40 | 22 | M12 | 22 | 100 | 400 | M12×30 | ||

| 45 | 25 | 125 | 450 |

Segment keys according to GOST 8786-68.

Fig. 3. Basic designations of segmental keys and keyways.

Table 4. Dimensions and maximum deviations of segment keys and keyways according to GOST 8786-68.

| Shaft diameter d | Key dimensions b×h×D | Keyway | |||||||

| Transmitting torque | Fixing elements | Width b | Depth | Rounding radius r or chamfer s1 x 45° | |||||

| Shaft t1 | Bushing t2 | ||||||||

| Nom. | Prev. off | Nom. | Prev. off | no less | no more | ||||

| From 3 to 4 St. 4 » 5 | From 3 to 4 St. 4 » 6 | 1×1,4×4 1,5×2,6×7 | 1,0 1,5 | 1,0 2,0 | +0,1 0 | 0,6 0,8 | +0,1 | 0,08 | 0,16 |

| St. 5 » 6 » 6 » 7 | St. 6 » 8 » 8 » 10 | 2×2,6×7 2×3,7×10 | 2,0 | 1,8 2,9 | 1,0 1,0 | ||||

| St. 7 to 8 | St. 10 to 12 | 2,5×3,7×10 | 2,5 | 2,7 | 1,2 | ||||

| St. 8 to 10 » 10 » 12 | St. 12 to 15 » 15 » 18 | 3×5×13 3×6,5×16 | 3,0 | 3,8 5,3 | +0,2 0 | 1,4 1,4 | |||

| St. 12 to 14 » 14 » 16 | St. 18 to 20 » 20 » 22 | 4×6,5×16 4×7,5×19 | 4,0 | 5,0 6,0 | 1,8 1,8 | 0,16 | 0,25 | ||

| St. 16 to 18 » 18 » 20 | St. 22 to 25 » 25 » 28 | 5×6,5×16 5×7,5×19 | 5,0 | 4,5 5,5 | 2,3 2,3 | ||||

| St. 20 to 22 | St. 28 to 32 | 5×9×22 | 7,0 | +0,3 | 2,3 | ||||

| St. 22 to 25 » 25 » 28 | St. 32 to 36 » 36 » 40 | 6×9×22 6×10×25 | 6,0 | 6,5 7,5 | 2,8 2,8 | ||||

| St. 28 to 32 | St. 40 | 8×11×28 | 8,0 | 8,0 | 3,3 | +0,2 | 0,25 | 0,40 | |

| St. 32 to 38 | St. 40 | 10×13×32 | 10,0 | 10,0 | 3,3 |

Wedge keys according to GOST 24068-80.

Fig. 4. Basic designations of wedge keys and keyways.

Table 5.1 Dimensions and maximum deviations of wedge keys and keyways according to GOST 24068-80.

| Width b (h9) | Height h (h11) | Rounding radius r or chamfer s1 x 45° | Length l (h14) | Key head height | ||

| no less* | no more | from | before | |||

| 2 | 2 | 0,16 | 0,25 | 6 | 20 | — |

| 3 | 3 | 6 | 36 | — | ||

| 4 | 4 | 8 | 45 | 7 | ||

| 5 | 5 | 0,25 | 0,40 | 10 | 56 | 8 |

| 6 | 6 | 14 | 70 | 10 | ||

| 8 | 7 | 18 | 90 | 11 | ||

| 10 | 8 | 0,40 | 0,60 | 22 | 110 | 12 |

| 12 | 8 | 28 | 140 | 12 | ||

| 14 | 9 | 36 | 160 | 14 | ||

| 16 | 10 | 45 | 180 | 16 | ||

| 18 | 11 | 50 | 200 | 18 | ||

| 20 | 12 | 0,60 | 0,80 | 56 | 220 | 20 |

| 22 | 14 | 63 | 250 | 22 | ||

| 25 | 14 | 70 | 280 | 22 | ||

| 28 | 16 | 80 | 320 | 25 | ||

| 32 | 18 | 90 | 360 | 28 | ||

| 36 | 20 | 1,00 | 1,20 | 100 | 400 | 32 |

| 40 | 22 | 100 | 400 | 36 | ||

| 45 | 25 | 110 | 450 | 40 | ||

| 50 | 28 | 125 | 500 | 45 | ||

| 56 | 32 | 1,60 | 2,00 | 140 | 500 | 50 |

| 63 | 32 | 160 | 500 | 50 | ||

| 70 | 36 | 180 | 500 | 56 | ||

| 80 | 40 | 2,50 | 3,00 | 200 | 500 | 63 |

| 90 | 45 | 220 | 500 | 70 | ||

| 100 | 50 | 250 | 500 | 80 |

Continuation.

Table 5.2 Dimensions and maximum deviations of wedge keys and keyways according to GOST 24068-80.

| Shaft diameter | Key section bхh | Keyway | ||||||

| Width b | Depth | Rounding radius r or chamfer s1 x 45° | ||||||

| Shaft and sleeve (D10) | Shaft t1 | Bushing t2 | ||||||

| Nom. | Prev. off | Nom. | Prev. off | no less | no more | |||

| From 6 to 8 | 2x2 | 2 | 1,2 | +0,1 0 | 0,5 | +0,1 0 | 0,08 | 0,16 |

| St. 8 to 10 | 3x3 | 3 | 1,8 | 0,9 | ||||

| St. 10 to 12 | 4x4 | 4 | 2,5 | 1,2 | ||||

| St. 12 to 17 | 5x5 | 5 | 3,0 | 1,7 | 0,16 | 0,25 | ||

| St. 17 to 22 | 6x6 | 6 | 3,5 | 2,2 | ||||

| St. 22 to 30 | 8x7 | 8 | 4,0 | +0,2 0 | 2,4 | +0,2 0 | ||

| St. 30 to 38 | 10x8 | 10 | 5,0 | 2,4 | 0,25 | 0,40 | ||

| St. 38 to 44 | 12x8 | 12 | 5,0 | 2,4 | ||||

| St. 44 to 50 | 14x9 | 14 | 5,5 | 2,9 | ||||

| St. 50 to 58 | 16x10 | 16 | 6 | 3,4 | ||||

| St. 58 to 65 | 18x11 | 18 | 7 | 3,4 | ||||

| St. 65 to 75 | 20x12 | 20 | 7,5 | 3,9 | 0,40 | 0,60 | ||

| St. 75 to 85 | 22x14 | 22 | 9 | 4,4 | ||||

| St. 85 to 95 | 25x14 | 25 | 9 | 4,4 | ||||

| St. 95 to 110 | 28x16 | 28 | 10 | 5,4 | ||||

| St. 110 to 130 | 32x18 | 32 | 11 | 6,4 | ||||

| St. 130 to 150 | 36x20 | 36 | 12 | +0,3 0 | 7,1 | +0,3 0 | 0,70 | 1,00 |

| St. 150 to 170 | 40x22 | 40 | 13 | 8,1 | ||||

| St. 170 to 200 | 45x25 | 45 | 15 | 9,1 | ||||

| St. 200 to 230 | 50x28 | 50 | 17 | 10,1 | ||||

| St. 230 to 260 | 56x32 | 56 | 20 | 11,1 | 1,20 | 1,60 | ||

| St. 260 to 290 | 63x32 | 63 | 20 | 11,1 | ||||

| St. 290 to 330 | 70x36 | 70 | 22 | 13,1 | ||||

| St. 330 to 380 | 80x40 | 80 | 25 | 14,1 | 2,00 | 2,50 | ||

| St. 380 to 440 | 90x45 | 90 | 28 | 16,1 | ||||

| St. 440 to 500 | 100x50 | 100 | 31 | 18,1 |

APPENDIX 3 (for reference). Maximum deviations for the dimensions of keyed connections

APPENDIX 3 Reference

Tolerances on the dimensions of keys and grooves must correspond to: for the height of the key - (OST 1024); for the groove depth of the shaft and bushing - (OCT 1015); for the length of the parallel key - (OST 1010 and GOST 2689-54); for the length of the shaft groove for the parallel key (OST 1010).

The maximum deviations for the dimensions of the keys, grooves on the shafts and in the bushings (hub) in width must correspond to those indicated in Tables 1 and 2.

Table 1

| Type of connection | Maximum dimensional deviation | Purpose of landings |

| dowels | shaft groove | sleeve groove |

| Fixed tension on the shaft sliding in the sleeve | For individual and serial production (general engineering) | |

| Fixed tension along the shaft, running in the bushing | For mass production (automotive industry) | |

| Fixed, tight along the shaft, running in the bushing | For guide keys |

table 2

| Nominal width of key and groove, mm | Maximum deviation of the size of the grooves of the shaft and bushing, microns | |||

| top | lower | top | lower | |

| From 1 to 3 | -10 | -50 | +55 | +10 |

| St. 3 » 6 | -10 | -55 | +65 | +15 |

| 6 » 10 | -15 | -65 | +75 | +20 |

| » 10 » 18 | -20 | -75 | +85 | +25 |

| » 18 » 30 | -25 | -90 | +100 | +30 |

| » 30 » 50 | -32 | -105 | +120 | +35 |

| » 50 » 80 | -40 | -125 | +140 | +40 |

| » 80 » 120 | -50 | -150 | +160 | +45 |

Steel 45 calibrated

Calibrated steel St45 has long proven itself to be a very durable, reliable raw material. Blanks made from this type of material are excellent for their subsequent processing and production of all kinds of parts and spare parts for various types of equipment. As a rule, calibrated steel 45 serves as the basis for creating shafts, couplings, plungers, flywheels and other parts. Since it is able to function in extremely difficult working conditions, it can be safely used in a variety of industrial production sectors:

- In the construction of buildings and structures

- In the production of machines and special equipment

- For the manufacture of ships and aircraft

Due to its chemical composition, which contains nickel, phosphorus and chromium, calibrated steel 45 is resistant to corrosion, although not very high, since the percentage of these substances is small. And the presence of such components as carbon, silicon, manganese, sulfur, arsenic and copper in the structure of this alloy allows it to withstand various mechanical stress. If necessary, St45 can be replaced with brands 40X, 50G2, St50 that are approximately similar in characteristics.

Features and application of key material

A key is an oblong-shaped part of machines and mechanisms inserted into the groove of the connected parts of a key connection to transmit torque.

Key material serves as raw material for manufacturing

prismatic keys according to GOST 23360-78. Such keys are used as a wedge locking element in axial rotation parts of mechanisms and equipment to prevent them from turning and transmitting rotation from one element to another. At the same time, the key is a kind of fuse against overloads when the rotation is jammed - in such a situation, the key takes on all the excess force, and it is “cut off”, keeping expensive gears, shafts, pulleys and other parts of the mechanisms intact.

The key material is calibrated cold hardened steel 45. The cutting length is 1 meter. It is used as a raw material for the manufacture of parallel keys in accordance with GOST 23360-68.

Assortment of sections of key material

Sales from 1 meter. Shipping within Ukraine by transport companies.

You can download GOST 8787-68 in the “Specification” section

Key blanks and squares GOST 8787-68, TU 14-11-245-88

| Name | GOST | steel grade |

| Keyed steel 7x8mm | 8787-68 | St45 |

| Keyed steel 8x10mm | 8787-68 | St45 |

| Keyed steel 8x12mm | 8787-68 | St45 |

| Keyed steel 9x14mm | 8787-68 | St45 |

| Keyed steel 10x16mm | 8787-68 | St45 |

| Keyed steel 11x18mm | 8787-68 | St45 |

| Keyed steel 12x20mm | 8787-68 | St45 |

| Keyed steel 14x22mm | 8787-68 | St45 |

| Keyed steel 14x24mm | 8787-68 | St45 |

| Keyed steel 14x25mm | 8787-68 | St45 |

| Keyed steel 16x28mm | 8787-68 | St45 |

| Keyed steel 18x32mm | 8787-68 | St45 |

| Keyed steel 20x36mm | 8787-68 | St45 |

Keyed steel 14.5x20mm Steel 45

| Square (keyed) calibrated according to GOST 8559-78, GOST 8797-68 | ||

| Type-size | GOST | Become |

| Square 4 | 8559-78 | St20 |

| Square 5 | 8559-78 | St45 |

| Square 6 | 8559-78 | St20 |

| Square 7 | 8559-78 | St45 |

| Square 8 | 8559-78 | St20 |

| Square 10 | 8559-78 | St45 |

| Square 12 | 8559-78 | St20 |

| Square 13 | 8559-78 | St20 |

| Square 14 | 8559-78 | St20 |

| Square 16 | 8559-78 | St20 |

| Square 18 | 8559-78 | St45 |

Parallelism tolerance of the ends of the keyway

There's something I didn't quite understand. Something like that?

Should I give it too? I just thought that one indication of this diameter would be enough, but now I doubt it, because there are gear wheels on the way and in general...

The teacher tells me: “Watch Lelikov-Dunaev or lectures.” In the book, I’m sure, this particular point is not reflected (being in my third year, I seem to have learned it by heart), but, I confess, I don’t have any lectures. Although in theory everything should be quite clear here.

The teacher also told me that parallelism should be ensured relative to the vertical axis of the section, from which I concluded that this axis should be taken as the base and the parallelism tolerance should be given not relative to the “BV”, but relative to the new base. I found a similar case on this page. Combining what the teacher told me with what I saw on this link, and adding a portion of my incompetence, I got what I posted in the first message: Modified on 05/29/2011 09:28 by }/{yk

Main settings

Making prismatic keys with your own hands is a complex and ineffective process. To obtain a part with precise geometric parameters, today people have special machines.

The manufacturing process begins with the selection of a workpiece. The main materials for the future product are steels and alloys, for example, carbon Steel 45. It has high strength and endurance, can withstand temperature fluctuations, and is also resistant to various physical and chemical influences. Depending on the conditions where the mechanism or equipment in which the key will be used will be used, you can choose another material that meets certain operating requirements.

The further stage of manufacturing is cold or hot drawing of the workpiece, followed by calibration. The significance of calibration in this process is to approximate the required dimensions and characteristics of the part according to GOST. After this, the workpiece is cut using drilling, milling or cutting machines. Further processing takes place on milling equipment, which helps achieve the required dimensions of the parallel keys.

The geometric parameters of the keys vary depending on each other. Thus, a prismatic key din 6885, with a height and width of 4 mm, can have a length in the range of 8–28 mm. A further increase in length with the declared width and height is unacceptable, since the reliability and durability of the product sharply deteriorates. The table below shows the dimensions of din 6885 made of steel.

It is worth noting that it can also be made of stainless steel. This will allow, in some cases, the use of a workpiece of smaller thickness at the required length.

The dimensions of the keys must comply with state standards, regardless of their type.