Benefits of the product

The benefit of a homemade walk-behind tractor from Druzhba is that purchasing a factory-made device is quite expensive.

Having a small plot or using a walk-behind tractor infrequently, purchasing it is not always advisable. And you can assemble a generally productive homemade device from what you have lying around at home. Parts can be assembled absolutely free if desired. And it would not be a pity to spoil them under unfavorable circumstances. The chainsaw engine itself is quite economical and unpretentious. You can use inexpensive fuels and lubricants, which also affects the overall benefit.

A walk-behind tractor is not the only thing that can be made from a Druzhba chainsaw; using this tool you can make many other useful devices; read about how and what is needed for this in the article at this link.

What homemade products can you make from a chainsaw?

A chainsaw is a very convenient tool for making homemade items. By adapting it to a special platform with wheels and connecting the chain to the shaft on which the blades will be installed, you can get a powerful lawn mower. By the way, in order not to bother for a long time, you can install a sprocket from the rear wheel of a bicycle on the shaft.

In addition, a chainsaw can be used to make an excellent sawmill, since reworking this tool, in this case, is also reduced to a minimum.

In general, all homemade chainsaws can be divided into two large groups:

- The first group includes those homemade products, in the manufacture of which there is practically no need to disassemble and modernize the chainsaw;

- The second group of homemade products includes all kinds of equipment: snowblowers, mopeds, snowmobiles, ATVs, etc. In other words, complex mechanical devices, for the manufacture of which you will have to radically disassemble the chainsaw, make a water or air cooling system, in general, completely change this petrol tool.

Let's look at what can be made from a chainsaw, which will definitely come in handy in the household.

So, for example, based on the Druzhba chainsaw you can make the following homemade products:

- Powerful boat engine;

- Gasoline grinder;

- Sawmill;

- Motor cultivator;

- Lawnmower.

When it comes to car homemade products, then from almost any chainsaw you can make:

- Moped, if you install a chainsaw on a bicycle;

- Snowmobile and snowmobile;

- Snow blower;

- Quad bike;

- Scooter.

Of course, the second group of homemade chainsaws requires a thorough approach and a complete study of the design.

Also, you will need to purchase all the necessary materials, and in some cases, you cannot do without a welding machine.

Chainsaw sawmill

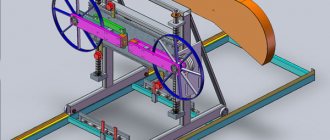

The easiest to make is a homemade sawmill from a Ural, Taiga or Druzhba chainsaw. The essence of how a homemade sawmill works is that there is one large guide along which the chainsaw moves back and forth on a movable sled.

As a guide, you can use a rail or several long but even metal corners. The platform on which the chainsaw will subsequently be attached is made of a piece of thick steel, the thickness of which must be at least 5 mm.

The moving part of the sawmill deserves special attention, the one through which the platform moves along the guide. Here you can use a metal pipe with a rubberized surface as rollers

It is very important that the width of the moving part matches the width of the guide

As you can see in the photo, a log located next to the sawmill is quite easily cut into several parts using a chainsaw moving along a guide. Thus, you can save a lot on the purchase of a sawmill, and, as you can see, the chainsaw practically does not need to be altered, disassembled, etc. in any way.

Walk-behind tractor from a chainsaw

As mentioned above, you can use a chainsaw to make various homemade products for your home and garden. Some of these homemade products are a mower and a walk-behind tractor. With a mower made from a chainsaw, things are not as difficult as with a walk-behind tractor, for the manufacture of which you will have to weld a metal frame, and then fit two wheels on the side to it.

The principle of making a walk-behind tractor from a chainsaw is to use several sprockets that could transmit rotating force to the knives. For these purposes, the sprockets are located on the sides of a metal shaft on which several knives are welded.

A homemade walk-behind tractor from a Ural or Druzhba chainsaw will become a real helper for those who have a fairly large garden. Perhaps such a walk-behind tractor will not be very powerful, but it will be quite enough to solve the main task of cultivating the land.

DIY chainsaw walk-behind tractor

When creating a walk-behind tractor from a Druzhba brand chainsaw, you must use exclusively metalworking skills. In this case, turning work will not be needed. The normal speed limit of the device being created in first gear will be equivalent to 2.5 kilometers per hour. In this case, the engine power is four horsepower. For soil milling, the indicated indicators are quite sufficient.

In its essence, the structural component of the walk-behind tractor is as simple and accessible as possible. A collar flange RU-32 is carefully placed on the main shaft. It allows you to easily screw on bridge type gearboxes. It is quite possible to take it from the Uazovsky Bridge. There, the diameter of the element in question is approximately thirty millimeters. In order to increase the total distance from the ground to the gear axle, it is necessary to use a double-row chain together with two sprockets from a VAZ vehicle. Timing belt type stars allow you to increase the distance to the ground by a full fifteen centimeters.

Case-type bearings must be attached to the main axle. Direct bearings have an internal diameter of thirty millimeters. A moped motor from the Karpaty brand acts as a gearbox and gearbox. In this case, a standard centrifugal clutch is actively used. Chinese models of Delta mopeds are perfect for installation on a walk-behind tractor with their chains and sprockets.

A steel tube is mounted on a wheel axle or a milling cutter.

A fully completed work process will allow you to thoroughly enjoy the created masterpiece.

The main advantages of a self-assembled walk-behind tractor are:

1. Complete absence of lubricant requirements;

2. Complete absence of requirements for combustible materials;

Making a walk-behind tractor from a chainsaw with your own hands

According to the owners of land plots, who have already experienced all the features of handicraft motor vehicles from a gasoline saw, assembled with their own hands, “Druzhba” demonstrates excellent results after modernization. With the right choice of power plant for a homemade unit, it works no worse than its industrial prototypes.

The absolute advantages of this device are:

- high power, reaching up to 4 horsepower in some samples;

- lightness - a small mass will not make the unit heavier and will increase its mobility;

- compact size - a small engine does not require reinforcement of the frame, which reduces the financial costs of its manufacture;

- economical consumption of fuel and lubricants;

- performance, which is determined by readiness for prolonged loads;

- possibility of using all kinds of fuels and lubricants;

- functioning in a completely autonomous mode;

- applicability for various types of work.

The assembly procedure depends on the drawing used and may vary, but the main points of assembly include the following activities. The frame is assembled in accordance with the drawing.

The work process is organized as follows:

- we take a metal pipe with a cross-section of at least 20 mm and bend it so that the overall appearance looks like 2 spars, the end of which is directed upward;

- a motorcycle handlebar is welded in the rear area of the spar;

- we strengthen the base with crossbars;

- We electric weld the support platform for the battery to the rear bends of the side members.

Further work continues on the following points.

- Now we mount a specialized flange, with the help of which the shaft will be fixed to the main structure of the unit from a gasoline saw.

- We buy sprockets from a UAZ car at the used parts market. Through them, ground clearance (ground clearance) will be formed between the ground plane and the connecting wheel beam.

- We take bearings with a 30 mm diameter. We fix them to the main bridge.

- The gearbox, equipped with a gearbox, is assembled from a motorcycle engine.

- The wheels and cutters of a handicraft cultivator are installed on a metal pipe of the required diameter.

- Due to the fact that the walk-behind tractor has a low speed, a forced-type cooling system is required. The simplest solution is to install a fan. And so that the air flow is directed towards the cylinder, a protective coating is used. It could be an old motorcycle gas tank.

After completing the assembly work, be sure to test the equipment, doing this with extreme caution.

How to make a walk-behind tractor from a chainsaw with your own hands: several design options

A walk-behind tractor based on a chainsaw can be recreated using different methods:

- universal, designed for any type of powerful chainsaw;

- specific, applicable to a specific modification, for example, “Friendship” or “Ural” of the Soviet or modern type.

Walk-behind tractor from a chainsaw: the easiest and most universal way

For it we will need:

- motor base from any productive professional chainsaw;

- steering wheel (motorcycle steering wheel will do);

- a transmission that can be removed from an old car or moped;

- electric welding;

- stainless steel pipes;

- metal sheet for designing lugs or old wheels from used equipment;

- connecting parts that will be needed to fasten the frame and engine.

The home production process can be divided into several stages:

- drawing up a detailed drawing. If it is missing, you can use the one we offer;

- frame production;

- modification of the power plant;

- design and assembly of additional units - clutch, gearbox, steering, headlights for night work, chassis.

Making a frame for a walk-behind tractor from a chainsaw

The work process looks like this:

- we take a metal pipe with a cross-section of at least 20 mm and bend it so that the overall appearance resembles 2 spars, the edge of which is directed upward;

- We weld the steering wheel in the rear part of the spar;

- we strengthen the base with crossbars;

- We weld a support platform for the battery to the rear bends of the side members.

Assembly of the motor block

For a homemade walk-behind tractor from a chainsaw, it is ideal if the motor power is in the range of 10-13 hp.

The creation of a power plant in the presence of a ready-made, serviceable engine is carried out as follows:

- Take a pipe 7 cm in diameter, from which 250 mm is cut with a grinder - it will become the future muffler. It is filled with wood waste and diverted so that the exhaust is directed away from the operator. Ensure that the exit circumference does not exceed 1.6 cm in diameter;

- A frame made in the form of a slide is adapted from a stainless steel pipe with a cross-section of about 4 cm. To secure bolt ties, we weld metal brackets to its periphery and middle part;

- We connect the engine and the frame structure.

After that we move on to the chassis.

The most popular ways to recreate it are:

- the use of old Zhiguli tires (all 4 pieces), which are connected in pairs by axle shafts reinforced with a cotter pin;

- assembly of lugs based on tires without rubber (drawing below). For better adhesion to the soil, they are retrofitted with a metal corner.

After installing the transmission, steering wheel, and gas tank on the homemade product, the unit can be tested in the field.

Step-by-step instructions for making a walk-behind tractor from “Friendship”

The manufacturing process depends on the chosen design option and drawing. Step-by-step analysis of one of the modifications:

- Two bases (spars) are made from a steel pipe or profile with a diameter of at least 20 mm. The bend is made so that the ends are bent upward.

- On the long part, a steering wheel is welded, either welded at random or taken from a motorcycle. The bases are connected and reinforced by cross members. Also, platforms for the battery and gas tank are welded or screwed to the bend of the base.

- To mount the engine, a structure in the form of a slide is made from pipes or profiles. The motor is attached to it, and then to the base.

- Next, the RU-32 collar flange from the VAZ car is installed. Thanks to it, the shaft transmitting forces from the motor will be fixed. It is also recommended to use a VAZ gearbox shaft as a shaft. To fix the shaft in the flange, bearings with a diameter of 30 mm are used.

- The transmission link is made from sprockets from any old car or moped. One is mounted on the gearbox shaft, the other on the shaft on which the cutters or wheels are located. A chain from an old motorcycle is connected to each other.

- Next, all parts are installed and connected.

- You can also make wheels and cutters yourself, using old wheels from a car or agricultural machinery as a base. The resulting parts are mounted on a steel pipe or circle of the required diameter.

You also need to consider an effective forced-type cooling system. Several options are offered. The simplest option is to install a fan. More complex designs offer the use of water cooling.

Features of creating a cultivator from a Druzhba chainsaw

A DIY chainsaw cultivator “Druzhba” will become an indispensable assistant when cultivating soil in small areas. The big advantage of this method will be the absence of the need to resort to turning work - you can limit yourself to spot metalwork modifications. Future homemade chainsaw motor cultivators will operate in only two gears, and the maximum speed of the units will reach 2.5 km/h. The engine power will be a little more than 4 liters. With. Such indicators will be quite sufficient for effective soil milling, hilling and digging up potatoes.

The creation of an aggregate is performed according to the following algorithm:

- To begin, place a metal collar flange RU-32 on the main shaft;

- After this, screw on the axle gear sprocket;

- Next, attach the shaft of the bridge gearbox - the part can be taken from a UAZ car and polished to a diameter of 3 cm;

- To increase the distance between the gearbox axle and the ground, use a double-row chain and two “VAZ” sprockets - they will increase the cultivator’s ground clearance to 150 mm;

- Next, install and secure the housing bearing on the main axle - its internal diameter should be no more than 3 cm;

- The engine from the Karpaty moped can serve as a gearbox and gearbox;

- To complete the configuration, take a centrifugal clutch from the same moped;

- To install the cutters and wheels, use a steel pipe 32 cm long.

At the end we test the manufactured cultivator. The great advantage of the finished design is its unpretentiousness to fuel and oils. Another advantage is the autonomy of the unit. Unlike an electric cultivator, you can operate the structure you have made anywhere and at any time.

Thanks to a completely sealed fuel supply system and a membrane-type carburetor, the owner will be able to work with the unit in any conditions, be it heavy rain or unbearable heat. The manufactured structure can be successfully used in areas with a total area of 10 to 20 acres.

Step-by-step instructions for making a walk-behind tractor from “Friendship”

The manufacturing process depends on the chosen design option and drawing. Step-by-step analysis of one of the modifications:

- Two bases (spars) are made from a steel pipe or profile with a diameter of at least 20 mm. The bend is made so that the ends are bent upward.

- On the long part, a steering wheel is welded, either welded at random or taken from a motorcycle. The bases are connected and reinforced by cross members. Also, platforms for the battery and gas tank are welded or screwed to the bend of the base.

- To mount the engine, a structure in the form of a slide is made from pipes or profiles. The motor is attached to it, and then to the base.

- Next, the RU-32 collar flange from the VAZ car is installed. Thanks to it, the shaft transmitting forces from the motor will be fixed. It is also recommended to use a VAZ gearbox shaft as a shaft. To fix the shaft in the flange, bearings with a diameter of 30 mm are used.

- The transmission link is made from sprockets from any old car or moped. One is mounted on the gearbox shaft, the other on the shaft on which the cutters or wheels are located. A chain from an old motorcycle is connected to each other.

- Next, all parts are installed and connected.

- You can also make wheels and cutters yourself, using old wheels from a car or agricultural machinery as a base. The resulting parts are mounted on a steel pipe or circle of the required diameter.

You also need to consider an effective forced-type cooling system. Several options are offered. The simplest option is to install a fan. More complex designs offer the use of water cooling.

DIY chainsaw cultivator Friendship

Among all the methods, this is one of the simplest. When making a motor cultivator from a Soviet saw, the designer will not need to perform turning work, because during work you can get by with only minor metalwork modifications.

The motor-cultivator, created on the basis of the Druzhba chainsaw, will stand out with its solid power, which reaches 4 hp. With. This will give the agricultural unit the opportunity to reach a speed of up to 2.5 km/h, cultivating the soil to a depth of 10 to 25 cm.

The Druzhba chainsaw cultivator must be assembled on the basis of pre-prepared drawings. The diagram is needed to tell the designer the correct procedure for assembly.

After studying the drawings, you can begin manufacturing.

Assembling a motor cultivator from a chainsaw should be done in the following sequence:

- First of all, the main shaft of the engine used will need to be equipped with a collar flange of the RU-32 type;

- Then it is necessary to screw into the structure a sprocket taken from the gearbox, which must be connected to the bridge;

- Next, the operator must connect the shaft of the same gearbox. An element dismantled from a UAZ car is suitable for this. Before installation, the part will need to be sanded so that its diameter is reduced to 3 cm;

- To increase the distance between the ground and the bridge from the gearbox, you can take a 2-row chain and 2 sprockets from a VAZ car. Thanks to their use, the ground clearance of the cultivator will increase to 15 cm;

- After this, the main axle will need to be equipped with a housing bearing. To do this, the internal diameter of the element must be at least 3 cm;

- Then the chainsaw motor cultivator must be equipped with a transmission. To do this, many designers use a ready-made mechanism from the Karpaty moped;

- Next, you need to install a clutch into the agricultural unit, which can also be taken from the same moped;

- At the end of the assembly, a metal pipe with a diameter of 32 cm will remain attached to the structure of the homemade motor cultivator. You will need to install wheels and pre-sharpened cutters on it.

The finished cultivator made from a chainsaw must be painted and tested. At the same time, it is important to make sure that the homemade product does not make loud extraneous sounds and does not smoke while plowing the area.

snow blower

If in the previous design you replace the shaft with plowshares or harrow spokes with an auger mechanism, add a casing, an intake device and a pipe for throwing out snow, the cultivator will turn out to be quite a decent snow blower. Many home craftsmen design their homemade products with replaceable attachments for different seasons. Motor from a Shtil saw with a power of 3-5 hp. It will cope quite well with cultivating the garden in spring and autumn, and with removing loose snow from a summer cottage in winter. The most important unit is the screw mechanism.

Homemade snow blower

If you are not a professional designer, then it is better to download ready-made drawings from the Internet. The auger blades are made of thick rubber, for example, from a conveyor belt. The intake device is made of galvanized steel. A plastic sewer pipe is suitable for the snow disposal pipe.

Creating a walk-behind tractor from a Druzhba chainsaw

The Druzhba chainsaw is considered the best choice for making a walk-behind tractor. This simple and very productive technique is probably in the arsenal of many owners. Using its structural elements, you can make a fairly powerful walk-behind tractor, as it has the following features:

- Due to its low weight, such equipment can be used for work of any complexity.

- Very productive engine.

- Compact and durable.

Based on this device, a high-quality walk-behind tractor is obtained, the speed of which is 2.5 km/h and the power is about 4 hp.

The process of creating a unit is similar to the method that is used for all other models, but it also has its own nuances:

- The main shaft of the future design is equipped with a special flange, which is of the collar type, RU-32, which will then make it possible to easily screw on bridge type gearboxes.

- Sprockets are taken from the UAZ and, together with a double-row chain, are installed on the future device and allow you to increase the distance from the gear axle to the ground. Timing sprockets allow you to increase the distance to the soil by 15 cm.

- The housing type bearings are screwed to the main axle and their diameter is 30 mm.

- The gearbox with gearbox can be constructed from the motor from the Karpaty motorcycle; it is necessary to provide a standard centrifugal clutch.

- To install the cutters and then install the wheels, you need to use steel pipe.

You need to install a load in front of the frame that can hold the center of gravity.

A pipe with a diameter of 30 mm is welded as handles.

As soon as the chainsaw walk-behind tractor is ready, it can be tested on the site. To do this, fill up with fuel and try to complete the work. Modify your device if necessary.

The advantages of such a unit are:

- the ability to use a variety of lubricants and combustible materials;

- work in completely autonomous mode;

- suitability for any type of work.

To create this type of technique from a chainsaw, you do not need specific knowledge. All it takes is a little ingenuity and the desire to get an effective technique. A homemade walk-behind tractor suitable for use on private plots and dachas.

Features of making a motor cultivator from a Druzhba chainsaw

A homemade cultivator made from a Druzhba chainsaw allows you to cultivate small areas. Its parameters are enough to perform various tasks: the soil is milled, potato tubers are hilled and dug up.

Specifications:

- Engine power is about 4 liters. With.;

- Availability of two gears;

- The maximum level of developing speed is 2.5 km/h.

Features of a chainsaw motor cultivator:

- The main shaft is connected to a metal collar flange RU-32;

- The sprocket of the bridge gearbox is screwed on;

- Connect the shaft of the bridge gearbox with a diameter of 3 centimeters;

- The distance between the gearbox and the soil can be increased using a double-row chain and two sprockets from VAZ. So the clearance can be within 15 cm;

- A housing bearing with a diameter of 3 centimeters is installed and secured on the main axle;

- To install the mortise and wheels, you will need a steel pipe 32 centimeters long.

Application specifics:

- The cultivator made from a hand chainsaw is unpretentious to the liquids used;

- The unit is autonomous, so it can be used regardless of time and place;

- The internal structure of the device is sealed, so the cultivator works both in the rain and in extreme heat;

- The finished equipment can be used in areas with an area of 10-20 acres.

If you don’t have the opportunity or time to make your own cultivator, you should pay attention to the Forza motor-cultivator, which can cope with tasks of varying complexity.

What does it take to make a moped from a chainsaw and a bike?

For the most part, converting a bicycle into a moped with your own hands by attaching a chainsaw motor to it does not require any special skills of a mechanic or engineer. If you are new to this business, then numerous drawings of a moped made from a chainsaw, as well as educational video reviews, will help you. Also, not every man has everything he needs in his garage to make a motorbike from a chainsaw with his own hands. Therefore, before assembly, it is recommended to study the list of necessary parts, fasteners and spare parts and buy the missing elements.

Moped

In specialty stores you can find entire kits that include a ready-to-install engine, fasteners and other parts that are necessary to transform a bicycle into a moped. This kit will greatly facilitate the process of assembling a motorcycle, since there is no need to select an engine, suitable power, fasteners, battery, transmission belt, cable, etc.

Assembly instructions and drawings of a homemade moped

Firstly, we will first look at the simplest and most affordable option for how to make a moped from a chainsaw from the photo above. When assembling, the question often arises of how to install a chainsaw motor on a bicycle.

It is important that it is securely attached and does not move while riding. For this type of homemade motorcycle, you need to secure the following parts with clamps in certain places:

- the battery is installed on the top tube;

- the chainsaw bicycle motor itself is mounted at the intersection of the lower front and seat tubes;

- fuel tank - near the engine.

The next step in the conversion is to create and install the pulleys on the bike. They are needed so that engine operation provokes rotation of the rear wheel. Typically, pulleys use external barrier wheels, which are about the size of CDs.

DIY moped

When selecting wheels, take into account the strength and reliability of both the material itself and the fasteners. To install the pulleys, the front wheel is attached to the motor shaft, and the second pulley is attached to the rear wheel hub.

Next you need to put the belt on the pulleys. Sometimes men use a chain instead of a belt. In this case, the pulleys are replaced with a chain, and the principle of its installation is no different.

If we talk about a more complex option, then as a result you will get a homemade vehicle that is most similar to a real motorcycle. The main differences from the previous design are a more reliable and durable frame, wider wheels that can be removed from an old moped, the presence of shock absorption and the installation of an engine from a chainsaw.

The most convenient place for the engine will be a separate platform welded at the bottom of the frame. You can also place a fuel tank there. An exhaust pipe is also attached to the engine. As for the battery, owners of homemade mopeds recommend placing it closer to the steering wheel. The next step will also be the transmission and connecting the engine. You can watch all the nuances of how to properly make a motorcycle from a chainsaw with your own hands in the video.

How to make a cultivator from a chainsaw with your own hands?

To avoid errors during assembly, the farmer will need to follow a certain assembly order.

The manufacturing algorithm is as follows:

- At the very beginning you need to weld the support frame. It should be shaped like a cube. To do this, the corners are welded together so that the overall structure has dimensions of 32x32 cm. The welded areas will need to be cleaned using a grinding machine. As a last resort, you can use a special disc for an angle grinder;

- Before installing all other elements, the finished frame must be painted. The paint will protect the frame from rust. To do this, all metal parts of the frame must be coated with a primer. After it has completely dried, paint is applied to the parts;

- While the paint dries, you need to remove the chainsaw engine. This must be done carefully to prevent rupture of hoses or loss of small parts;

- The finished motor must be installed on the transverse corners of the frame. In this case, you need to lay a rubber mat between the frame and the engine. It will dampen engine vibrations, which will make working with equipment much more convenient;

- Immediately after installing the engine, the fuel tank should be installed. It is best to mount it using brackets;

- Next, you will need to secure the intermediate shaft on the corner posts located vertically;

- To install the running shaft, its bearings must be attached to the longitudinal angles;

- To make handles for the cultivator, you need to use metal pipes. Their diameter should not exceed 3 cm. The pipes will also have to be painted. After the paint has completely dried, rubber anti-slip pads must be installed on the upper ends of the pipes;

- To ensure the transmission of torque to the wheels of the equipment, a 41-tooth sprocket must be installed in the design. Before doing this, you need to make sure that none of its teeth are damaged, and that there are no cracks or other defects on the star itself.

After assembling the cultivator, you will need to fill its tank with a fresh fuel mixture of gasoline and motor oil. When preparing it, you should follow the same proportion as indicated in the operating instructions for the chainsaw. Then you need to lubricate the gearboxes and sprockets. Transmission oil is suitable for this.

After refueling the cultivator, it should be tested. To do this, you should do a test run of the equipment on the site. First, the opener must be set to the minimum working depth position. During the first pass, you need to monitor the operation of the motor - it should not smoke or vibrate too much. After the initial check, the opener must be set to a position for deeper soil cultivation. If during the second run of the equipment it does not make creaking noises or smoke, then the manual cultivator is completely ready for use.

Walk-behind tractor with chainsaw motor

So, we have a gasoline saw that is not used very often or is completely idle. In this situation, having made certain calculations and selected the necessary materials, our chainsaw becomes an excellent walk-behind tractor. The concept of creating handicraft agricultural machinery, depending on the manufacturer’s brand, may change, but the basic rules consist of the following steps.

- The most important step is to develop a drawing, following which you will manufacture the necessary device. Drawing documentation and diagrams of a walk-behind tractor from a gasoline saw can be made either independently or by downloading ready-made calculations from the Internet. Finding them won’t be the slightest bit difficult; just type a search query into your browser and select the assembly project you like.

- When the drawings are available, it is time to assemble the frame for the future walk-behind tractor.

- After the frame is ready, the saw engine and its fuel tank are fixed to it.

- Lastly, the auxiliary components of the system, which are responsible for control and other capabilities, are installed.

To implement the idea, prepare the following list of devices and materials.

- The engine is from an existing gasoline saw. The Druzhba or Ural chainsaw is best suited for this.

- A handlebar removed from a motorcycle or moped.

- Welding machine.

- Sheets of iron and pipes in the quantity necessary to construct the frame of the unit.

- Wheels from old equipment.

- Power transmission (transmission).

Having prepared all the structural components and mounted them according to the drawing, you will get a unit with good features.

- Powerful. Some handicraft devices have a power of 9 horsepower.

- Lightweight.

- Compact.

- The engines used in gasoline saws have a large margin of safety, which makes it possible to work on a homemade unit for a long time.

- Low cost.

As a sample for assembly, let's talk about the engine removed from the Druzhba chainsaw. It is more suitable for our idea.

How to make a walk-behind tractor from a chainsaw with your own hands

Having small plots available, purchasing a walk-behind tractor for crazy money is, in fact, unjustified. In addition to the actual device, you have to regularly buy other necessary elements:

1. Spare parts;

2. Additional equipment;

3. Lubricants;

4. Combustible substances.

That is why, to ease financial waste, you should try to create a walk-behind tractor yourself from a chainsaw.

The immediate active process begins with the manufacture of the frame. It has the shape of a cube with corners of 32*32 millimeters. The main engine is attached to the transverse upper frame corners. The fuel tank is mounted slightly lower on brackets. The vertical uprights of the front plan accommodate intermediate shaft supports. In order to install running shaft bearings, it is necessary to connect specially designed supports to the longitudinal angles.

As a result of the entire process described above, an excellent walk-behind tractor with a center of gravity located above the wheel support surface is obtained. It is quite possible to use a metal weight on the front frame element. By using pipe crossbars with diameters of thirty millimeters, you can achieve excellent manual control. A rubberized roller can become a material for the direct manufacture of wheels.

The self-made walk-behind tractor uses two specialized sprockets. One of them plays a leading role, and the second affects the intermediate shaft.

How to make a cultivator from a Ural chainsaw with your own hands?

If a rotary disk cultivator is used infrequently and in small areas, then the purchase of a unit is considered quite unjustified. In addition, you will have to purchase additional canopies.

A homemade chainsaw motor cultivator includes the following parts:

- Motor;

- Fuel tank;

- Ramu;

- Intermediate shaft.

The chainsaw has these elements; you only need to find the frame.

Algorithm for manufacturing the unit:

- The old chainsaw is untwisted, the engine, gearbox and gas tank are dismantled;

- The frame is welded. You will need metal corners with a cross section of 32*32 mm. The design must be durable, not afraid of constant vibration during operation and withstand additional loads;

- The motor is attached to the upper transverse corners;

- The fuel tank is installed and secured under the engine using special brackets. The lower part should be protected by a metal plate;

- The intermediate shaft supports are secured to the front frame strut with longitudinal angles;

- The control is created by a crossbar made of metal, the length of which is 30 centimeters;

- Also, wheels can be attached to the lower cross member of the frame for easy transportation of the unit. Wheels from an old car are suitable.

Application specifics:

- After assembly, the cultivator must be tested. The engine starts, you need to make one pass through the beds;

- The structure becomes heavier. The load is located on the front of the frame. The weight is secured so that it does not move when the unit vibrates and damage the engine/countershaft.

The Ural chainsaw motor cultivator has little power, so it is not possible to use large canopies. But you can purchase a hitch for using a homemade harrow and plow.

When working with such a unit, you need to take frequent breaks so that it does not overheat and fail.

Pros and cons of homemade design

Having analyzed the results of this homemade product, based on reviews from owners and videos of operation, the conclusion suggests itself that the design is effective. With a competent approach to business, a walk-behind tractor with an engine from Druzhba is not much inferior in its characteristics to its factory counterparts.

The main advantage of homemade products, of course, is saving money. You can find the necessary parts and materials by simply rummaging around in your garage or shed, or you can purchase them for a small amount of money.

Also among the advantages of a homemade unit are:

- sufficient power of the resulting device – up to 4 hp;

- compactness, small dimensions of the walk-behind tractor;

- light weight, maneuverability, mobility;

- economical fuel consumption;

- the Druzhba engine is not whimsical in terms of the choice of fuels and lubricants;

- The walk-behind tractor is capable of performing various operations.

The engine used in chainsaws, especially in the Soviet “Druzhby” chainsaws, is durable and capable of withstanding long-term loads.

The main disadvantage of a homemade walk-behind tractor from a Druzhba chainsaw is that with any design you won’t be able to get a real walk-behind tractor. The power of the walk-behind tractor is enough to cultivate areas with good soil. There are also restrictions on operations. It will most likely not be possible to use the entire arsenal of attachments on a factory walk-behind tractor.

Additional units

Before making a light motor cultivator, you will need to prepare drawings of this unit. The design of the manufactured machine is simple: the engine rotates the gears, transmitting increased traction force to the drive wheel.

To make a snow blower, it is recommended to decide on the design and loads that will be placed on the machine. If you need to clear a small area of snow, then a homemade snow blower can be equipped with a motor from Druzhba. To assemble a more powerful unit, you will need a Shtilev engine (power 3 kW). To create a simplified model, ordinary sled runners are used.

When carrying out the above work, special attention is paid to the screw unit. It begins to move due to a gear pair and chain

Thick cord rubber is used to make the blades. The intake device can be made of galvanized steel. For easy operation of the resulting machine, a sewer pipe is installed under the snow thrower.

How to make a snowmobile from a chainsaw

The snowmobile is manufactured according to one of 2 schemes:

- single-track (2 skis in front, 1 track in back);

- two-track (1 ski in front, 2 tracks in back).

Any snowmobile device has the following design:

- Engine.

- Supply system.

- Oil injection system.

- Transmission.

- Chassis.

- Steering.

- Frame.

- Electrical equipment.

Before you begin making a homemade snowmobile from a chainsaw and its further assembly, you need to design drawings of all working components and the general appearance of the vehicle. It is better to draw each assembly unit separately and take out the dimensions.

During the development process, the brand of gasoline tool is taken into account.

The Druzhba chain saw has a simple design. The disadvantage is the low motor power (1 kW) with a large mass of the tool (12 kg).

The Ural has a weight of 11.7 kg and an engine power of 3.68 kW.

Advantages of the model:

- ability to work at low temperatures;

- high environmental friendliness.

When making a snowmobile from a chainsaw with your own hands, you can choose the Shtil brand. It is characterized by noiselessness during operation, a power of 1.5 kW, and has a nominal weight of only 3.9 kg.

Racks

The initial stage is the manufacture of the base of the frame structure from welded spars. For the middle part, corners 50x63 mm made of hardened steel are used, the front and rear are made of S2 steel with a flange at an angle of 90°. All elements must have holes of the same diameter for mounting with the track wheel and drive shaft. Brackets for road wheels are welded to the bottom of the frame.

The racks are made from 30x30 mm corners and connected by metal crossbars. The result should be a structure in the form of a small portal. A platform is required for the mounting location of the chain saw gearbox and the chain drive shaft. Sheet steel of the required size is selected, usually 2-3 mm thick, and welded to the center of the right side of the module and the portal.

At the back of the portal and at the same time in the middle of the module, a place is formed for the seat, which is subsequently made from boards and fabric or removed ready-made from old equipment, for example, a moped.

The front spar and the drive axle traverse are installed to the beam, which is a standard water pipe with a radius of 0.75 mm. Steering ski bushings are welded at both ends, and a stand for the engine subframe is welded in the center. The mounting points for the supports are reinforced with 2-mm metal gussets for strength and stability of the structure.

Caterpillar

The mechanism from the Buran unit is used as a caterpillar, the belt is shortened by 0.75-1 m. The gears of the gear drive are planted on the transverse shafts, then the web is laid. The caterpillar gear is made from a nylon sheet measuring 15 mm.

Drive shaft

To make the drive shaft, a metal pipe with a diameter of 14 mm is taken, and flanges are installed on top to fix the wheel teeth. At the ends of the mechanism, pin tips are pressed in and welded with space provided for bearings.

Engine

The snowmobile engine is the most important component that affects the operation of all self-propelled equipment. Therefore, experts recommend using a power plant from a Shtil chainsaw with an engine power of 1.5-3 kW. The motor is mounted on a stable support of the cross beam. The gearbox is rotated 180°, fixed on the platform, and the intermediate shaft of the 2-speed transmission is also mounted. The fuel tank is installed on top.

Asterisks

The drive sprocket with an internal key made of St20 is attached to the shaft with an M12 nut and a spring washer. For precise fixation, a thread of the required parameter is cut on the tip. It is taken into account that the 1st transmission stage corresponds to a large sprocket with the maximum gear ratio (on the Ural engine there are 38 teeth), the 2nd stage corresponds to a small drive sprocket with 10 teeth.

The chains are of a standard type, with a pitch of about 16 mm.

Brake system

If the snowmobile is designed to travel at low speeds of up to 30 km/h, then the braking system may not be provided. Vehicles are stopped by friction in the chassis and transmission systems.

Steering

Control - steering on support-steering skis. The support arms are rigidly connected to the steering shaft bipod. The steering wheel is two-handed, with a gas handle mounted on the right side.

Making a cultivator from a Ural chainsaw

Buying a motor cultivator for the purpose of cultivating small areas around the house is in most cases unjustified. After all, in addition to it, one way or another, you will have to purchase attachments. We should also not forget that some store-bought options are quite demanding on oils and fuel. In this case, you can make a motor cultivator from a chainsaw with your own hands. Homemade units, as well as their expensive counterparts, consist of the following elements:

- Engine;

- Fuel tank;

- Frames;

- Intermediate shaft.

All these components, except the frame, can be taken from an old chainsaw. Before you start making your homemade product, you need to prepare an approximate drawing.

It will serve as a kind of plan by which you can navigate the manufacturing process. The further creation algorithm is as follows:

- First, unwind the old chainsaw and remove the motor, gearbox and fuel tank;

- After that, start welding the frame. To make it, use metal corners with a cross-section of 32x32 mm. The design must be strong enough to easily withstand vibration and additional load;

- Attach the motor to the upper transverse corners of the frame;

- Install and secure the fuel tank under the engine on special brackets. Its lower part will need to be protected with a metal plate;

- The intermediate shaft supports should be secured to the vertical front frame struts;

- To secure the running shaft bearings, connect the supports with longitudinal angles;

- Next, proceed to create the control - a metal crossbar 30 cm long is suitable for this;

- If necessary, attach wheels to the lower cross member of the frame - you can “borrow” them from an old car or buy two small wheels for a utility wheelbarrow.

After assembly, the unit must be tested. To do this, start the engine and walk with the cultivator along the garden bed. Surely, you will notice that the structure needs to be heavier. To do this, you can take any weight and place it in the front of the frame. Be sure to secure the weight, otherwise vibration may cause it to become dislodged and damage the motor or intermediate shaft.

Cultivators made on the basis of the Ural saw will not have sufficient power to use large-sized attachments. They are intended for plowing, however, they can still be equipped with a coupling device. To do this, you need to buy a hitch at any agricultural equipment store and equip the structure with it. Cultivators designed in this way can be used in tandem with a small homemade harrow or plow. However, you need to remember that when working with this type of equipment you need to take short breaks.

Improvement of the chassis

The first thing users of a walk-behind tractor think about is how to make a cart with a seat for it. Using equipment in normal mode using levers requires the application of great physical effort. However, the use of a trailer reduces the stability of the vehicle. This problem can be eliminated by extending the wheelbase.

This is done using extensions that are attached to the axle shaft with pins or bolts. Having solved the stability problem, the operator is faced with another issue: the unit is poorly controlled. The differential for the walk-behind tractor helps to give it good maneuverability. This device is made by analogy with components of passenger cars. Homemade unlockers for walk-behind tractors are made using ordinary household tools - an angle grinder, welding and a sharpening machine.

The low weight of the walk-behind tractor causes poor traction between the wheels and the ground. Slipping is a common occurrence when lifting virgin soil, working on wet ground or driving in snow. To avoid slipping, weights are attached to walk-behind tractors.

These devices are divided into the following categories:

- Wheeled. They are discs that are mounted on wheels or hubs. Disks are made monolithic from metal, concrete or hollow, filled with sand. The weight of wheel weights can be 30-70 kg.

- External. Made from any heavy material (steel, lead, concrete). Attached to the body using hooks or bolts. Some craftsmen weld a frame from a corner to the body. Sandbags, bricks, scrap metal and other heavy objects are placed in it.

You can improve the transmission by installing a homemade variator on the engine. The system of belts and discs will allow you to smoothly change the speed of the unit, without jerking or vibration.

Selecting a power plant

You can make a homemade walk-behind tractor with your own hands from almost anything that could be lying around in the garage, but the homemade products will be structurally different. Most often the following are used as power plants:

- automobile engine (mainly a four-wheeled, powerful design on a frame, which can also be used for transporting goods);

- a chainsaw of the “Friendship” type, which, despite its small dimensions, has good performance (a two-wheeled small-sized design that copes well with ordinary agricultural tasks);

- the power unit of a moped (often “Karpaty”), especially a motorcycle (“Minsk”, “Voskhod”) will make it possible to make a more powerful two-wheeled homemade product up to 13.5 liters. With;

- electrical installations (motoblock from a washing machine, for example) are also used, but are not very popular.

The most successful basis is a chainsaw and a motorcycle (moped), which allows you to make a non-bulky simple unit. The difference is in power and size. However, from the point of view of the feasibility of a homemade walk-behind tractor and its economy, the power plant of a chainsaw is undoubtedly better.

How to make a walk-behind tractor from a chainsaw

A walk-behind tractor differs from a multi-cultivator; the former can be turned into a mini-tractor. If motor cultivators are only suitable for loosening the soil, then improved walk-behind tractors even replace vehicles when transporting various cargo (hay, logs, livestock feed, etc.).

Let's look at how to make a walk-behind tractor with your own hands from a chainsaw. To do this, you need to spend time studying the circuit diagram of this equipment and purchasing all the necessary spare parts. Having drawings of a homemade frame, you can assemble very powerful equipment. When assembling the unit, spare parts from scooters, cars, Druzhba chainsaws, Ural motorcycles, etc. are used. Manufacturing will require metalworking skills, since all work is done manually.

The design of a homemade unit looks something like this: motor - intermediate shaft - wheel. A homemade walk-behind tractor made from a chainsaw is mounted on a frame to which the engine and gearbox are attached. The fuel tank is mounted on a bracket. The entire emphasis of the unit falls on the wheels. A working tool is installed at the rear of the mechanism.